Page 1

Bulletin E-90-BPC

Series 4B, 8B, 16B and 32B Microprocessor

Based Temperature Process Control

Specifications - Installation and Operating Instructions

LOVE CONTROLS

A DIV. OF DWYER INSTRUMENTS INC.

P.O. BOX 338 - MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000 www.love-controls.com

Fax: 219/872-9057 e-mail:love@love-controls.com

Page 2

TABLE OF CONTENTS

Model Number Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Panel Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Front Panel Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Security Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Control Operation Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Programming and Operation for Ramp and Soak Feature . . . . . . . . . . . . . . . . 11-13

Programming and Operation for PID Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Description of Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operation Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16

Regulation Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-19

Initial Setting Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-22

Alarm Output Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Communication Register List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

Diagnostic Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Input Sensor Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Page 2

Page 3

MODEL NUMBER IDENTIFICATION

OPTIONS

32B

OPTIONS

16B

OUTPUT 1

2 = Voltage Pulse

3 = Relay

5 = Current

6 = Linear Voltage

OPTIONS

-LV = Low Voltage

4B

OUTPUT 1

2 = Voltage Pulse

3 = Relay

5 = Current

6 = Linear Voltage

OPTIONS

Blank = none

1 = Event input

2 = Current Transformer

-LV = Low Voltage

OUTPUT 2

2 = Voltage Pulse

3 = Relay

OPTIONS

OUTPUT 2

2 = Voltage Pulse

3 = Relay

OUTPUT 1

2 = Voltage Pulse

3 = Relay

5 = Current

6 = Linear Voltage

OPTIONS

Blank = none

1 = Event input

2 = Current Transformer

-LV = Low Voltage

8B

OUTPUT 1

2 = Voltage Pulse

3 = Relay

5 = Current

6 = Linear Voltage

OPTIONS

Blank = none

1 = Event input

2 = Current Transformer

-LV = Low Voltage

OUTPUT 2

2 = Voltage Pulse

3 = Relay

OPTIONS

OUTPUT 2

2 = Voltage Pulse

3 = Relay

GETTING STARTED

1. Install the control as described on page 4.

2. Wire your control following the instructions on pages 6-7. Please read the

Precautions section located at the end of this manual before wiring the control.

3. For best results when programming changes are necessary, make all changes to the

Initial Setting mode (Pages 20-22) before making changes to the Regulation Mode

(Pages 17-19) or Operation Mode (Pages 15-16). If any error messages occur, check

the Diagnostic Error Message Section (Page 26) for assistance.

Page 3

Page 4

INSTALLATION

Mount the instrument in a location that will not be subject to excessive temperature, shock,

or vibration. All models are designed for mounting in an enclosed panel.

Select the position desired for the instrument on the panel. Prepare the panel by cutting and

deburring the required opening per the panel cut out dimensions listed below. Follow the

mounting instructions listed on page 5. Lastly, wire the controller per the appropriate wiring

diagram listed on page 6.

