Page 1

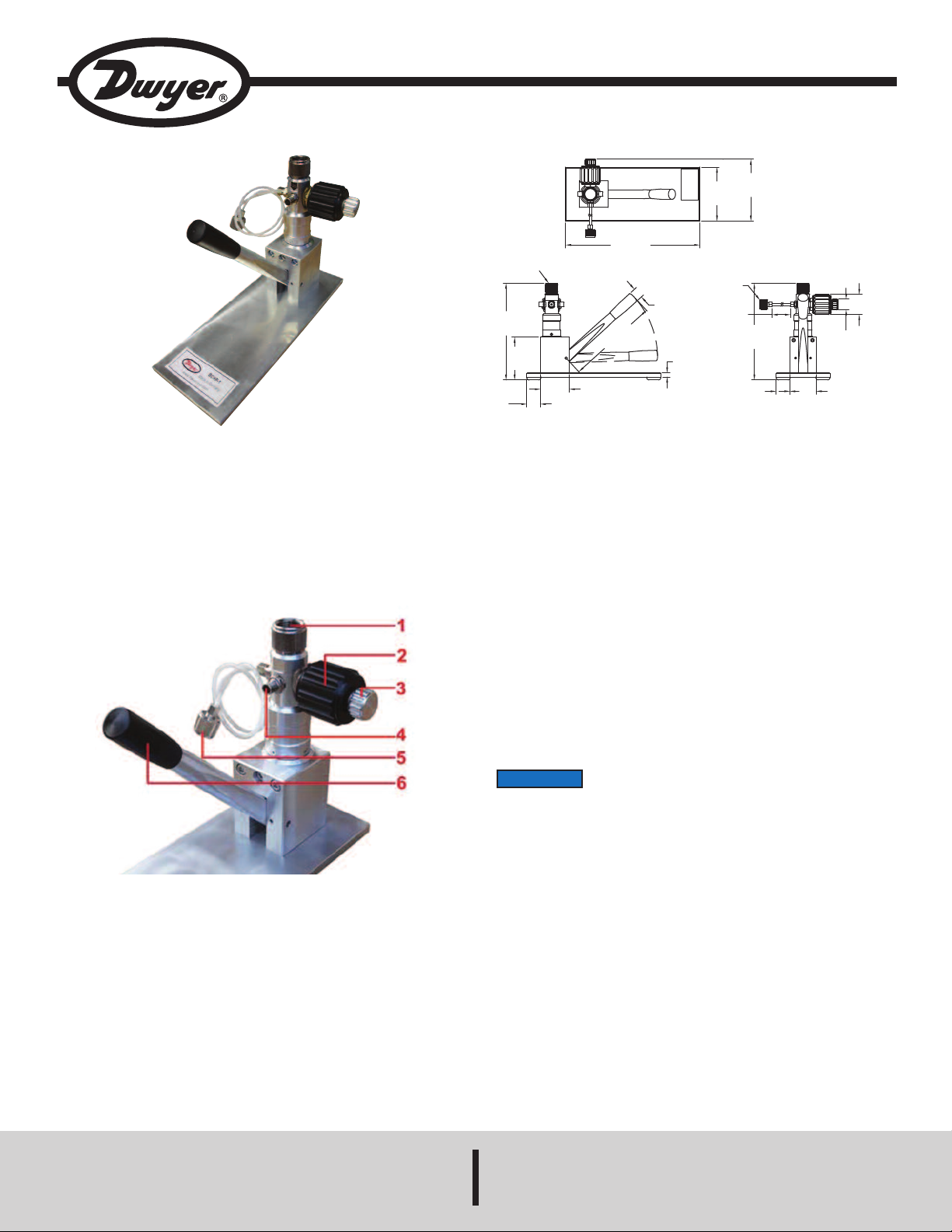

Series BCHP Low Pressure Hand Pump

11/32

[

8.67]

9

/64

[

3.61]

11/32

[8.91]

3-3/16

[81.02]

4

3/64

[

16.88]

A

PPROX. 18˝

1/4˝ FEMALE BSP W/

O-RING TEST GAGE

CONNECTION

29/64

[11.54]

7/8

[22.07]

61/64

[24.26]

29/64

[11.43]

1

-13/32

[

35.83]

3

-3/16

[

81.02]

1/2˝ FEMALE BSP

W/ O-RING

REFERENCE PORT

4-27/64

[112.40]

1-25/32

[45.16]

2

-3/64

[

51.85]

3

-1/64

[

76.57]

Specifications - Installation and Operating Instructions

The Series BCHP Calibration Test Pump is able to generate pressure

and vacuum for adjusting or calibrating pressure gauges, transmitters, or

switches. The pump is hand operated and has a pneumatic pressure

range of -28 in Hg to 870 psi (-0.95 bar to 60 bar). Dual pressure ports

allow two instruments to be connected to the pump without additional

fittings. The Series BCHP can be used in laboratories and production

areas. The fine adjustment valve on this pump ensures precise

measurements.

