Page 1

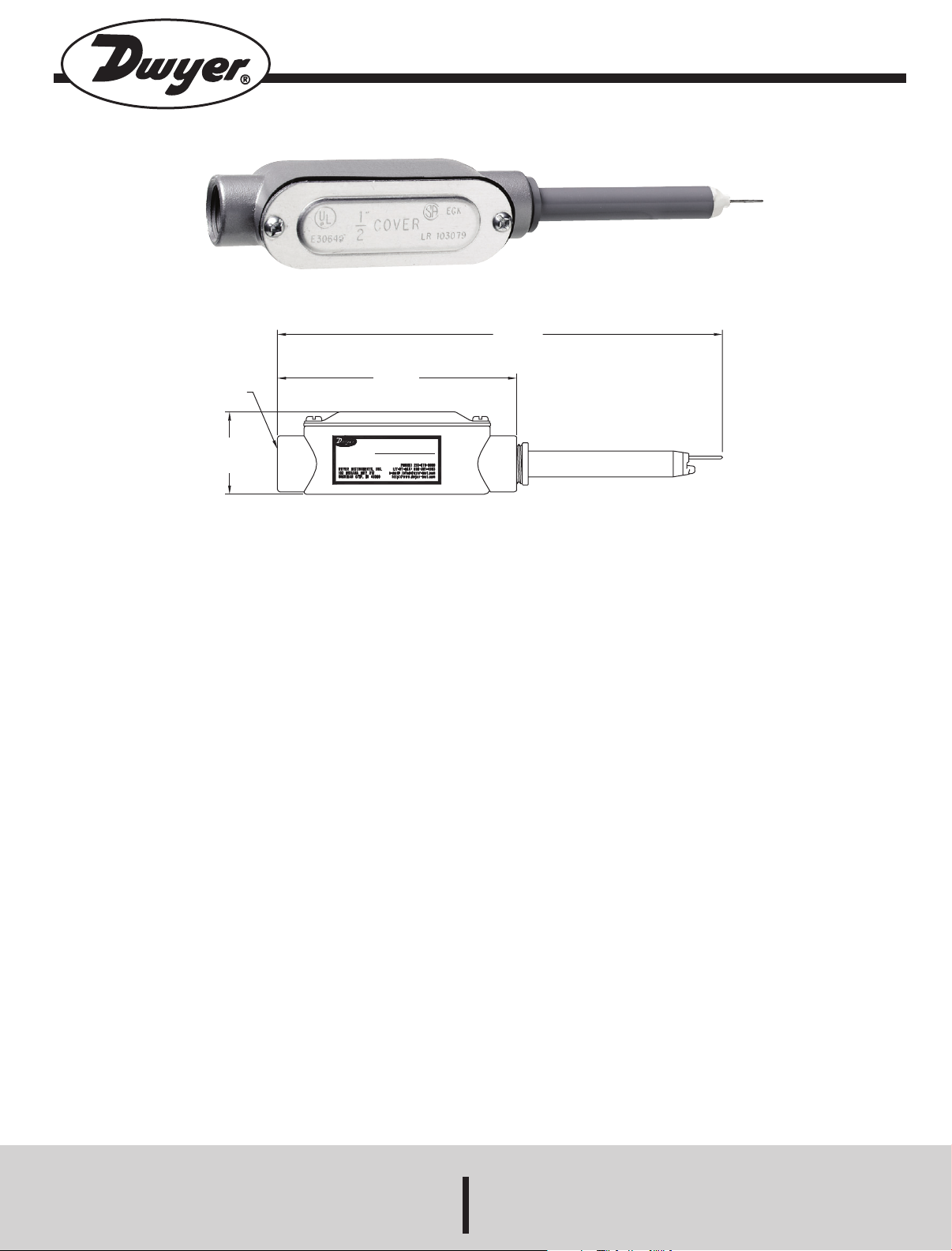

1/2 NPT

1-23/32

[43.66]

Bulletin E-66-B

Series 641B Air Velocity Transmitter

Specifications - Installation and Operating Instructions

9-1/4

[235.0]

4-31/32

[126.21]

The Series 641B Air Velocity Transmitter uses a heated

mass flow sensor technology. It has 4 user selectable

ranges from 250 FPM to 2000 FPM with corresponding

metric ranges of 1.25 MPS to 10 MPS. The 641B provides

an isolated 4-20 mA output proportional to the velocity.

