Page 1

INSTRUCTIONS FOR THE 16L SERIES

FM

®

MICROPROCESSOR BASED

TEMPERATURE / PROCESS LIMIT CONTROL

LOVE CONTROLS DIVISION

Dwyer Instruments, Incorporated

®

December, 1998 Page 1 of 28 949-1270

PO Box 338 Michigan City, IN 46361-0338

(800) 828-4588 (219) 879-8000 FAX (219) 872-9057

m

m

www.love-controls.com

m

Page 2

CONTENTS

MODEL IDENTIFICATION ...................................................................... 2

GETTING STARTED ............................................................................... 3

INSTALLATION .......................................................................................4

WIRING ................................................................................................... 5

Wiring for 4 to 20mA Transmitter inputs ........................................... 6

Wiring for Optional Inputs and Outputs.............................................6

FRONT PANEL KEY FUNCTIONS.........................................................8

NOTATION CONVENTIONS FOR THE MENUS .................................10

THE HOME DISPLAY ........................................................................... 11

OPERATION AND PROGRAMMING OF OPTIONS ............................ 11

MENU SELECTIONS...........................................................................14

PRIMARY MENU ..................................................................................14

SECONDARY MENU ............................................................................ 14

SECURE MENU....................................................................................17

DIAGNOSTIC ERROR MESSAGES ..................................................... 22

SPECIFICATIONS ................................................................................ 24

DIMENSIONS ....................................................................................... 27

MODEL IDENTIFICATION

Model 1 6 L 2 0 — —

OPTIONS

Output 1

1 = SSR

2 = 15 VDC

Options:

934 Analog Retransmission of Process Variable, 4 to 20 mAdc.

936 Analog Retransmission of Process Variable, 0 to 10 Vdc.

948 4-Stage Set Point.

992 RS-485 Serial Communications.

993 RS-232 Serial Communications.

9502 12 - 24 Vdc/Vac 50-400Hz power supply (control operates on low

voltage equipment).

Note: Only Option 9502 may be combined with another option.

© 1998, Love Controls Division, Dwyer Instruments, Incorporated. All rights reserved. No

portion may be copied without the express written consent of Love Controls.

949-1270 Page 2 of 28 December, 1998

3 = Relay, NO

4 = Relay, NC

8 = DC SSR

Output 2

0 = None

1 = SSR

2 = 15 VDC

3 = Relay, NO

4 = Relay, NC

8 = DC SSR

Page 3

GETTING STARTED

1. Install the control as described on page 4.

2. Wire your control following the instructions on page 5. If you are

using a two-wire transmitter as an input, see the drawing and

instructions on page 6. Option wiring instructions are on Page 7.

Option descriptions and specific instructions start on page 16.

3. Most controls do not need many (if any) program changes to work

on your process. For best results when programming changes are

necessary, make all the necessary changes in the Secure Menu

(page 26) before making changes to the Secondary Menu (page 19).

If error messages occur, check the Diagnostic Error Messages on

page 35 for help.

Take the example of a Model 16L2010 that comes from the factory

programmed for type J thermocouples. Suppose for this example you

wish to change the input to type K and limit the set point range between

0° and 1000° C.

First, enter the Secure menu as instructed on page 5. Press the INDEX

key until the display shows Inp and press the DOWN ARROW until the

display shows CA. Don't forget to press the ENTER key to retain your

setting.

Next, press the INDEX key to display Unit. Press the DOWN ARROW

until the display shows C. Press ENTER.

Next, press the INDEX key until SPL is displayed (pass the dPt and InPt

selections). Press the UP ARROW until the display shows 0. Press

ENTER.

Finally, press INDEX key to display SPH. Press the DOWN ARROW

until the display shows 1000. Press ENTER.

The necessary program changes are now complete. After 30 seconds

the display will switch back to the temperature reading. If you want to

return faster, press the UP ARROW and ENTER keys (at the same time)

and then press the DOWN ARROW and INDEX keys ( again at the same

time). This will 'back out' of the menu and immediately display the

temperature reading.

December, 1998 Page 3 of 28 949-1270

Page 4

INSTALLATION

Mount the instrument in a location that will not be subject to excessive

temperature, shock, or vibration. All models are designed for mounting in an

enclosed panel.

