Page 1

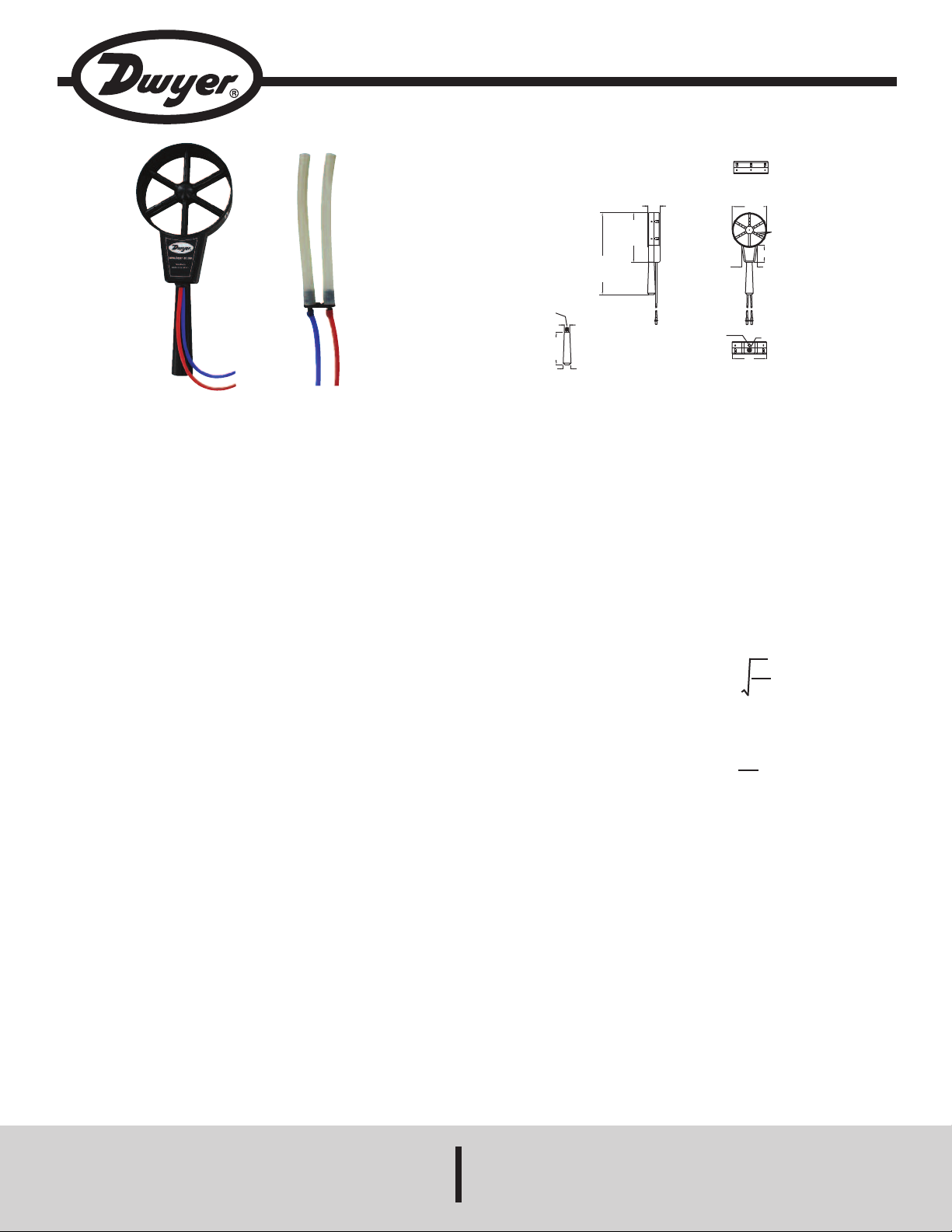

Model ANE-1 Differential Pressure Anemometer

1-37/64

[39.97]

