Page 1

Series 672 Low Pressure Transducer

Specifications - Installation and Op erating Instructions

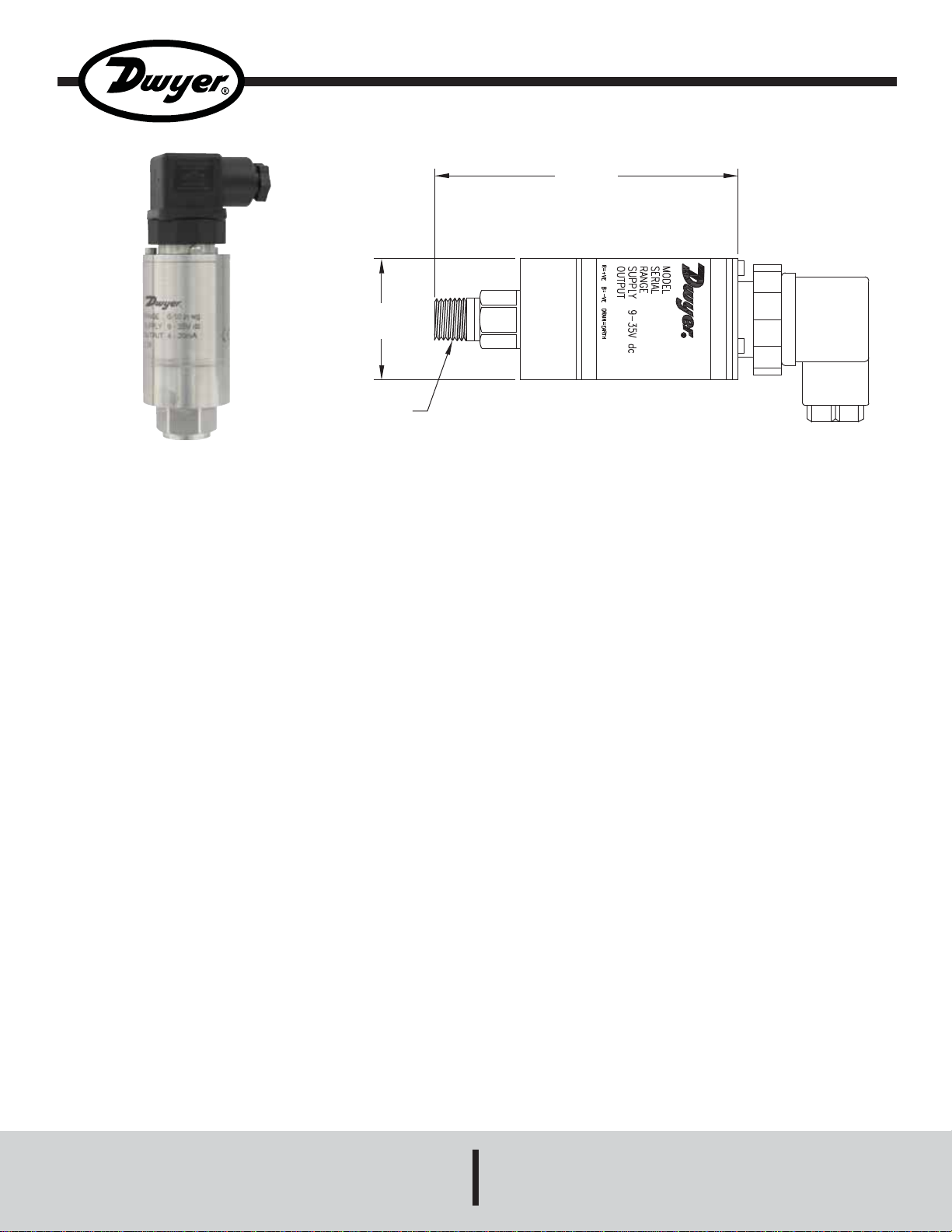

3-3/4 [95.48]

ø1-1/2 [38.10]

1/4 MALE NPT CONNECTION

Bulletin A-3 0 - 6 7 2

The Series 672 Low Pressure Transducer is a perfect solution to any

application where a very accurate low pressure transducer is necessary.

Using variable capacitance technology, the series 672 is designed to

measure pressures as low as 10˝ w.c. up to 400˝ w.c., very low ranges for

a single pressure transducer. The 672 also features a 0.25% F.S. accuracy.

Use the Series 672 in liquid level, flood warning, waste water, clean room,

and open channel flow applications.