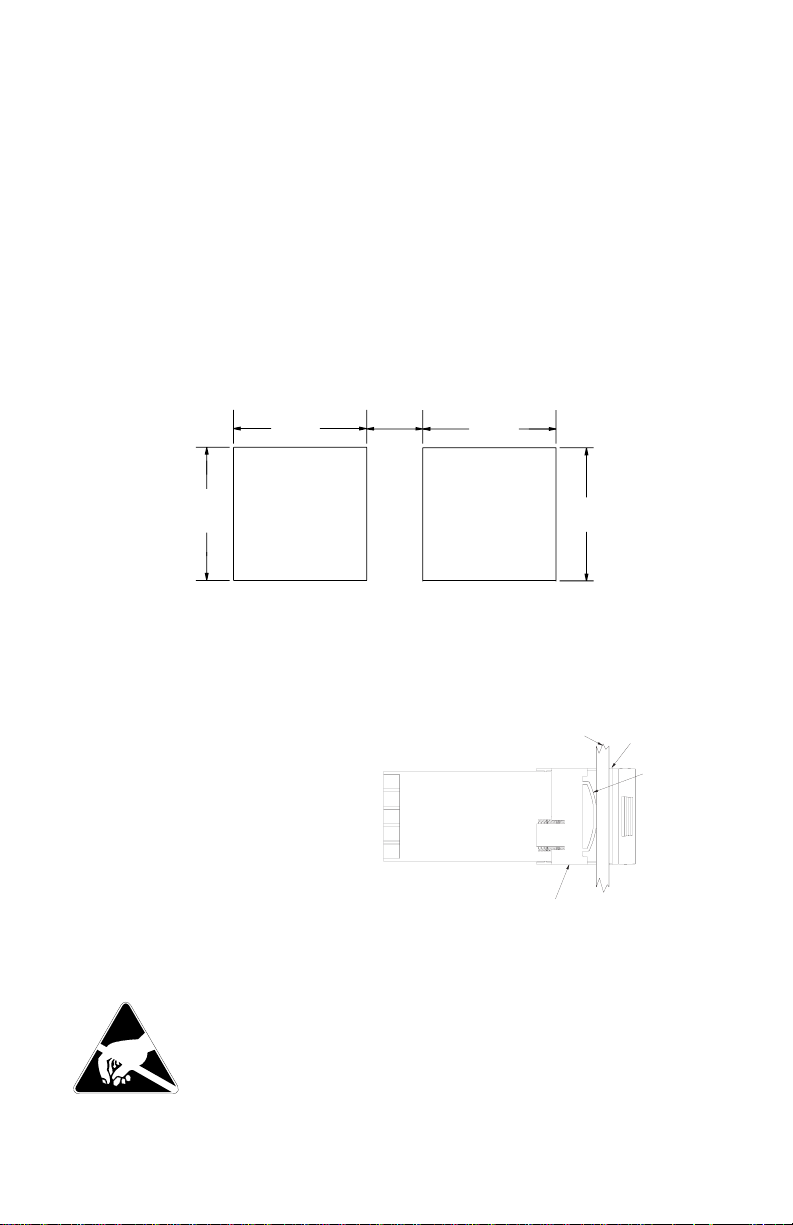

Select the position desired for the instrument on the panel. If more than one

instrument is required, maintain the minimum of spacing requirements as

shown on the drawing below. Closer spacing will structurally weaken the

panel, and invalidate the IP66, UL type 4 rating of the panel.

Prepare the panel by cutting and deburring the required opening.

45mm

(1.77in)

45mm

(1.77in)

Cut Out

19mm

(0.75in)

45mm

(1.77in)

Cut Out

45mm

(1.77in)

All Tolerances are -0.00 +0.60mm (-0.000 +0.020)

From the front of the panel, slide the housing through the cut out. The

housing gasket should be against the housing flange before installing.

From the rear of the panel slide

the mounting collar over the housing. Hold the housing with one

PANEL

10mm (0.25")

MAX.

GASKET

SPRING LOOP

hand and using the other hand,

push the collar evenly against the

panel until the spring loops are

slightly compressed. The ratchets will hold the mounting collar

and housing in place.

MOUNTING COLLAR (SHOWN IN POSITION)

SLIDE COLLAR ONTO THE HOUSING

BEFORE WIRING THE REAR TERMINALS

CAUTION: It is not necessary to remove the instrument

chassis from the housing for installation. If the instrument chassis is removed from the housing, you must

follow industry standard practice for control and protection against Electro-Static Discharge (ESD). Failure

to exercise good ESD practices may cause damage to

the instrument.

949-1270 Page 4 of 28 December, 1998

Page 5

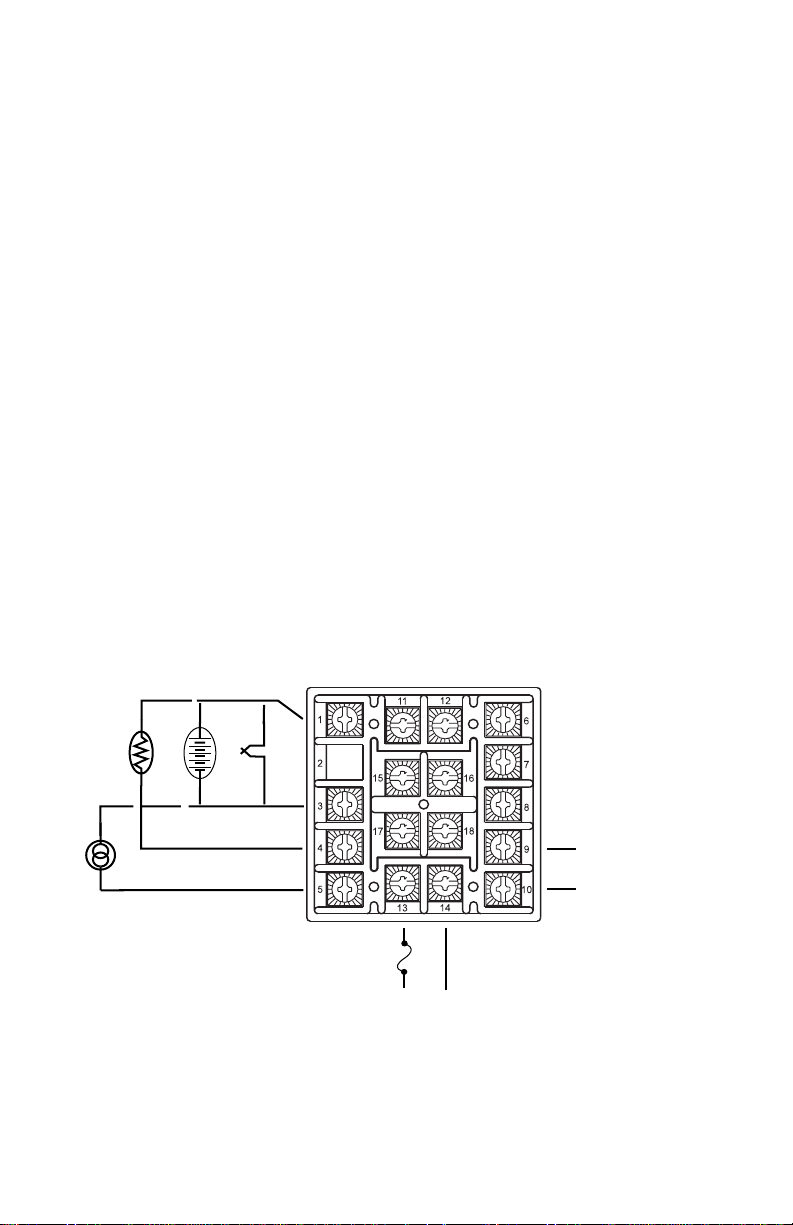

WIRING

Do not run thermocouple or other class 2 wiring in the same conduit as

power leads. Use only the type of thermocouple or RTD probe for which

the control has been programmed. Maintain separation between wiring of

sensor, auxiliary in or out, and other wiring. See the "Secure Menu" for input

selection.

