Page 1

BULLETIN A-30-65

Series 645 Wet/Wet Differential Pressure Transmitter

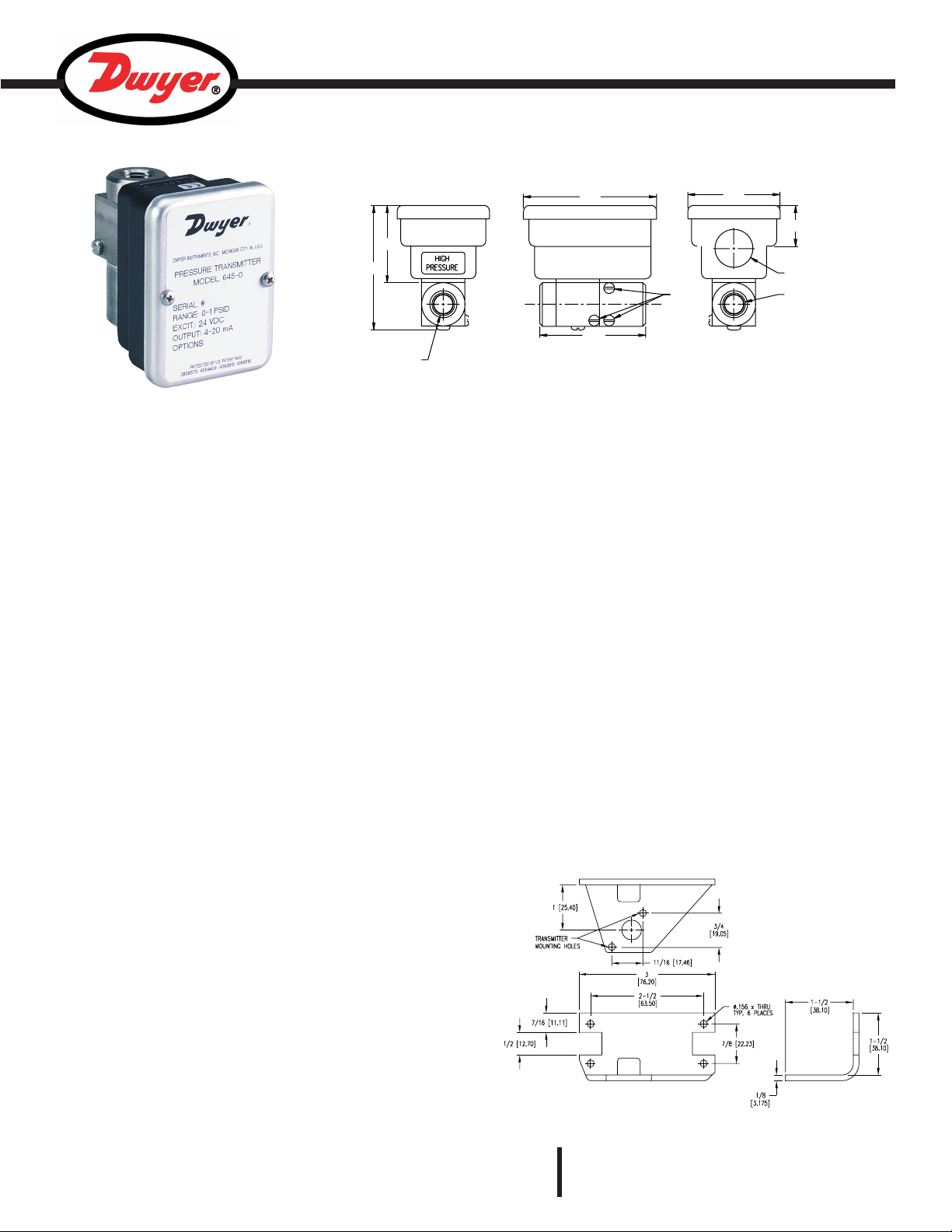

Specifications - Installation and Operating Instructions

1.750

2.840

1/4-18 NPT

HIGH PRESSURE PORT

GENERAL

The Series 645 Wet/Wet Differential Pressure Transmitter

is designed for use with any gas or liquid compatible

with 17-4 PH stainless steel, 300 Series stainless steel,

Viton and Silicone O-rings and bleed screw seals. Units

can accurately measure the differential pressure even

when liquid is applied to both ports. The transmitter

contains a fast response capacitance sensor and a

unique isolation system.

The isolation system transmits the motion of the differential pressure sensing diaphragm from the high line

pressure environment to the dry enclosure where it

moves one of a pair of capacitance plates proportionally to the diaphragm movement. The variable capacitance is converted to a current proportional to the differential pressure by the capacitance sensing and signal

conditioning circuit located in the enclosure. The electronic circuit linearizes output versus pressure, standardizes the output, and compensates thermal effects of

the sensor.