GENERAL WARNIN G S

• Transducer should not be subjected to greater than the maximum

allowable pressure or temperature as defined in the specifications.

• Transducer should not be subjected to mechanical impact.

• In the event of fire the end user must ensure that the system pressure is

vented to a safe area.

• The effects of decomposition of unstable fluids should be considered

when placing this device in service.

• The pressure transducer has no means of draining or venting, this must

be performed by another component in the end user’s system.

• The pressure range of the transducer must be compatible with the

maximum pressure being measured.

• Pressure media must be compatible with the transducer wetted parts

which are: UNS 31803 Stainless Steel, Ceramic, and Fluoroelastomer

(FKM).

• Exposed end of cable must be kept free from moisture.

• Liquid must not be allowed to freeze in the pressure port.

• Avoid mounting the transducer near a heat source that is likely to create

a temperature gradient across the instrument. If this is unavoidable, use

a heat shield to deflect uneven radiated heat or wrap the transducer in

insulation so that even temperature is assured throughout.

• The transducer should not be removed while the measured system is at

pressure.

• Care must be taken not to touch the pressure sensitive diaphragm while

cleaning the pressure port. This may cause irreparable damage.

SPECIFICATIONS

Service: Compatible liquids and gases.

Wetted Materials: 318 Duplex SS, Ceramic, Fluoroelastomer (FKM).

Housing Material: 318 Stainless Steel.

Accuracy: ±0.25% F.S. (RSS). *Includes non-linearity, hysteresis, and

non-repeatability.

Stability: 0.25% F.S./1 year.

Temperature Limits: -40 to 212°F (-40 to 100°C).

Pressure Limits: 29 PSI (2 bar) for up to 85˝ w.c. (0.2 bar) ranges; 58 PSI

(4 bar) for 85˝ to 140˝ w.c. (0.2 to 0.35 bar); 73 PSI (5 bar) for 141˝ to

400˝ w.c. (0.35 to 1 bar).

Compensated Temperature Limits: -5 to 140°F (-20 to 60°C).

Thermal Effects:

Zero: 1.0%F.S./100°F (2.0%F.S./100°C).

Span: 1.0%F.S./100°F (2.0%F.S./100°C).

Power Requirements:

4-20 mA: 9-35 VDC

0-5 VDC: 7.5-35 VDC

Output Signal: 4-20 mA (2-wire) or 0-5 VDC (3-wire).

Zero & Span Adjustment: ±10% F.S. each (by Potentiometer).

Response Time: 5 ms.

Max Loop Resistance: 1.325 kΩ.

Electrical Connections: Large DIN 43650 connector with mating plug.

Enclosure Rating: NEMA 4X (IP65).

Process Connection: 1/4”-18 NPT male.

Weight: 11.6 oz (330 g).

Agency Approval: CE.

CE STANDARDS TESTED TO:

ELECTRO MAGNETIC COMPATIBILITY

Standards Applied

EN50081-1:1992

EN61000-6-2:1999

TEST METHODS/PROCEDURES

EN50081-1:1992

EN61000-6-2:1999

EN6100-4-2:1995 + A1:1998

EN61000-4-3:1996

EN61000-4-4:1995

EN61000-4-6:1996

DWYER IN S TRU MENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

MOUNTING

The pressure transducer is designed to be attached by the coupling

thread, and can be mounted in any plane or direction. To tighten the fit, use

a 5/8 UNF AF (M16) wrench on the hexagon provided and apply a

maximum torque of 20 lb-ft (27 N-m). The customer must assure that the

pressure seal is suitable for the application.