For thermocouple input always use extension leads of the same type

designated for your thermocouple.

For supply connections use No. 16 AWG or larger wires rated for at least

75°C. Use copper conductors only. All line voltage output circuits must

have a common disconnect and be connected to the same pole of the

disconnect.

Input wiring for thermocouple, current, and RTD; limit reset function; and

output wiring for 15 VDC is rated CLASS 2.

Control wiring is as shown.

INPUTS

Current

RTD*

Voltage

Thermocouple

+

+

-

-

-

+

F1

3/8 A @250 VAC

Medium Lag

Line Input See Rating

Label for details

* For 2-wire RTD use terminals 1 & 3, and

place a jumper wire between terminals 3 & 4.

ALARM

RESET

An external

normally open

contact may

be wired

across

terminals 9 &

10 for remote

reset.

Multiple units

can not share

common

contacts.

Terminals 9 &

10 share a

common

ground with

the input.

December, 1998 Page 5 of 28 949-1270

Page 6

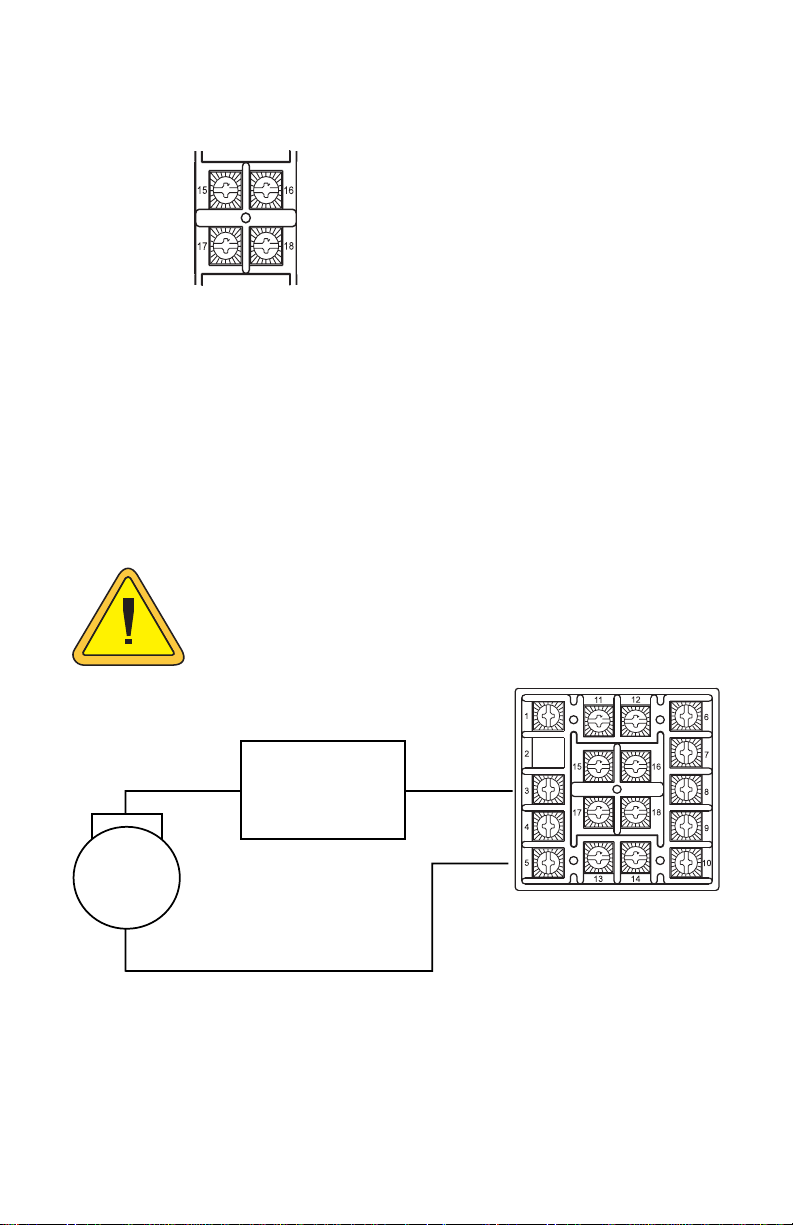

OUTPUTS

Output A

Output B

+ -

For relay, NO (Order Code 3) or SSR (Order

Code 1) outputs, 15 & 16 and 17 & 18 are

Normally Open.

For relay, NC (Order Code 4) outputs, 15 & 16

and 17 & 18 are Normally Closed.

+ -

For Pulsed DC (Order Code 2) and DC SSR

(Order Code 8) outputs, 15 & 17 are positive

and 16 & 18 are negative.

Wiring for 4 to 20mA Transmitter inputs

Wire power and outputs as shown above. Two-wire transmitters wire as

shown below.

For three or four wire transmitters follow the wiring instructions provided

with your transmitter.

CAUTION: DO NOT WIRE THE 24 VOLT POWER SUPPLY

ACROSS THE INPUT OF THE CONTROL. DAMAGE TO

THE CONTROL INPUT CIRCUITRY WILL RESULT.

Power Supply

+

Transmitter

15 to 28 VDC

+

-

-

+

-

Wiring for Optional Inputs and Outputs

Wire power and outputs as shown on page 5 and 6. Wiring for options is

shown opposite. All wiring shown below is Class 2. Shielded twisted pair

is required for Option 992.

949-1270 Page 6 of 28 December, 1998

Page 7

CAUTION: DO NOT RUN SIGNAL WIRING IN THE SAME

CONDUIT OR CHASE AS THE POWER WIRING. ERRATIC OPERATION OR DAMAGE TO THE CONTROL

CIRCUITRY WILL RESULT.

SWITCH CONTACTS FOR OPTION 948 MUST BE ISOLATED AND CAN

NOT SHARE WIRING WITH OTHER CONTROLS.

