Page 1

Series 650 Temperature Transmitter

Specifications - Installation and Operating Instructions

Bulletin E-62

The Dwyer Series 650 Temperature Transmitter provides a 4-20 mA

control signal output which varies in linear relationship to the temperature

of the silicon transducer in the sensing probe. The low cost and small size

of the Series 650 Temperature Transmitter make it ideal for a wide variety

of multipoint temperature monitoring applications. Non-polarized power

connections simplify electrical connection to any power source providing

12-35 volts DC.

Models are stocked in three popular ranges, all with factory calibration

within 0.3% and linearity within 0.25% of span. Units can be field calibrated

to limits shown in chart at right. See calibration instructions on page 2 for

procedure.

INSTALLATION

Location: Select a location where the temperature of the unit will remain

between 0° and 70°C. The location must also be within the 7 foot length

of the sensing probe cable. The power supply and the receiving control

device can be located up to several hundred feet from the transmitter itself.

Position: The Series 650 can be mounted in any position. It is advisable

to keep the adjustment screws and connector plug easily accessible for

future re-calibration or service.

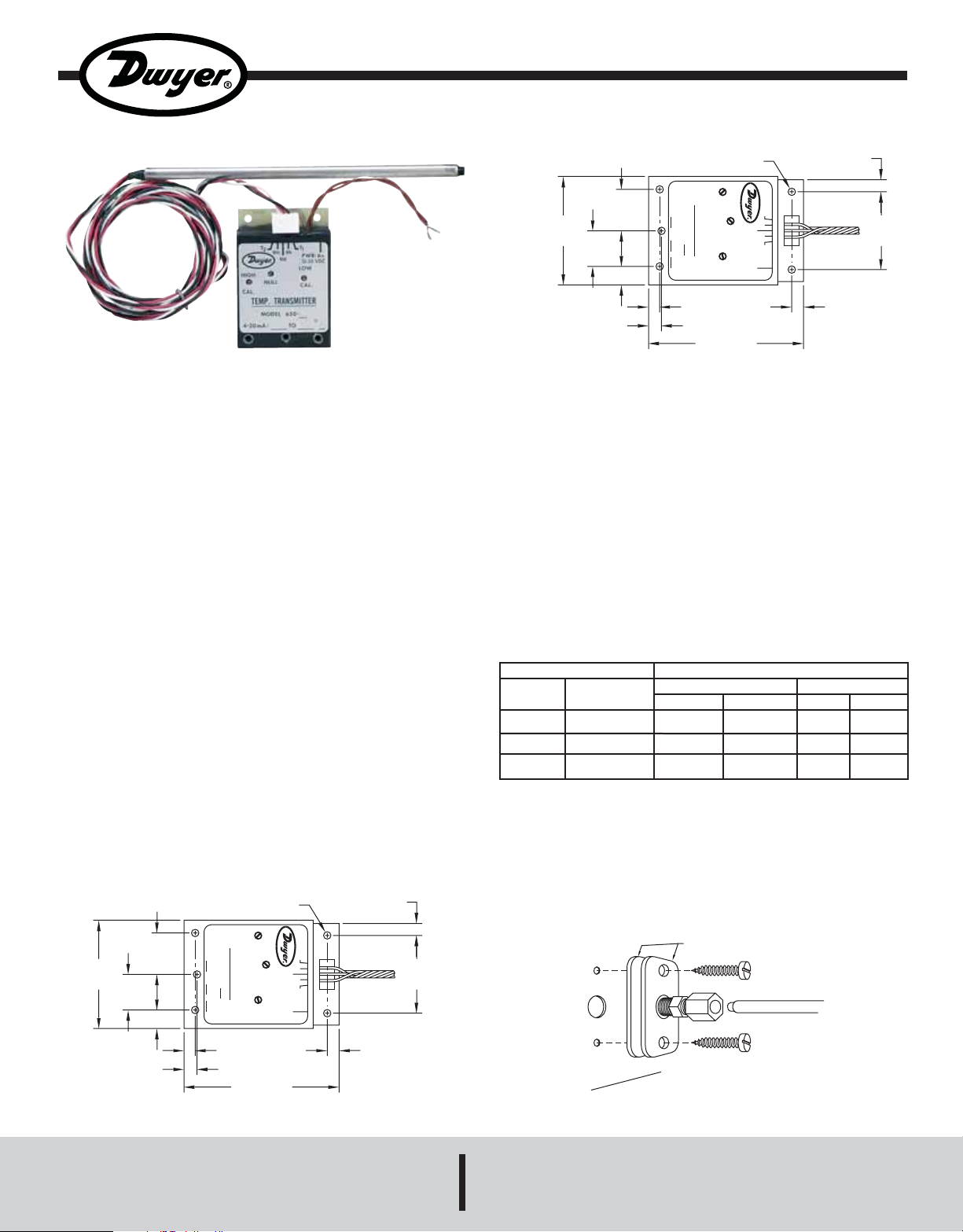

Mounting: The Series 650 electronics package can be attached to

mounting surface by means of the five holes provided. Refer to the

dimensional drawing, Figure A for these hole spacings. The small size of

the transmitter electronics package allows it to be mounted inside a

standard household single gang electrical box, if preferred. When mounting

the temperature sensing probe in a sheet metal duct or on other thin walled

enclosures, the use of the Dwyer Model A-325 Duct Mounting Kit is

Ø1/8 [3.18]

13/64

[5.16]

13/64

[5.16]

13/64 [5.16]

1-5/16

[33.34]

1-53/64

[46.43]

19/32

[15.08]

45/64

[17.86]

5/16 [7.94]

Ø1/8 [3.18]

3/16 [4.76]

7/32 [5.56]

2-5/8 [66.68]

