Page 1

Bulletin E-69ES

2-1/2 [63.50]

TYP

1-11/16

[42.86]

5-5/16

[134.94]

1/4NPT

1/2NPT

2-7/8 [73.03]

1/16 [1.59]

25/32 [19.84]

03-3/8 [85.73]

3/4 NPT

1-9/16

[39.69]

(3) #10-32 x 1/4 [6.35] DP HOLES

EQUALLY SPACED ON A 2-1/2 [63.50] B.C.

Series 634ES Pressure Transmitter

Specifications - Installation and Operating Instructions

The Series 634ES Pressure Transmitter senses a single air, compati-

ble gas or liquid pressure and converts it into a standard 4-20 mA output

signal. Ranges are available from 0-10 through 0-6000 psi. All models

are field adjustable so any range within these limits can be achieved by

recalibration using the easily accessible span and zero potentiometers.

Positive pressure can be measured within an accuracy of ±0.5% of span.

The Series 634ES uses an isolated piezoresistive pressure sensor to

produce a resistance change across a wheatstone bridge. The signal is

conditioned and converted into a 4-20 mA output signal.

For applications requiring direct pressure or percent of full span readings, the optional A-701 digital readout makes an ideal companion

device, providing a bright .6” high, 3-1/2˝ digit LED and supplying power

to the Series 634ES Transmitter.

Series 634ES Models and Ranges in PSI (bar)

Model

634ES-0

634ES-1

634ES-2

634ES-3

634ES-4

634ES-5

634ES-6

634ES-7

634ES-8

634ES-9

As Stocked

10 (.69)

30 (2.07)

50 (3.45)

100 (6.9)

200 (13.8)

300 (20.7)

500 (34.5)

1000 (69)

2000 (138)

4000 (276)

Min. Range

10 (.69)

20 (1.38)

40 (2.76)

60 (4.14)

100 (6.9)

250 (17.2)

350 (24.1)

600 (41.4)

1250 (86)

2500 (172)

Max. Range

20 (1.38)

40 (2.76)

60 (4.14)

120 (8.3)

250 (17.2)

350 (24.1)

600 (41.4)

1250 (86)

2500 (172)

6000 (414)

Max. Pressure

30 (2.07)

60 (4.14)

100 (6.9)

200 (13.8)

400 (27.6)

500 (34.5)

1000 (69)

2000 (138)

4000 (276)

7500 (517)

PHYSICAL DATA

GENERAL

Maximum Pressure: See chart on this page.

Wetted Parts: 316, 316L SS.

Housing: Designed to meet NEMA-4X.

ELECTRICAL

Power Supply: 12.3-35 VDC-2 wire.

Output Signal: 4-20 mA DC (limited at 38 mA DC).

Loop Resistance: 0 - 1100 ohms from 12.3 to 35 VDC.

Vps - 12.3V

=

R

L max

20 mA

Current Consumption: DC: 38 mA max.

MATERIALS

Housing: Cast aluminum; textured gray polyurethane finish.

Pressure Connection: Stainless Steel.

MECHANICAL

Weight: 1 lb, 12 oz (.8 kg).