INSTALLATION

Location: Select a location where the temperature will be

within 32 to 140°F (0 to 60°C). The transmitter may be

located any distance from the receiver provided that the

total loop resistance does not exceed 600 ohms. The

probe should be located where conditions are representative of the overall environment being monitored. Avoid locations where turbulence, stagnation, or rapidly fluctuating

velocities or temperatures are present as these conditions

may affect the readings. The filter setting may be used to

average velocity readings in turbulent conditions.

Position: The transmitter is not position sensitive and may

be mounted in any orientation.

Mounting: The 641B should be connected to conduit or

other connection means with the 1/2˝ NPT conduit connection. Ensure connection is installed properly so that dust

and debris can not enter housing.

Airflow: The 641B is intended for use with dry air. Dust

accumulation on sensor may impair the velocity measurement and will require probe cleaning.

SPECIFICATIONS

Service: Air and compatible, non-combustible gases.

Accuracy:

5% FS Process gas: 32 to 122° F (0 to 50°C).

6% FS Process gas: -40 to 32°F & 122 to 176°F

(-40 to 0°C & 50 to 80°C).

Response Time: Flow: 1.5 seconds to 95% of final value

(Output filter set to minimum).

Temperature Limits: Process: -40 to 176°F (-40 to

80°C). Ambient: 32 to 140°F (0 to 60°C).

Humidity Limit: Non-Condensing.

Power Requirements: 12–35 VDC, 10–16 VAC.

Output Signal: 4-20 mA, isolated 24V source, 3 or

4-wire connection.

Output Filter: Selectable 0.5 –15 (seconds).

Loop Resistance: 600 ohms max.

Current Consumption: 300 mA max*.

Electrical Connections: Screw terminal.

Enclosure Rating: Designed to meet NEMA 4X.

Mounting Orientation: Unit not position sensitive.

Weight: 12.6 oz (357.2 g).

* A brief current transient exceeding 300 mA may be seen

on startup.

See maintenance section for additional cleaning details.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

Page 2

NOTE: Where conduit connections are not made, a 1/2˝

NPT cable seal should be used to prevent contaminants

from entering the case. Where conduit connections are

made, make sure that any possible condensation within the

conduit will not flow into the transmitter housing.

ELECTRICAL CONNECTION

The 641B has been designed for easy and flexible connection to power and loop receivers. Electrical connection is

made inside the body of the device with a “Euro” style terminal block. The device features a current loop that is fully

isolated from the power source. The current loop has an

internal 24V isolated supply so no external loop power is

required. With full isolation, loop grounding is not a concern.

The input power requirements are also very flexible. The

device may be powered from either an AC or DC power

source.