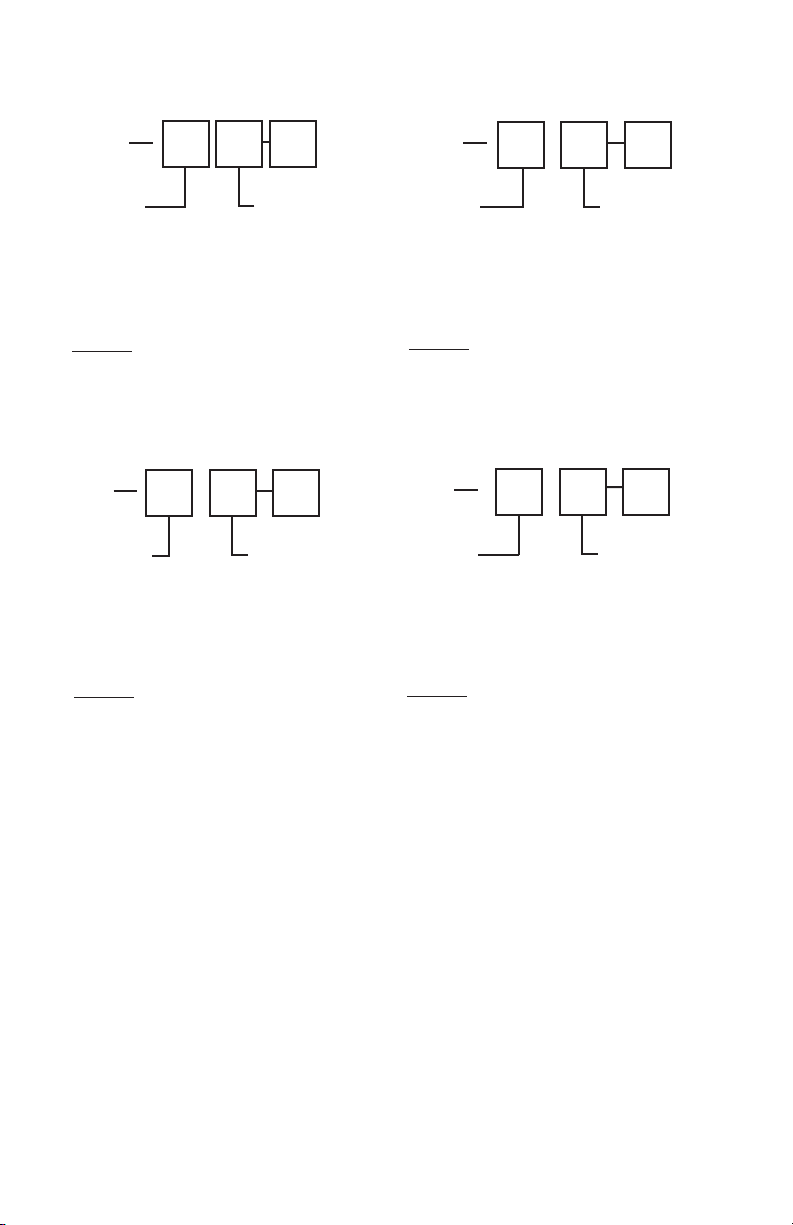

PANEL CUTOUT DIMENSIONS

Page 4

Page 5

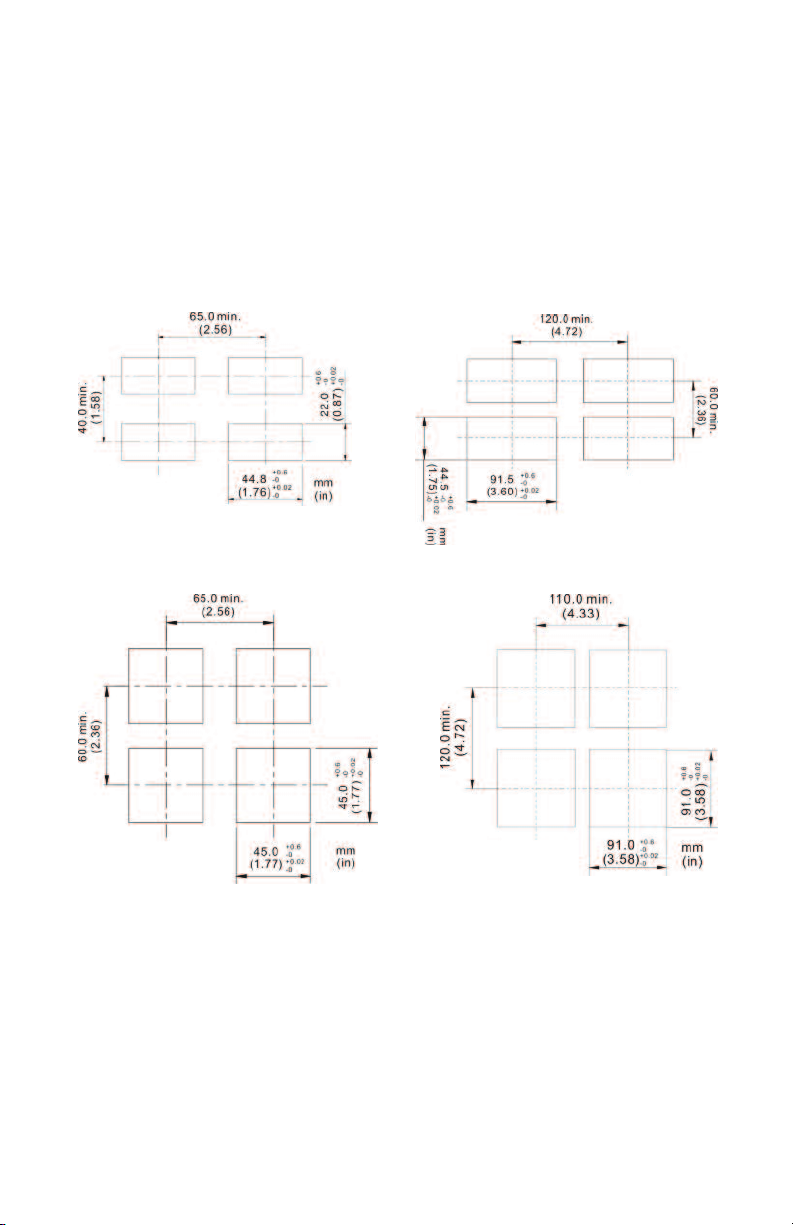

MOUNTING METHOD

Step 1: From the front of the panel, slide the controller housing through

the cut out. The housing gasket should be against the housing

flange before installing.

Step 2: Insert the mounting brackets into the mounting grooves on the

top and bottom of the controller (16B, 8B, and 4B). For the 32B,

slide the mounting collar over the housing from the rear of the

panel.

Step 3: Push the mounting brackets forward until the bracket stops at

the panel wall.

Step 4: Insert and tighten the screws on the bracket to secure the

controller in place. (The screw torque should be 0.8 kgf-cm).

Mounting Bracket Installation

16B/4B/8B Mounting Method

32 Mounting Method

Page 5

Page 6

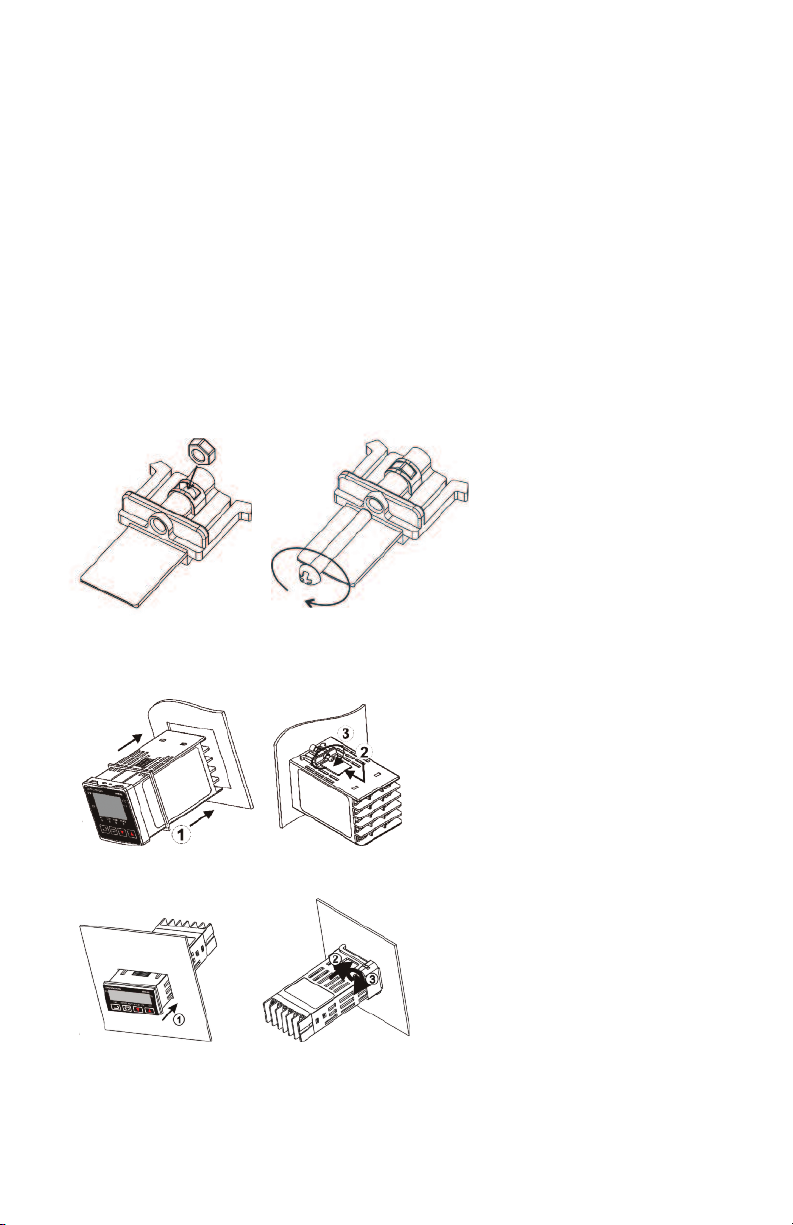

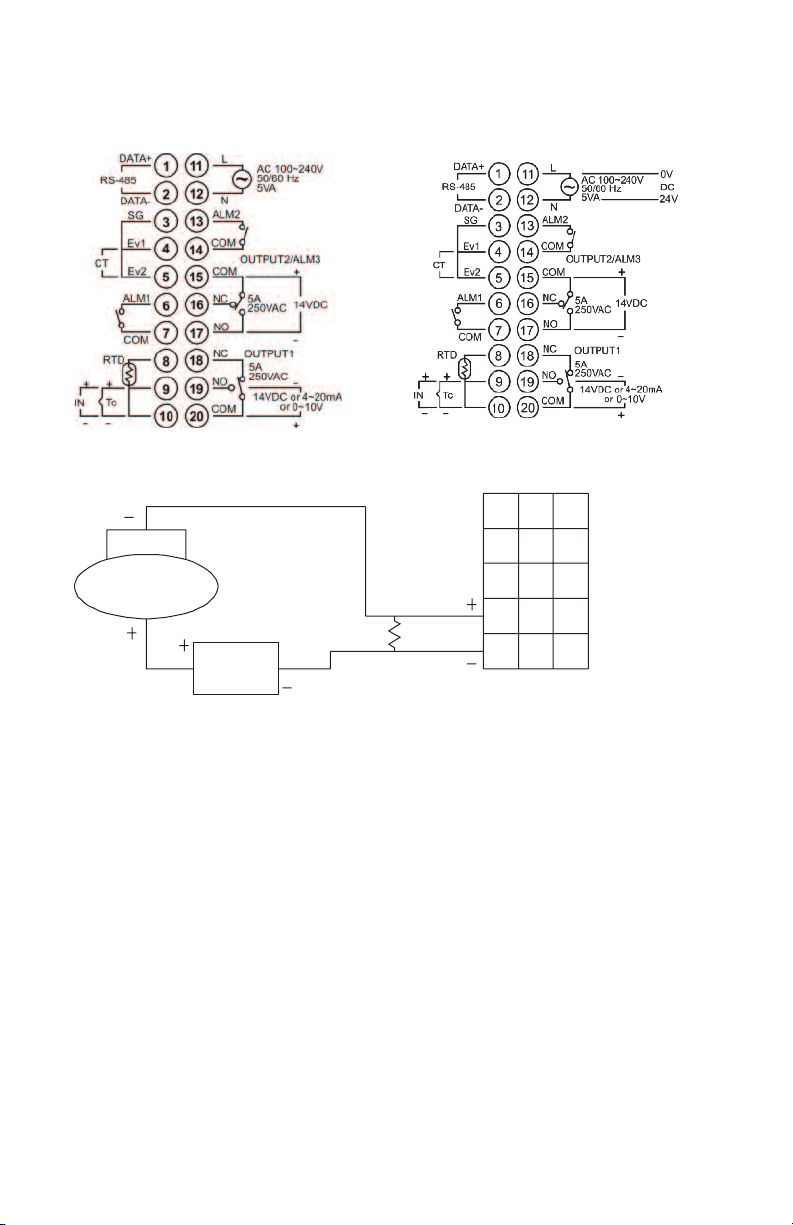

WIRING

140VDC

OR

4-20MA

OR

0-10V

-

+

OUT1

NO

COM

16 11

EV2

EV1

L

CT

N

AC 100-24OV

50/60 HZ

5VA

122

7

RTD

SG

38

++

-

-

Tc

13

OUT2

DATA-

49

5

10

RS-485

DATA+

14

15

COM

3A

250VAC

ALM1

3A

250VAC

Do not run thermocouple or other class 2 wiring in the same conduit as power leads. Use

only the type of thermocouple or RTD probe for which the control has been programmed.

