Page 1

Bulletin PC-BAP

Series BAP Bin Aerator Pad

Specifications - Installation and Operating Instructions

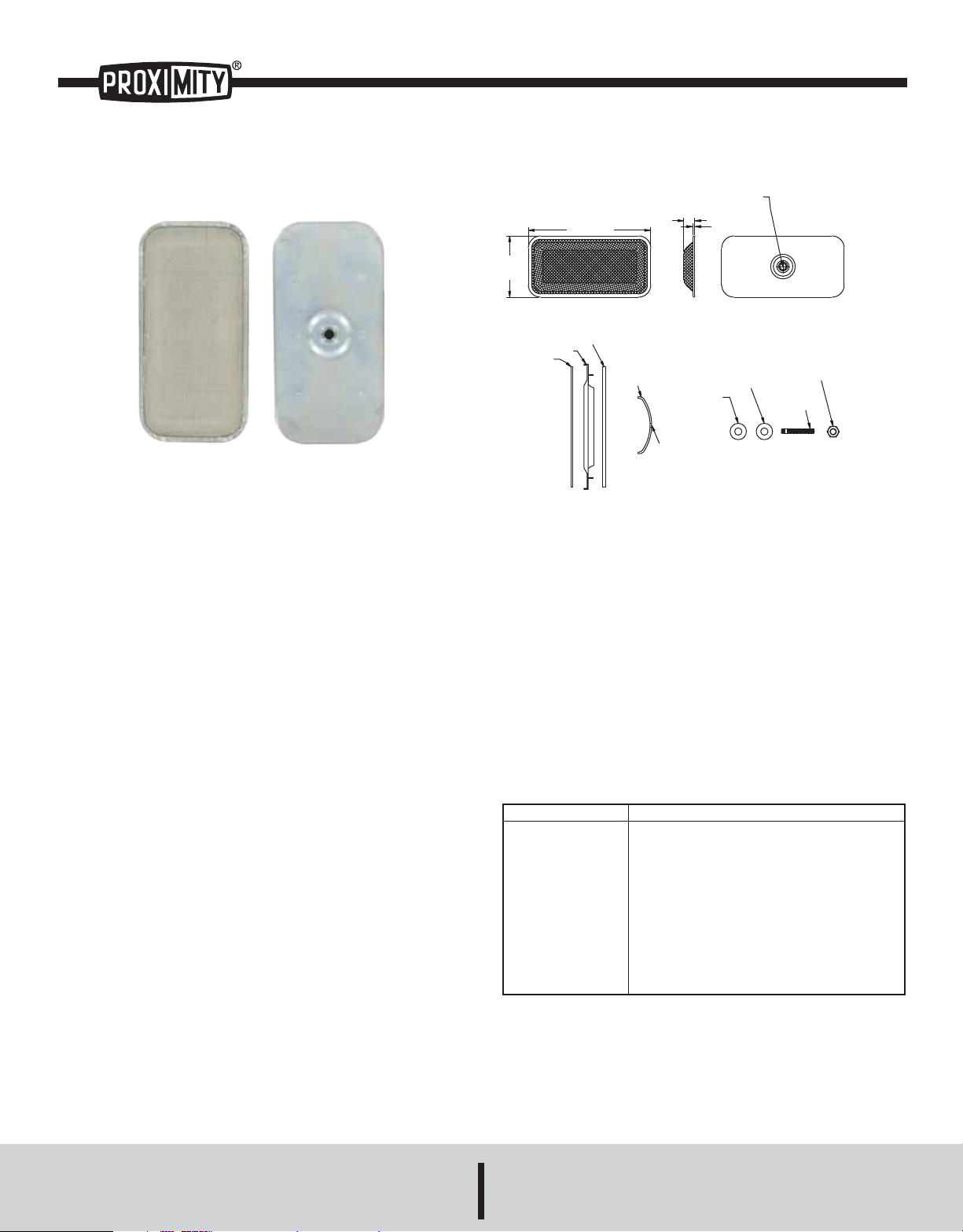

1/8 FEMALE NPT

FOR TANK NIPPLE

3-3/4

[95.25]

MOUNTING BRACKET

1/16˝ GASKET

3/16˝ GASKET

7-1/2

[190.50]

SPRING

STEEL

CLAMP

11/16

[17.46]

BAP AERATOR

2X WASHERS

5/32

[3.81]

RUBBER

GASKET

1/8 NPT X 2˝

TANK NIPPLE

3/4˝ NUT

Series BAP Bin Aerator Pad provides positive flow of dry, finely

ground materials from any bin using the proven principle of

aeration. Low pressure air is introduced into the product, restoring

its natural ability to flow. In this way congestion, bridging and ratholing are overcome without resorting to brute force. Almost all

flow problems inherent to dry, fine materials are caused by

compaction. When low pressure air is introduced to a finely ground

material it will flow like water – uniformly and quickly. Series BAP is

non-clogging and provides equal distribution and consumption of

air. The aerator pads feature simple and quick installation, are

inexpensive, and adapt to any bin configuration.