SPECIFICATIONS

Power Supply: 12-35 volts DC.

Output Signal: 4-20 mA DC.

Voltage Stability: Output error less than 0.01% of span over the specified

supply voltage range.

Linearity: Within 0.25% of span.

Initial Calibration: Within 0.3% of span at 20°C/68°F ambient.

Thermal Drift: Less than 0.5% of span over ambient temperature range of

0-50°C, 32-122°F.

Ambient Operating T emperatur e (Electr onics): 0-70°C, 32-158°F.

Maximum T emperatur e (Pr obe): 204°C/400°F.

Probe Construction: 6˝ long, 0.25˝ O.D., Type 304 Stainless Steel.

Note: Special factory calibrated ranges are available within the limits of - 55°C

and + 180°C. Contact factory with specifications for price and availability.

SERIES 650 TRANSMITTER MODELS & RANGES

FACTORY CALIBRATION

MODEL

NUMBER

650-1

650-2

650-3

RANGE AS

STOCKED

-23° to + 10°C

-7° to + 49°C

0° to + 100°C

TOTAL RANGE LIMITS LOW END LIMITS

MIN. SPAN

FIELD CALIBRATION

MAX. SPAN

24°C

37°C

37°C

48°C

150°C

150°C

MIN.

- 32°C

- 12°C

- 12°C

MAX.

- 14°C

+ 6°C

+ 6°C

T o achieve TOTAL RANGE LIMITS above (with 4-20 mA output), the lowest

temperature being sensed (at 4 mA) must be between the minimum and

maximum values under LOW END LIMITS.

recommended. Refer to Figure B for details on this arrangement. Other

customer designed probe mounting configurations can be used as long as

the tip of the sensing probe is in the space where temperature is to be

controlled.

A-325 DUCT MOUNTING KIT

45/64

19/32

[15.08]

[17.86]

5/16 [7.94]

3/16 [4.76]

7/32 [5.56]

2-5/8 [66.68]

1-53/64

[46.43]

FIGURE A

DWYER INSTRUMENTS, INC.

13/64 [5.16]

1-5/16

[33.34]

DUCT

Phone: 219/879-8000 www.dwyer-inst.com

A-345 FLANGE W/GASKET

[2]#10X1 TYPE A

PAN HD. SHT. MTL.SC

FIGURE B

650 PROBE

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

ELECTRICAL CONNECTIONS

CAUTION: DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RATINGS.

PERMANENT DAMAGE NOT COVERED BY WARRANTY WILL RESULT.

THIS UNIT IS NOT DESIGNED FOR AC LINE VOLTAGE OPERATION.

