Page 1

Bulletin E-43-WL

[

]

Series 616WL Differential Pressure Transmitter

Specifications - Installation and Operating Instructions

The Dwyer Series 616WL Differential Pressure Transmitter senses the

pressure of air and non-combustible, compatible gases and sends a standard 4-20 mA output signal.

All models, including those featuring the 3 digit LCD digital read-out, are

factory calibrated to specific ranges as listed in the chart below.

Positive, negative and differential pressures can be measured within a full

span accuracy of ±0.50%. This weatherproof unit is enclosed in a polycarbonate case, designed to meet (IP66/NEMA 4X).

The Span and Zero controls are for use when checking calibration. They

are not intended for re-ranging to a significantly different span.

INSTALLATION

1. Location: Select a clean, dry mounting location free from excess

vibration where the temperature will remain between 20 and 120˚F (-6.7

and 49˚C). Distance from the receiver is limited only by total loop resistance. See Electrical Connections below. The tubing supplying pressure to

the instrument can be practically any length required, but long lengths will

increase response time slightly.

SERIES 616WL TRANSMITTER MODELS & RANGES

MODEL

NUMBER

616WL-2

616WL-4

616WL-12

616WL-14

616WL-22

616WL-32

616WL-25

616WL-35

616WL-2-LCD

616WL-4-LCD

616WL-12-LCD

616WL-14-LCD

616WL-22-LCD

616WL-32-LCD

616WL-25-LCD

616WL-35-LCD

PRESSURE

RANGE

0-0.25 in. w.c.

0-1 in. w.c.

0.25-0-0.25 in. w.c.

1-0-1 in. w.c.

0-60 Pa

60-0-60 Pa

0-250 Pa

250-0-250 Pa

0-0.25 in. w.c.

0-1 in. w.c.

0.25-0-0.25 in. w.c.

1-0-1 in. w.c.