INSTALLATION

The Series 645 Differential Pressure Transmitter is supplied with a mounting bracket and two 6-32 ⫻ 3/8 hex

head screws. First attach the bracket to mounting location using holes or band clamp notches available on

large section of the bracket. Attach the transmitter to the

bracket by using the two 6-32

and the two tapped holes located on the underside of

the transmitter. See Figure 1 at right.

⫻ 3/8 hex head screws

2.960

2.440

BLEED

SCREWS

2.150

.940

Ø.875 CONDUIT OPENING

1/4-18 NPT

LOW PRESSURE PORT

SPECIFICATIONS

Service: Compatible gases or liquids applied to both pres-

sure and reference ports.

Output: 4 to 20 mA, two-wire.

Supply Voltage: 11 to 30 VDC.

Loop Resistance: 0 to 1000Ω.

Maximum Line Pressure: 250 psig.

Maximum Overload Pressure: (High side) 1 to 5 psi: 20 ⫻

FS, 10 to 25 psi: 10 ⫻ FS, 50 psi: 5 ⫻ FS, 100 psi: 2.5 ⫻ FS;

(Low side) 2-3 ⫻ FS.

Zero and Span: Adjustable, non-interactive, ±1 mA.

Accuracy: ±0.25% FS.

Temperature Limits: Operating: 0 to 175°F (-22 to 80°C),

Storage: -65 to 260°F (-54 to 126°C).

Response Time: 30 to 50 msec.

Thermal Effects: (includes zero and span) ±0.02% FS/°F, 30

to 150°F (-1 to 65°C).

Wetted Parts: 17-4 PH stainless steel, 300 Series stainless

steel, Viton and Silicone O-rings and bleed screw seals.

Housing: Stainless steel/Aluminum.

Process Connection: 1/4 - 18 NPT(F).

Electrical Connection: Barrier strip terminal block with con-

duit enclosure and .875 (22 mm) diameter conduit opening.

Weight: 14.4 oz (0.4 kg).

Mounting

R1-124069-00

DWYER INSTRUMENTS, INC.

P. O. BOX 373 MICHIGAN CITY, INDIANA 46361, U.S.A.

Telephone 219/879-8000

Fax 219/872-9057

Page 2

NOTE:

