Page 1

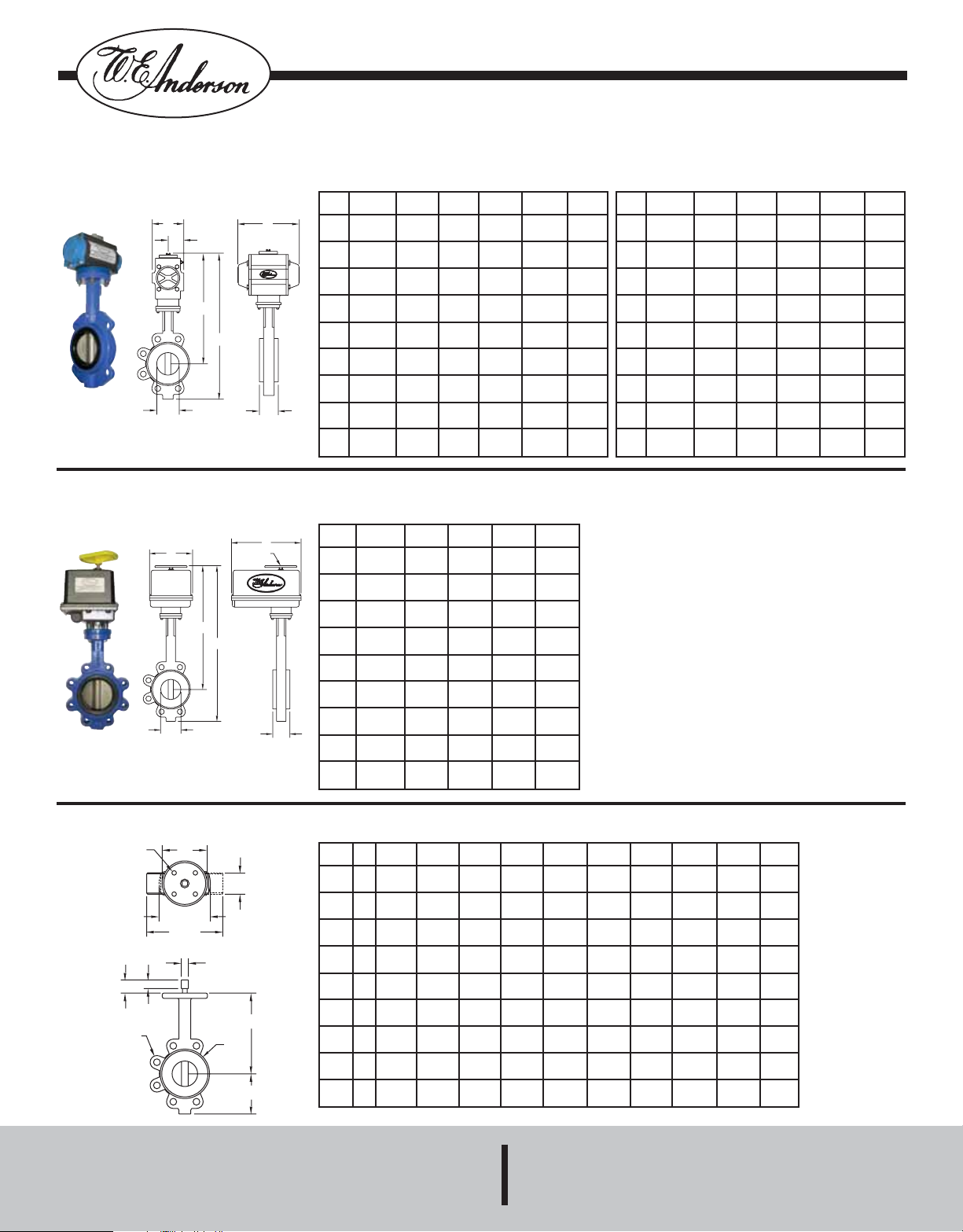

Series ABFV Automated Butterfly Valves

C

G

B

F

A

E

D

C

B

F

A

4x C

ØE

C

D (WAFER)

D (LUG)

