Page 1

Series 608 Differential Pressure Transmitter

Specifications - Installation and Operating Instructions

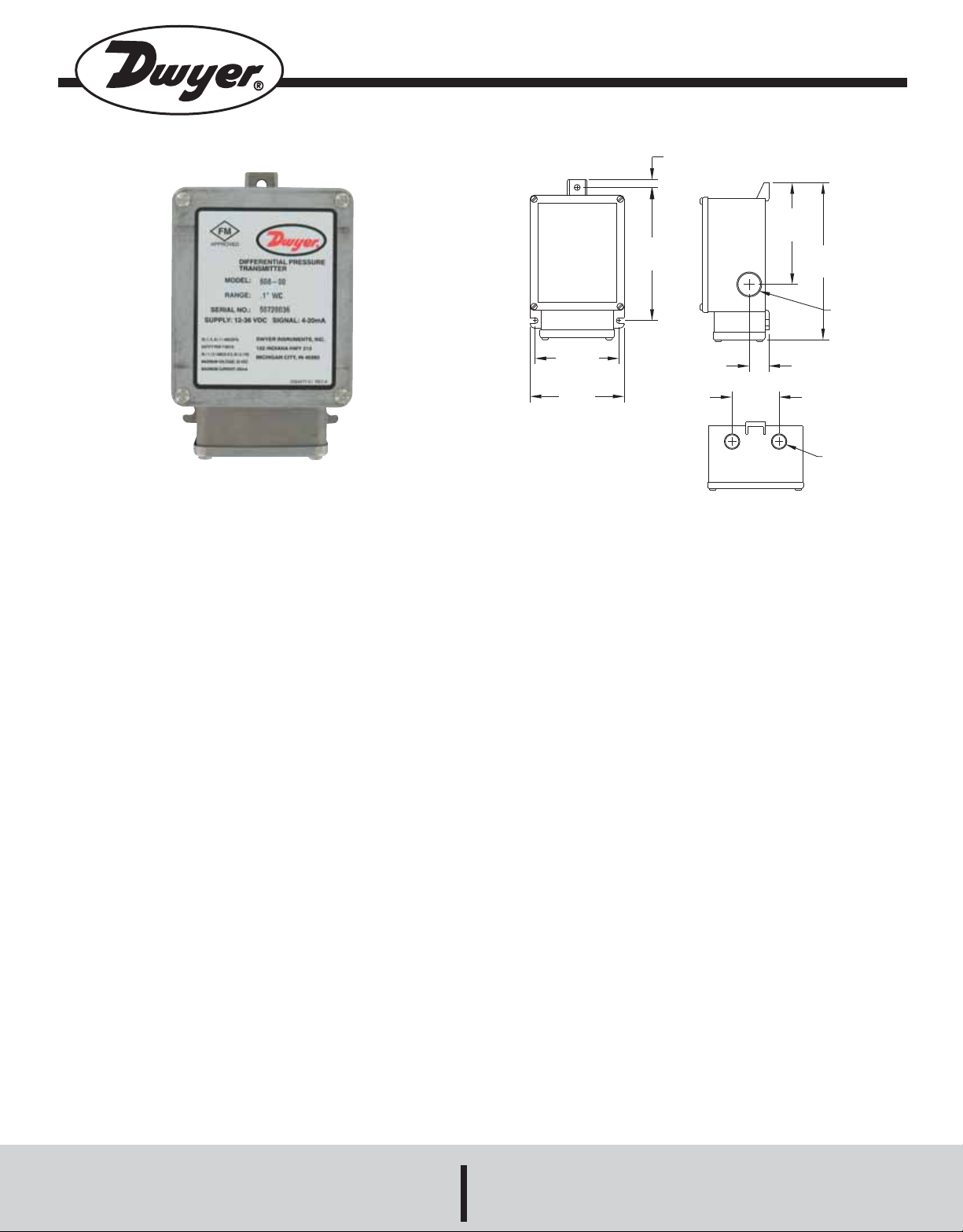

1/4

[6.35]

3-1/4

[82.55]

4-1/2

[107.95]

Bulletin E-60

5-1/32

[127.79]

1/2 NPT

TYP 2 PLACES

The Series 608 Differential Pressure Transmitter converts

positive, negative (vacuum), or differential pressures of clean, dry

air or other non-conductive, non-corrosive gases into a standard

two wire, 4-20 mA output signal. Several factory calibrated models are available with ranges from 0-0.1˝ (0-2.5 mm) w.c. up to 025˝ (0-634.4 mm) w.c. All models employ a variable capacitance

transducer with a micro-machined, ultra thin silicon diaphragm

enabling precision measurement and control of very low differential pressures while withstanding a high static working pressure of

100 psig (6.89 bar). The Series 608 is FM approved intrinsically

safe for use in the specified hazardous locations when used with

an approved intrinsic safety barrier. It also features a NEMA 4X

enclosure that allows for indoor and outdoor installations. This

rugged housing design makes this transmitter ideal for use in

industrial and process plant environments.

