Page 1

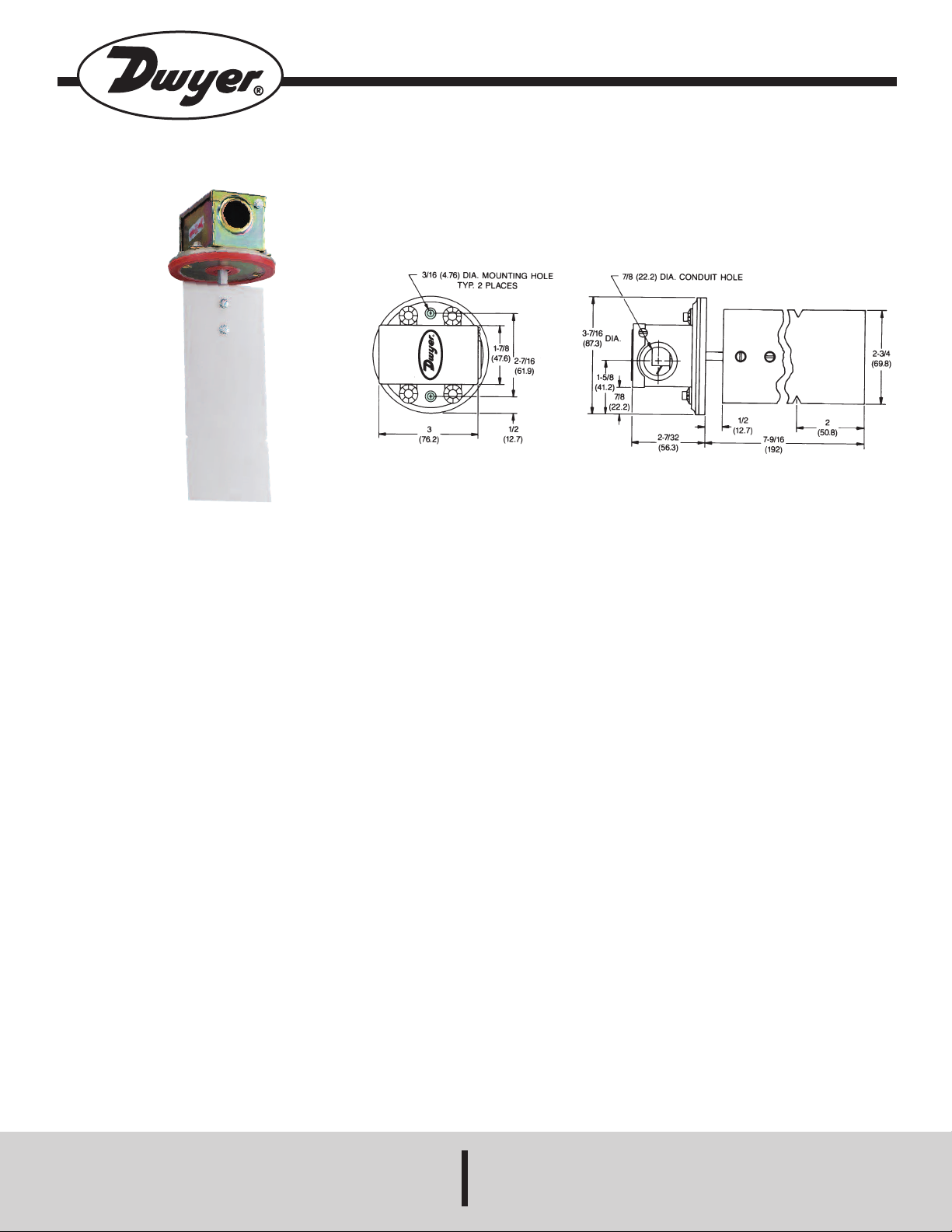

Model 530 Air Flow Switch

Specifications - Installation and Operating Instructions

Bulletin E-65

The Model 530 Air Flow Switch provides excellent sensitivity and

reliability at a very reasonable price. Quality features include rugged

die cast zinc body, stainless steel vane, silicone rubber gasket and

SPDT snap switch. Unit is easily field adjustable from 400-1600 FPM.

Mounting is fast and simple, requiring only two screws. Vane fits 6 in.

or larger ducts. UL approved. To order, specify Dwyer Instruments, Inc.

Model 530 Air Flow Switch.

CAUTION: For use only with air or non-combustible, non-corrosive

gases. Unit is not sealed against dust.

SPECIFICATIONS

Service: Air and non-combustible gas flow.

Wetted Materials: Contact factory.

Vane: SS.

Temperature Limit: 180°F (82°C).

Switch Type: SPDT.

Electrical Rating: 125 VAC - 9.8 amp full load 58.8 amp locked rotor.

250 VAC - 4.9 amp full load 29.4 amp locked rotor. Pilot Rating: 470 VA

at 125, 250 VAC. Resistive: 15 amp at 125, 250, or 480 VAC.

Electrical Connections: Screw type terminal.

Conduit Connection: 7/8˝ conduit hole.

Mounting Orientation: Horizontal duct flow

Set Point Adjustment: Screw type.

Weight: 1 lb, 1 oz (481.94 g)

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Page 2

CAUTION: Vane edges are sharp. Use care when handling.