Maintain separation between wiring of sensor, auxiliary in or out, and other wiring. See the

Initial Setting Menu for input selection.

For thermocouple input always use extension leads of the same type designated for your

thermocouple.

For supply connections use No. 16 AWG or larger wires rated for at least 75˚ C. Use

conductors only. All line voltage output circuits must have a common disconnect and be

connected to the same pole of the disconnect.

Input wiring for thermocouple, current, and RTD; and output wiring for current 14 VDC is

rated CLASS 2.

Control wiring as show below:

Terminal Identification

32B

16B

AC

DC

AC, Event / CT InputAC, No Event / CT Input

DC, No Event/CT Input

Page 6

Page 7

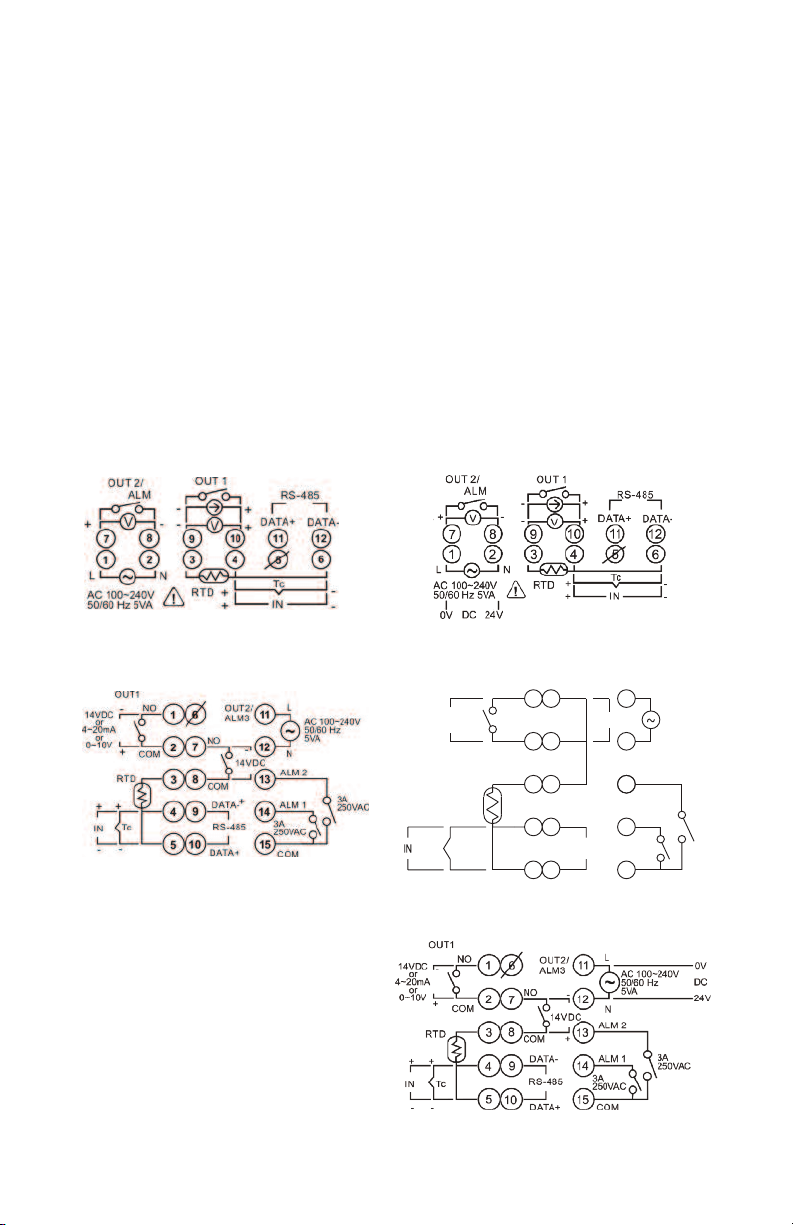

Terminal Identification (Continued)

TRANSMITTER

POWER

SUPPLY

A-277

250 OHM

PRECISION

RESISTOR

1

2

3

4

5

6

7

8

9

10

11

12

13

14

10

4B/8B

AC

Wiring for 4 to 20 mA Transmitter Inputs

Note: 16B terminal layout used in above example. Use appropriate terminal layout for

selected controller.

DC

Page 7

Page 8

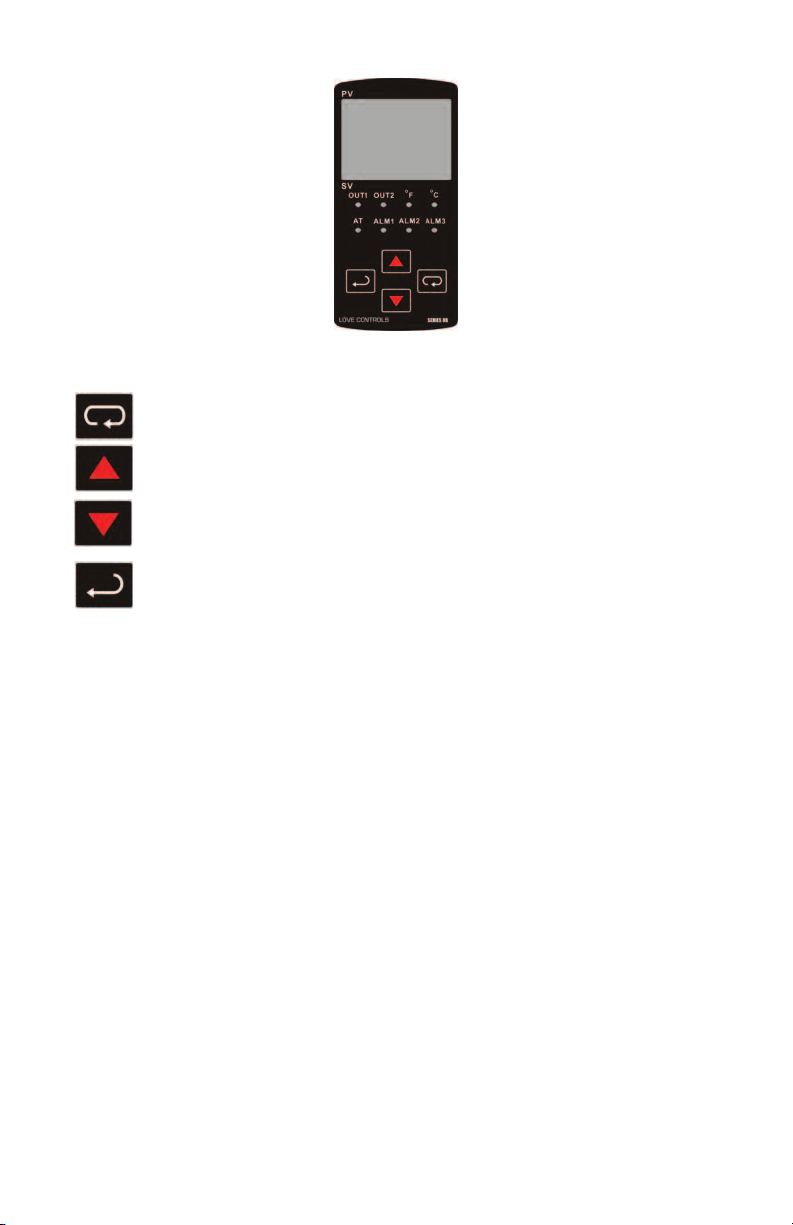

FRONT KEY FUNCTIONS

Key functions are as follows:

INDEX: Pressing the INDEX key advances the display to the next menu item.