ØK

J

M

LUG

BODY

WAFER

BODY

B

A

E

D

MANUAL

OVERRIDE

Bulletin V-28

®

Specifications - Installation and Operating Instructions

Pneumatic Actuated - DAX and SRX Actuators

Pneumatic Size Chart - DA Series

A

2˝

(250.83)

10-27/64

2-1/2˝

(264.72)

11-3/32

3˝

(281.78)

11-27/32

4˝

(300.83)

13-29/64

5˝

(341.71)

13-31/32

6˝

(354.81)

15-5/16

8˝

(388.94)

18-1/4

10˝

(463.55)

21-55/64

12˝

(555.23)

Electric Actuated - UXX and VXX Actuators

Electric Size Chart

A

2˝

2-1/2˝

3˝

4˝

5˝

6˝

8˝

10˝

12˝

B

9-7/8

B

12-15/64

(310.75)

12-25/32

(324.64)

13

(330.2)

13-3/4

(349.25)

16-25/64

(416.32)

16-29/32

(429.42)

18-1/4

(463.55)

23-9/64

(587.77)

24-29/32

(632.62)

C

2-13/16

(41.44)

2-13/16

(41.44)

3-11/64

(80.57)

3-11/64

(80.57)

4-11/64

(105.97)

4-11/64

(105.97)

4-11/64

(105.97)

5-25/64

(136.92)

7-3/8

(187.33)

C

4-1/4

(107.95)

4-1/4

(107.95)

4-1/4

(107.95)

4-1/4

(107.95)

7

(177.8)

7

(177.8)

7

(177.8)

10

(254)

10

(254)

D

1-45/64

(43.26)

1-13/16

(46.04)

1-13/16

(46.04)

2-1/16

(52.39)

2-13/64

(55.96)

2-13/64

(55.96)

2-3/8

(60.33)

2-11/16

(68.26)

3-5/64

(78.18)

1-45/64

(43.26)

1-13/16

(46.04)

1-13/16

(46.04)

2-1/16

(52.39)

2-13/64

(55.96)

2-13/64

(55.96)

2-3/8

(60.33)

2-11/16

(68.26)

3-5/64

(78.18)

D

E

5-1/2

(139.7)

5-1/2

(139.7)

6-25/64

(162.32)

6-25/64

(162.32)

9-23/64

(237.73)

9-23/64

(237.73)

9-23/64

(237.73)

12-59/64

(328.22)

22-41/64

(575.07)

6-57/64

(175.02)

6-57/64

(175.02)

6-57/64

(175.02)

6-57/64

(175.02)

(177.8)

(177.8)

(177.8)

10

(254)

10

(254)

E

7

7

7

F

13-1/64

(330.6)

13-59/64

(353.62)

14-27/32

(337.03)

16-21/64

(414.74)

18-29/64

(468.71)

19-7/16

(493.71)

22-13/64

(563.96)

26-1/4

(666.75)

31-25/64

(797.32)

15-3/8

(390.53)

16-9/32

(413.54)

16-3/4

(425.45)

18-1/4

(463.55)

21-25/64

(543.32)

22-3/8

(658.33)

25-9/64

(638.57)

31-1/8

(790.58)

34-7/16

(874.71)

F

G

1-5/8

(41.28)

1-5/8

(41.28)

1-25/32

(45.24)

1-25/32

(45.24)

2-15/16

(58.74)

2-15/16

(58.74)

2-15/16

(58.74)

2-7/8

(73.03)

3-61/64

(100.41)

Pneumatic Size Chart - SR Series

A

2˝

2-1/2˝

3˝

4˝

5˝

6˝

8˝

10˝

12˝

B

10-15/16

(261.94)

10-55/64

(275.83)

11-3/4

(298.45)

12-15/16

(328.61)

13-31/32

(354.81)

15-9/16

(395.29)

17

(431.8)

20-3/32

(510.38)

23-7/8

(606.43)

3-11/64

(80.57)

3-11/64

(80.57)

3-11/64

(80.57)

4-11/64

(105.97)

4-11/64

(105.97)

5-25/64

(136.92)

5-25/64

(136.92)

5-25/64

(136.92)

7-3/8

(187.33)

D

C

1-45/64

(43.26)

1-13/16

(46.04)

1-13/16

(46.04)

2-1/16

(52.39)

2-13/64

(55.96)