0-60 Pa

60-0-60 Pa

0-250 Pa

250-0-250 Pa

MAXIMUM

PRESSURE

2 psig

4 psig

2 psig

4 psig

13.8 kPa

13.8 kPa

27.6 kPa

27.6 kPa

2 psig

4 psig

2 psig

4 psig

13.8 kPa

13.8 kPa

27.6 kPa

27.6 kPa

DIGITAL

DISPLAY

-

-

-

-

-

-

-

0-.250

0-1.00

-.250-0-.250

1.00-0-1.00

0-60.0

-60.0-0-60.0

0-250

250-0-250

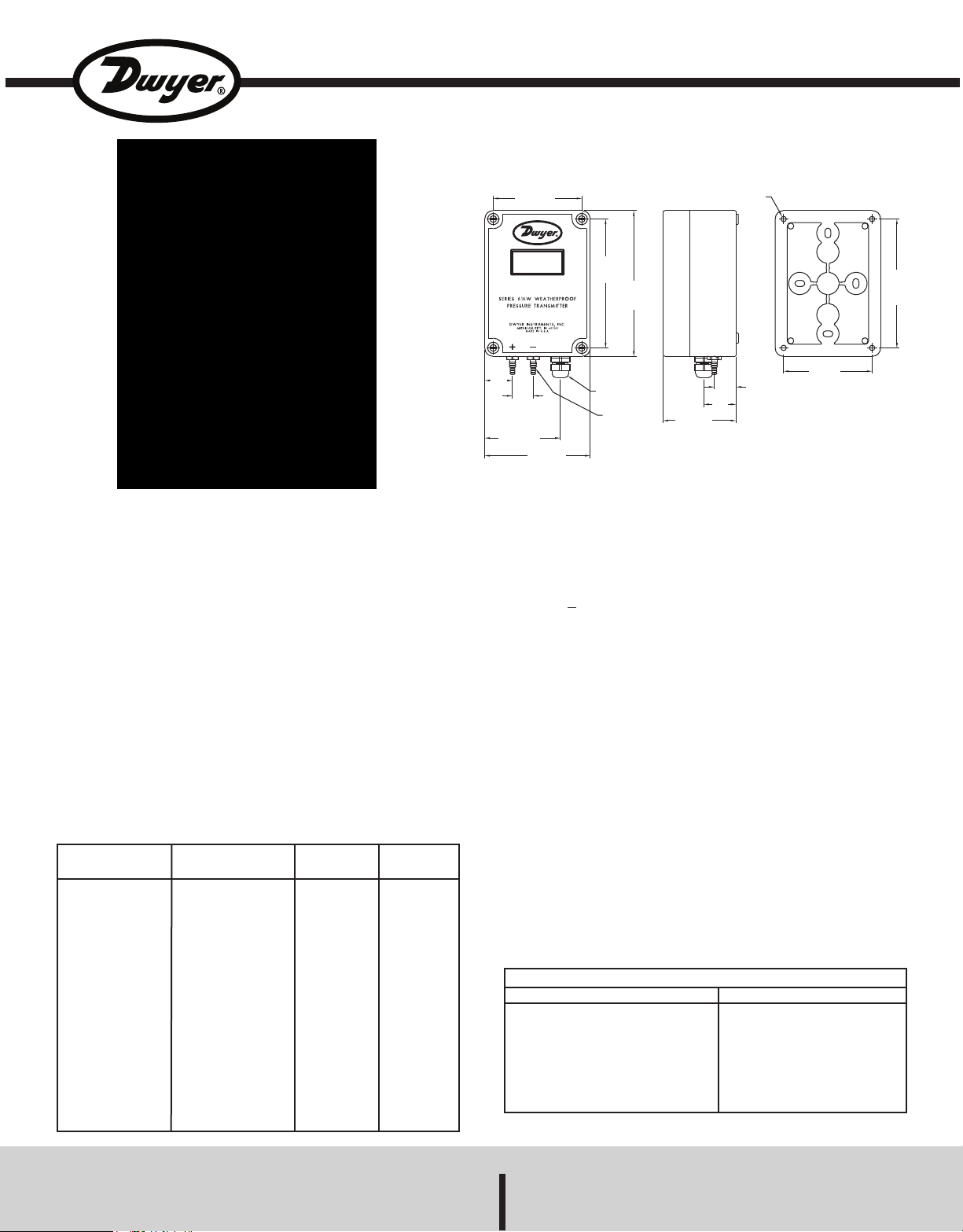

63/61

[25.00]

3/16 [4.76]

MOUNTING HOLES

TYP 4 PLCS

1-1/8

[28.58]

2-37/64

[65.48]

49/64

[19.45]

3-1/8

[79.38]

[79.38]

47/64

[18.65]

2-21/32

[67.47]

3-1/8

3-45/64

94.06

4-17/32

[115.09]

5-1/8

[130.18]

FITTING TO

ACCOMODATE

CABLE DIAMETERS

OF .100 - .260

1/8 AND 3/16

[3.18 AND 4.76]

I.D. TUBING

Fig. A

SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult factory.

Accuracy: ±0.50% F.S., display accuracy ±0.5%.

Stability: +

Temperature Limits: 0 to 140°F (-17.8 to 60°C).

Compensated Temperature Limits: 32 to 120°F (0 to 48.9°C).

Pressure Limits: See chart.

Thermal Effect: ±0.02% F.S./°F (0.036% F.S./°C) from 77°F

(25°C).

Power Requirements: 12-30 VDC (2-wire).

Output Signal: 4 to 20 mA.

Zero and Span Adjustments: Digital, Push Button Adj.

Loop Resistance: DC; 0-900 ohms maximum.

Current Consumption: DC; 38 mA maximum.

Electrical Connections: Screw-type terminal block.

Process Connections: Barbed, dual size to fit 1/8˝ and 3/16˝

(3.12 and 4.76 mm) I.D. rubber or vinyl tubing.

Enclosure Rating: NEMA 4X (IP66).

Mounting Orientation: Vertical, consult factory for other position

orientations.

Weight: Without LCD 17 oz (482 g); with LCD 18 oz (510 g).

Agency Approvals: CE.

CE The following standards were used for CE approval:

Specifications

CENELEC EN 61000-4-2: 2001

CENELEC EN 61000-4-3: 2002

CENELEC EN 61000-4-4: 1995

CENELEC EN 61000-4-5: 2001

CENELEC EN 61000-4-6: 2003

CENELEC EN 55011: 1998

CENELEC EN 61326: 2002

1% F.S./yr.