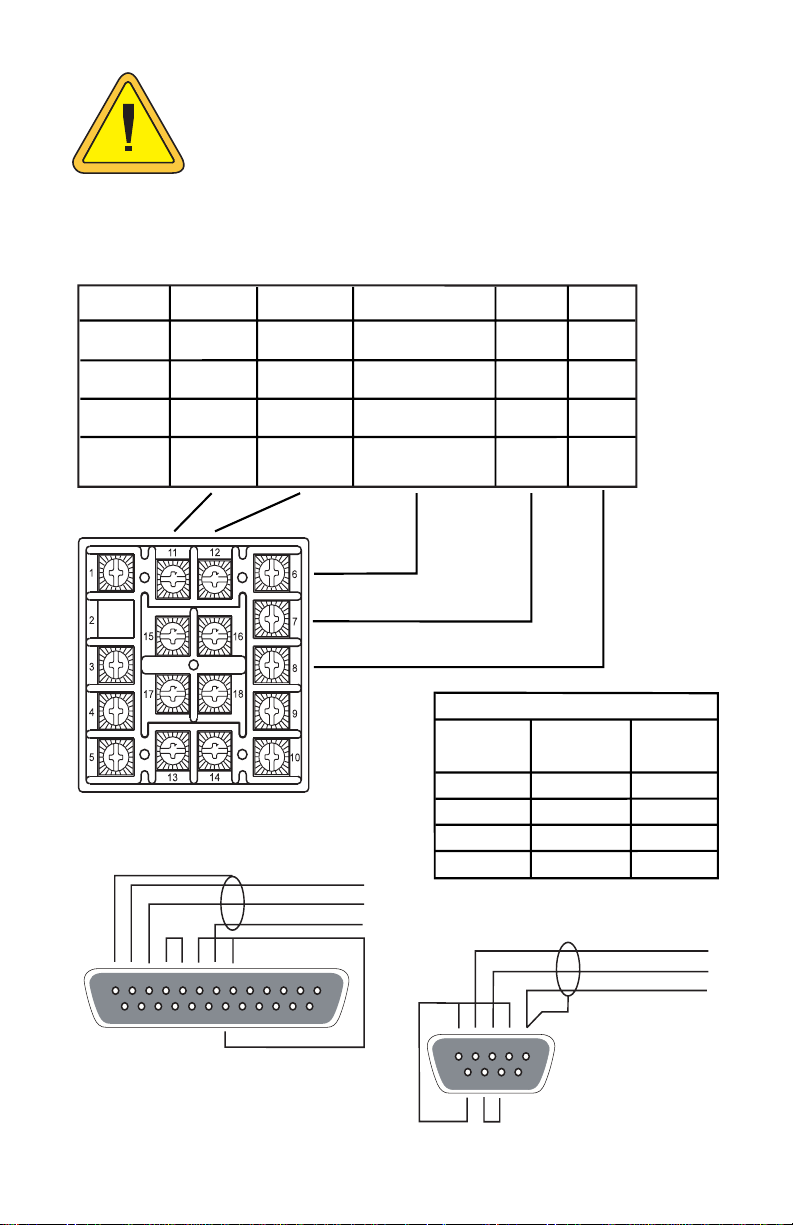

OPTION 11 12 6 7 8

934, 936 + - na na na

948 na na Signal Ground A B

992 B A na na na

993 Data In Data Out Signal Ground na na

948 Truth Table

AB

7 to 6 8 to 6 SP

OPEN OPEN 1SP1

CLOSED OPEN 2SP1

RS-232 DB-25 WIRING

(VIEWED FROM WIRE SIDE)

DATA IN 11

DATA OUT 12

DATA GROUND 6

1 2 3 4 5 6 7 8 9 10 11 12 13

14 15 16 17 18 19 20 21 22 23 24 25

PIN DESCRIPTION

1 SHIELD

2 TRANSMIT

3 RECEIVE

4 RTS

5 CTS

PIN DESCRIPTION

6 DSR

7 GROUND

8 DCD

20 DTR

December, 1998 Page 7 of 28 949-1270

OPEN CLOSED 3SP1

CLOSED CLOSED 4SP1

RS-232 DB-9 WIRING

(VIEWED FROM WIRE SIDE)