INSTALLATION

1. Location: Select a clean location free of excess vibration where

the temperature of the unit will be between 0°F (-18°C) and 160°F

(71°C). Distance from the receiver is limited only by total loop

resistance. See “Electrical Connections”. The tubing supplying

pressure to the transmitter can be run practically any distance.

Long tubing lengths will not affect accuracy but response time will

be increased slightly.

2-11/16

[68.26]

3

[76.20]

5/8

[15.88]

1-1/2

[38.10]

1/4 NPT

TYP 2 PLACES

SPECIFICA T IONS

Service: Clean/dry air and compatible gases.

Wetted Materials: Consult factory.

Accuracy: ±0.5% or ±0.25% full scale.

Stability: ±0.5% F.S./year.

Pressure Limits: 100 psig (6.89 bar); 15 psid (1.03 bar).

Temperature Limits: -20 to 185°F (-28 to 85°C).

Compensated Temperature Range: 0 to 160°F (-18 to 71°C).

Thermal Effect: 0.5% Accuracy: ±0.02% F.S./°F;

0.25% Accuracy: ±0.01% F.S./°F.

Power Requirements: 12 to 36 VDC (2-wire).

Output Signal: 4-20 mA DC.

Zero and Span Adustments: Potentiometers for zero and

span.

Response Time: 250 ms.

Loop Resistance: DC: 0-1045 ohms maximum.

Current Consumption: 4-20 mA.

Electrical Connections: Screw terminal: Two 1/2˝ female NPT

conduit.

Process Connections: Two 1/4˝ female NPT.

Enclosure Rating: NEMA 4X (IP65).

Mounting Orientation: Not position sensitive.

Weight: 2 lb (0.9 kg).

Agency Approvals: FM approved intrinsically safe for use in

Class I, Div. 1, Groups A, B, C, D; Class II, Div. 1, Groups E, F, G;

Class III, Div. 1 when wired with approved intrinsically safe barrier.

