Page 1

Outdoor Air St atic Pressure Pickup Port

8

Installation & Operation Instructions

20596_ins_Dwyer_A420

How It Works

Building static pressure is the pressure difference between the inside and the outside of a building. The outdoor static

pressure is simply the atmospheric pressure at the building site. The building may have positive, neutral or negative

pressure with respect to the outside atmosphere. Differences in pressure are due to powered supply or exhaust fans and

are usually less than 0.1 inches of water.

A complication in measuring the building static pressure is the dynamic action of the wind. A gentle breeze of 10 MPH

provides a pressure of 0.048 inches of water, a gale of 40 MPH is 0.772 inches and a hurricane of 75 MPH is 2.716 inches.

Clearly , the wind’s pressure may be more than the desired building static pressure. Measuring the wind’ s pressure instead

of the true outdoor static pressure will radically alter the actual static pressure reading.

Mounting the unit with the plate parallel to the earth’s surface, as shown in Figure 2 allows the predominantly horizontal

flow of the wind an omni-directional entry between the plate and the housing. The plate forces the wind to move perpendicularly to the pressure orifice in the housing, irrespective of the wind’s direction, greatly minimizing the dynamic air pressure.

Mounting the unit vertically, as on the side of a roof top air-conditioning unit (RTU), will only provide a true static pressure

reading if the wind is blowing within 15 to 20 degrees of the direction of the opening. If the wind is blowing at a vertically

mounted Outdoor Air St atic Pressure Pickup Port it will “pile up” providing a higher than correct static pressure reading. If

the wind is blowing away from the sensor it will be in the wake of the RTU providing a lower than correct static pressure

reading.

rev.