DATA OUT 12

DATA IN 11

DATA GROUND 6

PIN DESCRIPTION

1 2 3 4 5

6 7 8 9

1 DCD

2 RECEIVE

3 TRANSMIT

4 DTR

5 GROUND

6 DSR

7 RTS

8 CTS

Page 8

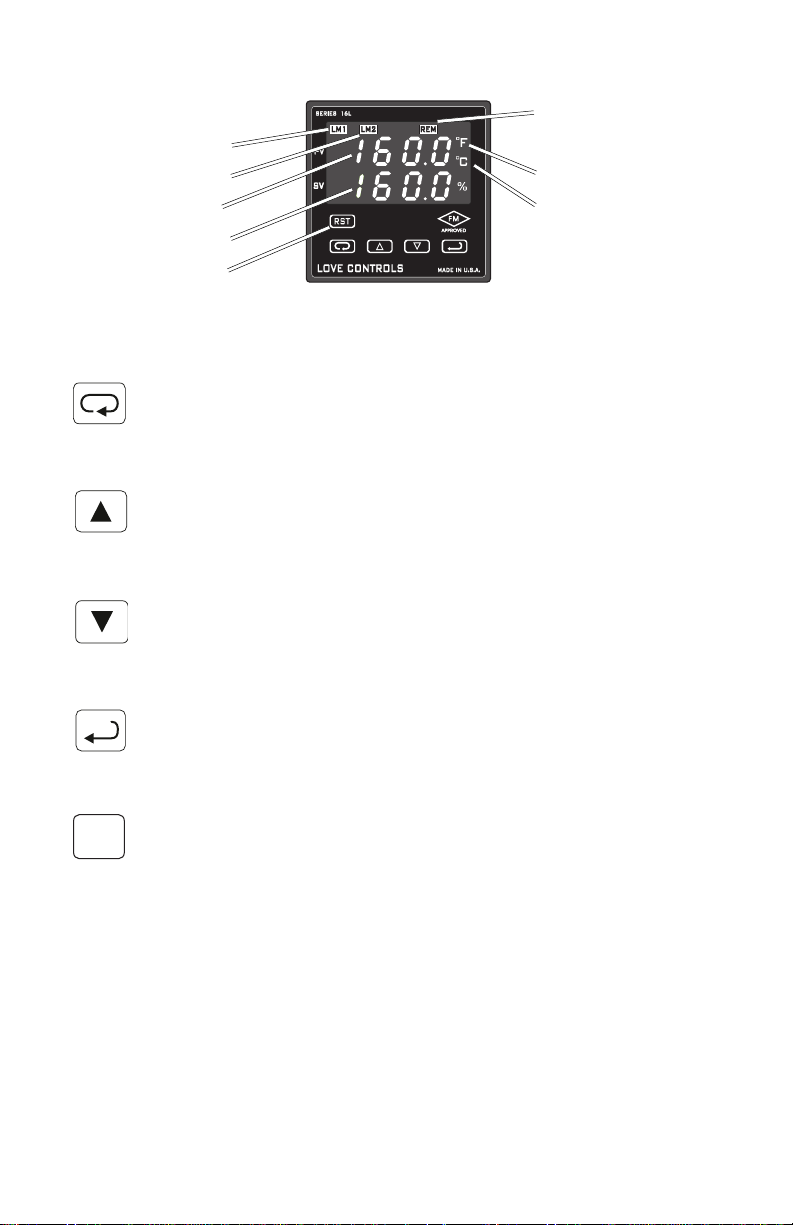

FRONT PANEL KEY FUNCTIONS

Remote Indicator

Limit 1 Lamp

Limit 2 Lamp °F Indicator

Process Display °C Indicator

Set Point Display

Limit Reset Key*

* Limit Reset key flashes when limit condition is present.

Keys are illuminated when pressed. Key functions are as follows:

INDEX: Pressing the INDEX key advances the display to the next

menu item. May also be used in conjunction with other keys as noted

below.

UP ARROW: Increments a value, changes a menu item, or

selects the item to ON. The maximum value obtainable is 9999

regardless of decimal point placement.

DOWN ARROW: Decrements a value, changes a menu item, or

selects the item to OFF. The minimum value obtainable is -1999

regardless of decimal point placement.

ENTER: Pressing ENTER stores the value or the item changed. If

not pressed, the previously stored value or item will be retained. The

display will flash once when ENTER is pressed.

RST

UP ARROW & ENTER: Pressing these keys simultaneously brings up

the secondary menu starting at the SP1d menu item. Pressing these keys

for 5 seconds will bring up the secure menu.

INDEX & DOWN ARROW: Pressing these keys simultaneously will allow

backing up one menu item, or if at the first menu item they will cause the

display to return to the primary menu.

949-1270 Page 8 of 28 December, 1998

LIMIT RESET: This key resets the limit when the limit condition has

been removed. Press and hold for three seconds to activate.

Page 9

INDEX & ENTER: Pressing these keys simultaneously and holding them

for 5 seconds allows recovery from the various error messages. The

following menu items will be reset:

S1iH: Set Point 1 limit inhibit S2iH: Set Point 2 limit inhibit

OPEn InP: Input error message CHEC CAL: Check calibration error

Correct the problems associated with the above conditions before

using these reset keys. More than one error could be present. Caution is

advised since several items are reset at one time.

While in the Primary or Secondary Menu, if no key is pressed for a period

of 30 seconds, the display will return to the HOME position displaying the

temperature value. While in the Secure Menu, if no key is pressed for a

period of 60 seconds, the display will return to the HOME position displaying

the temperature value. Outputs are disabled (turned off) when the Secure

Menu is active.

NOTE: To move to the Primary Menu quickly from any other menu, press

the UP ARROW & ENTER keys followed by pressing the INDEX & DOWN

ARROW keys.

SECURITY LEVEL SELECTION

Four levels of security are provided. The display shows the current security

level. To change security levels change the password value using the UP &

DOWN ARROW keys and pressing the ENTER key. Refer to the password

table (following) for the correct value to enter for the security level desired.

The SECr menu item security level may be viewed or changed at any time

regardless of the present security level.

To set the access level to, for example, 2, at the SECr menu item press the

UP ARROW key until the upper display show the password, 1101. Press

the ENTER key. The display will blink, and return with the level value, 2, in

the upper display.

The password values shown in the table cannot be altered, so retain a copy

of these pages for future reference. This is the only reference made to

password values in this instruction book.

December, 1998 Page 9 of 28 949-1270

Page 10

PASSWORD TABLE

Security Level

Menu Status

Primary Locked

Secondary Locked

Secure Locked

Primary Unlocked

Secondary Locked

Secure Locked

Primary Unlocked

Secondary Unlocked

Secure Locked

Primary Unlocked

Secondary Unlocked

Secure Unlocked

Displayed Value

When Viewed

1

2

3

4

Password Value

To Enter

1110

1101

1011

111

NOTATION CONVENTIONS FOR THE MENUS

Because of the number of features available in this control, information is

included that may not apply to your specific control. All usable features are

included in this book, but may not be used in your process. To increase

clarity the following conventions are used:

1. Certain features, Menu Items, and functions shown in this book may or

may not appear on your control, depending on other Menu Item selections.

At various places in the Menus there are notes identifying Menu Items that

"control" or "direct" other menu items. If you are looking for a particular

menu item and can't find it, check the menu item that is its "control" for

proper setting.

2. The "#" symbol is used in two ways. It is used inside a group of

characters to indicate which set point function (SP1 or SP2) is being

affected. It is also used before a group of characters of a menu item to

indicate that there may be more than one selection or value for that menu

item.

3.

Features that apply only to Options will be printed in Italics.

