Page 1

Bulletin P-648B

1

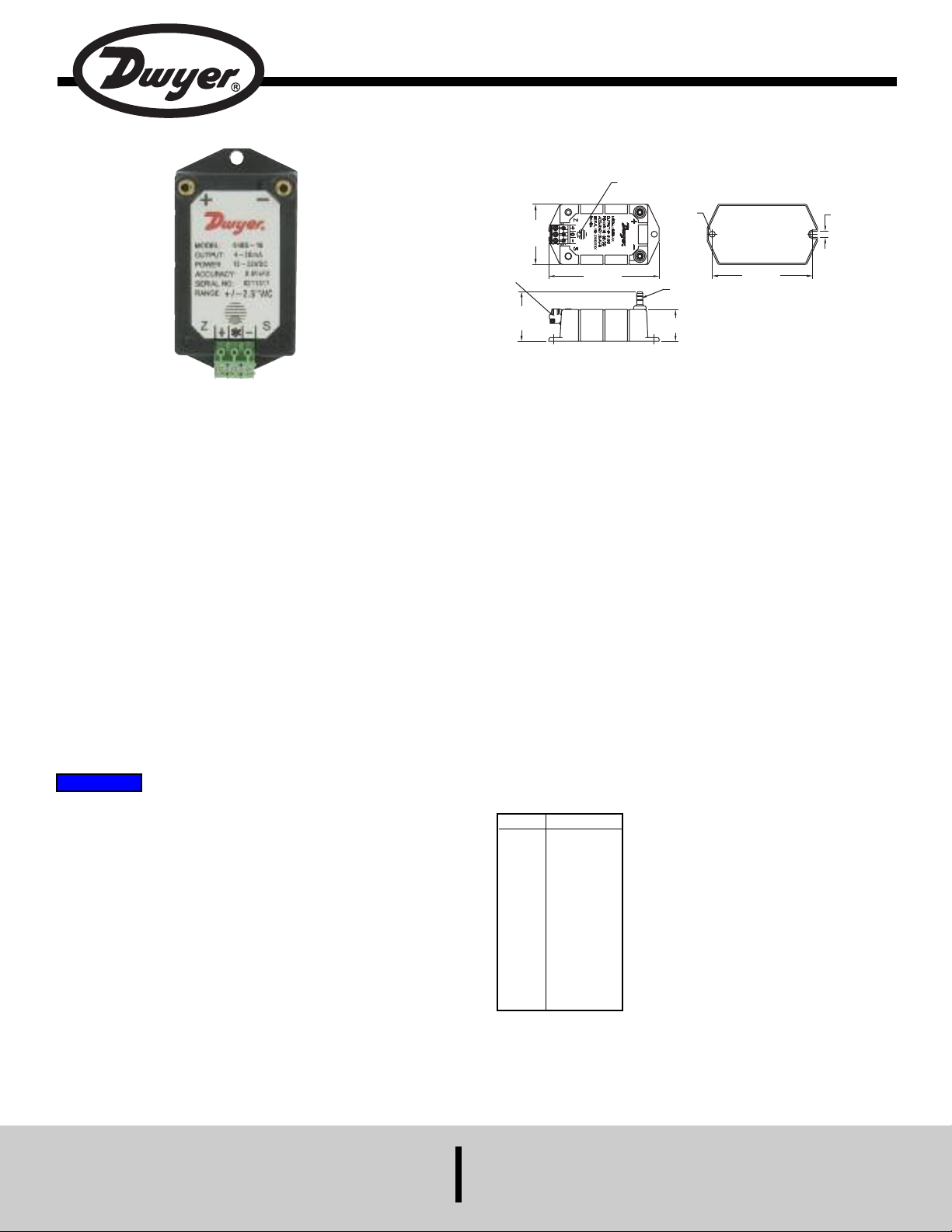

-57/64

[48.00]

T

ERMINAL

BLOCK

1-9/16

[39.50]

3-15/32

[88.00]

1

[25.40]

B

RASS

HOLE

B

ARBS

3

-5/32

[80.00]

Ø

3/16

[Ø4.80]

3

/16

[4.80]

LED

Series 648B and 648C Differential Pressure Transmitter

Specifications - Installation and Operating Instructions

he Series 648B and 648C Differential Pressure Transmitters are designed to

T

be used with clean, dry air and other non-corrosive gases. Each unit features a

push-activated zero function and an associated LED light indicator. With the

convenient push-button, zero calibration can be performed without any additional

equipment, which significantly reduces time and cost for users. The dual color

ED indicates if the transmitter is at normal operation, overpressure, or in the

L

rocess of zero calibration. The enclosure consists of a flame retardant plastic

p

op cover and a stainless steel bottom plate for ruggedness. The pressure ranges

t

vary from 0.1 in w.c. to 25 in w.c. unidirectional and 0.25 in w.c. to 5 in w.c.

bidirectional. Series 648B comes standard with ±0.8% FS* accuracy, while 648C

models are available in ±0.4% FS* accuracy for more demanding applications.