UP ARROW: Increments a value or changes a menu item. If pressed

during the Operation Mode, the set point value will be increased.

DOWN ARROW: Decrements a value or changes a menu item. If pressed

during the Operation Mode, the set point value will be decreased.

ENTER: Stores the value or item change. If not pressed, the previously

stored value or item will be retained. When pressed during the Operation

Mode, the controller switches to the Regulation Mode. If held for more

than 3 seconds during the Operation Mode, the controller switches to the

Initial Setting Mode. If pressed during the Regulation Mode or Initial Setting

Mode, the controller will return to the Operation Mode.

SECURITY FEATURES

The B series controller has two built in security lock settings to prevent unauthorized

personnel from changing parameter settings. These parameters are set in the Operation

Mode.

The LoC1 setting affects all parameters in the controller. If LoC1 setting is enabled, the

operator will have to unlock the controller to make any changes to the controller’s

parameters.

The LoC2 setting affects all parameters except the set point. If LoC2 setting is enabled, the

only parameter that the operator will be able to change is the set point. In order to change

any other parameters, the operator will have to unlock the control before making a change.

In order to unlock the control, the operator must depress the ENTER and INDEX key

simultaneously.

Page 8

Page 9

CONTROL OPERATION DESCRIPTION

The HOME display is the normal display while the control is operating. If no errors or

functions are active, the HOME display will indicate the Process Variable (the temperature,

pressure, flow, %RH, etc.) that is being measured on the top display and the Set Variable on

the bottom display.

Items that can change the HOME display are the Ramp and Soak function and any error

messages. Descriptions of these special displays follow.

If the Ramp and Soak feature is active, then bottom display will show the current execution

pattern and current execution step. The UP and DOWN arrows can be pressed to change

the bottom display to show the Set Point (SP) of the current execution step or the Time

Remaining (r-ti) of the current execution step. After changing the bottom display to either the

Time Remaining or the Set Point, the ENTER key must be pressed to display the values.

Error Messages are shown on page 26.

OPTIONS

Event Input

When the controller is ordered with the Event Input Option (See page 3 for ordering

information), two event inputs are available. The event input is triggered by contact closure

between event 1 (EV1) or event (EV2) contact terminal and signal ground (SG) contact

terminal.

Event 1 controls the output operation of the control. When the event 1 contact terminals are

open, the output is active. When the event 1 contact terminals are closed, the output is deactivated. The outputs can also be controlled via the Run/Stop parameter using the front

keypad or by using the RS-485 communications.

Event 2 allows the user to switch between two temperature set points. Each temperature set

point has independent control parameters.

Current Transformer Alarm Function

The current transformer option allows the user to have an alarm contact trigger due to a loss

of current or a surge in current to the control output. When using the current transformer

input, the desired alarm contact should be set to alarm type 13 in the Initial Setting Menu

(Page 21). The current transformer should be wired according to the appropriate wiring

diagram on page 6 and page 7. The high and low alarm set points can be set from 0.5 to 30

Amps. The display resolution is 0.1 Amps and the accuracy is ±0.5 Amps with the included

current transformer.

Page 9

Page 10

Heating, Cooling or Dual Loop Control

Temperature Control can be achieved by either heating or cooling. In the B series controllers,

heating and cooling can be operated simultaneously using Dual Loop Output Control to

maintain a temperature set point. When Dual Loop Output Control is used, control outputs

must be connecting to the heating and cooling devices. Please refer to the following for the

operation of each setting.

Control Modes are selected by changing the S-HC parameter in the Initial Setting Mode.

Select HEAt, for heating or reverse acting control for output 1. If selected, output 2 will

become alarm 3.

Select CooL, for cooling or direct acting control for output 1. If selected, output 2 will become

alarm 3.

Select H1C2 or C1H2 for Dual Loop Output Control for output 1 and 2. If H1C2 is selected,

output 1 would be fore heating or reverse acting control and output 2 would be for cooling or

direct acting control. If C1H2 is selected, output 1 would be for cooling or direct acting control

and output 2 would be for heating or reverse acting control.

Setting the control mode to PID when the controller is set for Dual Loop Output Control

Activates the Proportional Band Coefficient (CoEF) parameter and the Dead Band (dead)

parameter.

The Proportional Band Coefficient (CoEF) sets the Proportional band value for Output 2

based on the Proportional band of output 1. The Proportional Band of Output 2 would be

equal to the Proportional Band (Pn) of Output 1 multiplied by the Proportional Band

Coefficient (CoEF). The Integral Time (in) and the Derivative Time (dn) will be the same for

both Outputs.

The Dead Band (dEAd) parameter sets an area in which the heating and cooling outputs are

operating at 0% on. The Dead Band is centered on the Set Point in Dual Loop Output Control

mode. Please see the Dead Band illustrated on page 19.

Page 10

Page 11

RAMP/SOAK PROGRAMMING AND OPERATION

The ramp/soak feature offers a great deal of flexibility by allowing changes in the set point

to be made over a predetermined period of time.

Theory of Operation

The B series controls offer a very simple approach to programming a ramp function. Rather

than requiring the operation to calculate an approach rate (usually in degrees per minutes),

the B series does the calculation internally. Thus, the operator only needs to program the

target set point and the time desired to reach that point. When the ramp segment is executed

by the control, it calculates the ramp required to move the process from the starting value

(current PV) to the desired value (programmed SP) in the time allowed.

Soaks (or dwells) are ramp segments where the target set point is the same as the beginning

process value. This allows for multistage ramps without wasting intermediate soak steps.

Care must be taken, however, that the process does actually reach the soak value before

the soak time starts. If not, the next segment will calculate a slope from the starting PV to

the target SP. Depending on your process requirements, this difference may be important.

Make sure to test any program for desired results before running production material.

Do not operate auto-tuning while a ramp function is operating. The ramp function will

prevent self tune from operating properly. Make sure that all tuning is set up before

operating ramp/soak.

Page 11

Page 12

Program Setup

All of the programming for the Ramp/Soak function is done in the Initial Setting Mode. You

may wish to work out your program on paper before going into the programmer menu

sequence.

In the Initial Setting Mode, go to the Control Mode (CtrL) parameter. Set the parameter to

ProG. Press INDEX to the Pattern Editing parameter (PAtn). Use the arrows to select the

desired pattern to edit. By setting the Pattern Editing parameter to off, pressing the INDEX

key brings up the next parameter in the Initial Setting mode. The Ramp and Soak function

is supported by 8 different patterns (pattern numbers 0 to 7). Each pattern contains 8 steps

(step numbers 0 to 7) for set point and execution times, one link pattern (Linn) parameter,

one cycle parameter (CyCn), and one actual step parameter (PSYn).

The default of step 0 in pattern 0 is a soak function. The control should be programmed to

reach the Set Point (SV) temperature, X, after the execution time, T. The unit will control the

process temperature (PV) to reach temperature X and the keep the temperature at

temperature X. The execution time T is determined by the execution time (ti00) for step

number 0. The target set point (SP00) for step number 0 should equal the Set Point (SV)

temperature.

After the first step, program SP01 and ti01 through SP07 and ti07 for the first pattern. The

target set point value (SP0n) is in actual units just like your Set Point (SV). If the control is

set for temperature, then the target set point displays are in temperature. If the control is

programmed for some other engineering unit, the target set point displays will be set in that

unit. The target execution time (ti0n) is in units of time, (hh.mm). The step parameters will

be followed by the Actual Step parameter, Cycle parameter, and the Link parameter for each

pattern.

The Actual Step parameter (PSYn) sets the last executable step for the current pattern. For

example, if the Actual Step parameter is set to 2 for pattern 0, then the program will only run

steps 0, 1, and 2 for pattern 0.

The Cycle parameter (CyCn) determines how many times the current pattern is repeated.

For example, if the Cycle parameter for pattern 0 is set to 2, the steps in pattern 0 will be

repeated twice before moving on to the next pattern.