949-1270 Page 10 of 28 December, 1998

Page 11

THE HOME DISPLAY

The home display is the normal display while the control is operating. The

HOME display may be programmed to operate in one of three different

ways. This is controlled by the diSP menu item in the Secure Menu.

If diSP is set for Pro, the HOME display will show only the Process Variable

(the temperature, pressure, flow, RH, etc., that is being measured) on the

top display with the bottom display blank. If diSP is set for SPt, the home

display will show only the Set Variable (Set Point 1) on the top display with

the bottom display blank. If diSP is set for both, the HOME display will

indicate the Process Variable on the top display and the Set Variable on the

bottom.

If no errors or functions are active, the HOME display as programmed will

be shown.

OPERATION AND PROGRAMMING OF OPTIONS

Option 934, 936, Isolated Analog Retransmission.

The analog retransmission option allows the Process Variable or the

Set Variable to be sent as an analog signal to an external device.

The signal may be either 0 to 10 VDC (Option 936) or 0 (or 4) to 20

mADC (Option 934). The output may be changed in the field from

one to the other by the toggle switch located on the top printed circuit

board.

Wire the output as shown on page 7.

To set up the analog retransmission, first determine the scale range

that the analog signal will represent. The maximum scale is 9999°F,

5530°C, or 9999 counts. In the Secondary Menu set POL for the

scale value that will be represented by the low end of the analog

signal (0 Volts or 0 mA). Set POH for the scale value that will be

represented by the high end of the analog signal (10 Volts or 20 mA).

If you require a suppressed scale or output, you may use the

following equations to determine the proper settings for POL and

POH.

K = (Highest desired scale reading - Lowest desired scale reading) /

(Maximum desired analog signal - Minimum desired analog signal).

POH = ((Maximum possible analog output - Maximum desired analog

signal) * K) + Highest desired analog reading.

December, 1998 Page 11 of 28 949-1270

Page 12

POL = Lowest desired scale reading - ((Minimum desired analog

output) * K).

Next select whether you want the retransmission signal to follow the

Process Variable or the Set Variable. Usually the Process Variable

is sent to recorders or other data acquisition devices. Usually the

Set Variable is sent to other controls to be used as an analog remote

set point. If you want the analog retransmission signal to follow the

PV, in the Secondary Menu set POSr to InP. If you want the analog

retransmission signal to follow the SV, set POSr to SPt.

Operation is automatic. There are no further programming steps

required.

Option 948, 4-Stage Set Point.

The 4-stage set point option allows four different values to be used

for SP1. The control will switch to a given stage when an external

contact or contacts are made or opened across the appropriate

terminals at the rear of the control (when SPSA, Set Point Switch

Action, is set for remote, rE), or when the stage is selected from the

Secondary Menu, SP (when SPSA is set for Int). When the state of

a contact changes (or the stage number is changed in the Secondary

Menu), the values in use are stored and the previously stored values

for the new stage are used.

Wire the input as shown on page 7.

Usually the control is configured for external switching of the stages.

In this case, the operation is usually automatic, selected by the

external switches driven by the machine logic. If it is necessary to

program the stages in advance, you may select the stage to modify

with the SP menu item. When SP is changed while the SPSA is set

for rE, the selected stage is displayed for modification, but only used

when the appropriate contact is made.

Option 992, 993, Serial Communication.

The serial communications options allow the control to be written to

and read from a remote computer or other similar digital device.

Communication is allowed either through a RS-485 (Option 992)

port, or a RS-232 (Option 993) port.

949-1270 Page 12 of 28 December, 1998

Page 13

Wire the communication lines as shown on Page 7. Wiring for the

RS-485 is run from control to control in a daisy chain fashion with a

termination resistor (120 ohms) across the transmit and receive

terminals of the last control in the chain.

Select the control address and communication baud rate with the

Addr and bAUd menu items in the Secure Menu. THE BAUD RATE

AND ADDRESS MENU ITEMS WILL TAKE EFFECT ON THE NEXT

POWER UP OF THE CONTROL. BE SURE TO POWER CYCLE

THE CONTROL BEFORE USING THE NEW BAUD RATE AND

ADDRESS.

In operation, you have the option of preventing a write command

from the host computer. To prevent the host from writing to the

control change the LOrE menu item in the Secondary Menu to LOC.

To allow the host to write commands to the control set LOrE to rE.

(The host does have the ability to change the LOrE state, but it is not

automatic.)

If your system depends on constant reading or writing to and from

the host, you may wish to set the No Activity Timer (nAt) to monitor

the addressing of the control. When the LOrE is set to rE and the

nAt is set to any value other than Off, the control will expect to be

addressed on a regular basis. If the control is not addressed in the

time set by the value of nAt, then the control will display the error

message CHEC LOrE. To clear the message set LOrE to LOC.

December, 1998 Page 13 of 28 949-1270

Page 14

MENU SELECTIONS

PRIMARY MENU Press INDEX to advance to the next menu item. Press UP ARROW or DOWN ARROW to change the value in the display. Press ENTER to retain

the value.

#SP1 (Option 948, 4-Stage Set Point) or

SP1 Set Point 1 Adjust, Limit Point 1.

SP2 Set Point 2 Adjust (if equipped), Limit Point 2.

SECONDARY MENU

Hold UP ARROW & ENTER. Press INDEX to advance to the next menu

item. Press UP ARROW or DOWN ARROW to change the value in the

display. Press ENTER to retain the value.

SP1d Set Point On-Off Differential (hysteresis). Select 1 to 9999 (when

S1F=Lo) or -1 to -9999 (when S1F=Hi). Set the value for the

amount of difference between the turn on point (Set Point 1) and

the turn off point. See the following chart.

S2F = Hi

S2F = Lo

DEVIATION ALARM

SP2 WHEN S2t = dE

SP2

SP1

SP2

SP1

ABSOLUTE ALARMS

SP2 when S2t = ABS

High Alarm

S#F = Hi

Low Alarm

S#F = Lo

SP1

SP#

SP#

High Alarm

Low Alarm

The following menu items apply only if your control is equipped with

a second set point (last digit of model number is not zero). If your

control does not have a second set point, jump to the "SP" menu item

below.