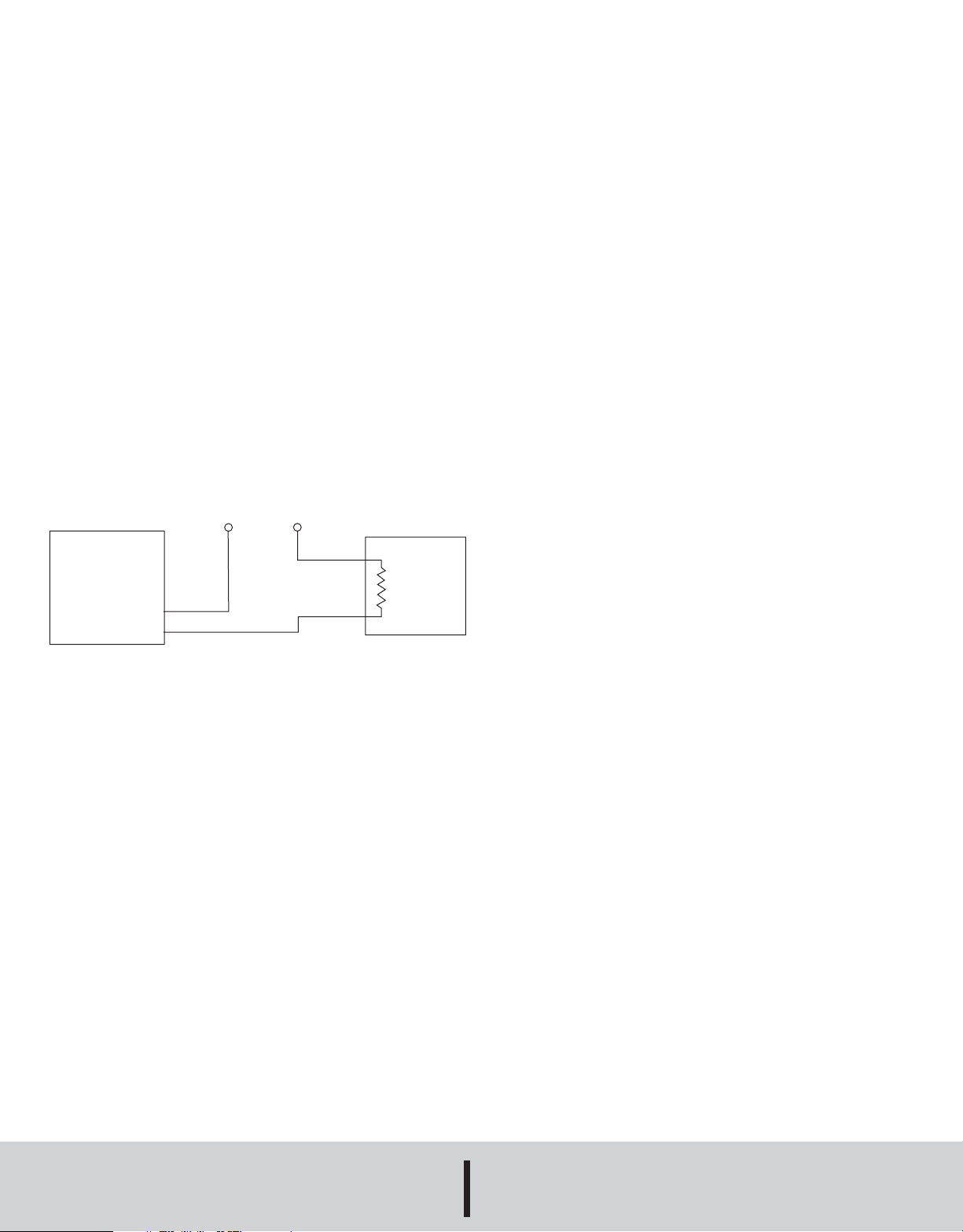

The Series 650 Transmitter is a two wire device and the two brown leads

exiting from the transmitter electronics package need only be connected in

series with the control loop power supply and the desired receiver. The

power supply should be capable of delivering a minimum of 30 milliamps

at any voltage between 12 and 35 VDC. Refer to the schematic diagram in

Figure C for details on the electrical connections. The transmitter

connections are non-polarized so either brown lead can be utilized when

making the control loop connections as shown. The insulation has been

stripped from the ends of these brown leads to provide easy connection to

a terminal block or to allow solder connections to the control loop circuit.

Before energizing the control loop power supply, connect the temperature

sensing probe cable to the electronics package by means of the five pin

cable plug and the circuit board connector. Be sure the cable plug is

properly oriented according to the lead colors as indicated on the

transmitter label. When the plug is properly inserted, the three temperature

sensor leads will lead away from the electronics package. Do not make any

connections to the cable connector pins labeled T1 and T2 as these are

used only for recalibration purposes; refer to the next section on

Temperature Recalibration.

To change the temperature range, follow this procedure.