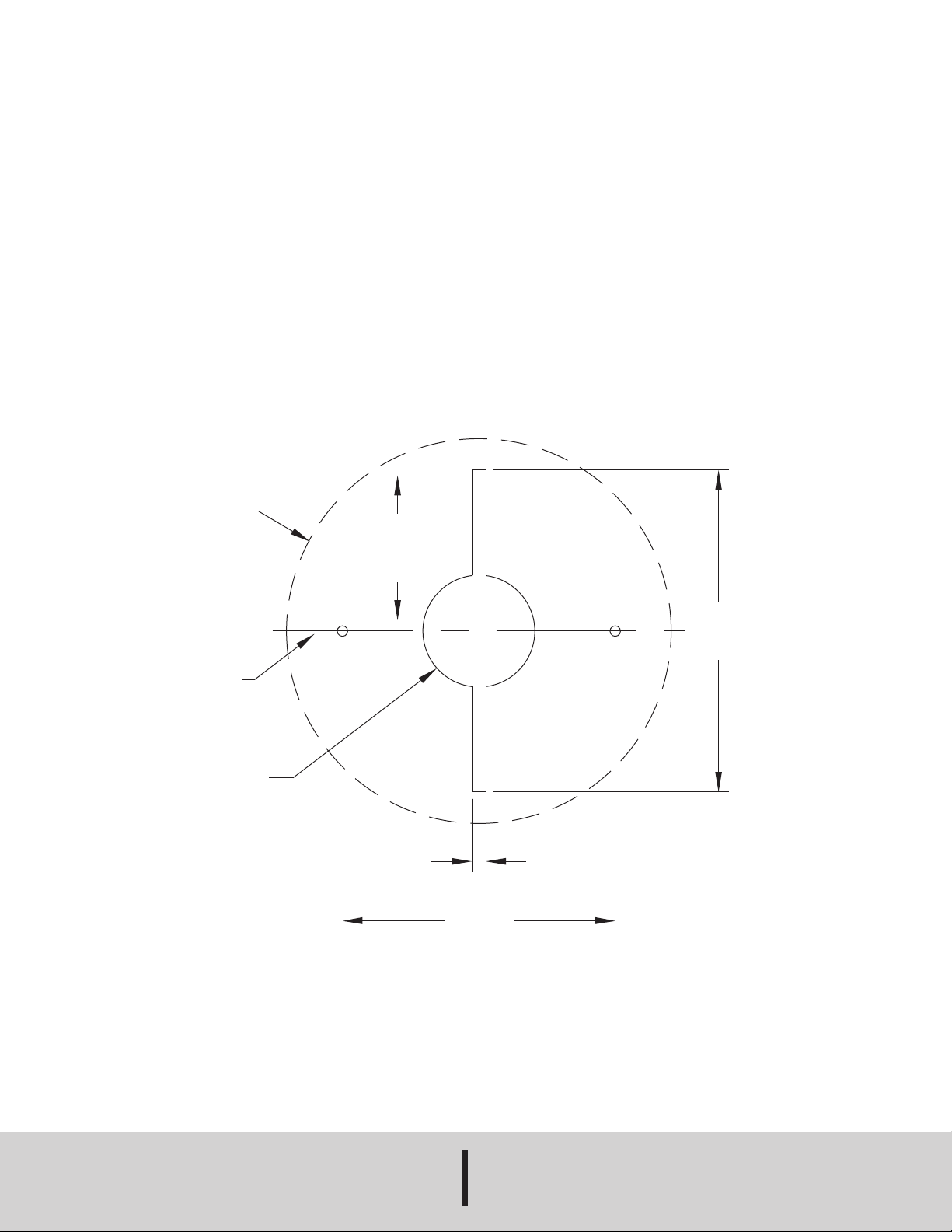

FLOW SWITCH

ø3-7/16 (87.31)

ø3/32 (2.38)

TYP 2 PLACES

ø1 (25.40)

2-7/16

(61.91)

1/8

(3.18)

TYP

2-7/8

(73.03)

AIR

FLOW

INSTALLATION

1. Select a location in a horizontal duct at least 10 duct diameters from

fans and 7 diameters from elbows, size changes, etc. which can cause

turbulence. Also, avoid areas with excess vibration or where the

temperature limits might be exceeded. Switch must be mounted on top

of a horizontal duct.

4. To make electrical connections, loosen the retaining screw and remove

the conduit enclosure cover. The SPDT snap switch has screw terminals

marked common, normally open and normally closed. A ground screw is

also provided. On increasing flow the normally open contacts will close

and the normally closed contacts will open as the set point is passed.

5. To adjust set point, turn the hex screw located near the ground screw.

Rotate clockwise to increase setting or counter-clockwise to decrease.

2. Use vane as received for 8″ (203 mm) or larger ducts. Trim at notch

for 6″ (152 mm) ducts.

3. Cut a mounting hole and slot for the vane and drill two 3.32” (2.38

mm) screw holes as shown in the full size drawing on the reverse side.

Insert switch through slot and rotate 90° so arrow on switch enclosure

points in direction of air flow. Attach switch to duct with sheet metal

screws provided.

Full Size Mounting Template

6. After all electrical connections and adjustments are complete, replace

conduit enclosure cover.

MAINTENANCE

The only adjustment is that of the set point. Care should be taken to keep

switch dry and free of dust, dirt and oil. No lubrication or routine

maintenance is necessary in normal service.

©Copyright 2014 Dwyer Instruments, Inc. Printed in U.S.A. 3/14 FR# 2C-440532-00 Rev.4

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...