PECIFICATIONS:

S

edia: Air.

M

utput Ranges: -28 in Hg to 870 psi (-0.95 to 60 bar).

O

Process Connections: 1/4˝ female BSP

Gauge Connection: 1/2˝ female BSP.

Materials: Anodized aluminum, brass, and ABS.

Weight: 8.4 lb (3.8 kg).

Bulletin TE-BCHP

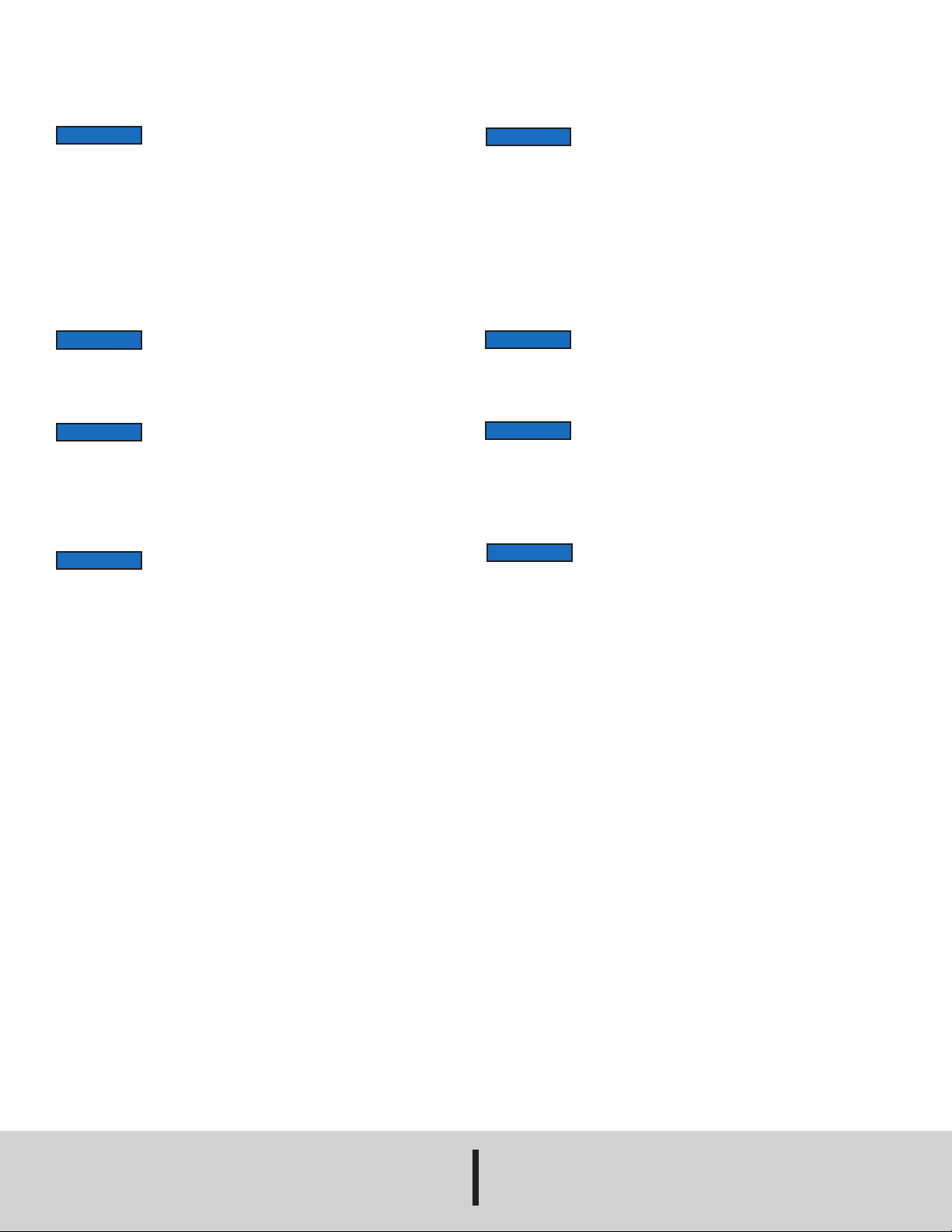

PRODUCT OVERVIEW

1. Pressure connector

for reference instrument

1/2˝ BSP female rotating

2. Fine adjustment knob

3. Pressure relief knob

Figure 1

4. Change-over switch for

pressure/vacuum generation

5. Pressure connector for test

instrument 1/4˝ BSP female

rotating

6. Pump handle

MOUNTING INSTRUCTIONS

The reference instrument is to be mounted on the top connection of the

pump. Fastening with the knurled nut by hand is sufficient. An integral Oring seals the reference instrument pressure port without the use of

teflon tape.