4/23/0

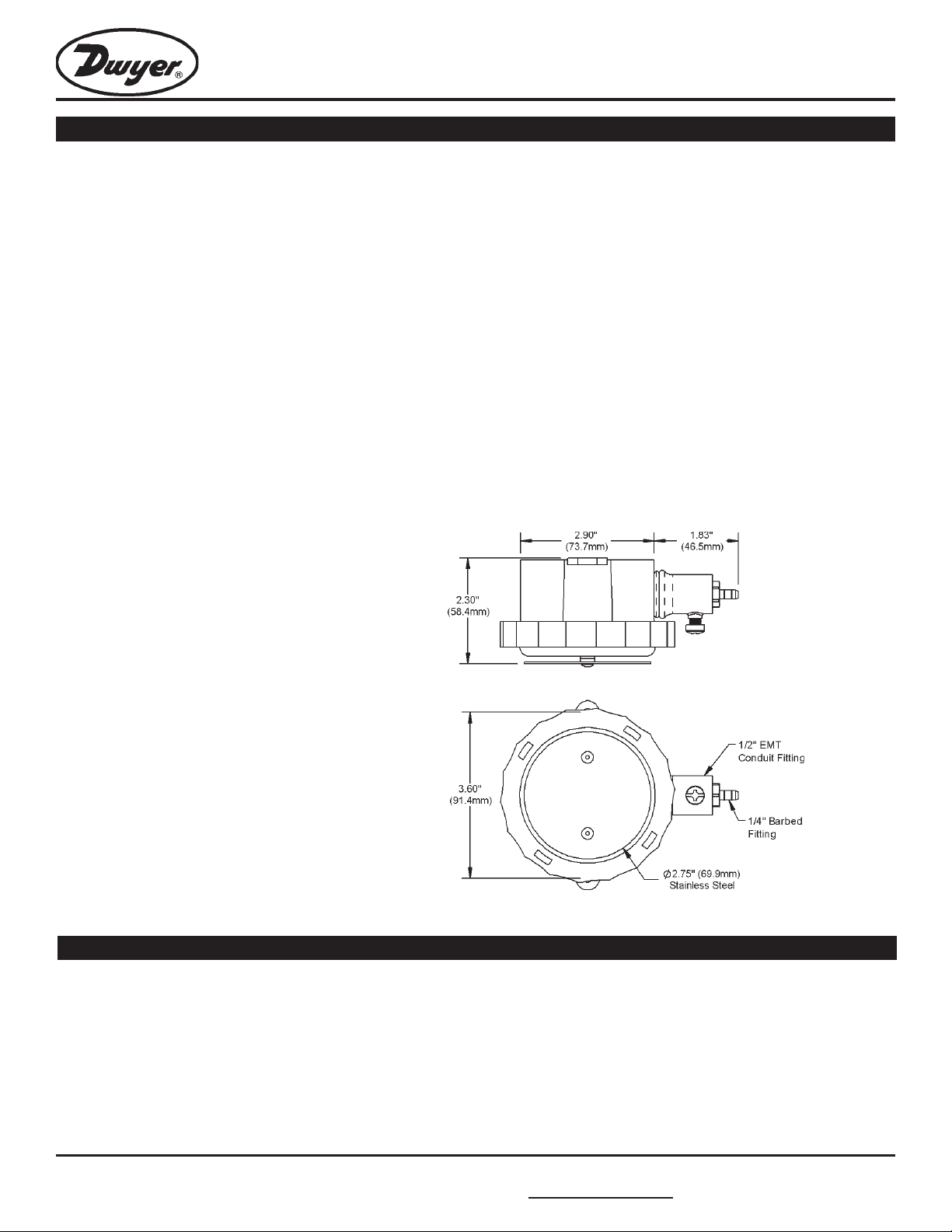

Figure 1: Outdoor Air S tatic

Pressure Pickup Port

Mounting

The Outdoor Air S tatic Pressure Pickup Port should be mounted at least 12 inches above surrounding obstacles so that

you get the true static pressure reading. Also supplied is a brass bulkhead fitting to get your pressure signal inside the

building envelope, the user supplies all necessary pressure tubing and the 1/2 inch EMT conduit mounting support.

Mount the unit so that other equipment on the building cannot physically or mechanically obstruct it. Do not mount under

awnings or other projections within fifteen feet. If the unit cannot be roof mounted with an unobstructed view of the horizon,

then do not mount near economizers, intake or exhaust fans, or barometric dampers. Do not mount near building corners.

Mount near the center of the building away from balconies and opening windows. Mount at least 24 inches from the wall.

Specifications subject to change without notice.

Dwyer Instruments Inc., 102 Indiana Hwy . 212, Michigan City , IN 46361 USA

T el: 800/872-9141 or 219/879-8000 • Fax: 219/872-9057 • E-mail: info@dwyer-inst.com • Web: www .dwyer-inst.com

1

Page 2

20596_ins_Dwyer_A420

8

Outdoor Air St atic Pressure Pickup Port

Installation & Operation Instructions

4/23/0

rev.