1. With the transmitter connected to a companion receiver and an

appropriate power supply, apply power to the system. W ith the sensor at

the required low end of the temperature range, select a low DC voltage

range on the VOM and connect the meter across the control loop pins on

the connector labeled T1 and T2. If a down scale reading is obtained,

reverse the volt meter connections until an up scale reading is obtained.

Using a small screwdriver, turn the screw identified on the transmitter label

as NULL until the voltage across pins T1 and T2 is zero. Keep switching to

a lower voltage range while making this adjustment. Ideally, when the

adjustment is completed there will be less than one millivolt difference

between pins T1 and T2.

2. Switching to a full scale range of approximately 30 mA on the VOM,

insert the meter in series with one of the current loop leads to monitor the

current flow in the loop. Again, if a down scale reading is obtained, reverse

the leads to the VOM. With the sensing probe stabilized at the low end of

the required temperature range, adjust the screw labeled LOWCAL for a

reading of exactly 4 mA on the VOM.

3. Increase the temperature of the sensor probe tip to the high end of the

range chosen. When the temperature has stabilized at the high end, adjust

the screw labeled HIGH CAL for a reading of exactly 20 mA on the VOM.

4. As the above adjustments are independent of one another, no further

adjustment is required. Remove the VOM from the current loop and

proceed with final installation of the transmitter.

LOOP POWERSUPPLY

12-35 VDC

SERIES

650

BROWN

RECIEVER

TRANSMITTER

BROWN

ELECTRICAL CONNECTIONS

FIGURE C

TEMPERATURE RECALIBRATION

Each Series 650 Transmitter is factory calibrated to the range given in the

model number chart and marked on the transmitter label. However , special

calibrations can also be achieved by following the procedure below. For

purposes of clarification in these instructions, the low end of the range is

defined as that temperature which applied to the sensor produces 4 mA of

current in the loop. The high end of the range is that temperature which

applied to the sensor produces 20 mA of current. The range or span is the

difference between low and high end temperatures. See examples at right

illustrating use of Model and Range chart on page 1.

To recalibrate, you will require accurately known low and high temperature

sources along with a sensitive volt-ohm-milliamp (VOM) meter. One

convenient 0°C/32°F temperature source is an ice bath in an insulated

bottle.* A laboratory temperature chamber can also be used or, if forced to

improvise, a laboratory grade mercury thermometer of the proper range in

a thermal mass along with the probe can be used. However, the latter

approach is not likely to achieve the specified accuracy of the Series 650

Transmitter.

*Note: The sensing probe tip is hermetically sealed and may be used to

monitor water temperature.

EXAMPLES

A. Can any of the standard models be recalibrated to a temperature range

of -16°C to +20°C?

YES. Referring to specifications for Model 650-1, -16°C is within low end

limits of -32°C to -14°C and the span of 36°C (-16 to +20) is within the total

range limit of 24°C to 48°C.

B. Can any of the standard models be recalibrated to a temperature range

of -20°C to +80°C?

NO. Referring to specifications for Model 650-1, -20°C is within low end

limits of -32°C to -14°C but the total range of 100°C (-20 to +80) exceeds

the limit of 24°C to 48°C. While the range is within limits for Models 650-2

and 650-3, the -20°C minimum temperature is lower than the low end

limits of -12°C to +6°C for those two models.

MULTIPLE RECEIVER INSTALLATION

An advantage of the standard 4-20 mA output signal provided by the

Series 650 Transmitter is that any number of receivers can be connected

in Series in the current loop. Thus, an A-701 Digital Readout Accessory, an

analog panel meter, a chart recorder, process controlling equipment, (or

any combination of these devices) can be operated simultaneously. It is

only necessary that these devices all be equipped with a standard 4-20 mA

input and that proper polarity of the input connections be observed when

inserting the device in the current loop. If any of the receiving devices

displays a negative or downscale reading, this indicates that the signal

input leads are reversed.

MAINTENANCE

Upon final installation of the Series 650 Transmitter and the companion

receiver, including the A-701 Digital Readout, no routine maintenance is

required. A periodic check of system calibration is recommended. The

Series 650 Temperature Transmitter is not field serviceable and should be

returned to the factory if service is required. The A-701 Digital Readout

should be returned to the manufacturer if service is required. Refer to the

A-701 instruction sheet.

Note: Interchanging sensing probes requires recalibration to maintain

published accuracies.

©Copyright 2007 Dwyer Instruments, Inc. Printed in U.S.A. 8/07 FR# R5-440495-00 Rev.1

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...