R1-700442-01

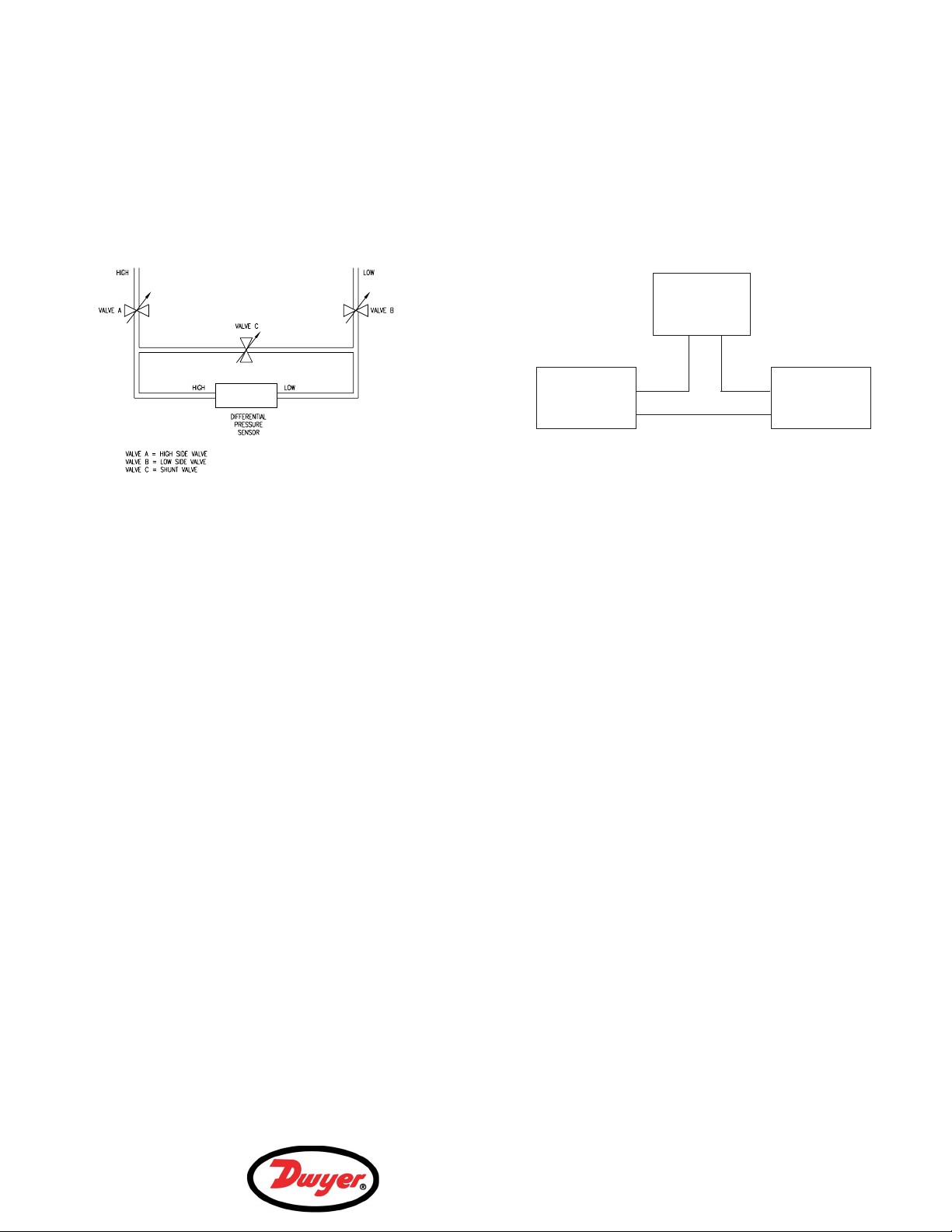

For differential pressure measurements at high line pressure (250 psig max.), it is recommended that the pressure sensor be installed with a valve in each line, plus a

shunt valve across the high and low (reference) pressure

ports as indicated in Figure 2 below. The high pressure

port is labeled with the word “HIGH”.

System Set-up

When making electrical connections, be sure to observe

polarity—units are designed to have current flow in one

direction only. The minimum supply voltage is 11 +.02 ⫻

(Resistance of receiver plus line. The maximum supply

voltage is 30 + .004 ⫻ (Resistance of receiver plus line).

To access electrical connections, remove cover on top

of the unit. See Figure 3 for correct electrical connections.

Wiring

Series 645

Transmitter

Figure 2

Valve C should be open and Valves A and B closed

whenever the system is first being wetted or pressurized. Valves A and B should then be opened slowly to

avoid hammering. Valve C can then be closed and the

system is operating. When removing the differential

pressure sensor, open Valve C first, then close Valves A

and B.

Bleeding the Pressure Ports

Three bleed screws are located on the side of the unit

(two for low pressure port, one for high pressure port).

Install the transmitter in its intended location and pressurize the ports. Back off the first bleed screw mounted

on the flat side of the sensor body (2 turns max.) until liquid begins to flow out. After only bubble-free liquid flows

out, retighten the bleed screw. Repeat the same procedure for the second set of bleed screws located on the

round section of the low pressure fitting.

Electrical Connections

The Series 645 Wet/Wet Differential Pressure

Transmitters are true 2-wire, 4-20 mA current output

devices and deliver rated current into any external load

of 0 to 800 ohms.

The units are supplied with a 7/8″ diameter knockout

intended for a 1/2″ ID conduit connection. It is suggested that any electrical cable shield be connected to the

system’s loop circuit ground to improve electrical noise

reduction.

©Copyright 1997 Dwyer Instruments, Inc.

Printed in U.S.A. 7/97

DWYER INSTRUMENTS, INC.

P.O. Box 373, Michigan City, Indiana 46360, U.S.A.

Phone: 219/879-8000 Fax: 219/872-9057

+

Power

Supply

- -

Figure 3

-

++

Load

(Monitor)

OPERATION

The Series 645 Wet/Wet Differential Pressure

Transmitters are carefully calibrated to the specific input

pressure range versus current output at the factory. Little

or no field calibrating is necessary.

Zero and Span Adjustment

To gain access to the zero and span adjustments,

remove the top cover of the transmitter. Loosen the 6-32

seal screws in the plastic terminal block. The zero and

span adjustments are located under the plastic terminal

block. Be careful not to disconnect any internal wiring.

After all adjustments are made, remember to re-install

the 6-32 seal screws. The Series 645 transmitters with

4-20 mA output are factory calibrated using a 250 ohm

load at 24 VDC. Zero and span adjustments are approximately ±1 mA, individually.

MAINTENANCE

After final installation of the Series 645 Wet/Wet

Differential Pressure Transmitter, no routine maintenance

is required. Periodic checks of connections is recommended. Please contact Dwyer Instruments, Inc. before

returning unit for repair to review information relative to

your application. When returning a product to the factory, carefully package and ship freight prepaid. Be sure to

include a complete description of the application and

problem and identify any hazardous material used with

the product.

FR R1-440983-00

Loading...

Loading...