The test instrument is attached to the connection at the end of the hose.

The optional NPT adapter set includes sealing gaskets and different

adapters to best fit the instrument being tested. The tube can also be

removed to attach the test instrument directly to the pump using the

same adapter.

NOTICE

Do not use tape sealant to seal the ports, as it may damage the

pump.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

PRESSURE OPERATION

Step 1: Check whether the change-over switch (4) has pressure selected.

(See label on neck of the pump) If pressure is not selected, use a small tool

to push the switch to the correct position.

OTICE

N

o not move the change-over switch (4) when the test pump is

D

nder operation.

u

Step 2: Make sure the pressure relief knob (3) is not completely closed.

VACUUM OPERATION

Step 1: Check whether the change-over switch (4) has vacuum selected.

(See label on the neck of the pump) If vacuum is not selected, use a small

tool to push it to the correct position.

NOTICE

Do not move the change-over switch (4) when the test pump is

under operation.

Step 2: Make sure the pressure relief knob (3) is not completely closed.

Step 3: Turn the fine adjustment knob (2) counter-clockwise until it stops.

Then, turn the knob three turns clockwise to ensure the adjustment is

adequate to increase or decrease the pressure.

Step 4: Turn the pressure relief valve (3) until it closes.

Step 5: Press down on the pump handle (6) until the approximate pressure

level has been reached.

NOTICE

Do not exceed a pressure of 650 psi (45 bar).

Step 6: Turn the fine adjustment valve (2) clockwise to increase the

pressure or counter-clockwise to decrease the pressure. Do this until the

required pressure level has been reached on the reference instrument.

NOTICE

connection, and the sealing gaskets. (If the pressure does not come to a standstill

within that time, check the ports to be sure they are sealed tightly.)

fter increasing the pressure, the reading may slightly drop for

A

about 30 seconds, due to thermodynamic effects, the tube

Step 7: To reduce the pressure in the pump, turn the fine adjustment valve

(2) counter-clockwise. If more pressure still needs to be decreased,

carefully turn the pressure relief knob (3).

NOTICE

Only remove the reference or test instrument when the relief

valve (3) is open and no pressure is in the test pump.

Step 3: Turn the fine adjustment knob (2) clockwise until it stops. Rotate

the knob counter clockwise three turns so that the vacuum pressure can be

increased or decreased.

Step 4: Turn the pressure relief knob (3) until it closes.

Step 5: Press down on the pump handle (6) until the approximate vacuum

level has been reached.

NOTICE

o not exceed a vacuum of -26.5 in Hg (-0.9 bar.)

D

Step 6: Turn the fine adjustment valve (2) clockwise to decrease the

vacuum or counter-clockwise to increase the vacuum. Do this until the

required pressure has been reached on the reference instrument.

NOTICE

ube connection, and the sealing gaskets. (If the vacuum does not come to a

t

tandstill within that time, check the ports to be sure they are sealed tightly. )

s

fter increasing the vacuum, the reading may slightly increase

A

for about 30 seconds, caused by thermodynamic effects, the

Step 7: To reduce the vacuum in the pump, turn the fine adjustment valve

(2) counter-clockwise. If additional vacuum pressure needs to be relieved,

carefully open the pressure relief valve (3).

NOTICE

Only remove the reference or test instrument when the relief

valve (3) is open and no vacuum is in the test pump.

FAULT INVESTIGATION

1. If the pressure or vacuum cannot be generated correctly or if the set

pressure and vacuum does not stay stable, it may be caused by incorrect

positioning or sealing of the gaskets. Be sure any adapters on the test

instrument have been sufficiently tightened.

2. Before assuming there is a leak in the pump, check if the pressure relief

valve (3) is closed and if the change-over switch (4) is correctly positioned.

3. Do not apply any force to the operating elements of the calibration test

pump and do not connect an external pressure supply to the pump.

MAINTENANCE/REPAIR

Upon final installation of the Series BCHP, no routine maintenance is

required. The Series BCHP is not field serviceable and should be returned

if repair is needed. Field repair should not be attempted and may void

warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website.

Contact customer service to receive a Return Goods Authorization number

before shipping the product back for repair. Be sure to include a brief

description of the problem plus any additional application notes.

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 7/14 FR# R6-444183-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Loading...

Loading...