The Link parameter (Linn) assigns the next pattern for the program to execute. For example,

if the Link parameter is set to 3 for pattern 0, the program will skip patterns 1 and 2 and start

executing pattern 3 after pattern 0 is complete. If the Link parameter is set to oFF, the

program will stop after executing the current pattern and the temperature will be maintained

at the set point of the last step executed.

Page 12

Page 13

Execution

The execution of the ramp and soak feature is initiated through the Run/Stop parameter, (rS) in the Operation Mode. The Run/Stop parameter has four possible values.

If the Run/Stop parameter is set to rUn, the program will start to execute in order from step

0 of the start pattern.

If the Run/Stop parameter is set to Program Stop (PStP), the program will stop and maintain

the temperature of the last set point before the program was halted. When the Run/Stop

parameter is restarted, the program will restart and execute from step 0 of the start pattern.

The start pattern selection (Ptrn) is only available when the Run/Stop parameter is set to

Program Stop.

If the Run/Stop parameter is set to Program Hold (PHod), the program will be paused and

the temperature will be maintained at the set point temperature that was active prior to the

program hold. Once the Run/Stop parameter is set back to run, the program will follow the

step before the hold and start to execute through the rest of the program.

Display

During ramp and soak program control, the SV default display is P-XX, where P indicates

the current execution pattern and XX indicates the display item to Set Point Value (SP) or

Residual Time (r-ti). The Set Point Value will display the temperature set point of the current

execution step in the SV display. The Residual Time will display the remaining time of the

current execution step in the SV display. After selecting the Set Point Value or Residual

Time, the ENTER key must be pressed to accept the display change.

Page 13

Page 14

PROGRAMMING AND OPERATION FOR PID

Theory of Operation

The PID method of control is based on the individual tuning of proportional band values,

integral time values, and derivative time values to help a unit automatically compensate for

changes in a control system. The proportional band is the range around the set point in

which the control’s proportioning takes place. The control increases or decreases the output

proportionately to the process temperature’s deviation from the set point. The integral time

eliminates undershoot and overshoot of the set point by adjusting the proportioning control

based on the amount of deviation from the set point during steady state operation. The

derivative time eliminates undershoot and overshoot by adjusting the proportioning control

based on the rate of rise or fall of the process temperature. The integral deviation offset

correction (ioFn) improves the speed in which the process value reaches the set point value.

If this parameter is set to zero, the output will be zero when the process value is equal to the

set point value. If the integral time parameter is used only to eliminate steady state error, it

may take a long time to reach the set point because it needs time to accumulate the error.

This parameter defines the default output level on start up. When the integral time is set at

0, then the proportional derivative offset correction (PdofF) would replace the integral

deviation offset correction, but serves the same function.

Program Set Up

In order to use the PID function in the B series controllers, the Control Mode will have to be

set to PID in the Initial Setting Menu. After changing the Control Mode, the PID parameters

can be accessed in the Regulation Menu. The PID parameters can either be programmed

manually or they can be set by the controller using the auto tune function. The auto tune will

use trial and error to tune the PID parameters to give the control the most precise control.

Since the time to accurately tune the control may differ depending on the process, the

controller can also be manually tuned to known PID values prior to running auto tune. The

Run/Stop parameter must be set to run in order to start auto tuning.

The B series controller has four user-defined profiles (PID0 to PID3) of PID values along with

an auto selection function (PID4). Each set of PID values includes a set point value (Svn),

proportional band (Pn), integral time (in), derivative time (dn), and integral deviation setting

(iofn). If PID4 is selected, the controller will pick which set of user defined parameters to use

based on how close the set point value of the profile is to the current process value.

Page 14

Page 15

DESCRIPTION OF MENU STRUCTURE

1234

r-S

rUn

StoP

PStP

PHod

Ptrn

SP

AL1H

The programming for the controller is broken down into three menus (Operation, Regulation,

and Initial Setting). Upon normal operation, control will be in the Operation Menu.

OPERATION MENU

Pressing the INDEX key will cycle through the below menu items. The parameter will be

displayed in the top display, while its value will be displayed in the bottom display, except for

the set point which is displayed in the bottom display on the Home Display. The UP and

DOWN arrows change the values of the parameters. The ENTER key must be pressed after

any changes.

Adjust the set point value - Can be any numerical value

between the upper and lower limit of the temperature range.

Select Run - Stop Output Control.

Activates outputs and Starts Ramp/Soak.

De-activates outputs and Stops Ramp/Soak.

Halts Ramp/Soak program, outputs remain active. Only

available during ramp/soak operation. Program restarts at

Step 0 of Start Pattern.

Pauses Ramp/Soak program, outputs remain active. Only

available during ramp/soak operation. Program restarts at step

prior to program being held.

Set Start pattern for Ramp/Soak. Only available when r - S set

to PStP.

Number of digits to the right of the decimal. Decimal Point

Position can be set for all Inputs except for B, S, and R type

thermocouples.

Alarm 1 High Set Point. May not appear depending on ALA1

setting in Initial Setting Menu.

Page 15

Page 16

AL1L

AL2H

AL2L

AL3H

AL3L

LoC

L0C1

L0C2

oUt1

oUt2

Alarm 1 Low Set Point. May not appear depending on ALA1

setting in Initial Setting Menu.

Alarm 2 High Set Point. May not appear depending on ALA2

setting in Initial Setting Menu.

Alarm 2 Low Set Point. May not appear depending on ALA2

setting in Initial Setting Menu.

Alarm 3 High Set Point. May not appear depending on ALA3

setting in Initial Setting Menu.

Alarm 3 Low Set Point. May not appear depending on ALA3

setting in Initial Setting Menu.

Set front panel security lock.

Lock all settings.

Lock all settings except the set point.

Display the % output value for output 1. In manual mode, this

value can be changed using the up and down arrows.

Display the % output value for output 2. In manual mode, this

value can be changed using the up and down arrows.

Page 16

Page 17

REGULATION MENU

AT

on

oFF

Pidn

Svn

Pn

in

dn

ioFn

Press the ENTER key while at the Home Display in order to access the Regulation Menu.

Pressing the INDEX key will cycle through the below menu items. The parameter will be

displayed in the top display, while its value will be displayed in the bottom display. The UP

and DOWN arrows change the values of the parameters. The ENTER key must be pressed

after any changes.

Auto Tune. The controller will evaluate the process and select

the PID values to maintain good control. Only available when

the control mode is set to PID.

Start learning the process. After the process has been learned

the menu will revert to oFF.

Disables Auto Tune.

Selection of PID profile. The controller can store up to 4 PID

profiles. The top display will show the PID profile and the

bottom display will show the target set value for that profile.

When Pid4 is selected, the controller will automatically select

which PID profile to use based on the target set values. Only

available when control mode is set to PID. See Programming

and Operation of PID function for more information.

(n = 0 to 4)

Target Set Value associated with each PID Profile.

(n = 0 to 3).

Proportional Band Setting associated with each PID

Profile. (n =0 to 3).

Integral time (reset time) associated with each PID

Profile. (n = 0 to 3).

Derivative time (rate time) associated with each PID

Profile. (n = 0 - 3).

Integral Deviation Offset Correction associated with

each PID Profile. (n = 0 to 4)

Page 17

Page 18

PD Offset Correction Setting. only available when control

PdoF

HtS

CtS

HtPd

CLPd

HCPd

mode is set to PID and integral time = 0. See Programming

and Operation of PID function for moving information.

Heating Hysteresis (Differential) Setting. Sets the value for the

amount of difference between the turn off point (set point) and

the turn on point. Figure A shows the output behavior for a

heating (reverse acting) application. Only available when

control mode set to on/off control.

Cooling Hysteresis (Differential) Setting. Sets the value for the

amount of difference between the turn off point (set point) and

the turn on point. Figure A shows the output behavior for a

cooling (direct acting) application. Only available when control

mode set to on/off control.

Figure A: Output behavior for Heating/Cooling On/Off Applications

Heating Control Cycle Setting. Defines the duration for one

output period or cycle for output 1. Only available when control

mode is set to PID or ProG and Output 1 is set for heating.

Cooling Control Cycle Setting. Defines the duration for one

output period or cycle for output 1. Only available when control

mode is set to PID or ProG and Output 1 is set for cooling.

