Page 1

Bulletin P-A-286

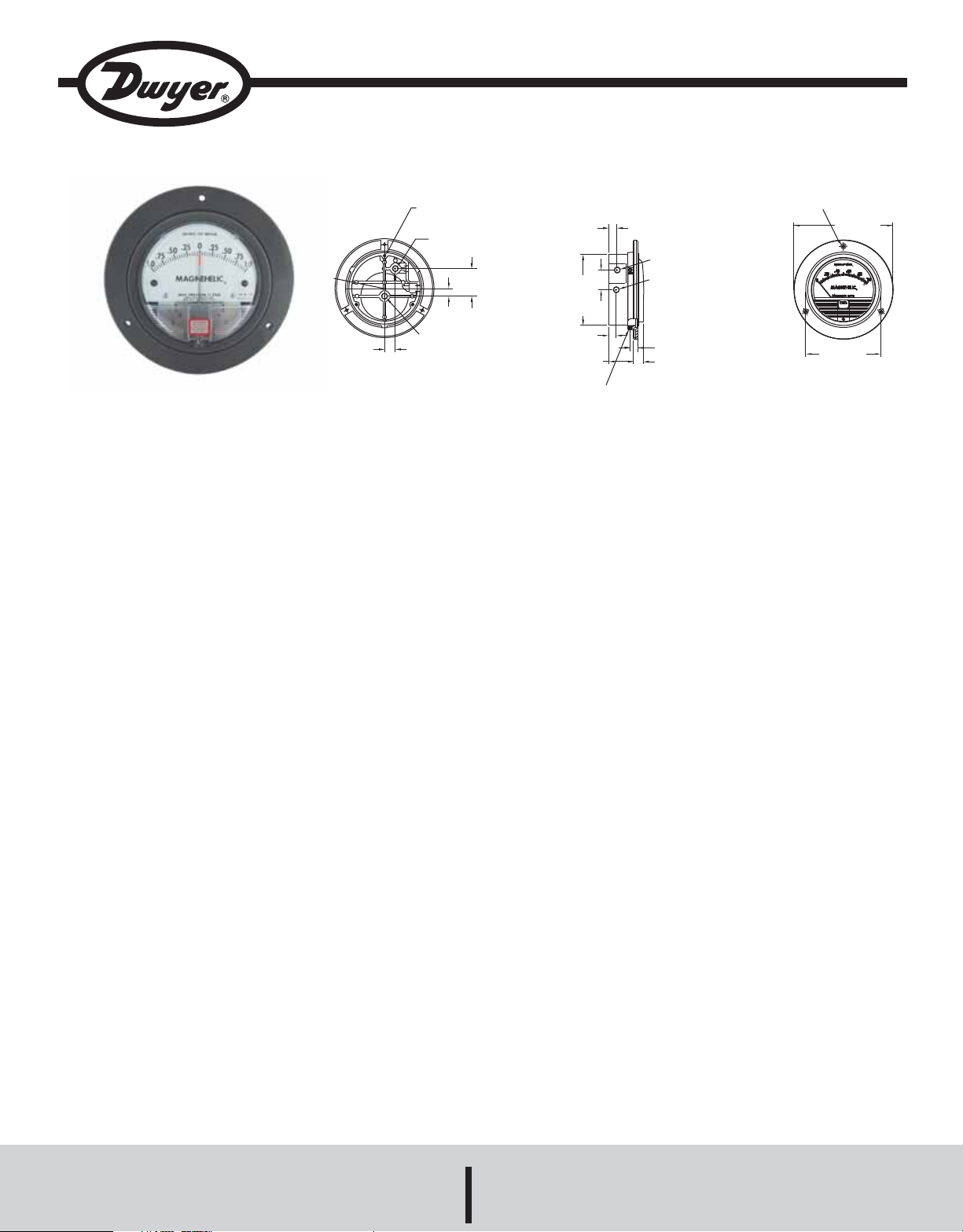

Series A-286 Magnehelic®Gage Panel Mounting Flange

Specifications - Installation and Operating Instructions

(3) #6-32 X 3/16 [4.76] OP HOLES

EQUALLY SPACED ON A ø4-1/8 [104.78]

BOLT CIRCLE FOR PANEL MOUNTING

1/8 FEMALE NPT HIGH

PRESSURE CONNECTION

1/2

[12.70]

11/16

[17.46]

1/8 FEMALE NPT LOW

PRESSURE CONNECTION

The new mounting flange can be used on any Dwyer Instruments, Inc.

gage that possesses a 4-1/2˝ (115 mm) diameter housing. The flange is

secured to the gage behind its bezel with three set screws. The set

screws hold the gage tight in place. The gage/flange can then be

attached to a surface or panel with a drill and the supplied mounting

screws. The flange’s three mounting holes follow the industry standard

mounting pattern. The flange is made of a robust plastic composite and

comes with three pre-installed set screws, an allen wrench for tightening and three flange mounting screws.

1-3/4

[44.45]

(3) #8-32 X 1/4˝ [6.35] LG

SET SCREWS EQUALLY SPACED

ø4-31/64

[113.90]

15/32

[11.91]

1019/32

[40.48]

SPECIFICATIONS

Flange Materials: Plastic.

Weight: 2.3 oz (65 g).