2-13/64

(55.96)

2-3/8

(60.33)

2-11/16

(68.26)

3-5/64

(78.18)

E

6-25/64

(162.32)

6-25/64

(162.32)

8-5/32

(207.17)

9-23/64

(237.73)

10-45/64

(271.86)

12-59/64

(328.22)

12-59/64

(328.22)

20-9/16

(522.29)

22-41/64

(575.07)

F

13-29/64

(341.71)

14-29/64

(367.11)

15-31/64

(393.3)

17-27/64

(442.52)

18-31/32

(481.81)

21-1/32

(534.19)

23-57/64

(606.83)

28-5/64

(713.19)

33-25/64

(848.12)

G

1-25/32

(45.24)

1-25/32

(45.24)

2-5/64

(52.78)

2-5/16

(58.74)

2-11/16

(68.26)

2-7/8

(73.03)

2-7/8

(73.03)

3-61/64

(100.41)

4-19/64

(109.14)

Valve Body Dimensions

ISO

A

Size

2˝

2-1/2˝

3˝

4˝

5˝

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U.S.A.

6˝

8˝

10˝

12˝

F07

F07

F07

F07

F07

F07

F07

F10

F10

3-5/32

(80.17)

3-1/2

(88.9)

3-3/4

(95.25)

4-1/2

(114.3)

(127)

5-31/64

(139.30)

6-57/64

(175.02)

(203.2)

9-17/32

(242.09)

B

6-11/32

(161.13)

6-57/64

(175.02)

7-9/64

(181.37)

7-7/8

(200.03)

5

8-25/64

(213.12)

8-29/32

(226.22)

10-1/4

(260.35)

8

11-1/2

(292.1)

13-9/32

(337.34)

C

1-45/64

(43.26)

1-13/16

(46.04)

1-13/16

(46.04)

2-1/16

(52.39)

2-13/64

(55.96)

2-13/64

(55.96)

2-3/8

(60.33)

2-11/16

(68.26)

3-5/64

(78.18)

D

D

Wafer

4-1/32

(102.39)

4-49/64

(121.05)

5-31/64

(139.3)

6-5/16

(160.34)

7-31/64

(190.10)

8-15/32

(215.11)

10-19/32

(269.08)

13-1/8

(333.38)

15-3/32

(383.38)

Lug

5-63/64

(152)

6-3/4

(171.45)

7-7/8

(200.03)

9-1/32

(229.39)

10

(254)

11-1/32

(280.19)

13-1/2

(342.9)

15-63/64

(406)

19-1/32

(483.39)

E

3-35/64

(90.09)

3-35/64

(90.09)

3-35/64

(90.09)

3-35/64

(90.09)

3-35/64

(90.09)

3-35/64

(90.09)

3-35/64

(90.09)

4-59/64

(125.02)

4-59/64

(125.02)

G

23/64

(9.13)

23/64

(9.13)

23/64

(9.13)

23/64

(9.13)

23/64

(9.13)

31/64

(12.3)

31/64

(12.3)

31/64

(12.3)

31/64

(12.3)

J

1-1/32

(26.19)

1-1/32

(26.19)

1-1/32

(26.19)

1-3/16

(30.16)

1-3/16

(30.16)

1-5/16

(33.34)

1-5/16

(33.34)

1-55/64

(47.23)

1-55/64

(47.23)

(14.29)

(14.29)

(14.29)

23/32

(18.26)

23/32

(18.26)

(22.23)

(22.23)

1-7/64

(28.18)

1-7/64

(28.18)

K

9/16

9/16

9/16

7/8

7/8

M

43/64

(17.07)

43/64

(17.07)

43/64

(17.07)

53/64

(21.03)

53/64

(21.03)

61/64

(24.21)

61/64

(24.21)

61/64

(24.21)

61/64

(24.21)

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

Page 2

The ABFV Series is offered with standard 316 SS disc, a

through shaft that does not come in contact with the media, and

choices of EPDM, BUNA-N, or fluoroelastmer liners for great

chemical compatibility. Valve design has integral ISO mounting for

direct mount actuators creating a more compact automated

package. Body is epoxy coated for durable and attractive finish.