There are many advantages of the Bin Aerator Pad. It provides a

positive, uniform, and easily controlled flow with quiet operation.

Also, it yields first in/first out flow. Heavy-Duty construction

features stiffeners to prevent crushing of air compartment. These

stiffeners eliminate the possibility of the Bin Aerator Pad being

crushed by a head of material or by a man stepping on it when

cleaning bin. The stiffeners do not obstruct the diffusion of air.

Aeration gives the best results on materials with a 60 mesh size or

smaller and with a 3% or less moisture content. Specific materials

that respond well to aeration content are as follows: Lime, Portland

Cement, Carbon Black, Diatomaceous Earth, Flour, Soda Ash,

Gypsum, Fly Ash, Pigments, Soap Powders, Bentonite, Bran,

Clay, Cereals, Fullers Earth, Detergents and many others.

Ø1/2˝ OPENING

OPTIONAL BAP-K MOUNTING KIT

IN CENTER

OF CLAMP

MOUNTING HARDWARE

SPECIFICA T IONS

Temperature Limit:

BAP-C and BAP-SSC: 180°F (82°C).

BAP-F and BAP-SSF: 600°F (316°C).

Supply Pressure: 3 to 5 psi (0.2 to 0.3 bar).

Air Consumption: See air suppy chart on next page.

Air Connection: 1/8˝ NPT male.

Materials: See model chart.