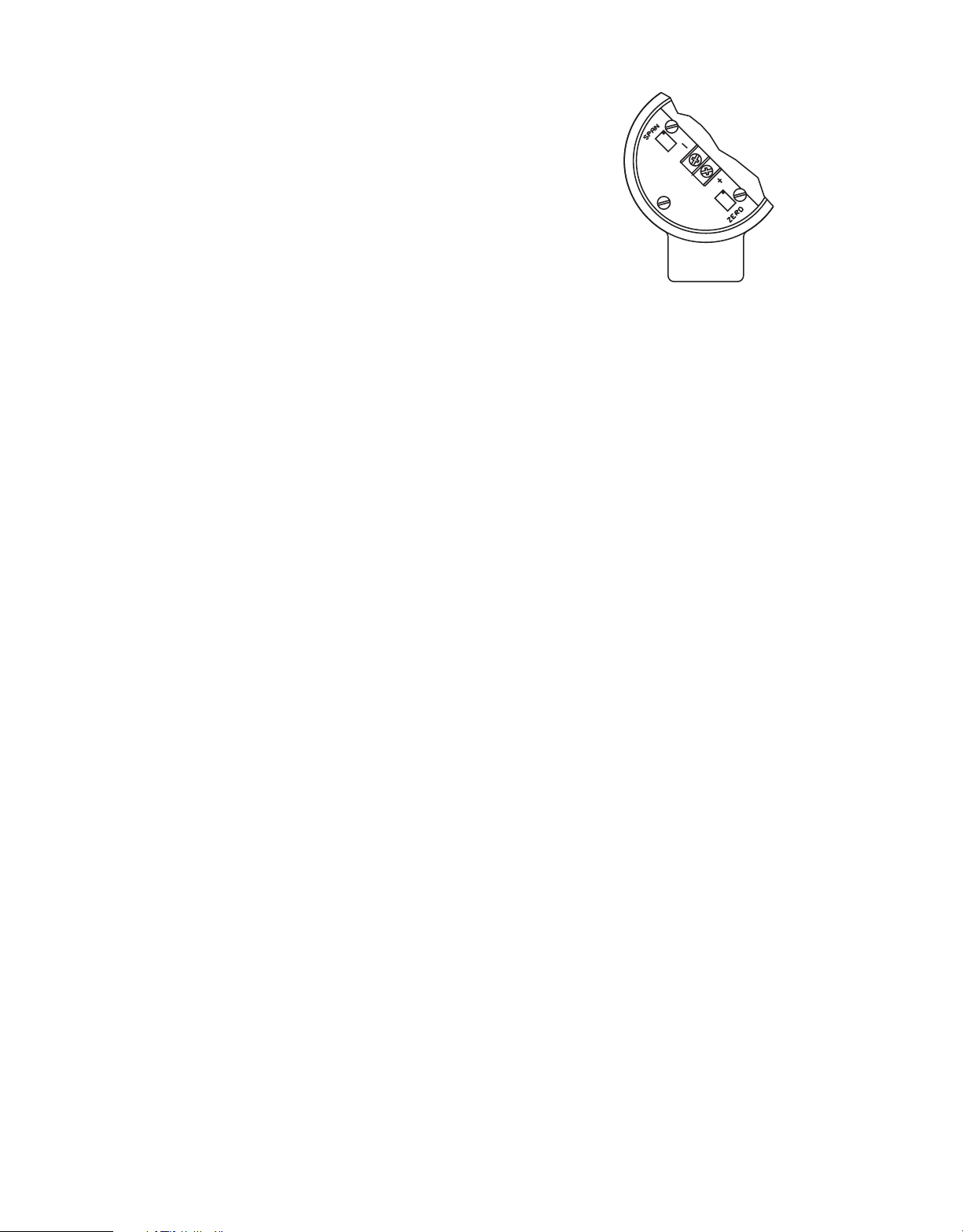

Span and Zero Adjustments: Protected potentiometers, located in

auxiliary housing.

Pressure Connection: 1/4˝ female NPT x 1/2˝ male NPT.

PERFORMANCE AT 70°F (21.1°C)

Zero Output: 4 mA DC.

Full Span: 16 mA DC.

Accuracy: ±0.5% of span.

Warm-up Time: 10 minutes.

STABILITY/ENVIRONMENTAL

Operating Temperature: 20 to 120˚F (- 6.7 to 48.9˚C).

Thermal Errors: ± 0.02%/˚F typical.

Stability: 1% F.S./yr.

STANDARD ACCESSORIES

(3) “Z” mounting brackets.

(3) 10-32 x 4˝ RH machine screws.

DWYER INSTRUMENTS, INC.

P.O. Box 373 • Michigan City, IN 46361 U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

INSTALLATION

LOCATION: Select a location where temperature of the unit will be

between 20°F and 120°F. Distance from the receiver is limited only by

total loop resistance. See “Electrical Connections.” The tube feeding the

pressure to the instrument can be run practically any length required, but

long lengths will slightly increase response time. Avoid surfaces with

excessive vibration.

POSITION: A vertical position is recommended, as all stocked models

are spanned and zeroed at the factory in this position. They can be used

at other angles, but final spanning and zeroing must be done while transmitter is in the alternative position.

PRESSURE CONNECTIONS: A single pressure connection is provided

at the bottom of the transmitter housing. It has1/4” female NPT and 1/2”

male NPT threads. Attach positive pressure to this port.

MOUNTING: The Series 634ES Transmitter can be mounted three ways:

(A) Supported directly by pipe providing pressure.

(B) Attached to a mounting surface with 10-32 x 1/4” machine screws

(included). The machine screws are installed through the mounting surface into tapped holes on back of unit.

(C) Mounted with “Z” brackets (included). Attach “Z” brackets to tapped

holes on back of unit and fasten to front of mounting surface.

ELECTRICAL CONNECTIONS

CAUTION: DO NOT EXCEED SPECIFIED SUPPLY VOLTAGE RAT-

INGS. PERMANENT DAMAGE NOT COVERED BY WARRANTY WILL

RESULT. THIS UNIT IS NOT DESIGNED FOR AC VOLTAGE OPERATION.

Electrical connections to the Series 634ES Transmitter are made inside

the enclosure. Remove the cover, feed stripped and tinned leads through

the conduit opening and connect to terminal block screws marked + and

-. See Figure A for locations of terminal block, span and zero adjust

potentiometers. See Figure B (Pg. 3) for schematic diagram.