Liner fully covers the body and assures tight seal with mating

flanges without additional gaskets. One-piece shaft ensures

positive valve positioning and is an anti-blowout design.

ABFV valves come in two-way and three-way packages. Threeway assemblies include valves and actuators mounted onto a

125# cast iron tee. When ordering you have the choice of valve

arrangement for mixing or diverting applications. Valves come in

lug or wafer style and wafer models have guide holes for bolts.

ABFV is an economical automated valve package with either an

electric or pneumatic actuator. Electrically actuated models are

weatherproof, NEMA 4, powered by standard 115 VAC supply,

and are available in either two-position or proportional control.

Two-position actuators use the 115 VAC input to drive each of the

valve ports open or closed, while the modulating actuator accepts

a 4 to 20 mA input for infinite valve positioning. Actuator features

include thermal overload protection to withstand stall conditions,

visual position indication and a permanently lubricated gear train.

The pneumatic double acting actuator uses an air supply to drive

each of the actuator ports. Spring return pneumatic actuators use

the air supply to drive the valve stem one direction, and internally

loaded springs return the valve to its original position. Also

available is the SV3 solenoid valve to electrically switch the supply

pressure between the air supply ports. Actuators are constructed

of anodized aluminum and are epoxy coated for years of corrosion

free service.

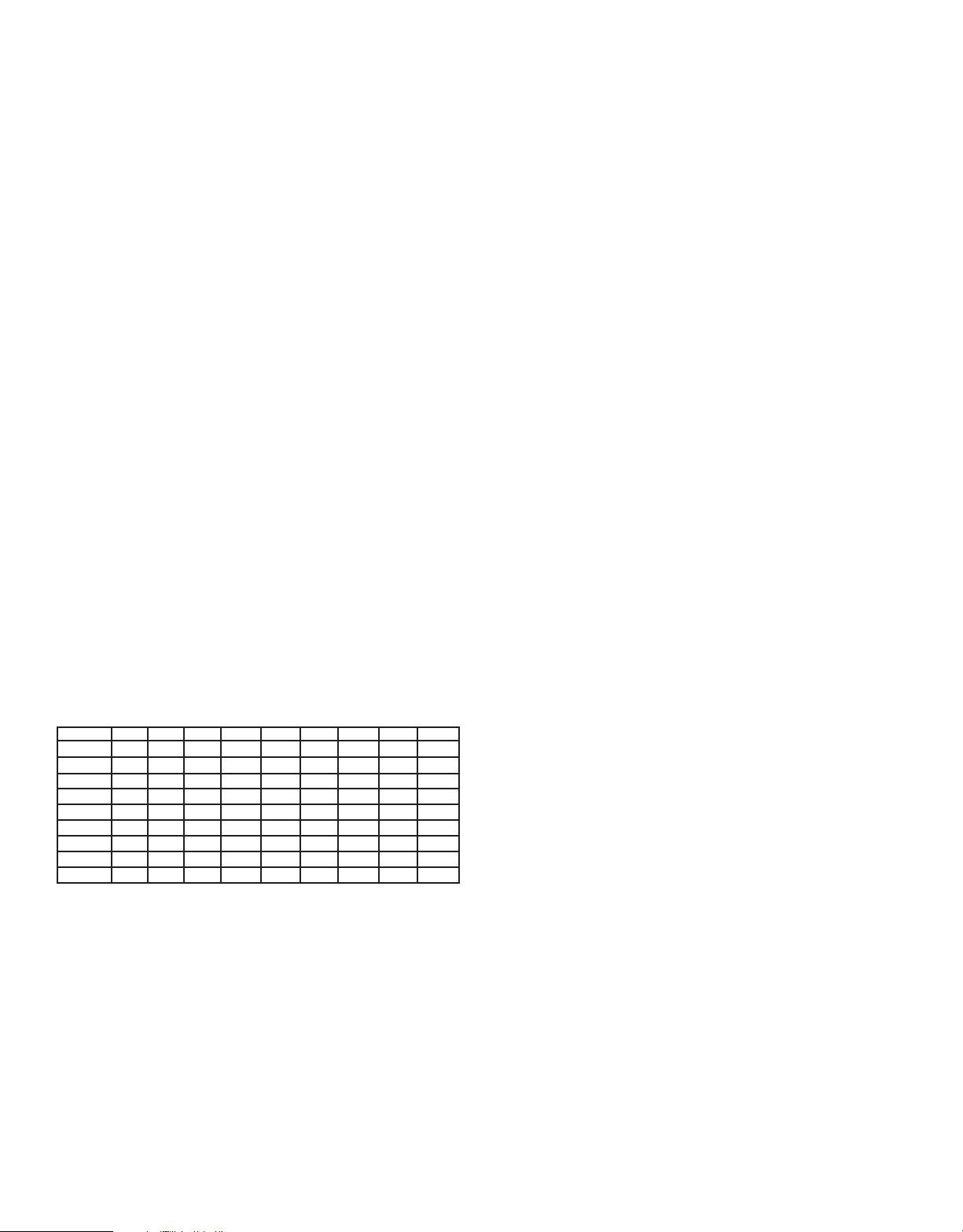

Cv Values

Valve Size

2-1/2˝

10˝

12˝

10°

20°

30°

40°

2˝

0.1

5

12

17

29

45

89

151

234

12

8

20

22

36

61

95

188

320

495

0.7

3˝

0.3

4˝

0.5

5˝

0.8

6˝

2

8˝

3

4

5

24

37

39

78

133

205

408

694

1072

50°

45

65

70

139

237

366

727

1237

1911

60°

64

98

116

230

392

605

1202

2034

3162

70°

