Page 1

Series 607 Differential Pressure Transmitter

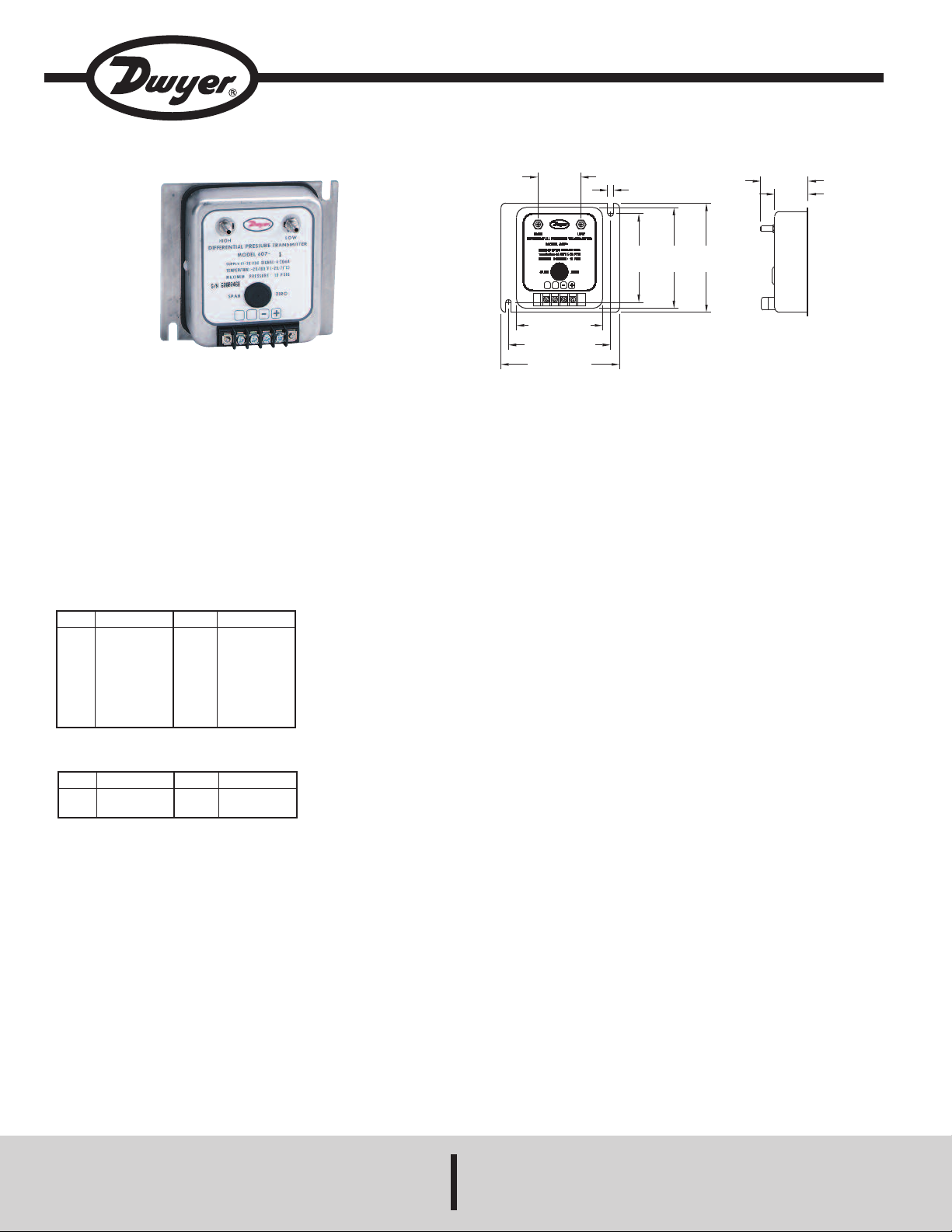

3-5/16 [84.12]

3-59/64 [99.62]

4-9/16 [115.9]

1-21/32

[

42.06]

7/32 [5.556]

3

-13/32

[

86.52]

3

-7/8

[

98.43]

4

-3/8

[

111.1]

®

1

-53/64 [46.53]

1-19/64 [32.94]

Specifications - Installation and Operating Instructions

ulletin E-76

B

The Dwyer Series 607 Differential Pressure Transmitter converts positive,

negative (vacuum) or differential pressures of clean, dry air or other non-

onductive, non-corrosive gases into a standard two wire, 4-20 mA output signal.

c

everal factory calibrated models are available with ranges from 0-.10˝ w.c. to 0-

S

5˝ w.c. All models employ a variable capacitance transducer with a micro-

2

machined, ultra thin silicon diaphragm enabling precision measurement and

control of very low pressures. Because no epoxies or other organics are used to

seal the sensor, performance is exceptionally stable and drift free. It is also highly

resistant to overpressure, shock and vibration. See specifications for complete

details.

Series 607 Transmitter Models & Ranges

Accuracy ±0.5% of Full Scale*

Range in w.c.

Model

0-.10

607-0

0-.25

607-1

0-.50

607-2

0-1.0

607-3

0-2.0

607-4

0-5.0

607-7

0-10

607-8

Accuracy ±0.25% of Full Scale*

Range in w.c.

Model

0-.10

607-01

0-.25

607-11

*Includes Linearity, Hysteresis, and Repeatability

Model

607-9

607-0B

607-1B

607-2B

607-3B

607-4B

607-7B

Model

607-21

607-71

Range in w.c.

0-25

.10-0-.10

.25-0-.25

.50-0-.50

1.0-0-1.0

2.0-0-2.0

5.0-0-5.0

Range in w.c.