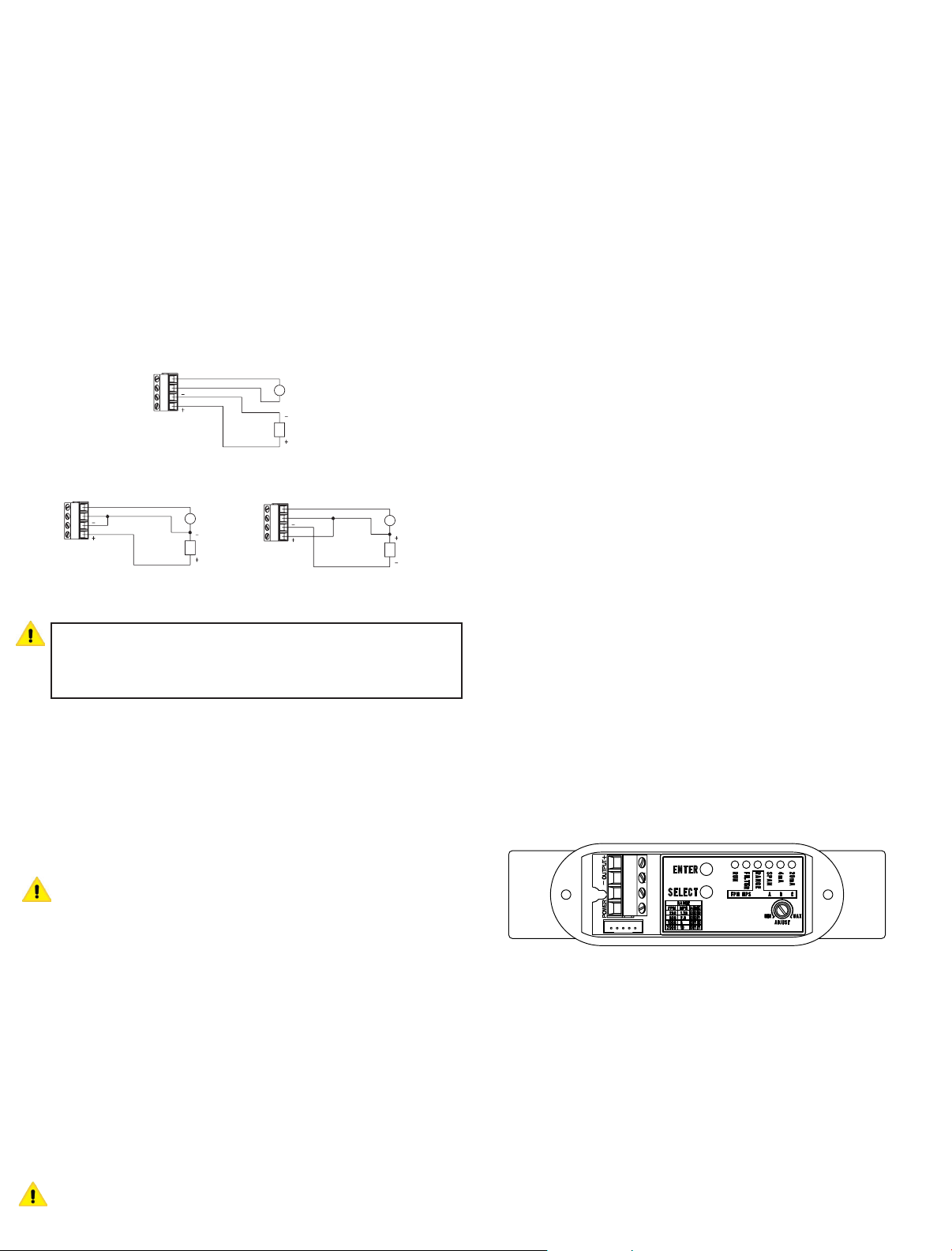

3 or 4-Wire Connection

POWER SUPPLY

AC OR DC

RECEIVER

4-WIRE

DC SUPPLY

ONLY

(EITHER

POLARITY)

RECEIVER

3-WIRE

RECEIVER NEGATIVE

COMMON

DC SUPPLY

ONLY

(EITHER

POLARITY)

RECEIVER

3-WIRE

RECEIVER POSITIVE

COMMON

CAUTION: Do not exceed the specified supply voltage rating. Permanent damage not covered by the warranty may

result. Do not use an external power source on the current

loop connection.

Receiver-Transmitter Connection — The 641B is

designed as a three or four wire 4-20 ma device. The current loop output is isolated from the power supply input and

provides an internal 24-volt loop supply. With a DC power

supply, a three or four-wire connection may be used. Do not

use a three-wire connection with an AC power source. In a

three-wire connection either power supply wire may be

used as the common. The total loop resistance should not

exceed 600 Ohms.

Wire Type and Length — The wire selection for an installation is often overlooked or neglected and may contribute

to improper or even intermittent operation. In all cases

ensure that the connection meets all applicable national

and local electrical codes. Although the 4-20 mA current

loop systems are relatively immune to wire or wiring related

problems, selection of the wire for some installations will be

an important factor in ensuring satisfactory system operation. Twisted conductors will usually be immune to most

stray electric and magnetic fields and to some extent electromagnetic fields, such as interference from RF transmitters. With twisted pair wiring the current loop and the

power connections should be separate pairs. Avoid using

flat or ribbon cable that has no regular conductor twist.

Where interference is possible, it is recommended that

shielded wire be used. The shield must not be used as one

of the conductors and should be connected to ground at

only one end, generally at the power supply. Similarly, if the

installation uses conduit, the conduit should be connected

to protective ground as specified by the applicable code

and the signal wiring must not be connected to the conduit

at more than one point or as specified by the code.