90

144

183

364

620

958

1903

3240

5005

80°

125

204

275

546

930

1437

2854

4859

7507

90°

135

220

302

600

1022

1539

3136

5340

8250

SPECIFICATIONS

Valve Body

Service: Compatible liquids and gases.

Body: 2-way or 3-way.

Line Size: 2˝ to 12˝.

End Connections: Wafer or lug pattern designed for flanges to

ANSI B16.1, BS4504, DIN 2501.

Pressure Limits: Up to 8˝: 225 psi (15.5 bar); 10˝ – 12˝: 150 psi

(10.3 bar).

Wetted Materials: Disc: 316 SS; Liner: EPDM BUNA-N, or

Fluoroelastomer.

Temperature Limits: EPDM: -30 to 275°F (-34 to 135°C); BUNAN: 10 to 180°F (-12.2 to 82.2°C); Fluoroelastomer: 400°F (204°C).

Other Materials: Shaft: 316SS; Bottom/Top Bushing: bronze;

Body: cast iron; Shaft Seal: EPDM.

ACTUATORS

Electric “U” and “V” Series

Power Requirements: 115 VAC, 50/60 Hz, single phase.

Optional 220 VAC, 24 VAC, 12 VDC, and

24 VDC.

Power Consumption: (Locked Rotor Current): U_1, V_1: .55A;

U_2, 3, 4, V_2, 3, 4: 0.75A; U_ 5, 6, 7, V_5, 6, 7: 1.1A; U_ 8, V_8:

2.6A; U_9, V_9: 2.9A. (Only for 115 VAC, for other voltages

contact the factory).

Cycle Time: (sec. per 90º): U_1, V_1: 2.5; U_2, 3, V_2, 3: 5; U_4,

V_4: 10; U_ 5, 6, V_5, 6: 15; U_7, V_7: 30; U_ 8, V_8: 12; U_9,

V_9: 14. (Only for 115 VAC, for other voltages contact the factory).

Duty Cycle: U_1: 75%; U_2 to 7: 25%; U_8, 9: 100%; V_1 to 7:

75%; V_8, 9: 100%.

Enclosure Rating: NEMA 4. Optional NEMA 7 (Class 1, Div. II

Groups A, B, C, D).

Housing Material: Aluminum with thermal bonding polyester

powder finish.

Temperature Limit: 0 to 150ºF (-18 to 65ºC).

Conduit Connection: 1/2˝ female NPT.

Modulating Input (V Series): 4 to 20 mA.

Standard Features: Manual override and visual position indicator

except modulating units.

Pneumatic “DA” and “SR” Series

Type: DA series is double acting and SR series is spring return

(rack and pinion).

Normal Supply Pressure: 80 psi (5.5 bar).

Maximum Supply Pressure: 120 psig (8 bar).