INCLUDED ACCESSORIES

3 Pre-installed metal set screws

3 Mounting screws

1 Allen wrench

1 Instruction manual with mounting template

1-1/4

[31.75]

(3) ø11/32 [8.73] X 82˝ COUNTERSINK

17/32

[13.49]

1/8 FEMALE NPT HIGH

PRESSURE CONNECTION

1/8 FEMALE NPT LOW

PRESSURE CONNECTION

15/32

[11.91]

5/8

[15.88]

ø3/16 [4.76] X THRU ON

BOLT CIRCLE FOR PANEL

MOUNTING WITH FLANGE

A 5-17/32 [140.49]

ø4-3/4

[120.65]

ø6-9/32

[159.54]

INSTALLATION

Cut out a circular hole using the template on this manual. The diameter

hole size depends on tightness of set screws securing the flange to the

gage. Typically, a sufficient flange tightness will produce a required

diameter cut-out between 5 1/16˝ – 5 1/8˝. See the included template to

locate on your panel this proper size diameter cut-out in relation to the

locations of the three mounting screws.

Next, alternating between the three set screws, use the included allen

wrench to turn each set screw 1/4 to 1/2 turns at a time to ensure an

even tightness so one screw doesn’t cause the flange to bow.

To properly secure flange to gage, 1 to 1.5 full revolutions of each set

screw will be required.

Last, install flange with secured gage to wall or panel using the three

included mounting screws.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

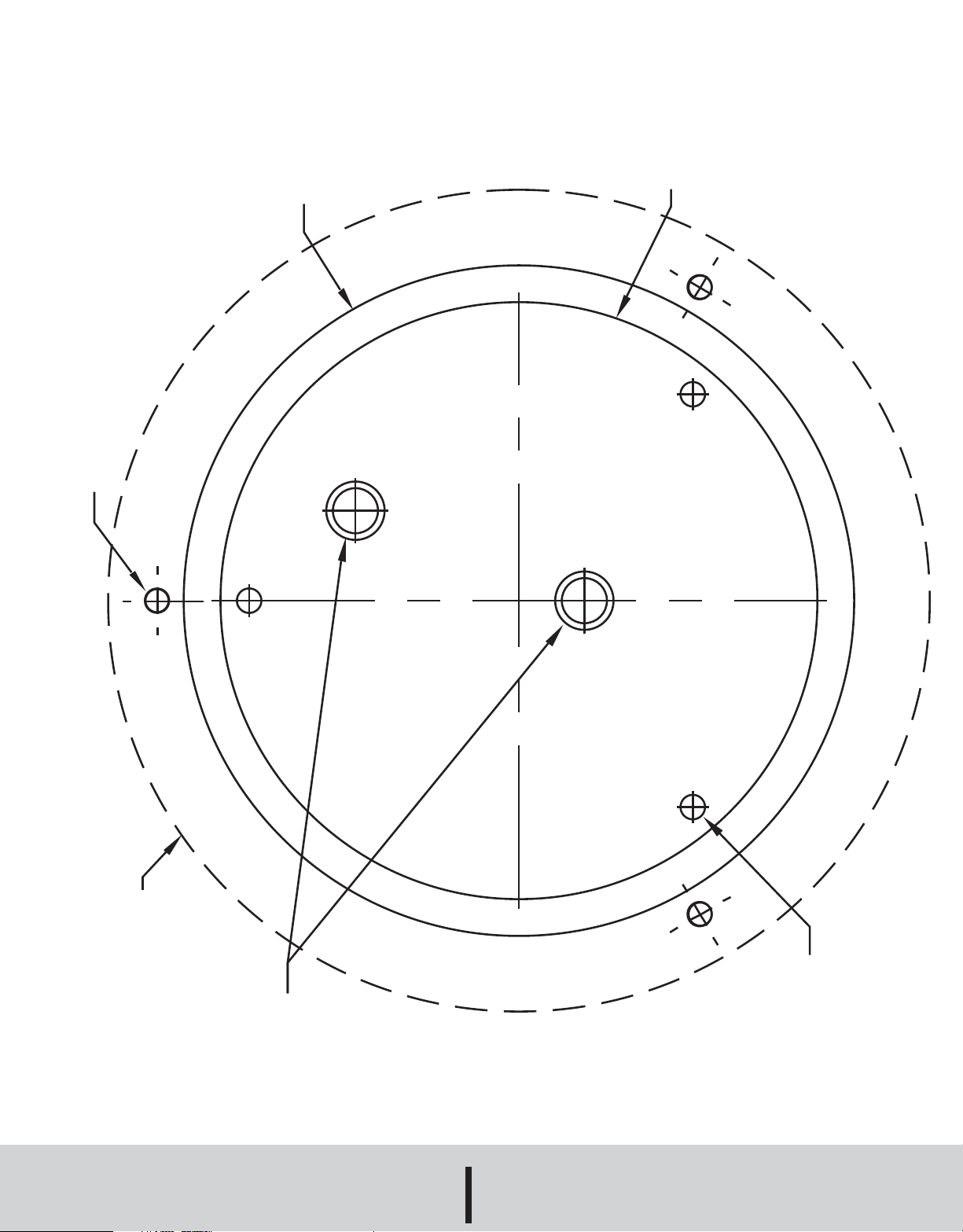

(3) SURFACE MOUNTING

HOLE LOCATIONS

THRU HOLE FOR

PRESSURE PORTS

OUTSIDE DIAMETER OF FLANGE

(3) FLANGE MOUNTING

HOLE LOCATIONS

MOUNTING HOLE

DIMENSION FOR FLANGE

ø5-1/8 [130.18]

STANDARD MOUNTING

HOLE DIMENSION

FOR MAGNEHELIC GAGE

ø4-9/16 [115.89]

Flange Mounting Template

©Copyright 2010 Dwyer Instruments, Inc. Printed in U.S.A. 7/10 FR# R1-443783-00 Rev. 2

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...