The maximum length of wire connecting the transmitter

and receiver is a function of the wire resistance and receiver resistance. The total loop resistance must not exceed

600 Ohms, including the receiver resistance and wire resistance. The power supply connection must be designed so

that the worst case voltage drop due to wire resistance will

not cause the power supply voltage at the transmitter to

drop below the specified value. Provided the power supply

voltage is maintained within the specified voltage range, the

641B is not affected by variations in power supply voltage.

TRANSMITTER SETUP

The 641B has been designed for easy setup. It has five

configuration parameters that may be adjusted by the user.

These parameters are Output Filter, Range (In English or

Metric), span, 4 mA set-point and 20 mA set-point. All of

these may be adjusted at any time in the field. These

adjustments may also be easily returned to factory default.

Interior Label Diagram

CAUTION: Do not use a receiver with an internal power

supply or use an external supply in the current loop. The

current loop is powered from within the 641B. Connecting

an external supply to the current loop may destroy the

transmitter. Using an external supply voids the warranty.

Power Supply Connection — The power supply may be

either AC or DC. The DC power may be from 12 to 35 Volts.

The power connection is not polarity sensitive so the positive and negative connections may be made to either power

terminal. The AC connection may be from 10 to 16 VAC

RMS. Do not exceed 20 VAC. When selecting a transformer

please note that the specified output for transformers is at

some specified current. With a load current less than the

specified current transformer output may be significantly

higher than the specified voltage. Transformers with secondary voltages of 10 to 16 VAC are recommended.

CAUTION: Do not use transformers with a secondary voltage rating greater than 16 VAC RMS.

A set of controls and indicators are provided within the unit

consisting of the select button, enter button, adjustment

control, and six LED indicators. When operating normally,

only the RUN LED indicator will be illuminated. During the

setup operation the LED indicators will indicate the parameter selected, when it is being adjusted, and status of the

adjustment process. If the unit is left in the setup mode for

several minutes without any activity it will return to the

normal operating mode.

Page 3

Two buttons and a potentiometer control the setup process.

The SELECT button is used to scroll between the setup

parameters.

The ENTER button allows access to each parameter for

adjustment.

The ADJUST potentiometer is used to change the value of

the parameters.

Holding the ENTER button for 2.5 seconds saves the new

parameter value.

Making Adjustments

The adjustment process has three steps: select the parameter, adjust the parameter, save the new value. These are

described in the following steps.

1. Select the parameter: Each time the SELECT button is pressed the LED indicator will advance to the next

parameter. When the last parameter, SPAN, is selected,

the next time the SELECT is pressed the unit will return

to RUN mode. Press the SELECT button until the LED

indicator illuminates the desired parameter. Press

ENTER. The selected indicator will begin to blink, showing the parameter may now be adjusted. If the unit is left

in the setup mode, after several minutes it will reset to

the operate mode.

2. Adjust the parameter: Turn the ADJUST potentiometer until the desired setting is made. This may be

adjusted using a small screwdriver or similar tool. Be

careful not to force the control past its stops or damage

will result.

3. Save the Parameter: To save the new parameter

press and hold the ENTER button. The LED indicator will

begin to flash at a faster rate. After about 2.5 seconds

all of the LED indicators will flash when the parameter is

saved. If you do not want to save the parameter press

the SELECT button without entering the parameter. The

adjusted value will be discarded and next LED indicator

will be illuminated.

Page 3

Range Selection

The range selection allows you to select one of four ranges

in either feet per minute (FPM) or meters per second (MPS).

Ranges:

FPM: 250, 500, 1000, 2000

MPS: 1.25, 2.5, 5, 10

Select the RANGE indicator by pressing ENTER when the

RANGE LED indicator is illuminated. The A,B,C LED indicators will display which range setting is currently active.

Press ENTER to enable adjustment. Turn the ADJUST until

the desired range indication is achieved. If you want to discard the adjustment press SELECT. If you want to save the

range press and hold ENTER. The RANGE LED will blink at

a faster rate for about 2.5 seconds then all of the LEDs will

flash indicating the value was saved.