Air Connections: DA1 to 5 and SR2 to 5: 1/8” female NPT, all

others: 1/4” female NPT.

Air Consumption: (cu. in. per stroke) DA1: 2.32, DA2: 6.59, DA3:

12.14, DA4: 16.32, DA5: 30.2, DA6: 45.3, DA7: 61.0, DA8: 106.9,

DA9: 137.9, DAA: 220.1, DAB: 348.1, DAC: 915.4, SR2: 7.7, SR3:

14.2, SR4: 17.2, SR5: 32.4, SR6: 54.4, SR7: 85.4, SR8: 122.1,

SR9: 146.5, SRA: 215.1, SRB: 462.6, SRC: 945.9.

Cycle Time: (sec. per 90º): DA1: .03, DA2: .04., DA3: .08, DA4:

.12, DA5: .19, DA6: 0.27, DA7: .47, DA8: .66, DA9: .93, DAA: 1.1,

DAB: 1.7, DAC: 4.5, SR2: .09, SR3: .14, SR4: .22, SR5: .33, SR6:

.46, SR7: .78, SR8: .90, SR9: .97, SRA: 1.34, SRB: 2.19, SRC:

6.20.

Housing Material: Anodized aluminum body and epoxy coated

aluminum end caps.

Temperature Limit: -4 to 180ºF (-20 to 82ºC).

Accessory Mounting: NAMUR standard.

Standard Features: Visual position indicator.

Page 3

ELECTRIC ACTUATOR

I. BASIC INSTALLATION

1. Operate valve manually and place in the open position. (NOTE: ALL

ELECTRIC ACTUATORS ARE SHIPPED IN THE OPEN POSITION.)

2. Remove any mechanical stops the valve might have. (DO NOT

REMOVE ANY PARTS NECESSARY FOR THE PROPER OPERATION

OF THE VALVE, SUCH AS THE PACKING GLAND, PACKING NUT,

ETC.)

3. Ensure that the actuator output shaft and valve stem are aligned

properly. If they are not, operate the valve manually until they are

correct.

4. Mount actuator to valve. Do not tighten nuts and bolts at this time.

5. Remove actuator cover.

6. Bring power to the actuator. CAUTION: Make sure power is OFF at

the main box.

7. Wire the actuator per the diagram attached to the inside of the

cover. Special actuators (those with positioner boards, etc.) will have

diagrams enclosed inside the cover.

8. Securely tighten bolts used to mount the actuator to a mounting

bracket or directly to the valve mounting pad if it is ISO5211 compliant.

9. Cycle the unit several times and check the open and closed

positions of the valve. Cams are pre-adjusted at the factory; due to the

variety of valve designs and types, however, slight adjustments might

be required. (SEE II and III).

10. Replace cover and tighten screws.

II. TO SET THE OPEN POSITION

1. Cycle the valve to the open position by applying power to terminals

#1 and #2. The top cam and switch control this position. In the open

position, the set screw in the top cam will be accessible.

2. If the valve is not open completely:

A. Slightly loosen the 8-32 x 1/4” set screw on the top cam.

B. Rotate the cam clockwise (CW) by hand until the switch

makes contact. Contact is made when a slight click can be

heard. By making incremental CW movements of the top

cam, the valve can be positioned precisely in the desired

position.

C. When the top cam is set, tighten the set screw securely.

3. If the valve opens too far:

A. Apply power to terminals #1 and #3. This will begin to

rotate valve CW. When valve is fully open and in the exact

position desired, remove power from actuator.

B. Loosen the set screw in the top cam.

C. Rotate the top cam counterclockwise (CCW) until the

switch arm drops off the round portion of the cam onto the

flat section. A slight click can be heard as the switch

changes state.

D. Continue applying power to terminals #1 and #3 until

valve is in the desired position.

III. TO SET THE CLOSED POSITION

1. Apply power to terminals #1 and #3 to move the valve toward the

closed position. The bottom cam and switch control the closed

position. In the closed position, the set screw in the bottom cam will

be accessible.

2. If the valve is not closed completely:

A. Slightly loosen the 8-32 x 1/4” set screw on the bottom

cam.