Wiring time is reduced with the removeable terminal block. Each unit features a

2-wire 4 to 20 mA output that is fully protected against short circuiting and

incorrect wiring.

Mounting

Series 648B and 648C transmitters are designed for mounting by using the two (2)

slots (suitable for #6 screws) that are provided on the mounting plate. For optimum

performance, isolate the instrument from vibration and provide relatively clean, dry

air to the pressure ports.

In most applications, preferred installation is with the baseplate mounted vertically

and located on a flat surface in a junction box or attached to a nearby beam. Quick

and easy field replacement is possible by removing the single case screw that

holds the housing to the baseplate and lifting the housing free. The baseplate will

remain mounted and can be used with the replacement units housing.

NOTICE

Piping

Two (2) 3/16˝ OD barbed pressure fittings are provided for pressure connection

with 1/8˝ ID push on tubing.

The overpressure limit with the new tension diaphragm construction is up to 15 psi

regardless of range.

The axis most sensitive to vibration is the one perpendicular to

the baseplate. Avoid mounting with maximum vibration along

axis.

SPECIFICATIONS

ervice: Air and non-combustible, compatible gases.

S

etted Materials: 302 SS, glass, nickel, silicon rubber, polyethylene, acrylic,

W

BS and brass.

A

Accuracy: 648B: ±0.8% FS* at room temperature.

648C: ±0.4% FS* at room temperature.

*RSS (Root Sum Square) includes non-linearity, hysteresis and non-

repeatability.

tability: ±1% FS/yr.

S

Temperature Limits:

Operating: 0 to 170°F (-18 to 77°C);

Storage: -65 to 185°F (-54 to 85°C).

Pressure Limits:

15 psi (100 kPa) proof pressure;

30 psi (200 kPa) burst pressure.

Thermal Effects: 648B: ±0.025% FS/°F (0.045%/°C); 648C: ±0.020% FS/°F

(0.036%/°C).

Power Requirements: 13 to 32 VDC.

Output Signal: 4 to 20 mA.

Zero and Span Adjustments: Push-button for zero, potentiometer for span.

Response Time: Approximately 10 ms.

Max. Loop Resistance: DC: 0 to 950 Ω.

Electrical Connection: Detachable euro-style terminal block.

Process Connections: 3/16˝ OD barbed fitting for 1/8˝ ID push-on tubing.

Housing: SS and PC+ABS alloy.

Weight: 3.8 oz (108 g).

Model

648B-1

648B-2

648B-3

648B-4

648B-5

648B-6

648B-7

648B-8

648B-13

648B-14

648B-15

648B-16

648B-17

Note: For units with ±0.4% FS* accuracy, change B to C in model number.

Ex. 648C-01.

Range in w.c.