0-.50

0-5.0

PECIFICATIONS

S

GENERAL

Maximum Pressure: 10 psig (0.69 bar).

Media Compatibility: Air and non-conductive, non-corrosive gases.

LECTRICAL

E

ower Supply: 12-36 VDC, unregulated.

P

utput Signal: 4-20 mA DC, two wire.

O

Loop Resistance: 0-1045 ohms Vmin. = 12V + [(.022A)(RL)].

Warm-up Time: 15 seconds.

PERFORMANCE AT 70° F.

Output at zero: 4 mA.

Output at full span: 20 mA.

Stability: ±0.5% of full span/year.

Response Time: 250 msec.

TEMPERATURE LIMITS

Operating: -20 to 160°F (-29 to 71°C), 10-95% RH, non-condensing.

Compensated: 35 to 135°F (2 to 57°C).

Storage: -40 to 180°F (-40 to 82°F).

Thermal Effects: ±0.015%F.S./°F (zero and span).

MECHANICAL

Housing: 300 Series stainless steel (NEMA 2).

Pressure Connections: 4˝ barbed stainless steel for 3/16˝ ID tubing.

Weight: 1.04 lb (472 g).

Span and Zero: Factory set to specified range. Externally accessible, non-

interactive, ±10% F.S. adjustment.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, IN 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

NSTALLATION

NOTE: RECEIVER MAY BE IN

SERIES WITH + or LEG OF CONTROL LOOP

POWER

SUPPLY

12-36 VDC

SEE FIG. C

RECEIVER (R

L

)

GROUND

OPTIONAL

SERIES 607

PRESSURE

TRANSMITTER

+

-

+

-

1100

1000

900

800

700

600

5

00

4

00

3

00

2

00

1

00

0

LOOP RESISTANCE (Ω)

O

PERATING RANGE

V

MIN

= 12V + (.022A x R

L

)

M

AXIMUM VALUE (1090)

0 5 10 12 20 25 30 36 40

POWER SUPPLY VOLTAGE - VDC

I

. Location: Select a clean, dry location free of excess vibration where the

1

emperature of the unit with be between -20 and 160°F. Distance from the

t

eceiver is limited only by total loop resistance. See “ Electrical Connections”. The

r

tubing supplying pressure to the transmitter can be run practically any distance.

Long tubing lengths will not affect accuracy but response time will be increased

slightly.

. Position: The Series 607 Transmitter is not position sensitive. However, it is

2

ecommended that you avoid mounting with pressure connections pointing up

r

ecause of the chance of condensed moisture entering the interior. Moisture can

b

also be avoided by routing tubing with a low point just ahead of the transmitter.

3. Mounting: Attach to mounting surface with two #8 or #10 screws in the

ounting slots provided.

m

. Pressure connections: The Series 607 Transmitter is shipped with a short

4

length of tubing installed between the ports to keep the interior clean. Remove it

and discard after unit is mounted. Connect positive (above atmospheric) pressure

to port marked “HIGH and vent the “LOW” port. Connect negative (vacuum)

pressure to port marked “LOW” and vent the “HIGH” port. For differential

ressures, connect the higher one to the “HIGH” port and the lower one to the

p

LOW” port.

“

ELECTRICAL CONNECTION

Caution: Do not exceed the specified supply voltage rating. Permanent damage,

not covered by warranty, may result. This unit is not designed for AC voltage

operation.

lectrical connections to the Series 607 Transmitter are made to the two screws

E

n the terminal strip labeled + and -. If polarity is inadvertently reversed, the loop

o

will not function properly but no damage will be done to the transmitter because

of internal circuit protection. An external power supply delivering 12 to 36 VDC

must be used to power the control loop in which the transmitter is connected.

Refer to Figure B for connection of the power supply, transmitter and receiver.

The power required to generate the 4-20 mA output signal depends on the loop

resistance of the circuit and is proportional to the resistance according to the

graph and formula in Figure C. The maximum length that can be used in the

current loop is a function of wire size and receiver resistance. A shielded two

conductor cable is recommended for control loop wiring. Make sure the total loop

resistance is within the operating region as shown in Figure C.

Figure C

ALIBRATION

C

Each Series 607 Transmitter is factory calibrated to the range listed in the model

number chart. Range is defined as that pressure which when applied to the

ransmitter will produce a 20 milliamp current in the loop. Zero pressure will

t

roduce 4 milliamps. If fine adjustment of calibration is required, used the

p

ollowing procedure:

f

1). With the transmitter connected to its’ companion receiver, insert a

milliammeter in series with the current loop. A controllable pressure source should

be teed to the high pressure port of the transmitter and to an accurate pressure

gage or manometer.

2). Apply electrical power to the system and allow 15 seconds form components

to stabilize.

3). With no pressure applied to the transmitter remove blowout disc and adjust

“zero” control so loop current is 4 mA.

4). Apply full span pressure and adjust loop current to 20 mA using “span” control.

5). Remove the milliammeter from the circuit, replace blowout disc, and place

system in service.

MAINTENANCE/REPAIR

After final installation of the Series 607 Differential Pressure Transmitter, no

routine maintenance is required. A periodic check of system calibration is

recommended. These devices are not field repairable and should be returned to

the factory if recalibration or other service is required. After first obtaining a

Figure B

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 5/13 FR# 01-440685-00 Rev. 1

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, IN 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Returned Goods Authorization (RGA) number, send the material, freight prepaid,

to the following address. Please include a clear description of the problem plus

any application information available.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City, IN 46360.

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...