B. Rotate the cam counter-clockwise (CCW) by hand until

the switch makes contact. Contact is made when a slight

click can be heard. By making incremental CCW movements of the bottom cam, the valve can be positioned precisely in the desired position.

C. When the top cam is set, tighten the set screw securely.

3. If the valve closes too far:

A. Apply power to terminals #1 and #2. This will begin to

rotate valve CCW . When valve is fully closed and in the exact

position desired, remove power from actuator.

B. Loosen the set screw in the top cam.

C. Rotate the top cam clockwise (CW) until the switch arm

drops off the round portion of the cam onto the flat section.

A slight click can be heard as the switch is no longer making contact with the round part of the cam.

D. Continue applying power to terminals #1 and #2 until

valve is in the desired position.

IV. MAINTENANCE

Once the actuator has been properly installed, it requires no

maintenance. The gear train has been permanently lubricated and in

most cases will never be disturbed. In the event it becomes necessary

to open the gear box for any reason, however, Shell Darina®#2 grease

is recommended for re-lubricating.

Darina® is a registered trademark of Shell Oil Company

Page 3

Most standard electric actuators are rated for 25% duty cycle at 100%

ambient temperature at the rated torque.

All actuators are equipped with thermal overload protection to guard

the motor against damage due to overheating.

All actuators are designed to withstand stall conditions. It is not

recommended to subject the unit to repeated stall conditions.

When ordering parts, please specify:

A. Model # B. Serial # C. Part Description

Recommended spare parts include:

A. Standard actuator: set of cams and switches.

B. Actuators w/positioner: set of cams and switches; 1K

potentiometer; valve positioner board.

IX. NEMA 7 ELECTRIC ACTUATORS

In general, operation and maintenance of a NEMA 7 electric actuator

is no different than that of a NEMA 4 actuator. However, some

precautions must be followed:

1. DO NOT under any circumstances remove the cover of the actuator

while in a hazardous location. Removal of the cover while in a

hazardous location could cause ignition of hazardous atmospheres.

2. DO NOT under any circumstances use a NEMA 7 electric actuator

in a hazardous location that does not meet the specifications for which

the actuator was designed.

3. Always mount and cycle test the actuator on the valve in a nonhazardous location.

4. When removing the cover, care must be taken not to scratch, scar

of deform the flame path of the cover and base of the actuator, since

this will negate the NEMA rating of the enclosure.

5. When replacing the cover on actuators rated for both NEMA 4 & 7,

take care that the gasket is in place to assure proper clearance after

the cover is secured. After the cover screws are tightened, the

clearance between the cover and the base should be checked. A

.002” thick by 1/2” wide feeler gauge is used for this; it must not enter

between the two mating faces more than .125".

6. All electrical connections must be in accordance with the

specifications for which the unit is being used.

7. Should the unit ever require maintenance, remove from the

hazardous location before attempting to work on the unit.

If the actuator is in a critical application, it is advisable to have a

standby unit in stock.

XI. TROUBLESHOOTING

SYMPTOM

Actuator does not

respond to control

signal

Actuator will not

open and/or close

completely

Valve oscillates

Actuator motor

runs but output

shaft does not

rotate

V. DUTY CYCLE

VI. THERMAL OVERLOAD

VII. MECHANICAL OVERLOAD

VIII. SPARE PARTS

PROBLEM

•Power is not on

•Actuator wired incorrectly

•Incorrect voltage

•Thermal Overload

•Actuator and Valve in

opposite positions when

actuator installed

•Travel limit switch set

incorrectly

•Valve torque too high

•Mechanical stops not

removed when installing

actuator

•Torque of valve too high

•Actuator without brake

installed on butterfly valve

•Motor brake misadjusted

•Gear damaged/sheared

pin

•Turn on Power

•Check wiring diagram;

re-wire

•Bring correct supply

to actuator

•Allow motor to cool;

resets automatically

•Remove actuator;

remount after 90° turn

•Set cams per

instructions

•Install correct unit

•Remove stops

•Torque of valve too

high

•Install brake

•Adjust brake; tighten

screw

•Contact factory

SOLUTION

Page 4

Page 4

PNEUMATIC ACTUATOR

PNEUMATIC ACTUATOR

NOTE: For optimal operation, 3PBV actuators should be run with a

supply of clean, lubricated air.

