Page 1

Series AFR Air Filter Regulator

3

.130

[

79.5]

3

.130

[79.5]

DRAIN

7

-3/4

[

196.8]

2

-19/32

[

65.8]

21/32

[

16.5]

2-53/64

[71.6]

I

NPUT

1

/4˝ NPT

3/8

[

9.6]

G

AUGE PORT

1

/4˝ NPT

OUTPUT

1/4˝ NPT

Specifications - Installation and Operating Instructions

Bulletin F-42-AFR

The Series AFR Air Filter Regulators are designed to provide clean,

accurate air pressure to instruments, valves and other automatic control

equipment under variable conditions. The regulators are designed for air

service only. Maximum allowable inlet pressure is 250 psi. Operating

temperature is 0 to 160°F. The Series AFR has a low capacity internal

relief which provides very limited down stream over pressure protection.

To avoid exceeding outlet pressure limits in service, a pressure relieving

or pressure limiting device should be used.

INSTALLATION

Install the regulator as close as possible to the instrument or tool it is to

service. For best filter drainage, orient the valve so it is at the lowest

point on the dripwell housing. The words “IN” and “OUT” are cast into the

body to indicate the direction of flow.

OPERATION

Turning the adjusting screw changes the force exerted by the range

spring on the diaphragm assembly. In equilibrium of set pressure, the

force exerted by the range spring is balanced by the force from the

output pressure acting underneath the diaphragm.

An unbalanced state between the output pressure and the set pressure

causes a corresponding reaction in the diaphragm and supply valve

assemblies. If the output pressure rises above the set pressure, an

upward force is exerted on the diaphragm assembly causing the relief

seat to lift and open. Excess pressure is vented to atmosphere until

equilibrium is reached. If the output pressure drops below the set

pressure, the unbalanced force of the range spring causes a downward

force on the diaphragm assembly. The supply valve then opens until the

pressure builds up once more to the equilibrium condition.

SPECIFICATIONS

Service: Air only.

Output Ranges: 0 to 10 psi (0 to 70 kPa), 0 to 30 psi (0 to 200 kPa), 0 to

60 psi (0 to 400 kPa), and 0 to 120 psi (0 to 800 kPa).

Maximum Supply Pressure: 250 psig (1700 kPa).

Port Size: 1/4˝ NPT(F) in, out, and gage.

Mounting: Pipe or through body.

3

Flow Capacity: 20 SCFM (33.0 m

/hr) at 100 psig (700 kPa) supply with

20 psig (140 kPa) output.

Exhaust Capacity: 0.1 SCFM (0.17 m3/hr) with downstream pressure 5

psig (35 kPa) above set point.

Sensitivity: 1˝ (2.5 cm) of water.

Air Consumption: Less than 6 SCFH (0.17 m3/hr).

Filter Size: 40 micron.

Effect of Supply Pressure Variation: Less than 0.2 psig (1.4 kPa) for 25

psi (170 kPa) change.

Materials of Construction: Body: Aluminum Alloy, Irridite, and baked

epoxy finish; Filter: Phenolic Impregnated Cellulose; Diaphragm and Valve

seat Plug: Nitrile Elastomer.

Weight: 1.6 lb (725 g).

Under forward flow conditions, the range spring force is balanced by the

diaphragm pressure force, with the supply valve open just enough to

maintain the required equilibrium pressure. When high flow occurs, a

specially designed aspirator helps maintain downstream pressure and

compensates for droop.

Prior to turning on supply air, back off adjusting screw until there is no

compression of the range spring. After turning supply pressure on, turn

the adjusting screw clockwise to increase outlet pressure.

