Page 1

Bulletin A-28

11/16

[17.46]

1/8 LOW

PRESSURE

7/16

[11.11]

1-11/16

[42.86]

1/2

[12.70]

1/8 NPT LOW

PRESSURE

1/8 NPT HIGH

PRESSURE

1/2

[12.70]

1/8 NPT HIGH

PRESSURE

Ø4-1/8 [104.78] BOLT

CIRCLE FOR PANEL MOUNTING

1

20 APART

1-1/4

[31.75]

Ø4-3/4

[120.65]

1-3/4

[44.45]

Series 2000 Magnehelic®Air Filter Gages

Specifications - Installation and Operating Instructions

he Magnehelic

T

molded flexible diaphragm.

a

®

age consists of two pressure-tight compartments separated by

g

The interior of the gage case serves as the “high” pressure compartment and a

sealed chamber behind the diaphragm serves as the “low” pressure compartment.

ifferences in pressure between the “high” and “low” sides of the diaphragm cause

D

he diaphragm to assume a balanced position between the two pressures. The

t

ront support plate of the diaphragm is linked to a leaf spring which is anchored at

f

one end. The spring provides calibrated resistance to the diaphragm motion.

Motion of the spring is transmitted through an exclusive magnetic linkage to the

pointer.

The Magnehelic

®

gage requires no maintenance. The only field adjustment

required is occasional zero setting of the pointer which is done by opening the

plastic vent valves and turning the adjustment of the gage.

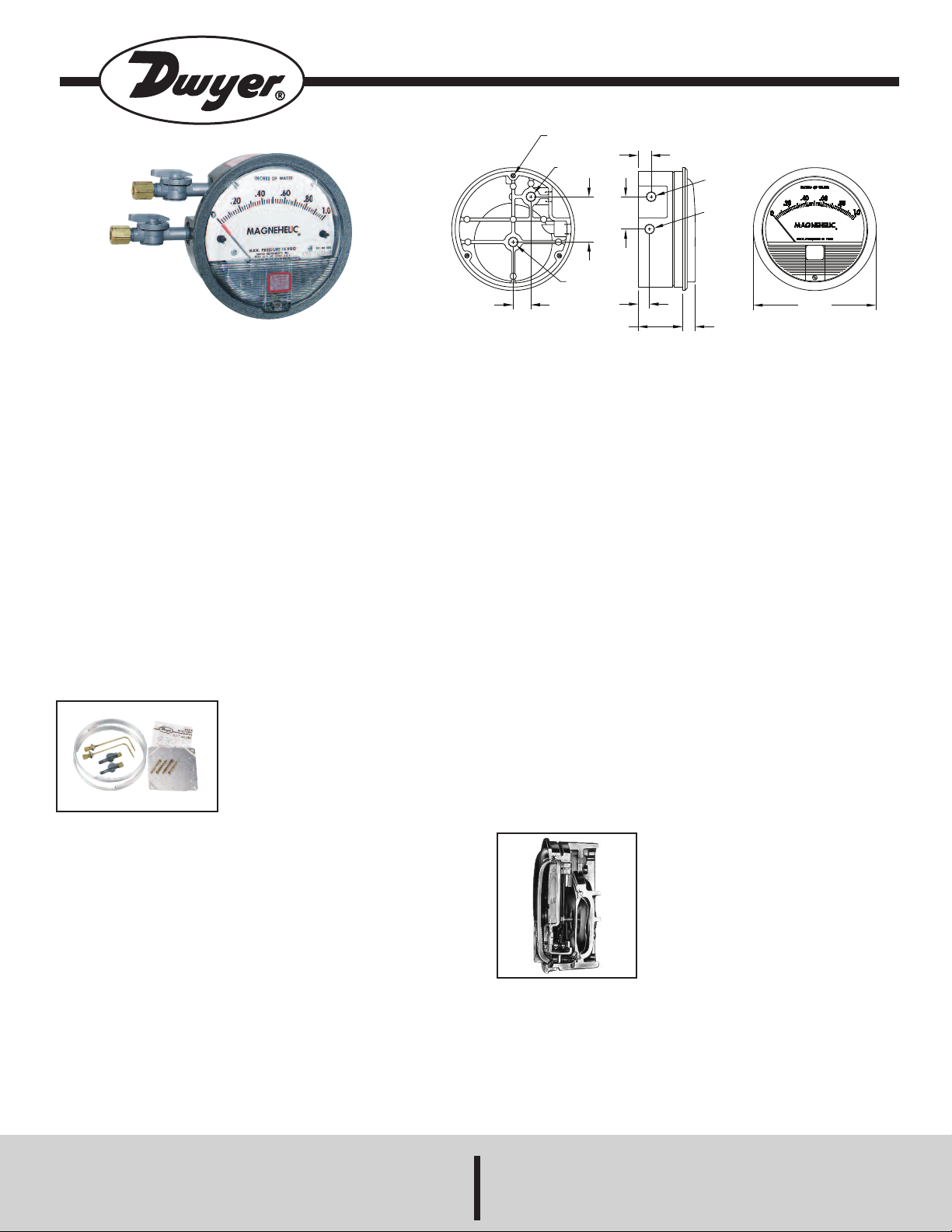

STANDARD ACCESSORIES FURNISHED

Two 1/8˝ NPT plugs for duplicate pressure taps, two 1/8˝ pipe thread to rubber

tubing adapter and three flush mounting adapters with screws. (Mounting and snap

ring retainer substituted for 3 adapters in MP & HP gage accessories.)