FIG. A

An external power supply delivering 12.3 to 35 VDC with minimum current capability of 40 mA must be used to power the control loop in which

the Series 634ES Transmitter is connected. See Figure B for connection

of the power supply, transmitter and receiver.

The range of appropriate receiver load resistance (RL) for the power supply voltage available is given by the formula and graph in Figure C on Pg.

3.

Shielded 2-wire cable is recommended for control loop wiring, and the

cable shielding may be grounded if desired. Note also that the receiver

may be connected in either the negative or positive side of the loop,

whichever is most convenient.

Should polarity of the transmitter or receiver inadvertently become

reversed, the loop will not function properly, but no damage will be done

to the transmitter.

Page 3

FIG. B

634ES

PRESSURE

TRANSMITTER

RECEIVER

SEE FIG. C

POWER

SUPPLY

12-35 VDC

OPERATING

REGION

MAXIMUM VALUE (1100 )

TOTAL RECEIVER RESISTANCE

Vps-12.3

20mA DC

Series 634ES Transmitters can be used with receivers requiring 1-5 volt

input rather than 4-20 mA. If the receiver requires a 1-5 volt input, insert a

250 ohm, 2 watt resistor in series with the current loop but in parallel with

the receiver input. Referring to Figure B, RLbecomes the 250 ohm resistor and points X and Y are connected to the receiver input, point X being

positive (+) and point Y negative (-) or ground. The resistor should be

connected at the panel end of the transmitter current loop close to the

receiver input to take advantage of the immunity of the current loop to

electrical noise pickup. Most electronic component distributors stock a

249 Ω, 2 watt, ± 1% tolerance metal film resistor which is adequate for

this application.

WIRE LENGTH - The maximum length of wire connecting transmitter

and receiver is a function of wire size and receiver resistance. Wiring

should not contribute more than 10% of receiver resistance to total loop

resistance. For extremely long runs (over 1000 feet) choose receivers

with higher resistances to minimize size and costs of connecting leads.

When wiring length is under 100 feet, lead wire as small as 22 AWG can

be used.

PRESSURE RANGING - Each Series 634ES Transmitter is factory-calibrated to the range given in the model number chart. However, special

calibration is also available. If this is the case, the transmitter will be so

marked. For purposes of clarification in these instructions, range is

defined as that pressure which, applied to the transmitter, produces 20

mA of current in the loop. Zero pressure is always assumed to be 4 mA.

If a transmitter pressure range other than that supplied is required, follow the re-ranging procedure described on Pg. 4.

FIG. C

Page 4

PRESSURE RE-RANGING PROCEDURE

1. With the transmitter correctly connected to the companion receiver, an

accurate milliameter with a full scale reading of approximately 30 mA

should be inserted in series with the current loop. A controllable pressure

source capable of achieving the desired range should be connected to

the pressure port of the transmitter and teed into an accurate reference

pressure gauge or manometer. The instrument must be ranged in the

same position in which it will be used. Vertical mounting is recommended.

2. Apply electrical power to the system and allow it to stabilize for 10

minutes.

MULTIPLE RECEIVER INSTALLATION

An advantage of the standard 4-20 mA output signal provided by the

Series 634ES Pressure Transmitter is that any number of receivers can

be connected in series in the current loop. Thus, an A-701 Digital

Readout Accessory, an analog panel meter, a chart recorder, process

controlling equipment, or any combination of these devices can be operated simultaneously. It is only necessary that these devices all be

equipped with a standard 4-20 mA input and that proper polarity of the

input connections be observed when inserting the device in the current

loop. If any of the receiving devices displays a negative or downscale

reading, this indicates that the signal input leads are reversed.

3. With no pressure applied to the transmitter, adjust “zero” control so

that loop current is 4 mA.

4. Apply full range pressure and adjust loop current to 20 mA using

“span” control.

5. Relieve pressure and allow transmitter to stabilize for two minutes.

6. Zero and span adjustments may be interactive, so repeat steps 3

through 5 until zero and full range pressures consistently produce loop

currents of 4 and 20 mA respectively.

7. Remove the milliameter from the current loop and proceed with final

installation of the transmitter and receiver.

MAINTENANCE

Upon final installation of the Series 634ES Transmitter and the companion

receiver, including the A-701 Digital Readout, no routine maintenance is

required. A periodic check of system calibration is recommended. The

Series 634ES Pressure Transmitter is not field serviceable and should

be returned, freight prepaid, to the factory if repair is required. The A-701

Digital Readout should be returned to the manufacturer if service is

needed. Refer to the A-701 instruction sheet.

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 9/09 FR# 00-440577-04 Rev. 4

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. Box 373 • Michigan City, IN 46361 U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...