Control Cycle setting for output 2. Defines the duration for one

output period or cycle for output 2. Only available when control

mode is set to PID and Dual Loop Output Control.

Page 18

Page 19

Proportional Band Coefficient. Sets the value of the

CoEF

dEAd

tPoF

Crh

CrLo

proportional band for output 2. The proportional band of

output 2 is equal to the proportional band of output 1

multiplied by the proportional band coefficient. This parameter

is only available when the control mode is set to PID and Dual

Loop Output Control.

Dead Band. The zone centered on the set point in which the

control is thought to be at the desired set level. The outputs

will be turned off at this point unless there is an integral

deviation offset or the dead band is negative. This parameter

is only shown when the control is set to Dual Loop Output

Control.

Output operation of ON/OFF control during dual loop output control.

PID control Dead Band is positive.

Figure B: Output Operation during dual loop control

Process Temperature Offset. This feature allows the input value to

be changed to agree with an external reference or to compensate

for sensor error.

Analog Output High Limit: Sets the actual upper limit of the

analog output when the control’s output is operating at 100%.

Only available for analog output models.

Analog Output Low Limit. Sets the actual lower limit of the

analog output when the control’s output is operating at 0%.

Only available for analog output models.

Page 19

PID control, Dead Band is negative.

Page 20

INITIAL SETTING MENU

t

U

L

b

S

r

n

E

t

J

Pt

JPt uu10

u5

A4

A0

inPt

tPUn

tP-H

tP-L

Press and hold the ENTER key for at least 3 seconds while at the Home Display in order to

access the Initial Setting Menu. Pressing the INDEX key will cycle through the below menu

items. The parameter will be displayed in the top display, while its value will be displayed in

the bottom display. The UP and DOWN arrows change the values of the parameters. The

ENTER key must be pressed after any changes.

Input Selection. Select one of the following input types from

the below table. For Current inputs, a 250 Ohm Resistor must

be wired across the input terminals.

Input Temperature Sensor Type LED Display Temperature Range

Thermocouple TXK type -328 ~ 1472°F (-200 ~ 800°C)

Thermocouple U type -328 ~ 932°F (-200 ~ 500°C)

Thermocouple L type -328 ~ 1562°F (-200 ~ 850°C)

Thermocouple B type 212 ~ 3272°F (100 ~ 1800°C)

Thermocouple S type 32 ~ 3092°F (0 ~ 1700°C)

Thermocouple R type 32 ~ 3092°F (0 ~ 1700°C)

Thermocouple N type -328 ~ 2372°F (-200 ~ 1300°C)

Thermocouple E type 32 ~ 1112°F (0 ~ 600°C)

Thermocouple T type -328 ~ 752°F (-200 ~ 400°C)

Thermocouple J type -148 ~ 2192°F (-100 ~ 1200°C)

Thermocouple K type -328 ~ 2372°F (-200 ~ 1300°C)

Platinum Resistance (Pt100) -328 ~ 1112°F (-200 ~ 600°C)

Platinum Resistance (JPt100) -4 ~ 752°F (-20 ~ 400°C)

0~50mV Analog Input -999 ~ 9999

0V ~ 10V Analog Input -999 ~ 9999

0V ~ 5V Analog Input -999 ~ 9999

4 ~ 20mA Analog Input -999 ~ 9999

0~20mA Analog Input -999 ~ 9999

Temperature Units. This parameter is only available for

thermocouple or RTD inputs.

Scale Hight Limit. Sets the upper limit of the temperature

range. If the process temperature exceeds this setting, the

display will flash an error code.

Scale Low Limit. Sets the lower limit of the temperature range.

If the process temperature exceeds this setting, the display will

flash an error code.

Page 20

Page 21

CtrL

PAtn

SPnY

tinY

PSYn

CYCn

Linn

S-HC

ALA1

ALA2

ALA3

Control Mode. Select method of control operation. Can be set

to PID, On-Off, Manual, or Ramp/Soak Programming.

Ramp/Soak Pattern Selection. Allows user to select which of

the 8 ramp/soak patterns to program. Each pattern has 8 steps

which gives a total of 64 possible steps in a single program. When

finished programming all ramp and soak patterns, the parameter

should be set to off. (n = 0 to 7)

Segment Set Point for pattern n and step y. For example the

first step of the first pattern would be SP00. The last step would be

SP77. (n = 0 to 7, y = 0 to 7)

Segment Time for pattern n and step y. For example the first

step of the first pattern would be ti00. The last step would be Ti77.

The value of this parameter will be in HH:MM.

(n = 0 to 7, y = 0 to 7)

Last Step for pattern n. Sets the last step that will be performed in

the current pattern. (n = 0 to 7)

Pattern Loop Setting for pattern n. Sets the number of times

that the current pattern will be repeated. (n = 0 to 7)

Pattern Link for pattern n. Sets the next pattern that will be

performed after the current pattern. When set to off, the

program will end and maintain last set point. (n = to 7)

Heat/Cool Selection. Assigns output 1 and output 2 to be

either heat or cool.

HEAt = Output 1 = Heating

CooL = Output 1 = Cooling

H1C2 = Output 1 = Heating; Output 2 = Cooling

H2C1 = Output 1 = Cooling; Output 2 = Heating

Alarm 1 Setting. Sets operation for Alarm 1. Please see

selection on Alarm Outputs for description of the outputs.

Alarm 2 Setting. Sets operation for Alarm 2. Please see

selection on Alarm Outputs for description of the outputs.

Alarm 3 Setting. Sets operation for Alarm 3. Please see

selection on Alarm Outputs for description of the outputs.

(not available for Dual Loop Output Control)

Page 21

Page 22

SALA

CoSH

C-SL

C-no

LEn

PrtY

StoP

System Alarm Setting. Selects which of the alarm outputs is

used if a system alarm occurs. The system alarms would be

an input error or a process control failure. This feature can be

disabled by turning this parameter to oFF.

Communications Write Function Feature. Allows parameters

to be changed via the RS-485 communications. Setting to oFF

prevents any changes from remote users.

Protocol Selection: Select whether to communicate using ASCII or

RTU Protocol. This value must match the protocol used by the host

computer.

Controller Address: Set from 1 to 247. This value must match

the controller address used by the host computer.

Communication Data Length. Choose either 7 or 8. This value

must match the communication data length of the host computer.

Communication Parity Bit. Set this value to even, odd, or none.

This value must match the communication parity bit of the host

computer.

Communication Stop Bit. Set this value to 1 or 2. This value

must match the communication stop bit of the host computer.

Page 22

Page 23

Alarm Output Configuration and Operation Table.

Set Value

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

(Note: AL-H and AL-L include AL1H, AL2H, AL3H and AL1L, AL2L, AL3L)

larm Type

A

Alarm function disabled

eviation upper- and lower-limit:

D

This alarm output operates when PV value is higher than

the setting value SV+(AL-H) or lower than the setting value

V-(AL-L).

S

Deviation upper-limit:

his alarm output operates when PV value is higher than

T

the setting value SV+(AL-H).

eviation lower-limit:

D

This alarm output operates when PV value is lower than

the setting value SV-(AL-L).

everse deviation upper- and lower-limit:

R

This alarm output operates when PV value is in the range of

the setting value SV+(AL-H) and the setting value SV-(AL-L).

Absolute value upper- and lower-limit:

This alarm output operates when PV value is higher than

the setting value AL-H or lower than the setting value AL-L.

Absolute value upper-limit:

This alarm output operates when PV value is higher than

the setting value AL-H.

Absolute value lower-limit:

This alarm output operates when PV value is lower than

the setting value AL-L.

Deviation upper- and lower-limit with standby sequence:

This alarm output operates when PV value reaches set

point (SV value )and the value is higher than the setting

value SV+(AL-H) or lower than the setting value SV-(AL-L).

Deviation upper-limit with standby sequence:

This alarm output operates when PV value reaches set

point (SV value) and the reached value is higher than the

setting value SV+(AL-H).

Deviation lower-limit with standby sequence:

This alarm output operates when PV value reaches the set

point (SV value) and the reached value is lower than the

setting value SV-(AL-L).