Entity parameters: V

max

= 36 VDC; I

max

= 250 mA; CI=12 nF; LI=0

mH.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

Bulletin E-60

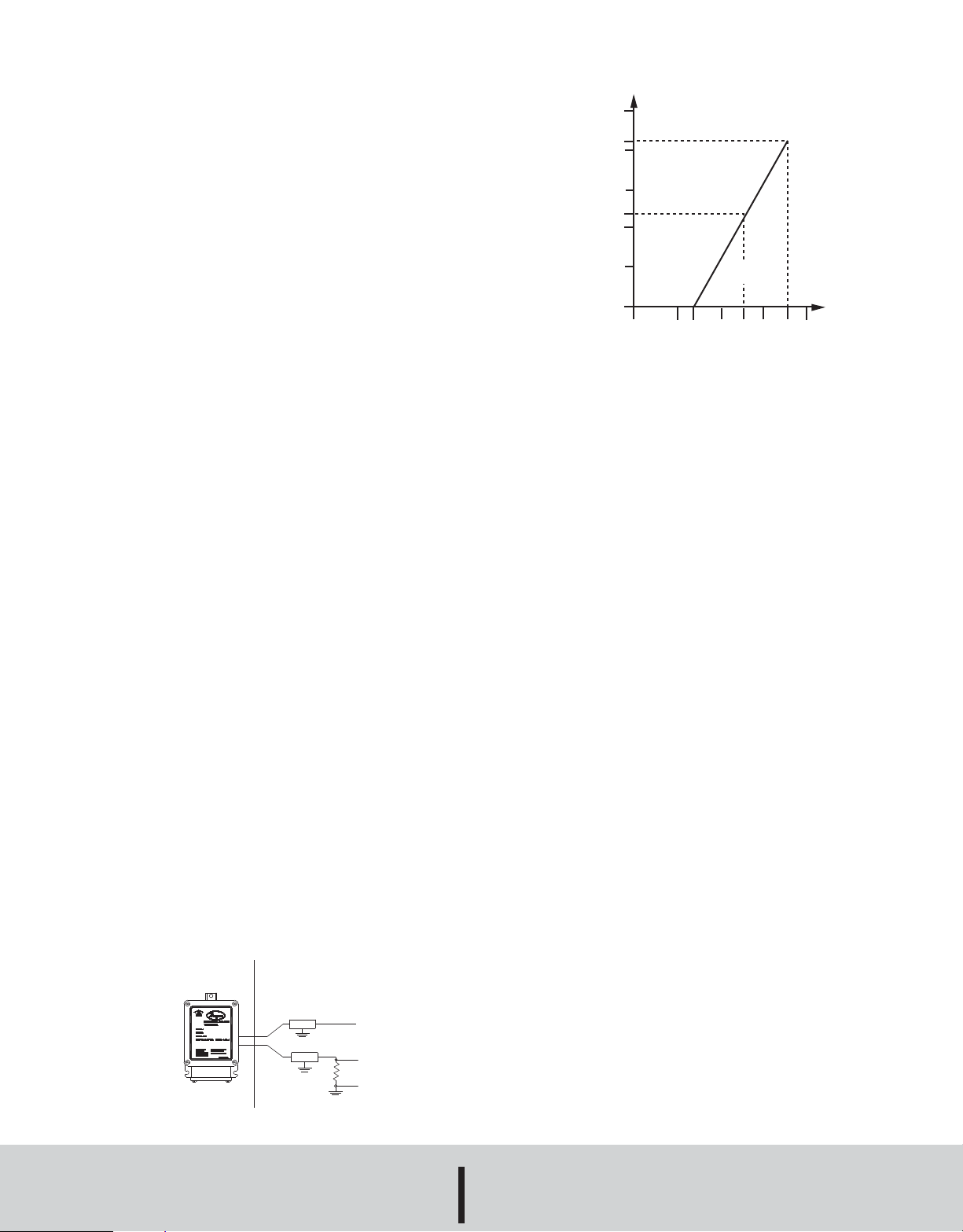

1250

1045

1000

750

545

500

250

0

0

10 12 20

24

30 36

40

OPERATING

REGION

LOOP RESISTANCE (Ω)

LOOP SUPPLY VOLTAGE (VDC)

2. Position: The Series 608 Transmitter is not position sensitive.

However, it is recommended that you avoid mounting with pressure connections pointing up because of the chance of condensed moisture entering the interior. Moisture can also be avoided by routing tubing with a low point just ahead of the transmitter.

3. Mounting: Attach to mounting surface with two #8 or #10

screws in the mounting slots provided.

4. Pressure Connections: The 608 series transmitter is shipped

with the “HIGH” and “LOW” pressure ports plugged to avoid

debris entering the unit. The plugs should be left in place until the

tubing and fittings are connected. For gage pressures, connect

positive (above atmospheric) pressure to the port marked “HIGH”

and vent the “LOW” port. To monitor vacuum, connect negative

(vacuum) pressure to port marked “LOW” and vent the “HIGH”

port. For differential pressure, connect the higher one to the

“HIGH” port and the lower one to the “LOW” port.

ELECTRICAL CONNECTION

Use in hazardous location: The Series 608 transmitter is FM

approved intrinsically safe for use in hazardous locations. See

specifications for details. Intrinsically safe approved devices require

the use of an approved intrinsic safety barrier when applied in hazardous locations. The barrier limits the amount of electrical or thermal energy in the instrument loop, to the level which would not

cause ignition in the hazardous location for which it is rated. The

barrier must be installed outside of the hazardous area and properly wired to the transmitter according to Figure B.

Load Limitations 4-20 mA Output Only

min

V

= 12V + (.022A x RL)

RL= RS+ R

RL= Loop Resistance (ohms)

RS= Sense Resistance (ohms)

RW= Wire Resistance (ohms)

W

Fig. C

CALIBRA TION

Each Series 608 Transmitter is factory calibrated to the range listed in the model number chart. Range is defined as that pressure

which when applied to the transmitter will produce a 20 milliamp

current in the loop. Zero pressure will produce 4 milliamps. If fine

adjustment of calibration is required, use the following procedure:

CAUTION: Do not exceed the specified supply voltage rating.

Permanent damage, not covered by warranty, may result. This unit

is not designed for AC voltage operation.

1. With the transmitter connected to its companion receiver, insert

a milliammeter in series with the current loop. A controllable pressure source should be tied to the high pressure port of the transmitter and to an accurate pressure gage or manometer.

The terminal connections can be accessed by unscrewing the four

cover screws and removing the terminal block access cover. Bring

cable wires in through one of the 1/2˝ female NPT conduit con-

2. Apply electrical power to the system and allow 15 seconds for

components to stabilize.

nections, plugging the unused entry. Attach the cable wires to the

appropriate terminals. If polarity is inadvertently reversed, the loop

will not function properly but no damage will be done to the trans-

3. With no pressure applied to the transmitter remove cover and

adjust “zero” control so loop current is at 4 mA.

mitter because of internal circuit protection. The power required to

generate the 4-20 mA output signal depends on the loop resistance of the circuit and is proportional to the resistance according

4. Apply full span pressure and adjust loop current to 20 mA using

“span” control.

to the graph and formula in Figure C. The maximum length that

can be used in the current loop is a function of wire size and

receiver resistance. A shielded two conductor cable is recom-

5. Remove the milliammeter from the circuit, replace cover, and

place system in service.

mended for control loop wiring. Make sure total loop resistance is

within the operating region as shown in Figure C.

HAZARDOUS AREA

SAFE AREA

ENTITY APPROVED

BARRIERS

SUPPLY

MAINTENANCE

After final installation of the Series 608 Differential Pressure

Transmitter, no routine maintenance is required. A periodic check

of system calibration is suggested. These devices are not field

repairable and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure to

RETURN

include a brief description of the problem plus any relevant application notes. Contact customer service to receive a return goods

authorization number before shipping.

Fig. B

©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 7/09 FR# R1-443350-00 Rev. 1

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...