SPRING RETURN ACTUATORS

Air to PORT 2 (the right hand port) causes the actuator to turn CCW.

Loss of air to PORT 2 causes air to exhaust and the actuator turns

CW. This is the FAIL CLOSE operation.

DOUBLE ACTING ACTUATORS

Air to PORT 2 (the right hand port) causes the actuator to turn CCW.

Air to PORT 1 (the left hand port) causes the actuator to turn CW.

DISASSEMBLING STANDARD ACTUATORS

IMPORTANT: Before beginning disassembly, ensure that the air

supply to the actuator has been disconnected, all accessories have

been removed and that the actuator has been dismounted from the

valve.

1. Loosen the end cap fasteners (22) with a wrench (size varies

depending on actuator model). On the spring return actuator , alternate

3 to 5 turns on each fastener until the springs are completely

decompressed. Use caution in removing the cap since the springs are

under load until the fasteners are fully extended.

2. Remove the pinion snap ring (10) with a lock ring tool. The indicator

(7) may now be removed.

3. Turn the pinion shaft (2) CCW until the pistons are at the full end of

travel. Disengage the pistons (11) from the pinion. (NOTE: Low

pressure air--3 to 5 P.S.I. MAXIMUM--might be required to force the

pistons completely from the body.) Note the position of the pistons

before removing them from the actuator body. The part numbers of the

pistons are located on the side and should be right-side up on an

actuator with a standard orientation.

4. Remove the pinion through the bottom of the actuator. The actuator

is now completely disassembled. All replacement parts may now be

put in. W.E. Anderson recommends that all wear parts (3, 4, 5, 6, 12,

13, 14) be replaced before reassembly.

REASSEMBLING STANDARD ACTUATORS

IMPORTANT: Be sure that the actuator surfaces are free of grit

and scratches before reassembling.

1. Apply a light film of grease to all o-rings and the pinion before

replacing.

2. Put the pinion (2) back through the actuator with the flats of the

pinion shaft running parallel with the body.

3. When reassembling the actuator, make sure that the piston racks

are square to the actuator body and returned to their original

orientation. (NOTE: The normal operation of all PBV pneumatic

actuators is FAIL CLOSED. To change the orientation to FAIL OPEN,

rotate the racks 180º to create a reverse operation.)

4. When replacing springs in a spring return actuator, ensure that the

springs are replaced in their identical position in the end cap from

which they were removed. (NOTE: In some circumstances, you might

want to change the standard 80 pound spring set to fit your

application and available air pressure. Changing the spring sets on

3PBV pneumatic actuators requires no special tools. Please refer to

the spring combination torque chart in our catalog for the inner and

outer spring combinations that will allow you to operate with the spring

set that you desire.)

4. Seal the end caps with a petroleum lubricant and bolt to actuator

body.

5. Check the seal of the actuator by covering seal areas (pinion, end

caps) with soapy water and using low pressure air to the actuator to

ensure that no bubbles are produced.

PNEUMATIC ACTUATOR PARTS LIST

1. Extruded aluminum housing

2. Nickel plated steel anti-blowout pinion

3. NBR 70 lower pinion O-ring

4. PTFE pinion spacer ring

5. NBR 70 top pinion O-ring

6. PTFE cam spacer ring

7. SS indicator cam

8. Nylon position indicator

9. SS pinion washer

10. Pinion snap ring

11. Die cast aluminum piston

*spring return actuators only parts subject to wear. Please contact the

factory or your W.E. Anderson distributor for replacement kits.

◊

◊

◊

12. Piston O-ring bushing

13. PTFE antifriction ring

◊

14. PTFE piston thrust block

15. SS stop bolt retaining nut

16. SS stop bolt

17. External spring*

18. Internal spring*

19. Die cast aluminum end cap (left)

20. Die cast aluminum end cap (right)

21. NBR end cap seats

22. SS end cap bolt

◊

◊

◊

MAINTENANCE

The Series ABFV Automated Butterfly Valves are not field

serviceable and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure to

include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return

goods authorization number before shipping.

©Copyright 2006 Dwyer Instruments, Inc. Printed in U.S.A. 12/06 FR# R2-443533-00

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...