Hysteresis upper-limit alarm output:

This alarm output operates if PV value is higher than the

setting value SV+(AL-H). This alarm output is OFF when

PV value is lower than the setting value SV+(AL-L).

Hysteresis lower-limit alarm output:

This alarm output operates if PV value is lower than the

setting value SV-(AL-H). This alarm output is OFF when

PV value is higher than the setting value SV-(AL-L).

CT alarm output:

This alarm operates when the current measured by

transformer (CT) is lower than AL-L or higher than AL-H

(This alarm output is available only for the controller with

current transformer).

When program control is end status, alarm output is ON.

When RAMP UP status happens to PID program control,

alarm output is ON.

When RAMP DOWN status happens to PID program

control, alarm output is ON.

When SOAK status happens to PID program control, alarm

output is ON.

When RUN status happens to PID program control, alarm

output is ON.

larm Output Operating

A

Output is OFF

Page 23

Page 24

Communication Register List

1. Supporting transmission speed: 2400, 4800, 9600, 19200, 38400 bps.

2. Non-supported formats: 7, N, 1 or 8, O, 2 or 8, E, 2.

3. Communication protocol: Modus (ASCII or RTU).

4. Function code: 03H to read the contents of register (Max. 8 words). 06H to

write 1 (one) word into register. 02H to read the bits data (Max. 16 bits). 05H to write

1 (one) bit into register.

5. Address and Content of Data Register:

Address Content Explanation

1000H Process value (PV) Measuring unit is 0.1, updated one time in 0.4 second. The

1001H Set point (SV) Unit is 0.1, oC or oF

1002H Upper-limit of temperature range The data content should not be higher than the temperature

1003H Lower-limit of temperature range The data content should not be lower than the temperature

1004H Input temperature sensor type Please refer to the contents of the “Temperature Sensor Type

and Temperature Range” for detail

1005H Control method 0: PID, 1: ON/OFF, 2: manual tuning, 3: PID program control

1006H Heating/Cooling control selection 0: Heating, 1: Cooling, 2: Heating/Cooling, 3: Cooling/Heating

1007H 1st group of Heating/Cooling control cycle 0~99, 0:0.5 sec

1008H 2nd group of Heating/Cooling control cycle 0~99, 0:0.5 sec

1009H PB Proportional band 0.1 ~ 999.9

100AH Ti Integral time 0~9999

100BH Td Derivative time 0~9999

100CH Integration default 0~100%, unit is 0.1%

100DH Proportional control offset error value, 0~100%, unit is 0.1%

when Ti = 0

100EH The setting of COEF when Dual Loop 0.01 ~ 99.99

output control are used

100FH The setting of Dead band when Dual Loop -999 ~ 9999

output control are used

1010H Hysteresis setting value of the 1st 0 ~ 9999

output group

1011H Hysteresis setting value of the 2nd 0 ~ 9999

output group

1012H Output value read and write of Output 1 Unit is 0.1%, write operation is valid under manual tuning

mode only.

1013H Output value read and write of Output 2 Unit is 0.1%, write operation is valid under manual tuning

mode only.

1014H Upper-limit regulation of analog linear output 1 Unit = 2.8uA(Current Output)=1.3mV(Linear Voltage Output)

1015H Lower-limit regulation of analog linear output 1 Unit = 2.8uA(Current Output)=1.3mV(Linear Voltage Output)

1016H Temperature regulation value -999~+999, unit: 0.1

1017H Analog decimal setting 0 ~ 3

101CH PID parameter selection 0~4

101DH SV value corresponded to PID value Only valid within available range, unit: 0.1 scale

1020H Alarm 1 type Please refer to the contents of the “Alarm Outputs” for detail

1021H Alarm 2 type Please refer to the contents of the “Alarm Outputs” for detail

1022H Alarm 3 type Please refer to the contents of the “Alarm Outputs” for detail

1023H System alarm setting 0 : None (default), 1~3 : Set Alarm 1 to Alarm 3

1024H Upper-limit alarm 1 Please refer to the contents of the “Alarm Outputs” for detail

1025H Lower-limit alarm 1 Please refer to the contents of the “Alarm Outputs” for detail

following reading value display indicates error occurs:

8002H : Initial process (Temperature value is not got yet)

8003H : Temperature sensor is not connected

8

004H : Temperature sensor input error

8

006H : Cannot get temperature value, ADC input error

8007H : Memory read/write error

range

range

Page 24

Page 25

Address Content Explanation

1026H Upper-limit alarm 2 Please refer to the contents of the “Alarm Outputs” for detail

027H Lower-limit alarm 2 Please refer to the contents of the “Alarm Outputs” for detail

1

028H Upper-limit alarm 3 Please refer to the contents of the “Alarm Outputs” for detail

1

029H Lower-limit alarm 3 Please refer to the contents of the “Alarm Outputs” for detail

1

102AH Read LED status b0 : Alm3, b1: Alm2, b2: F, b3: _, b4: Alm1, b5: OUT2, b6:

102BH Read push button status b0 : Set, b1 : Select, b2 : Up, b3 : Down. 0 is to push

102CH Setting lock status 0 : Normal, 1 : All setting lock, 11 : Lock others than SV value

02FH Software version V1.00 indicates 0x100

1

030H Start pattern number 0 ~ 7

1

1040H~ Actual step number setting inside the 0 ~ 7 = N, indicate that this pattern is executed from step 0 to

1047H correspond pattern step N

1050H~ Cycle number for repeating the execution of 0 ~ 99 indicate that this pattern has been executed for 1~100

1057H the correspond pattern times

1060H~ Link pattern number setting of the 0 ~ 8, 8 indicates the program end. 0~7 indicates the next

067H correspond pattern execution pattern number after executing the current pattern

1

000H~ Pattern 0~7 temperature set point setting -999 ~ 9999

2

203FH Pattern 0 temperature is set to

2080H~ Pattern 0~7 execution time setting Time 0 ~ 900 (1 minute per scale)

20BFH Pattern 0 time is set to 2080H~2087H

2000H~2007H

OUT1, b7: AT

6. Address and Content of Bit Register: ( First bit of reading will put into LSB, Write data =

FF00H for bit set, 0000H for bit clear)

Address Content Explanation

0810H Communication write-in selection Communication write in disabled: 0 (default), Communication

0811H Temperature unit display selection oC / linear input (default) : 1 , oF : 0

0812H Decimal point position selection Except for the thermocouple B, S, R type, all the other

0813H AT setting OFF: 0 (default), ON : 1

0814H Control RUN/STOP setting 0 : STOP, 1 : RUN (default)

0815H STOP setting for PID program control 0: RUN (default), 1: STOP

0816H Temporarily STOP for PID program control 0: RUN (default), 1: Temporarily STOP

write in enabled: 1

thermocouple type are valid. (0 or 1)

Page 25

Page 26

DIAGNOSTIC ERROR MESSAGES

Display Error Messages

Display

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

Description

b150

Display on Start Up

rr

No

No Input Probe Connection

Cont

Err

Input Error

inPt

2001

Process Value Flashes

0.0

when outside of range

Err

Error EEPROM

Pron

Action Required

No Action Required

Verify that sensor is wired to proper

terminals. Next, check that the

controller is programmed for the correct

input type. Most commonly seen when

controller is programmed for a RTD,

while a thermocouple is connected.

Verify that the input is wired to the

proper terminals. Next check to see if

the input type is set to the proper value.

Most commonly seen when controller is

programmed for a 4 to 20 mA input and

0 to 20 mA signal is wired to the

controller.

Input signals may normally go above or

below range limits. If not check input

and correct the process temperature or

increase temperature range limits using

tP-H and tP-L.

Attempt to reset the factory default

settings using the instructions in the

next section. If still has error, call

customer service for a return goods

authorization number to have the

controller evaluated at the factory.