SP2d Set Point On-Off Differential (hysteresis). Select 1 to 9999 (when

S2F=Lo) or -1 to -9999 (when S2F=Hi). Set the value for the

amount of difference between the turn on point (Set Point 2) and

the turn off point. See chart above.

949-1270 Page 14 of 28 December, 1998

Page 15

SP (Option 948, 4-Stage Set Point) Active Set Point Stage. Select

1SP1, 2SP1, 3SP1, 4SP1. (See Page 17 for more detail.)

1SP1 Set Menu Items to display Stage 1 for view and change

access. If SPSA is set for Int, 1SP1 is made active.

2SP1 Set Menu Items to display Stage 2 for view and change

access. If SPSA is set for Int, 2SP1 is made active.

3SP1 Set Menu Items to display Stage 3 for view and change

access. If SPSA is set for Int, 3SP1 is made active.

4SP1 Set Menu Items to display Stage 4 for view and change

access. If SPSA is set for Int, 4SP1 is made active.

#SP1 (Option 948, 4-Stage Set Point) Adjust Control Point 1 for Stage

selected above.

PEA The Peak feature stores the highest input the control has measured

since the last reset or Power On. At Power On PEA is reset to the

present input. To manually reset the value PEA must be in the lower

display. Press the ENTER key to reset. PEA will be reset and display

the present input value.

UAL The Valley feature stores the lowest input the Instrument has

measured since the last reset or Power On. At Power On UAL is reset

to the present input. To manually reset the value UAL must be in the

lower display. Press the ENTER key. UAL will be reset and display

the present input value.

InPC Input Correction: Select ±500 °F, °C, or counts. This feature

allows the input value to be changed to agree with an external

reference or to compensate for sensor error. Note: InPC is reset

to zero when the input type is changed, or when decimal position

is changed.

FiLt Digital Filter: Select OFF, 1 to 99. In some cases the time constant

of the sensor, or noise could cause the display to jump enough

to be unreadable. A setting of 2 is usually sufficient to provide

enough filtering for most cases, (2 represents approximately a 1

second time constant). When the 0.1 degree resolution is selected this should be increased to 4. If this value is set too high,

controllability will suffer.

POL (Option 934, 936, Analog Retransmission Output) Process Out-

put Low: Select -450°F, -260°C, or -1999 counts to any value less

than POH.

December, 1998 Page 15 of 28 949-1270

Page 16

POH (Option 934, 936, Analog Retransmission Output) Process Out-

put High: Select from any value greater than POL to +9999°F,

+5530°C, or 9999 counts.

LOrE (Option 992, 993, Serial Communications) Local / Remote Status:

Select LOC or rE.

LOC The host computer is advised not to send remote

commands. Any write commands sent to the controls

will be rejected.

rE The host computer is allowed to send write commands.If

the control is not addressed within the time set in the nAt

(No Activity Timer, see Secure Menu) the CHEC LorE

error message will be displayed.

Addr (Option 992, Serial Communications) Control Address: Set from 1

to 3FF. This number (hexadecimal, base 16) must match the

address number used by the host computer. Viewed only in this

menu. To change this parameter, see Addr in the Secure Menu.

949-1270 Page 16 of 28 December, 1998

Page 17

SECURE MENU

Hold UP ARROW & ENTER for 5 Seconds. Press INDEX to advance to the

next menu item. Press UP ARROW or DOWN ARROW to change the value

in the display. Press ENTER to retain the value.

OUTPUTS ARE DISABLED (TURNED OFF) WHILE CONTROL IS IN

SECURE MENU.

SECr Security Code: See the Security Level Selection and the Password

Table in this manual, in order to enter the correct password.

InP Input Type: Select one of the following. Refer to the Input wiring

section for the proper wiring.

J-IC Type “J” Thermocouple

CA Type “K” Thermocouple

E- Type “E” Thermocouple

t- Type “T” Thermocouple

L- Type “L” Thermocouple

n- Type “N” Thermocouple

r-13 Type “R” Thermocouple

S-10 Type “S” Thermocouple

b- Type “B” Thermocouple

C- Type “C” Thermocouple

P392 100 ohm Platinum (NIST 0.00392 Ω/Ω/°C)

n120 120 ohm Nickel

P385 100 ohm Platinum (DIN 0.00385 Ω/Ω/°C)

1P38 1000 ohm Platinum (DIN 0.00385 Ω/Ω/°C)

Curr DC Current Input 0.0 to 20.0 or 4.0 to 20.0 mA.

UoLt DC Voltage Input 0.0 to 10.0 or 2.0 to 10.0 volts.

diFF DC Voltage Input -10 to +10 mV.

---- Reserved

OSUP Zero Suppression: Select On or OFF. Only with Current and Voltage

input types.

OFF The input range will start at 0 (zero) Input.

On The input range will start at 4.00 mA or 2.00 V.

Unit F, C or None.

F °F descriptor is On and temperature inputs will be dis-

played in actual degrees Fahrenheit.

C °C descriptor is On and temperature inputs will be dis-

played in actual degrees Celsius.

nonE °F and °C descriptors will be Off. This is only available with

Current and Voltage Inputs.

December, 1998 Page 17 of 28 949-1270

Page 18

dPt Decimal Point Positioning: Select 0, 0.0, 0.00, 0.000, or .0000.

On temperature type inputs this will only effect the Process

Value, SP1, SP2, and InPC. For Current and Voltage Inputs all

Menu Items related to the Input will be affected.

0 No decimal Point is selected. This is available for all

Input Types.

0.0 One decimal place is available for Type J, K, E, T, L,

RTD’s, Current and Voltage Inputs.

0.00 Two decimal places is only available for Current and

Voltage Inputs.

0.000 Three decimal places is only available for Current and

Voltage inputs.

.0000 Four decimal places is only available for Current and

Voltage inputs.

diSP Home Display: Select Pro, SPt, or both.

Pro The upper display of the HOME display shows the

current Process Variable. The lower display is blank.

