Page 1

Series A6 Durable Pressure Switch

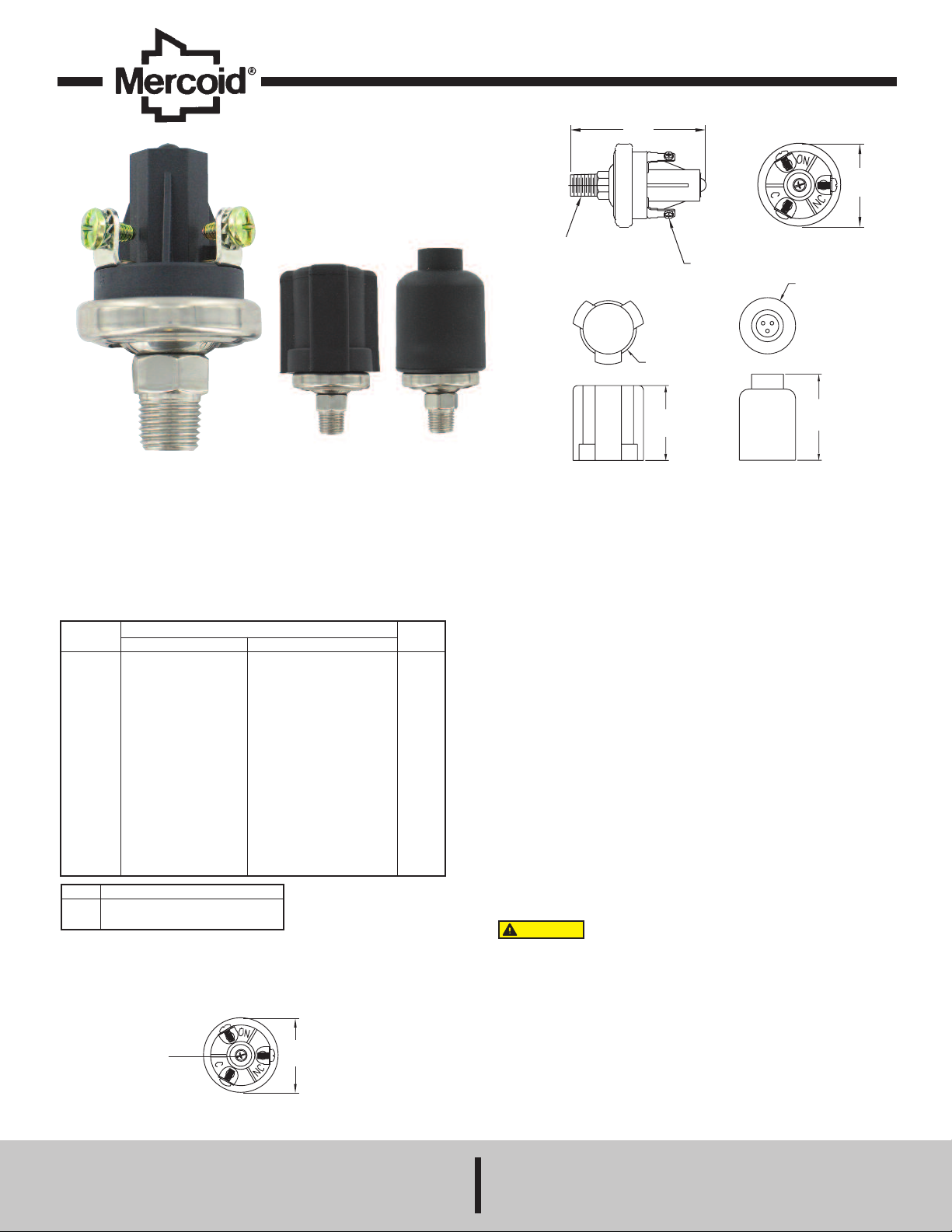

A-439

2

[50.8]

ø1-1/2

[ø38.1]

2

-7/16

[

62]

3X #8-32 SCREW TERMINALS

ø

1.500

[

ø38.1]

1

/4˝ MNPT

A-440

2-5/16

[58.74]

ø1-1/2

[ø38.1]

A

ø1.500

[ø38.1]

Specifications - Installation and Operating Instructions

-439

A

A-440

Bulletin IN-A6

Series A6 Durable Pressure Switches have been specifically designed to stand

up to extended duty applications. These switches are constructed with a polyimide

ilm diaphragm and are compatible with a variety of fluids. For ease of installation,

f

the switches come with a 1/4˝ male NPT process connection and can be mounted

in any orientation. The Series A6 pressure switches are compact and have great

setpoint integrity, and feature simple, easy set-point field adjustment.

INSTALLATION/MOUNTING

The switch can be mounted in any position. Do not twist the case when installing.