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

Page 2

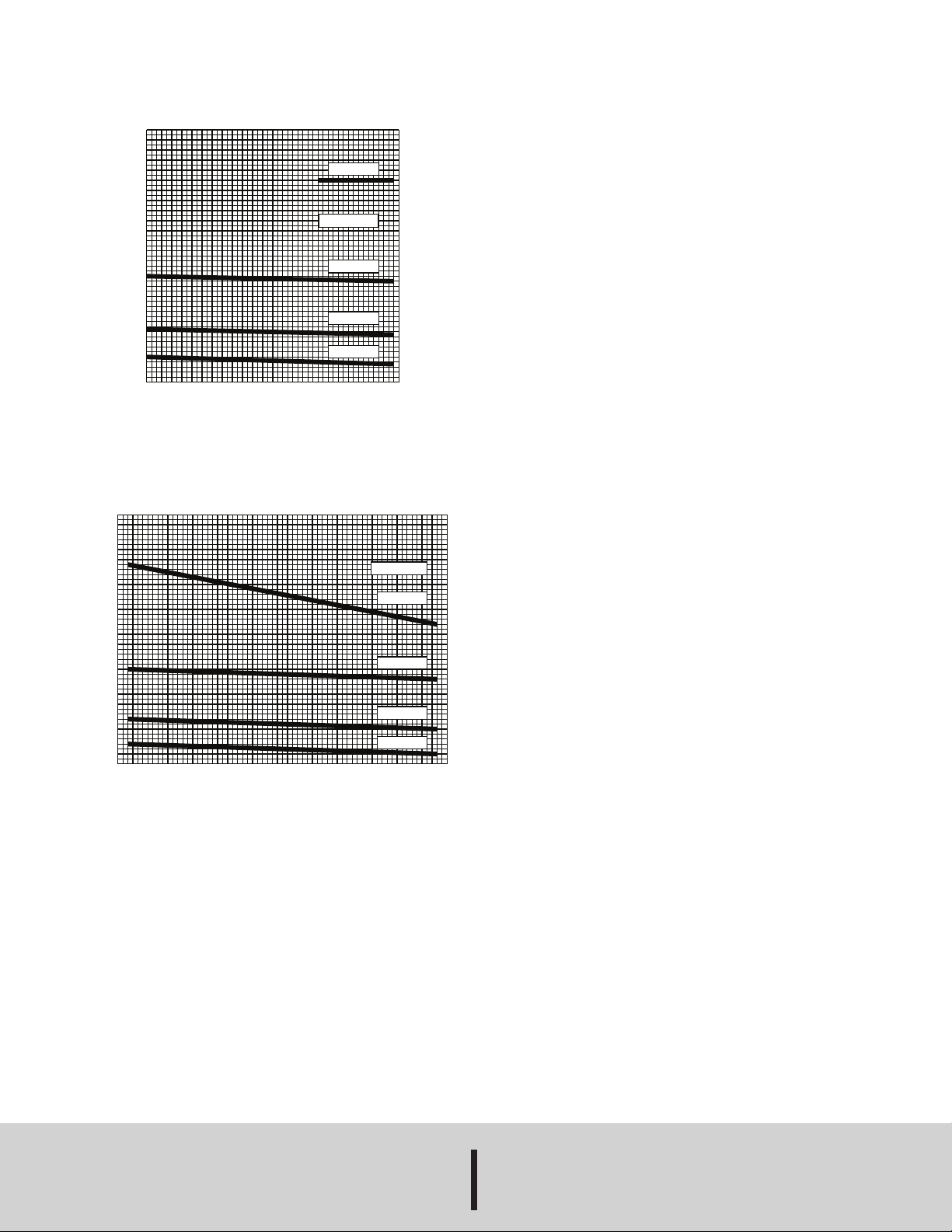

See Figures 1 and 2 below for additional performance characteristics.

100

90

80

70

6

0

50

40

30

20

1

0

0

(700)

(

620)

(560)

(480)

(420)

(

350)

(280)

(200)

(140)

(70)

OUTPUT PRESSURE, PSIG (kPa)

EFFECT OF UPSTREAM

PRESSURE VARIATIONS ON

REGULATED PRESSURE

I

NPUT PRESSURE, PSIG (kPa)

5

0

(345)

80

(

552)

100

(689)

90

(620)

70

(483)

60

(414)

RANGE PSIG (kPa)

0-60 (0-400)

0-30 (0-100)

0-10 (0-65)

0

-120 (0-800)

E

FFECT OF CHANGES IN FLOW

O

N REGULATED PRESSURE

100 PSI (6.9 bar) SUPPLY

100

90

80

70

6

0

50

40

30

20

10

0

(700)

(620)

(

560)

(480)

(420)

(350)

(280)

(

200)

(140)

(70)

OUTPUT PRESSURE, PSIG (kPa)

FLOW, SCFM (M3/hr)

2

(3.5)

20

(33.6)

18

(30.2)

16

(26.9)

14

(23.5)

12

(20.7)

10

(16.8)

8

(13.4)

6

(10.1)

4

(6.7)

RANGE PSIG (kPa)

0-60 (0-400)

0-30 (0-100)

0-10 (0-65)

0-120 (0-800)

Figure 1

WARNING

The Series AFR Air Filter Regulator is intended for use in industrial

compressed air systems only. Do not use these products where

pressures and temperatures can exceed those listed under

specifications.

Before using these products with fluids other than air, for non-industrial

applications, life-support systems, or other applications not within

published specifications, contact Dwyer Instruments, Inc.

MAINTENANCE

To Remove Condensate

Slowly open drain valve and bleed accumulated liquid.

To Clean Filter Element

1) Shut off air supply.

2) Drain condensate.

3) Remove four corner bolts from bottom of unit.

4) Remove dripwell housing and filter.

5) Clean parts and reassemble in reverse order.

MAINTENANCE

Upon final installation of the Series AFR Air Filter Regulator, no routine

maintenance is required. A periodic check of the system calibration is

recommended. This Series AFR is not field serviceable and should be

returned if repair is needed (field repair should not be attempted and

may void warranty). Be sure to include a brief description of the problem

plus any relevant application notes. Contact customer service to receive

a return goods authorization number before shipping.

Figure 2

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 4/14 FR# RP-440986-00 Rev. 5

PROXIMITY CONTROLS

A DIVISION OF DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyermail.com

Loading...

Loading...