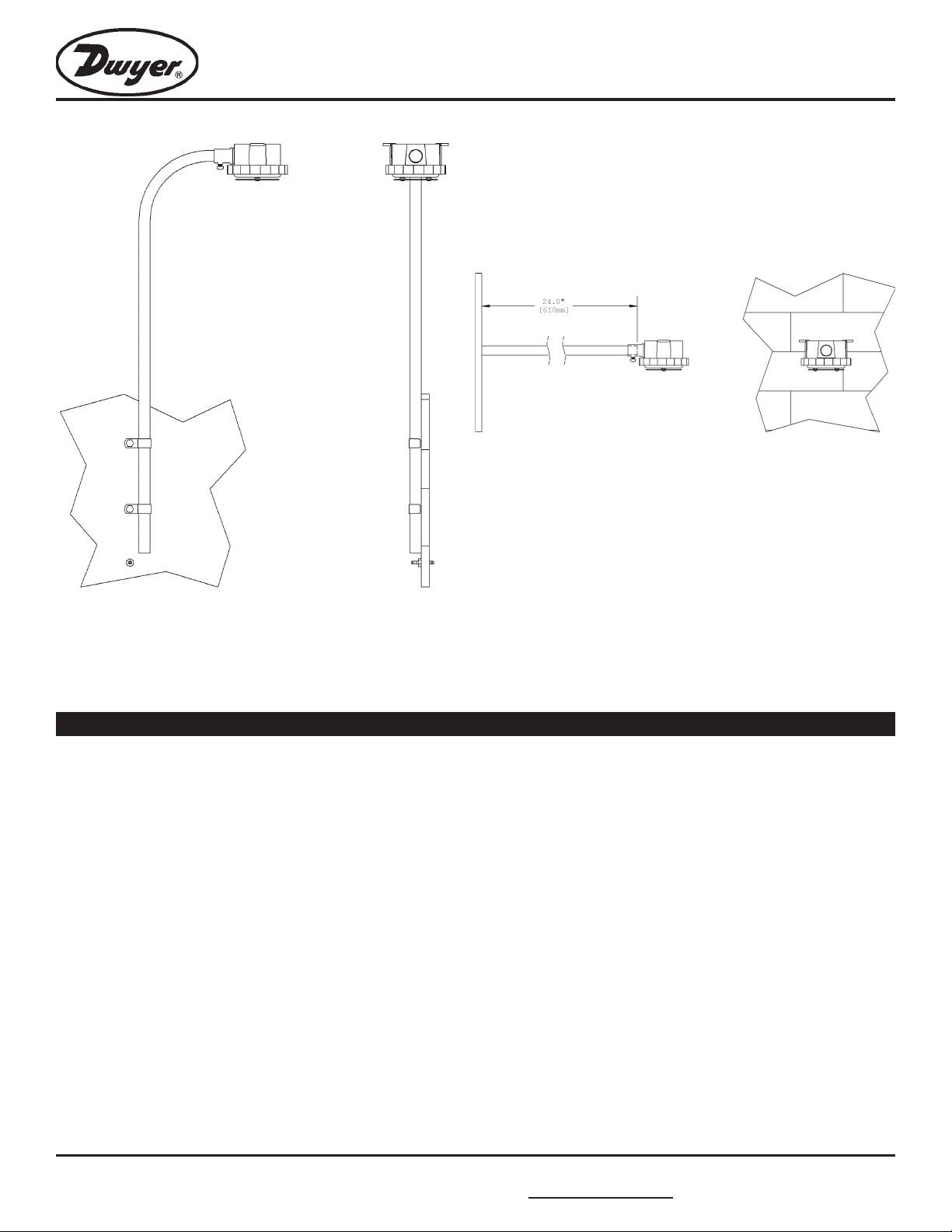

Figure 3: Wall Mounting,

1/2” EMT Conduit Mounting Support

Figure 2: Preferred Mounting,

1/2” EMT Conduit Mounting Support

Preferred Mounting

Figure 2 shows the Outdoor Air S tatic Pressure Pickup Port mounted on an RTU or air handler . A mounting support is field

fabricated from a piece of 1/2-inch EMT conduit bent to 90 degrees as shown. The short leg mounts the Out door Air St atic

Pressure Pickup Port. The long leg mounts the assembly to the side of the mechanical equipment. The length of the long

leg is dependent upon your installation site, just be sure that the Outdoor Air Static Pressure Sensor is at least 12 inches

above the top of the equipment. If you are mounting on mechanical equipment with a condenser fan or a building air

discharge, mount the Outdoor Air S t atic Pressure Pickup Port on the opposite end of the equipment. It is best to mount

the Outdoor Air Static Pressure Pickup Port to the compartment that contains the controls; usually there is a hole in the

compartment into the building envelope for control wiring.

Drill two holes in the sheet metal for the EMT conduit support brackets. Bolt the EMT conduit mounting support to the side

of the equipment. Place enough tubing on the Outdoor Air S tatic Pressure Pickup Port’s barbed fitting to reach beyond the

end of the EMT conduit mounting support. Slide the tubing down the inside of the EMT conduit and slide the Outdoor Air

St atic Pressure Pickup Port’s conduit fitting onto the EMT conduit. Position the Out door Air St atic Pressure Pickup Port

with the plate down and parallel to the earths surface. Tighten the Out door Air S tatic Pressure Pickup Port’s conduit fitting’ s

screw until the unit is secure on the EMT mounting support.

Drill a 5/16-inch hole in the sheet metal near the bottom of the EMT conduit mounting support for the bulkhead fitting.

Place the fitting through the sheet metal from the outside so that the nut is on the inside, tighten the nut securely but do

not over tighten. Place the tubing coming out the bottom on the EMT conduit mounting support onto the bulkhead fitting.

Place up to 150 feet of tubing on the bulkhead fitting’s inside port and run the tubing into the building to your pressure

transducer.

Specifications subject to change without notice.

Dwyer Instruments Inc., 102 Indiana Hwy . 212, Michigan City , IN 46361 USA

T el: 800/872-9141 or 219/879-8000 • Fax: 219/872-9057 • E-mail: info@dwyer-inst.com • Web: www .dwyer-inst.com

2

Loading...

Loading...