The range setting is displayed with the LED indicators. The

function of these indicators is summarized on the control

label inside the unit. The following table summarizes the

indicator status for each range setting

Range/Units

250 FPM

500 FPM

1000 FPM

2000 FPM

1.25 MPS

2.5 MPS

5 MPS

10 MPS

Run

1

1

1

1

0

0

0

0

Filter

0

0

0

0

1

1

1

1

Range

1

1

1

1

1

1

1

1

Span

A

0

0

0

0

0

0

0

0

4 mA

B

0

0

1

1

0

0

1

1

20 mA

C

0

1

0

1

0

1

0

1

1: Indicator on

0: Indicator off

Adjusting the Output Filter

The output filter may be adjusted to smooth the readings

when measuring turbulent flow. The time constant may be

adjusted from 0.5 seconds to 15 seconds. To adjust the filter time constant, select the FILTER indicator. Press ENTER

to enable adjustment. Turn the ADJUST until the desired

amount of damping is achieved. To save the value press and

hold the ENTER button until the LED indicators all flash, indicating the value was saved. To discard the adjustment press

SELECT before pressing the ENTER button.

OUTPUT FILTER RESPONSE (values in seconds)

% of Full Velocity

63%

90%

95%

99%

Filter Setting on Adjust Dial

Min.

0.5

1.1

1.5

2.3

Mid.

7.5

17.3

22.5

34.5

Max.

15

34.5

44.9

69.0

Page 4

Page 4

Span Setting

The 641B has been calibrated for standard sea level conditions. As a mass flow device it will always read the air velocity for standard conditions. Density changes due to barometric or absolute pressure are not corrected automatically.

The span setting allows correction for altitude or other static pressure conditions that affect the density of the process

air. This parameter allows for a ±50% adjustment in the

span value.

To make the span adjustment you will need to know either

the absolute static pressure or the corrected velocity of the

process air. Set the air velocity to a known value, ideally

about 3/4 of the full-scale range value. Press SELECT until

the SPAN LED indicator is illuminated then press ENTER.

The SPAN LED will begin to blink. Adjust the control for the

desired velocity then press and hold the ENTER button until

all of the LED’s flash, indicating the new value was saved. If

you know the absolute static pressure you can compute the

corrected velocity using the following equation:

Po

Vcor =

Vrdg

PA

Where:

P0 is the standard pressure of 29.9 in. Hg. or 760 mm Hg.

PA is the absolute pressure reading

Vrdg is the indicated velocity

Vcor is the corrected velocity

Restoring Factory Default Settings

The 4 mA, 20 mA, and Range settings override factory

default values. To restore these to the factory default settings, start with the unit in the RUN mode. Press and hold

the ENTER button. The RUN LED indicator will begin to

blink. After about 2.5 seconds all LED indicators will flash

indicating the factory settings have been restored. Range

and Filter settings are not affected by this operation. If you

are unsure whether any have been altered, press the

SELECT button six times to sequence through all settings.

When you return to the RUN mode, the RUN LED indicator

will blink several times if either the 4 mA, 20 mA, or span

settings have been changed. The RUN LED will otherwise

remain on.

MAINTENANCE

In general the 641B should require very little maintenance.

In some installations dust may accumulate on the sensor

over time. This can be removed by carefully brushing the

probe with a small camel hairbrush. A jet of air may also dislodge the accumulated buildup. Technical grade denatured

or isopropyl alcohol may be used where the dust accumulation does not respond to brushing. Always disconnect the

power when performing a cleaning operation.

Aside from the adjustments described above, the 641B

cannot be field calibrated. Because of specialized computer instrumentation required, these units must be returned to

Dwyer Instruments for factory calibration.

4 mA Setting

To make this setting you will need a milliammeter connected in the current loop. Press SELECT until the 4 mA LED

indicator is illuminated then press ENTER. The milliammeter

will now read approximately 4.0 mA. Adjust the control for a

4.0 mA reading on the milliammeter. Press and hold ENTER

to save the new setting. Pressing SELECT before pressing

ENTER will restore the previous calibration value.

20 mA Setting

With the milliammeter connected in the current loop, press

SELECT until the 20-mA LED indicator is illuminated. Press

ENTER to begin adjustment of the 20-mA set point. The 20

mA LED will now be blinking. Adjust the control until the milliammeter reads 20.0 mA. Press and hold ENTER to save

the new setting. Pressing SELECT before pressing ENTER

will restore the previous calibration value.

©Copyright 2005 Dwyer Instruments, Inc. Printed in U.S.A. 2/05 FR# 02-443205-20

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...