Test Result

PASS CRITERION A

PASS CRITERION B

PASS CRITERION B

PASS CRITERION A

PASS CRITERION A

PASS CRITERION B

PASS

4-17/32

[115.09]

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

2. Position: A vertical position, with the pressure connection pointing

+

+

ZERO ADJUST

SPAN ADJUST

ZERO

SPAN

down, is recommended. That is the position in which all standard models

are spanned and zeroed at the factory. They can be used at other angles,

but final spanning and zeroing must be done while transmitter is in that

alternate position.

3. Pressure Connections: Two integral barbed tubing connections are

provided. They are dual-sized to fit both 1/8˝ and 3/16˝ (3.2 and 4.8 mm)

I.D. tubing. Be sure the pressure rating of the tubing exceeds that of the

operating range. On ranges over 20 psi, we recommend use of a suitable

hose clamp to assure the integrity of the connection.

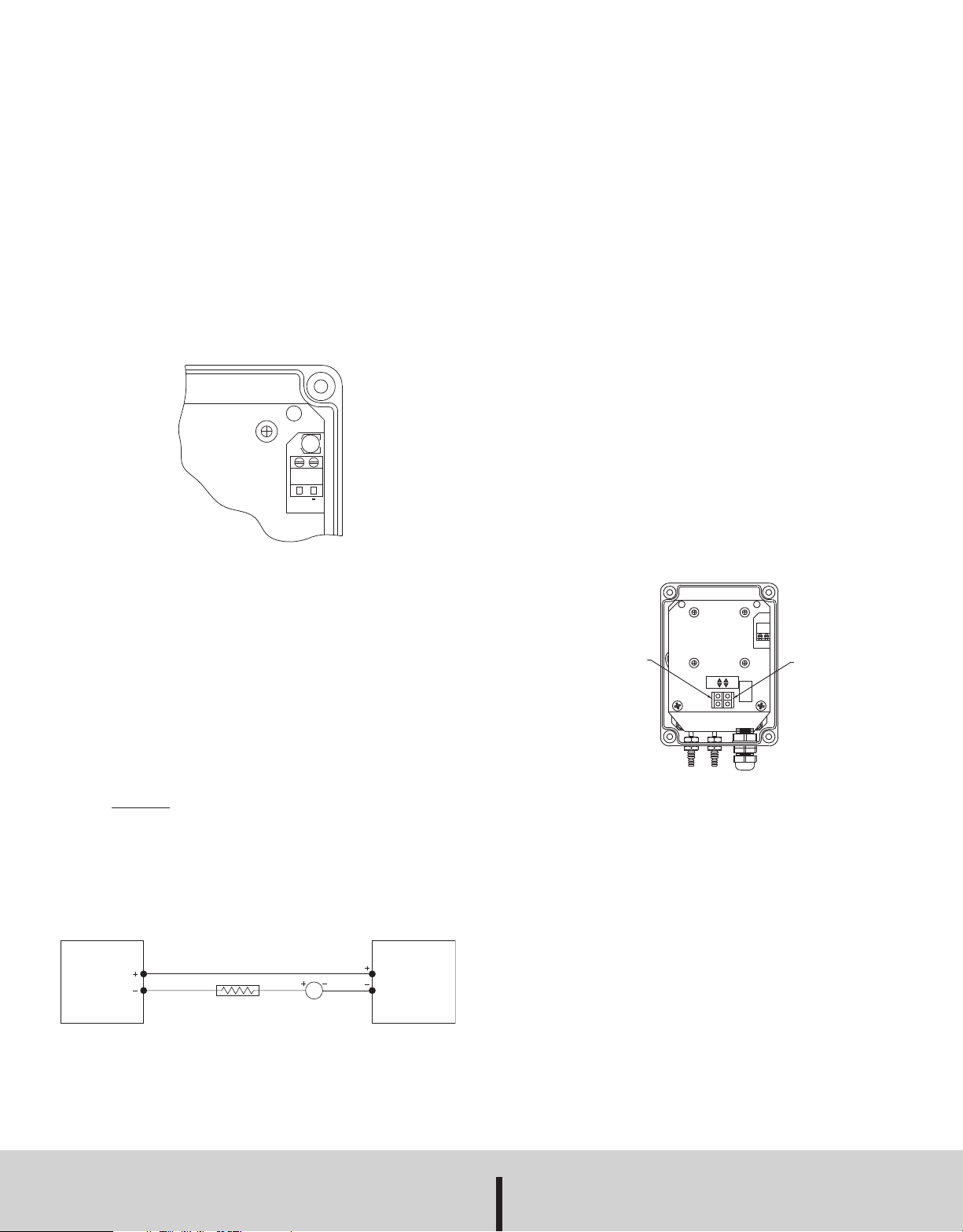

ELECTRICAL CONNECTIONS

CAUTION: Do not exceed specified supply voltage ratings.