Model Number

BAP-C

Description

Zinc Plated Steel Body with Galvanized

Steel Mesh and Cotton Diffuser

BAP-SSC

316 Stainless Steel Body with 316SS

Mesh and Cotton Diffuser

BAP-F

Zinc Plated Steel Body with Galvanized

Steel Mesh and Fiberglass Diffuser

BAP-SSF

316 Stainless Steel Body with 316SS

Mesh and Fiberglass Diffuser

BAP-K

Optional External Mounting Kit

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

Bin Aerator Pad Selection

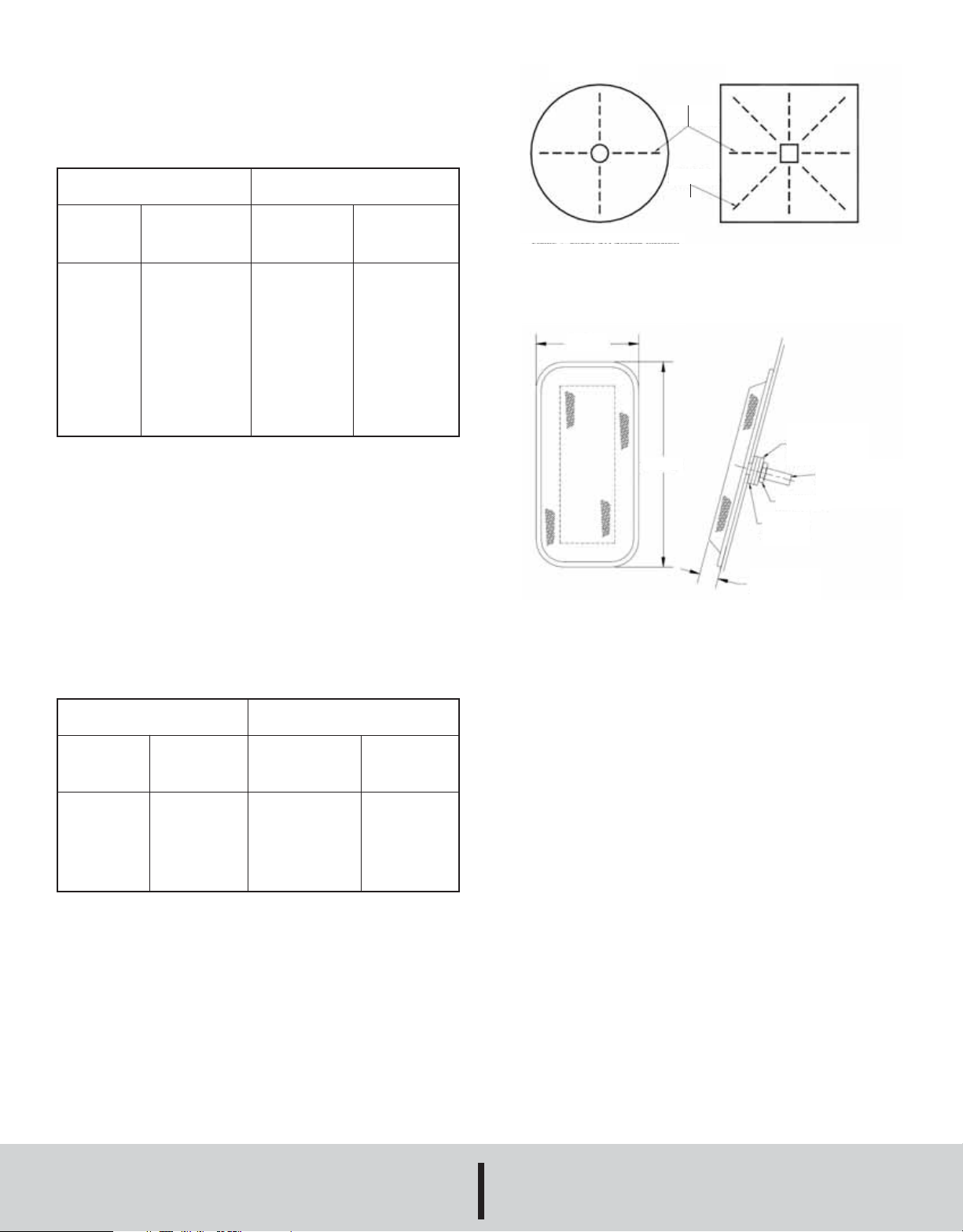

CONICAL HOPPER PYRAMIDAL HOPPER

TYPICAL

INSTALLATION

ALTERNATE

INSTALLATION

3-3/4˝

7-1/2˝

SPACER

WASHERS

1/8˝ NPT X 2˝

TANK NIPPLE

LOCKNUT

RUBBER

GASKET

11/16˝

For best results, locate lower bin aerator pads as close to the

discharge outlet as possible. If material is held in the bin for long

periods and/or compacted in transport, we recommend bin

aerator pads be installed on 12˝ centers.

Bin Aerator Pads

Aerators on 12˝ Centers

Length of

Sloping

Bin Wall

1´ 8˝- 2´ 7˝

2´ 8˝- 3´ 7˝

3´ 8˝- 4´ 7˝

4´ 8˝- 5´ 7˝

5´ 8˝- 6´ 7˝

6´ 8˝- 7´ 7˝

7´ 8˝- 8´ 7˝

8´ 8˝- 9´ 7˝

9´ 8˝- 10´ 7˝

Number of Bin

Aerator Pads

Per Row

2

3

4

5

6

7

8

9

10

Bin Aerator Pads

Aerators on 15˝ Centers

Length of

Sloping

Bin Wall

1´ 11˝- 3´ 1˝

3´ 2˝- 4´ 4˝

4´ 5˝- 5´ 7˝

5´ 8˝- 6´ 10˝

6´ 11˝- 8´ 1˝

8´ 2˝- 9´ 4˝

9´ 5˝- 10´ 7˝

10´ 8˝- 11´ 10˝

11´ 11˝- 13´ 1˝

Number of Bin

Aerator Pads

Per Row

2

3

4

5

6

7

8

9

10

Generally, four rows of bin aerator pads on 12˝ or 15˝ centers are

recommended. On conical bins, these rows are spaced equally.

On pyramidal bins, rows are spaced equally on sloping sides or in

valleys if material tends to hang up in these valleys.

Air Supply

Air supply must be clean and dry. We recommend positive

displacement, low pressure blowers. Plant air can be used, but the

pressure must be reduced to 3-5 psi, and a filter or moisture trap

used on the low pressure side. The volume of air needed is a

limiting factor on the use of plant air.

Figure 1: Typical Layouts

Figure 2: Series BAP Bin Aerator Pad Installed

Manifold Piping

Size Guide

Piping Size

3/4˝

1˝

1-1/4˝

Number of

Aerators

in a Row

1-5

6-9

10-12

Air Consumption Guide

Per Bin Aerator Pad

Air Pressure,

psi (bar)

Cubic Feet

Per Minute

(lpm)

1 (0.07)

2 (0.14)

*3 (0.21)

4 (0.28)

5 (0.34)

4.2 (118.9)

5.7 (161.4)

6.5 (184.1)

7.1 (201.0)

7.6 (215.2)

MAINTENANCE

Upon final installation of the Series BAP Bin Aerator Pad, no

routine maintenance is required. A periodic check of system

calibration is recommended. The Series BAP is not field

serviceable and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure to

include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return

goods authorization number before shipping.

Installation

Drill 7/16˝ holes through bin wall on predetermined centers (12˝ or

15˝ or customer’s preference). Insert special tank nipple through

hole and lock into place with locknut. Rubber gasket and spacer

washers are furnished.

If using BAP-K external mounting kit see bulletin PC-BAP-K.

©Copyright 2008 Dwyer Instruments, Inc. Printed in U.S.A. 11/08 FR# R5-443674-00

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...