Set Point Range psi (bar)

Model

A6-151221

A6-251221

A6-351221

A6-451221

A6-551221

A6-651221

A6-751221

A6-851221

A6-153221

A6-253221

A6-353221

A6-453221

A6-553221

A6-653221

A6-753221

A6-853221

Model

A-439

A-440

SETPOINT ADJUSTMENT

Setpoint is field adjustable within the range. In order to adjust setpoint remove

black plastic cover to expose the setpoint adjustment screw as indicated in the

figure below. Adjust top screw to change setpoint. Clockwise to increase setpoint

and counterclockwise to decrease setpoint.

Adjustment Screw

©Copyright 2011 Dwyer Instruments, Inc. Printed in U.S.A. 6/11 FR# R3-443563-00 Rev. 2

MERCOID DIVISION

DWYER INSTRUMENTS, INC.

P.O. BOX 258 • MICHIGAN CITY, INDIANA 46361 U.S. A.

NC

0.5 to 1 (0.03 to 0.07)

1.1 to 3 (0.08 to 0.21)

3.1 to 7 (0.21 to 0.48)

8 to 13 (0.55 to 0.90)

14 to 24 (0.97 to 1.66)

25 to 50 (1.73 to 3.45)

51 to 90 (3.52 to 6.21)

91 to 150 (6.28 to 10.35)

0.5 to 1 (0.03 to 0.07)

1.1 to 3 (0.08 to 0.21)

3.1 to 7 (0.21 to 0.48)

8 to 13 (0.55 to 0.90)

14 to 24 (0.97 to 1.66)

25 to 50 (1.73 to 3.45)

51 to 90 (3.52 to 6.21)

91 to 150 (6.28 to 10.35)

Description

Weatherproof IP65 Cover

Weatherproof IP65 w/ Fly-wire holes

NO

1.1 to 3.1 (0.08-0.21)

2.27 to 6.05 (0.16-0.42)

4.22 to 10.75 (0.29 to 0.74)

12.3 to 17.5 (0.85 to 1.21)

18.6 to 31.8 (1.28 to 2.19)

33.1 to 61 (2.28 to 4.21)

65.6 to 112.3 (4.53 to 7.75)

114.7 to 198.3 (7.94 to 13.68)

1.1 to 3.1 (0.08-0.21)

2.27 to 6.05 (0.16-0.42)

4.22 to 10.75 (0.29 to 0.74)

12.3 to 17.5 (0.85 to 1.21)

18.6 to 31.8 (1.28 to 2.19)

33.1 to 61 (2.28 to 4.21)

65.6 to 112.3 (4.53 to 7.75)

114.7 to 198.3 (7.94 to 13.68)

Base

Material

Brass

Brass

Brass

Brass

Brass

Brass

Brass

Brass

304 SS

304 SS

304 SS

304 SS

304 SS

304 SS

304 SS

304 SS

SPECIFICATIONS

Service: Air, motor oils, transmission oils, jet fuels, and similar hydrocarbon

media. (Not for water use).

Wetted Materials: Base: 304 SS; Diaphragm: Polyimide film.

Temperature Limits: -40 to 248˚F (-40 to 120˚C).

Pressure Limits:

Operating Pressure: 150 psi (10.3 bar) for 0.5-24 psi set point

ranges, 250 psi (17.2 bar) for 25-150 psi set-point ranges;

Proof Pressure: 500 psi (34.5 bar);

Burst Pressure: 750 psi (51.7 bar) for 0.5-24 psi set point ranges,

1250 psi (86.2 bar) for 25-150 psi set-point ranges.

Enclosure Rating: General purpose or with cover: IP65 - weatherproof.

Repeatability: ±10% of set-point.

Set Point Tolerance: ±15% of range.

Switch Type: 1 SPST NO, 1 SPST NC. NO and NC switch independent from

each other.

Electrical Ratings:

Resistive: 15 A @ 6 VDC, 8 A @ 12 VDC, 4 A @ 24 VDC;

Inductive: 1 A @ 120 VAC, 0.5 A @ 240 VAC.

Electrical Connections: #8-32 screw terminals.

Process Connection: 1/4˝ NPT male.

Mounting Orientation: Switch can be installed in any position.

Set-point Adjustment: Screw.

Agency Approval: CE.

Weight: 0.13 lb (0.06 kg).

WIRING

All wiring must conform to the National Electrical Code and local regulations. Do

not install the control to handle loads in excess of the electrical rating shown in

the specifications. The terminals are labeled on the switch itself.

CAUTION

switch. Use the control only with compatible medias.

MAINTENANCE

Upon final installation of the Series A6 Durable Pressure Switch, no routine

maintenance is required. A periodic check of the system calibration is

recommended. The Series A6 is not field serviceable and should be returned if

repair is needed (field repair should not be attempted and may void warranty). Be

sure to include a brief description of the problem plus any relevant application

notes. Contact customer service to receive a return good authorization number

before shipping.

No lubrication or periodic servicing is required. Mount the

control securely. Never exceed the electrical rating for the

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...