Page 26

Page 27

Communication Error Messages

Error Status

102EH/4750H

0001H

0002H

0003H

0004H

0005H

0006H

0007H

PV read back

1000H/4700H

N/A

8002H

8003H

8004H

N/A

8006H

N/A

Error Status

PV Unstable

Re-initialize, no temperature at

this time

Input sensor did not connect

Input Signal Error

Over Input Range

ADC fail

EEPROM read/write error

Page 27

Page 28

Reset Factory Default Settings

Note: Resetting Factory Default Settings erases all of the values entered by the user. Record

any necessary settings before proceeding.

Warning: Erasing the user entered values may result in a safety hazard and system

malfunction.

The following instructions will reset the controller to the original factory default settings.

Step 1. Press the INDEX KEY while at the Home Display until the

controller reads LoC in the process display. Use the UP

arrow to select LoC1. Press the ENTER KEY to save this

value.

Step 2. Press and hold the UP and DOWN arrows

simultaneously for one second. Upon releasing the

buttons, the display will read SHou in the PV display

and oFF in the SV display.

Step 3. Press the INDEX key once and the controller will read

PASS in the PV display and a 4321 in the SV display.

Adjust the value in the SV display to 1357 using the UP

and DOWN arrows. Press the ENTER KEY to save the value.

Step 4. Cycle the power on the controller. Upon power up, all of the

user set values have been erased.

Page 28

Page 29

SPECIFICATIONS

Input Voltage 100 to 240 VAC 50/60 Hz OR 24 VDC (depending on model).

Operation Voltage Range 85% to 110% of rated voltage.

Power Consumption 5VA max.

Memory Protection EEPROM 4K bit (non-volatile memory

(number of writes: 1000,000)).

Display Method 2 line x 4 character 7-segment LED display Process value

(PV): Red color, Set point (SV): Green color.

Sensor Type Thermocouple: K, J, T, E, N, R, S, B, L, U, TXK.

3-wire platinum RTD: Pt100, JPt100.

Analog input 0 to 5 V, 0 to 10 V, 0 to 20 mA, 0 to 50 mV.

Control Mode PID, ON/OFF, Manual or PID program control

(Ramp/Soak control).

Control Output Relay output: SPDT (SPST: 1/16 DIN and 1/32 DIN size),

Max. load 250 VAC, 3A resistive load.

Voltage pulse output: DC 14 V, Max. output current 40 mA.

Current output: DC 4 to 20 mA output (Load resistance: Max.

600Ω).

Linear voltage output: 0 to 5 V, 0 to 10 V *(B Series only).

Display Accuracy 0 or 1 digit to the right of the decimal point (selectable).

Sampling Range Analog input: 150 msec/per scan Thermocouple or Platinum

RTD: 400 msec/per scan.

RS-485 Communication MODBUS®ASCII/RTU communication protocol.

Vibration Resistance 10 to 55 Hz, 10 m/s2for 10 min, each in X, Y and Z directions.

Shock Resistance Max. 300 m/s2, 3 times in each 3 axes, 6 directions.

Ambient Temperature 32°F to 122°F (0°C to +50°C).

Storage Temperature -4°F to 150°F (-20°C to +65°C).

Altitude 2000 m or less.

Relative Humidity 35% tp 80% (non-condensing).

Modbus®is a registered trademark of schieder automation.

Page 29

Page 30

Thermocouple Type and Temperature Range

t

U

L

b

S

r

n

E

t

J

Pt

JPt uu10

u5

A4

A0

Input Temperature Sensor Type LED Display Temperature Range

Thermocouple TXK type -328 ~ 1472°F (-200 ~ 800°C)

Thermocouple U type -328 ~ 932°F (-200 ~ 500°C)

Thermocouple L type -328 ~ 1562°F (-200 ~ 850°C)

Thermocouple B type -212 ~ 3272°F (-100 ~ 1800°C)

Thermocouple S type -32 ~ 3092°F (0 ~ 1700°C)

Thermocouple R type -32 ~ 3092°F (0 ~ 1700°C)

Thermocouple N type -328 ~ 2372°F (-200 ~ 1300°C)

Thermocouple E type -32 ~ 1112°F (0 ~ 600°C)

Thermocouple T type -328 ~ 752°F (-200 ~ 400°C)

Thermocouple J type -148 ~ 2192°F (-100 ~ 1200°C)

Thermocouple K type -328 ~ 2372°F (-200 ~ 1300°C)

RTD Type and Temperature Range

Input Temperature Sensor Type LED Display Temperature Range

Platinum Resistance (Pt100) -328 ~ 1472°F (-200 ~ 800°C)

Platinum Resistance (JPt100) -4 ~ 752°F (-20 ~ 400°C)

Voltage Input Type and Input Range

Voltage Input Range LED DIsplay Temperature Range

0~50mV Analog Input -999 ~ 9999

0V ~ 10V Analog Input -999 ~ 9999

0V ~ 5V Analog Input -999 ~ 9999

Current Input Type and Input Range

Current Input Type LED Display Temperature Range

4 ~ 20mA Analog Input -999 ~ 9999

0~20mA Analog Input -999 ~ 9999

Page 30

Page 31

PRECAUTIONS

ANGER

D

Electric Shock!

1. Do not touch the AC terminals while the power is supplied to the controller

to prevent an electric shock.

2. Make sure power is disconnected while checking the unit inside.

3. The symbol indicates that this Controller is protected throughout by

DOUBLE INSULATION or REINFORCED INSULATION (equivalent to Class II

of IEC 536).

WARNING

Mount the controller in a location that will not be subject to excessive temperature,

shock, or vibration. All models are designed for mounting in an enclosed panel.

1. Always use recommended solder-less terminals: Fork terminals with isolation

(M3 screw, width is 7.0mm (6.0mm for 32B Series), hole diameter 3.2mm).

Screw size: M3 x 6.5 (With 6.8 x 6.8 square washer). Screw size for 32B

Series: M3 x 4.5 (With 6.0 x 6.0 square washer). Recommended tightening

orque: 0.4 N.m (4kgf.cm). Applicable wire: Solid/twisted wire of 2 mm

2

,

12AWG to 24AWG. Please be sure to tighten them properly.

2. Do not allow dust or foreign objects to fall inside the controller to prevent it

from malfunctioning.

3. Never modify or disassemble the controller.

4. Do not connect anything to the “No used” terminals.

5. Make sure all wires are connected to the correct polarity of terminals.

6. Do not install and/or use the controller in places subject to: Dust or corrosive

gases and liquid, high humidity and high radiation, vibration and shock, high

voltage and high frequency.

7. Power must be off when wiring and changing a temperature sensor.

8. Be sure to use compensating wires that match the thermocouple types when

extending or connecting the thermocouple wires.

9. Please use wires with resistance when extending or connecting a platinum

resistance sensor (RTD).

10. Please keep the wire as short as possible when wiring a platinum resistance

sensor (RTD) to the controller and please route power wires as far as

possible from load wires to prevent interference and induce noise.

11. This controller is an open-type unit and must be placed in an enclosure away

from high temperature, humidity, dripping water, corrosive materials, airborne

dust and electric shock or vibration.

12. Please make sure power cables and signals from instruments are all installed

properly before energizing the controller, otherwise serious damage may

occur.

13. Please do not use acid or alkaline liquids for cleaning. Please use a soft, dry

cloth to clean the controller.

14. Wait at least one minute after power is disconnected to allow capacitors to

discharge, and please do not touch any internal circuit within this period.

15. This instrument is not furnished with a power switch or fuse. Therefore, if a

fuse or power switch is required, install the protection close to the

instrument. Recommended fuse rating: Rated voltage 250 V, Rated current

1 A. Fuse type: Time-lag fuse.

16. Note: This controller does not provide overcurrent protection. Use of the

product requires that suitable overcurrent protection device(s) must be

added to ensure compliance with all relevant electrical standards and codes.

(Rated 250 V, 15 Amps max). A suitable disconnecting device should be

provided near the controller in the end-use installation.

Page 31

Page 32

External Dimensions

Dimensions are in millimeter (inch)

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 7/14 FR# R5-443601-10 Rev. 5

LOVE CONTROLS

A DIV. OF DWYER INSTRUMENTS INC.

P.O. BOX 338 - MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000 www.love-controls.com

Fax: 219/872-9057 e-mail:love@love-controls.com

Loading...

Loading...