Air Filter accessories furnished are mounting

panel with necessary screws, two static

pressure tips with integral compression

fittings, two five foot lengths of 1/4˝ aluminum

tubing and the two molded plastic vent valve

with compression fittings.

EATURES

F

Easiest reading for personnel accustomed to dial type gages.

•

• Lowest cost pointer type gage.

• Easy zeroing with molded plastic vent valves.

• Sensitivity to 0.01˝ w.c.

• Withstands vibration.

Unaffected by over range pressure surges.

•

PECIFICATIONS

S

Service: Air and non-combustible, compatible gases. (Natural Gas option

available.)

Wetted Materials: Consult Factory.

Housing: Die cast aluminum case and bezel, with acrylic cover, Exterior finish is

coated gray to withstand 168 hour salt spray corrosion test.

Accuracy: ±2% of full scale (±3% on - 0 and ±4% on - 00 ranges), throughout

range at 70°F (21.1°C).

Pressure Limits: -20˝ Hg. to 15 psig.† (-0.677 bar to 1.034 bar); MP option; 35

psig (2.41 bar), HP option; 80 psig (5.52 bar).

Overpressure: Relief plug opens at approximately 25 psig (1.72 kPa), standard

gages only.

Temperature Limits: 20 to 140°F.* (-6.67 to 60°C).

Size: 4˝ (101.6 mm) Diameter dial face.

Mounting Orientation: Diaphragm in vertical position. Consult factory for other

position orientations.

Process Connections: 1/8˝ female NPT duplicate high and low pressure taps one pair side and one pair back.

Weight: 1 lb 2 oz (510 g), MP & HP 2 lb 2 oz (963 g).

* Low temperature models available as special option.

† For applications with high cycle rate within gage total pressure rating, next higher

rating is recommended. See Medium and High pressure options at lower left.

®

The Magnehelic

gage with molded plastic vent valves for easy zeroing. Available

with adjustable signal flag (not shown; option “ASF” at extra cost) for immediate

visual reference to maximum allowable pressure drop; External front screw for zero

adjustment. Red and green scale overlays to highlight safe and dangerous

readings are also available.

Cutaway view of the Magnehelic

the actuating diaphragm, the leaf spring with

magnet, the helix which turns the indicating pointer

®

gage showing

in response to the position of the magnet without

mechanical linkages.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

FILTER WALL

AIR FLOW

HIGH PRESSURE

LINE

L

OW

PRESSURE LINE

12˝ BETWEEN

STATIC TIPS AND FILTER

ptions Not Shown:

O

Automatic signal flag integral with plastic gage cover

-

Not shown Scale plate overlays in green and red

-

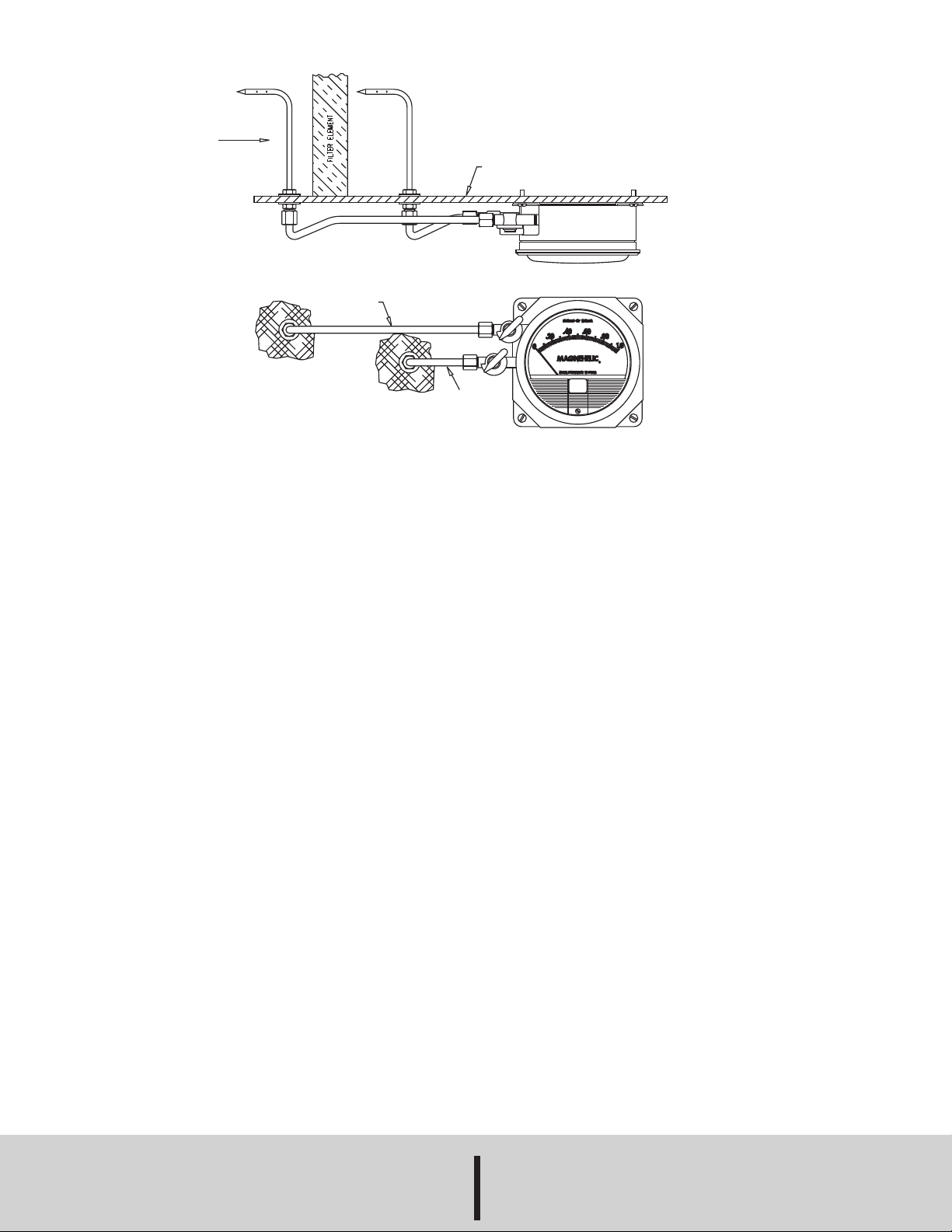

INSTALLATION PROCEDURE

1. Screw vent valves into side connections of gage. Be sure back connections of

gage are sealed with plugs provided with the gage. Attach gage to mounting

plate with three No. 6-32 screws provided.

2. Select a convenient location on filter wall and punch or drill four 1/8˝ dia. max.

holes for mounting plate as shown in drawing above. Attach mounting plate

to filter wall with four self-tapping screws provided. If gage is to be flush

mounted in control panel, refer to Bulletin No. A-27.

3. Drill two 7/16˝ holes in the duct, one on each side of the filter and at least 12”

distant*. Secure the static pressure tips as in the drawing above, with the tips

directed into the air flow.

4. Connect 1/4˝ metal tubing from the static pressure tips to the gage. The tip on

the downstream side of the filter is connected to the vent valve in the low

pressure connection of the gage. The tip on the upstream side is connected

to the vent valve in the high pressure connection.

5. Turn both vent valves to “VENT” position and adjust the gage pointer to zero

by means of the external adjustment screw in the face of the gage. After

zeroing, turn vent valves to “LINE” position.

*NOTE On location of static pressure tips: The location of static pressure tips

is of primary importance in securing reliable readings. For maximum accuracy, it is

essential that the influence of the velocity of the air be eliminated to permit sensing

the true static pressure. Note that some installations do not provide a straight duct

approach to the filter bank which may cause air to swirl and eddy.

Tips should be located as recommended by the specifying engineer or by the filter

manufacturer. In the absence of such recommendations, locate the tips at least 12˝

upstream and downstream from the filters in a zone of minimum turbulence.

INSTALLATION CHECK AND TROUBLE SHOOTING

Before putting your air filter gage into service or in the event of initial pressure drop

readings that do not agree with the filter manufacturer’s specified pressure drop,

make the following checks:

1. Check zero adjustment of the gage as described above.

2. Check all tubing connections for tightness from the gage to the static tip or

fitting connection.

3. Check plastic cover of gage to be sure it is securely in place and air tight.

4. Check static pressure tips or fittings to be sure they are not plugged.

5. Check installation of static tips or fittings*. Be sure static pressure tips point

directly into the air stream. A velocity pressure error can be created if the air

blows directly into the opening.

OPERATION

With vent valves in “LINE” position the gage will indicate pressure drop across the

filter. If the reading varies substantially from the filter manufacturer’s rating for a

clean filter, check the system for proper setting of controls, air balancing of system,

leakage in system and whether or not the correct filter has been installed.

When pressure drop across the filter reaches the minimum recommended by the

manufacturer, the filter should be serviced or replaced.

©Copyright 2013 Dwyer Instruments, Inc. Printed in U.S.A. 5/13 FR# 12-440238-00 Rev. 4

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...