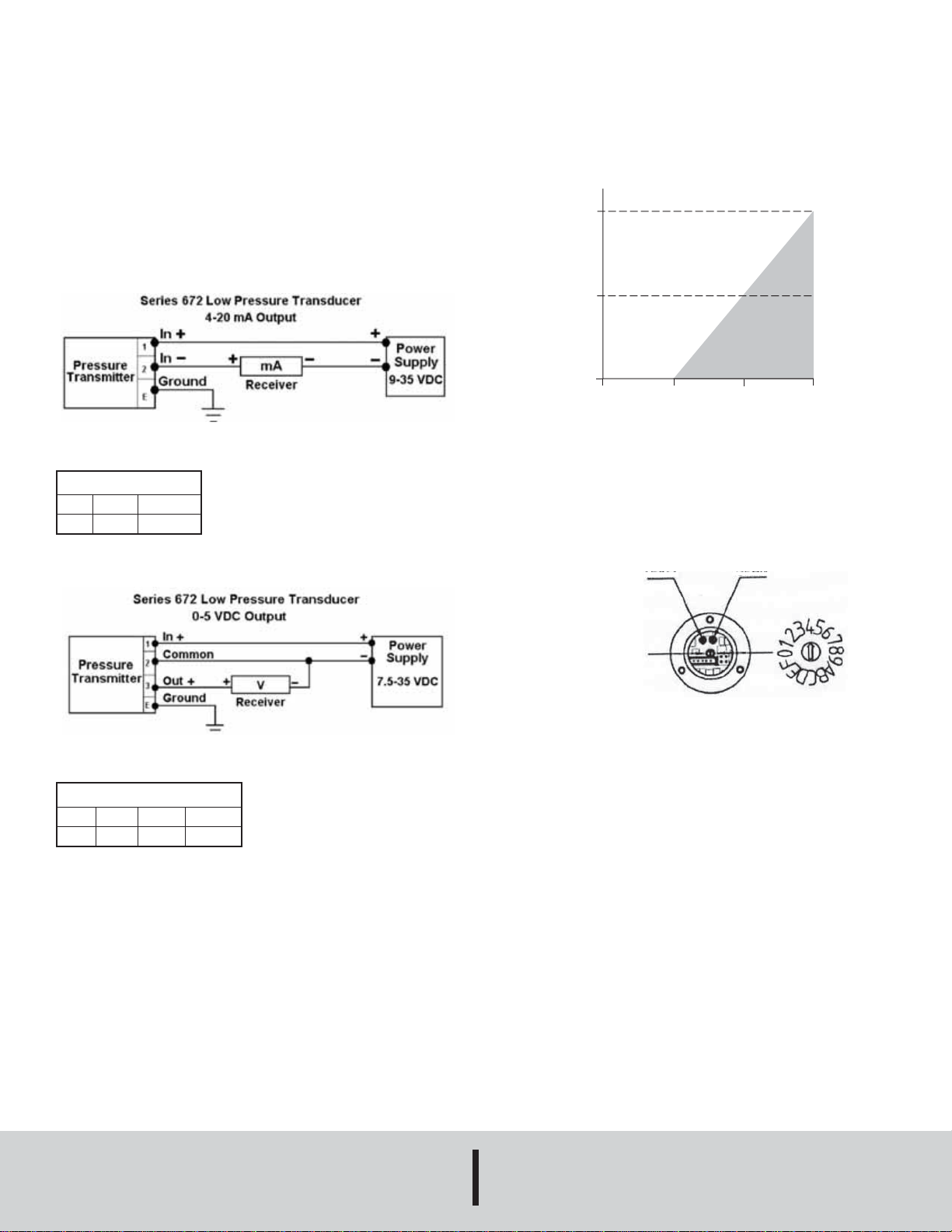

ELECTRICAL

Electrical Connections:

Electrical connections are made by way of a DIN 43650 connector with

mating plug.

Load Resistance (4-20 mA Transducer)

The total permissible resistive load in the loop (to include all cable

resistance) can be from zero to (50x supply voltage – 9) ohms, e.g. with a

12 VDC supply, the permissible load is from zero up to 150 ohms.

R

LOOP1MAX = 50 (V

1325

575

(OHMS)

TOTAL RESISTANCE

SUPP

-9)

4-20 mA Output

ln+1ln-2Ground

E

0-5 VDC O utp ut

ln+1Com2Out+

3

Ground

E

0

0

9

SUPPLY VOLTAGE

(VDC)

20

35

ZERO/SPAN ADJUSTMEN T

Zero and span controls are precisely set during manufacturing and should

only need adjustment if there is a change in the required pressure

measurement. Inquire with Dwyer Instruments, Inc. before adjustment.

ZERO

SPAN

RANGE SWITCH

MAINTE NA NCE

Routine inspection is not required except for periodic inspection of the

cable and molding to ensure that these are neither damaged nor softened

by incompatible liquid. A periodic check of the zero and span settings is

also recommended. Otherwise these transmitters are not field serviceable

and should be returned to the factory if repair is needed. Be sure to include

a brief description of the problem plus any pertinent application information

available.

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 4/09 FR# R1-443716-00

DWYER IN S TRU MENTS, IN C.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...