0 to 0.1

0 to 0.25

0 to 0.5

0 to 1

0 to 2.5

0 to 5

0 to 10

0 to 25

0 to ±0.25

0 to ±0.5

0 to ±1

0 to ±2.5

0 to ±5

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

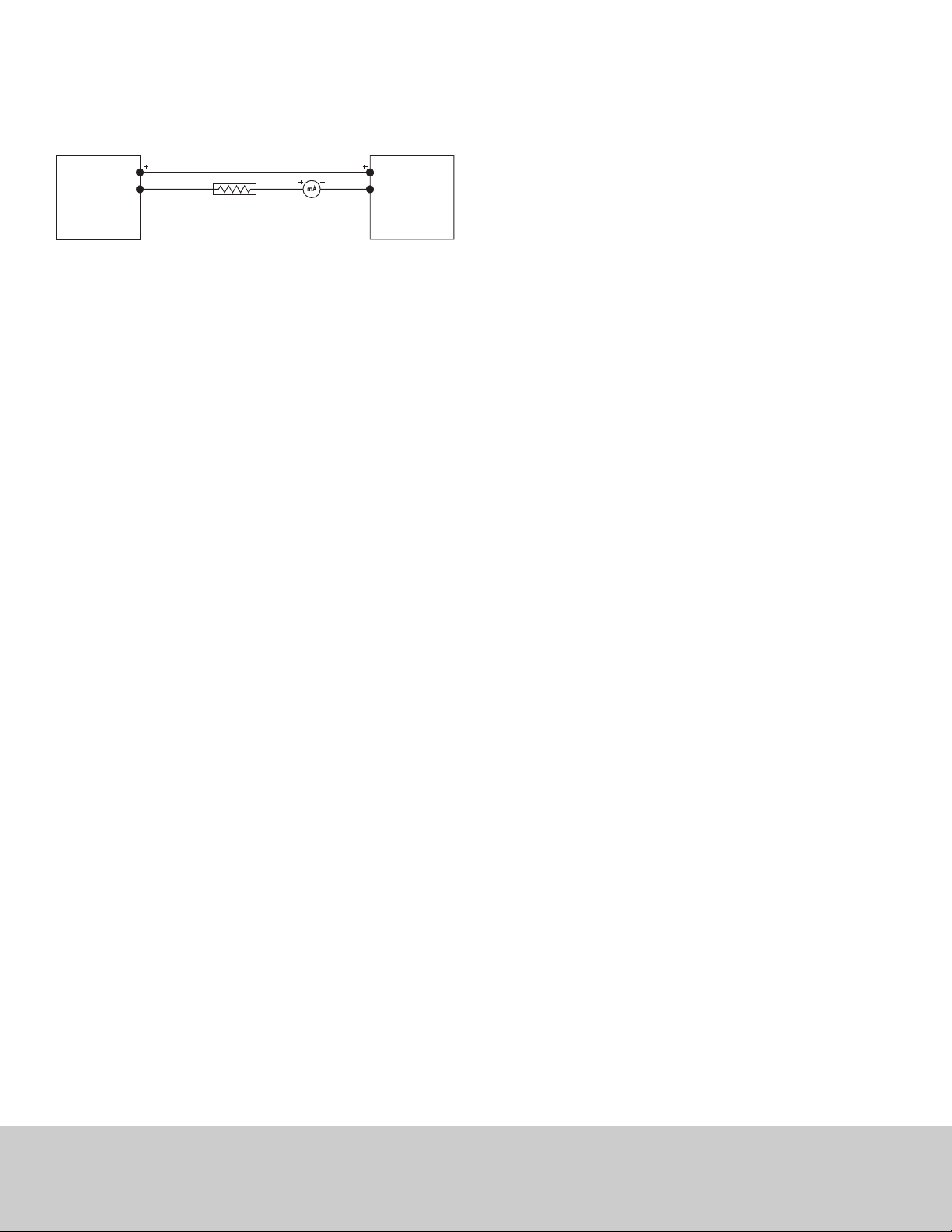

Electrical

P

OWER

S

UPPLY

13-32 VDC

PRESSURE

T

RANSMITTER

RECEIVER

he Series 648B and 648C are two (2) wire circuits (+SUPPLY, -RECEIVER) with 4

T

o 20 mA outputs. The units are calibrated at the factory using a 250 Ω load at 24

t

DC.

V

WIRING DIAGRAM FOR 648B SERIES

Calibration

he 648B and 648C series are factory calibrated and should require no field

T

djustment. However, both zero and span adjustments are provided near the screw

a

erminal strip. Whenever possible, any zero and/or span offsets should be corrected

t

by software adjustment in the user’s control system. Use the zero and span

adjustments only if absolutely necessary. The 648B and 648C transmitters are

calibrated in the vertical position at the factory (baseplate vertical). For use in any

other orientation, position the unit and follow the adjustment procedure listed below.

f a change in range is needed, contact the Customer Service Department for a

I

eplacement in the appropriate range.

r

Zero Adjustment

While monitoring the current output with both pressure ports open to atmosphere, the

zero may be adjusted. Use push-button adjustment on the front of the unit to reset

zero.

pan Adjustment

S

pan or output adjustments should only be done using an accurate pressure standard

S

(electric manometer, digital pressure gage, etc.). With FS pressure applied to the high

pressure port (reference open to atmosphere), adjust span to achieve 20 mA output.

MAINTENANCE/REPAIR

Upon final installation of the Series 648B and 648C, no routine maintenance is

required. The Series 648B and 648C are not field serviceable and should be returned

if repair is needed. Field repair should not be attempted and may void warranty.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sales” in our catalog and on our website. Contact

customer service to receive a Return Goods Authorization number before shipping the

product back for repair. Be sure to include a brief description of the problem plus any

additional application notes.

©Copyright 2012 Dwyer Instruments, Inc. Printed in U.S.A. 6/12 FR# R1-443886-00 Rev. 2

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...