Permanent damage not covered by warranty will result. This unit is

not designed for 120 or 240 volts AC line operation.

Electrical connections are made to the terminal block located on the inside

of the transmitter. Terminals are marked +, –. See Fig. B.

CONN 1

Fig. B

Calibration Check - Each Series 616WL Transmitter is factory calibrated

in the vertical position to the range given in the model chart. To check calibration and adjust if necessary, the following procedure should be used.

For purposes of clarification in these instructions, range is defined as that

pressure which, applied to the transmitter, produces 20 milliamps of current in the loop. Zero pressure is always assumed to be 4 milliamps.

1. With the transmitter connected to the companion receiver, insert an

accurate milliameter in series with the current loop. Full scale range

should be approximately 30 mA.

2. Connect a controllable pressure source to one leg of a tee with the other

two legs connected to the high pressure port of the

transmitter and the third leg to an accurate test gage or manometer, in

an appropriate range. The low pressure port should be vented to atmosphere. Calibration must be performed with the unit in the same position

in which it will be mounted.

3. Apply electrical power to the unit and allow it to stabilize for 15 minutes.

4. With no pressure applied to the transmitter, adjust ZERO control so that

loop current is 4 mA. Zero center units, ie. 1-0-1 in w.c. units, will output 12 mA with no pressure applied. To calibrate zero center units an

accurate pressure source must be used to apply the minimum pressure

then adjust zero control to 4 mA. Use the increase/decrease

buttons located on left side. See Fig. D.

5. Apply full range pressure and adjust loop current to 20 mA using SPAN

control. Use the increase/decrease buttons located on the right side.

See Fig. D.

6. Relieve pressure and allow transmitter to stabilize for 2 minutes.

7. Zero and span controls are slightly interactive, so repeat steps 4 through

6 until zero and full range pressures consistently produce currents of 4

and 20 mA respectively.

8. Remove the milliameter from the current loop and proceed with final

installation of the transmitter and receiver.

Wire Length - The maximum length of wire connecting transmitter and

receiver is a function of wire size and receiver resistance. Wiring should not

contribute more than 10% of the receiver resistance to total loop resistance. For extremely long runs (over 1000 feet), choose receivers with higher resistance to minimize size and cost of connecting leads. Where wiring

length is under 100 feet, hook-up wire as small as 22 AWG can be used.

2-Wire Operation - An external power supply delivering 12-30 VDC with

minimum current capability of 40 mA DC (per transmitter) must be used to

power the control loop. See Fig. C for connection of the power supply,

transmitter and receiver. The range of appropriate receiver load resistance

(RL) for the DC power supply voltage available is expressed by the formula.

RLMax = Vps - 12V

20mA DC

Shielded two wire cable is recommended for control loop wiring. If grounding is required, use the negative side of the control loop after the receiver.

Otherwise, in the 2-wire operation it is not necessary to observe polarity of

control loop connections.

2-Wire Connections

616W

LOW PRESSURE

TRANSMITTER

1

2

RECEIVER

mA

POWER

SUPPLY

12 -35 VDC

Fig. C

Fig. D

MAINTENANCE

Upon final installation of the Series 616WL Differential Pressure Transmitter,

no routine maintenance is required. A periodic check of the system calibration is recommended following the procedures explained under

Calibration Check. The Series 616WL Transmitter is not field serviceable

and should be returned, freight prepaid, to the factory if repair is required.

Please enclose a description of the problems encountered plus any available application information. Contact customer service to receive a return

goods authorization number before shipping.

©Copyright 2008 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

Printed in U.S.A. 10/08 FR# 01-440886-02 Rev 2

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...