11/16

[17.50]

63/64

[25.00]

4-9/64

[105.00]

MALE M10

CONNECTION

6-1/4

[158.79]

10-25/64

[

263.79]

FEMALE M10

CONNECTION

FOR HANDLE

4-23/64

[110.90]

T

UBING HOLE

2

[

50.80]

2

-1/8

[

54.05]

H

OLES FOR

A

IR INTAKE

Ø

4-23/64

[

110.90]

HANDLE

Specifications - Installation and Operating Instructions

Tubing Adapter

Bulletin TE-ANE-1

The Model ANE-1 Differential Pressure Anemometer is a robust and

durable bi-directional anemometer with no moving parts or sensing

electronics. With the installed tubing, the ANE-1 connects easily to any

manometer or applicable pressure sensing device and is capable of

measuring a wide velocity range. The air velocity range and accuracy is

dependent on the installed manometer, and the ANE-1 retains the

accuracy as long as it is dust free. The ANE-1 is made from high quality

ABS plastic, comes with a convenient handle, and includes 5´ of blue

and 5´of red silicone tubing (2 mm ID x 4.5 mm OD) with removeable

adapter sized 2 mm OD to 3/16˝ OD that has two removeable 5˝ clear

silicone 3/16˝ ID x 3/8˝ OD tubing versatile process options.

SPECIFICATIONS:

Service: Clean air only.

Wetted Materials: Anemometer: ABS; Tubing: Silicone; Handle:

Phenolic.

Dimensions:

Tubing: 2 mm ID x 4.5 mm OD;

Adapter: 2 mm OD to 3/16˝ OD connections.

Temperature Limits: 23 to 122°F (-5 to 50°C).

K-Factor: 0.843.

Process Connections: 2 removeable 5˝ (12.7 cm) tubing 3/16˝ ID.

Weight: 7.7 oz (220 g).

Assembly

The ANE-1 requires simple assembly of the handle. Locate the handle

and ANE-1 head. Line up the male screw connection of the handle to the

female screw connection of the ANE-1 head. Screw the handle in a

clockwise direction until secure. Do not overtighten.

HOW THE ANE-1 DIFFERENTIAL PRESSURE ANEMOMETER

WORKS

The ANE-1 Differential Pressure Anemometer consists of two pressure

sensing internal parts designed to measure the velocity pressure. The

device consists of several equally spaced holes.

The 3 holes on each of the branches, on the front and rear of the device,

face downstream or upstream of the airflow and sense total pressure.

The holes on the outer portion of the housing senses static pressure.

The total and static pressures are averaged and provide pressure in the

installed tubing. The pressure differentials across the tubing connections

constitute the output velocity pressure.

Calculations for air velocity can be based on the following data:

P

Air Velocity = 4006 x k

v

D

Where: Pa = Pressure in inches of water

D = Air density in #/cu. ft. typical

K = K-factor of units (0.843)

P

Air Density = 0.057 x

a

T

Where: Pa = Barometric pressure in inches of mercury

T = Absolute temperature (indicated temperature °F plus 460)

Flow in CFM = Duct area in square feet x air velocity in FPM.

MAINTENANCE/REPAIR

The Model ANE-1 requires no routine maintenance. The Model ANE-1 is

not field serviceable and should be returned if repair is needed. Field

repair should not be attempted and may void warranty.

MEASURING VELOCITY

Connect the red tubing to the positive pressure port and the blue tubing

to the negative pressure port on the pressure sensing instrument. The

ANE head should be placed into the air stream as indicated by the

arrows. Pressure readings should always be positive. If negative

readings are obtained, there may be a leak or blockage in the pressure

tubing or they may be incorrectly connected.

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 4/14 FR# R7-444085-00 Rev. 1

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our

website. Contact customer service to receive a Return Goods

Authorization number before shipping the product back for repair. Be

sure to include a brief description of the problem plus any additional

application notes.

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...