SPt The upper display of the HOME display shows the

current Set Variable. The lower display is blank.

both The upper display of the HOME display shows the

current Process Variable. The lower display shows the

current Set Variable.

InPt Input Fault Timer: Select OFF, 0.1 to 540.0 minutes. Whenever an

Input is out of range (UFL or OFL displayed), shorted, or open the

timer will start. When the time has elapsed, the controller outputs

will be forced into their de-energized states. If OFF is selected, the

Input Fault Timer will not be recognized (time = infinite).

SEnC Sensor Rate of Change: Select OFF, 1 to 4000 °F, °C, or counts

per 1 second period. This value is usually set to be slightly greater

than the fastest process response expected during a 1 second

period, but measured for at least 2 seconds. If the process is faster

than this setting, the SEnC bAd error message will appear. The

outputs will then be turned off. This function can be used to detect

a runaway condition, or speed up detection of an open thermocouple. Use the INDEX & ENTER keys to reset.

SCAL Scale Low: Select 100 to 9999 counts below SCAH. The total span

between SCAL and SCAH must be within 11998 counts. Maximum

setting range is -1999 to +9999 counts. For Current and Voltage

inputs, this will set the low range end. Viewable only for Thermocouple and RTD ranges.

949-1270 Page 18 of 28 December, 1998

Page 19

SCAH Scale High: Select 100 to 9999 counts above SCAL. The total span

between SCAL and SCAH must be within 11998 counts. Maximum

setting range is -1999 to +9999 counts. For Current and Voltage

inputs, this will set the high range end. Viewable only for Thermocouple and RTD ranges.

SPL Set Point Low: Select from the lowest input range value to SPH

value. This will set the minimum SP1 or SP2 value that can be

entered. The value for SP1 or SP2 will not stop moving when this

value is reached.

SPH Set Point High: Select from the highest input range value to SPL

value. This will set the maximum SP1 or SP2 value that can be

entered. The value for SP1 or SP2 will not stop moving when this

value is reached.

SP1O Set Point 1 Output Select: Select A or A-b.

A Set Point 1 is routed through Output A, Set Point 2 (if

equipped) is routed through Output B.

A-b Set Point 1 is routed through both Output A and Output

B. Set Point 2 menu items are suppressed. This allows

for both NO and NC (Order Code types 3 and 4) outputs

to be driven at the same time.

S1FSet Point 1 Function: Select Hi or Lo.

Hi Output is energized above set point.

Lo Output is energized below set point.

S1rE Set Point 1 Reset. Select OnOF or Hold.

OnOF Control will automatically reset when process passes

back through SP1d.

HoLd Manual Reset. Reset (acknowledge) by pressing the

LIMIT RESET key for 3 seconds.

S1Pi Set Point 1 Power Interrupt. Select On or OFF.

On Alarm Power Interrupt is On. Control will automatically

reset on power-up if no alarm condition exists.

OFF Alarm Power Interrupt is OFF. Control will power-up in

alarm condition regardless of condition of process.

S1iH Set Point 1 Inhibit: Select On or OFF.

On Alarm Inhibit is On. Alarm action is suspended until the

process value first enters a non-alarm condition.

OFF Alarm Inhibit is OFF.

December, 1998 Page 19 of 28 949-1270

Page 20

S1St Set Point 1 State: Select Eng or dEng.

Eng Output Energized. The output device (per Order Code)

will be energized at set point. (Normally Open contacts

will close, Normally Closed contacts will open.)

dEng Output De-energized. The output device (per Order

Code) will be de-energized at set point. (Normally Open

contacts will open, Normally Closed contacts will close.)

S1LP Set Point Lamp: Select O on or OoFF.

O on Lamp ON when Output is ON (energized).

OoFF Lamp OFF when Output is ON (energized).

If your instrument is not equipped with Set Point 2, then proceed to

the option section (next page). If the instrument has no Set Point 2 and

no options, then the menu ends.

S2t Set Point 2 type: Select Abs or dE.

AbS Absolute SP2. SP2 is independent of SP1, and may be set

anywhere between the limits of SPL and SPH.

dE Deviation SP2. SP2 is set as a deviation from SP1, and

allows SP2 to retain its relationship with SP1 when SP1 is

changed (tracking SP2).

S2F Set Point 2 Function: Select Hi of Lo.

Hi Output is energized above set point.

Lo Output is energized below set point.

S2rE Set Point 2 Reset. Select OnOF or Hold.

OnOF Control will automatically reset when process passes

back through SP2d.

HoLd Manual Reset. Reset (acknowledge) by pressing the

LIMIT RESET key for 3 seconds.

S2Pi Set Point 2 Power Interrupt. Select On or OFF.

On Alarm Power Interrupt is On. Control will automatically

reset on power-up if no alarm condition exists.

OFF Alarm Power Interrupt is OFF. Control will power-up in

alarm condition regardless of condition of process.

S2iH Set Point 2 Inhibit: Select On or OFF.

On Alarm Inhibit is On. Alarm action is suspended until the

process value first enters a non-alarm condition.

OFF Alarm Inhibit is OFF.

949-1270 Page 20 of 28 December, 1998

Page 21

S2St Set Point 2 State: Select Eng or dEng.

Eng Output Energized. The output device (per Order Code)

will be energized at set point. (Normally Open contacts

will close, Normally Closed contacts will open.)

dEng Output De-energized. The output device (per Order

Code) will be de-energized at set point. (Normally Open

contacts will open, Normally Closed contacts will close.)

S2LP Set Point 2 Lamp: Select O on or OoFF.

O on Lamp ON when Output is ON (energized).

OoFF Lamp OFF when Output is ON (energized).

SPSA (Option 948, 4-Stage Set Point) Switch Action: Select rE or Int.

rE Set Point Stage selected by external contact closures.

Int Set Point Stage selected by internal menu selection. See

SP menu item in Secondary Menu.

Addr (Option 992, 993, Serial Communications) Control Address: Set

from 1 to 3FF. This number (hexadecimal, base 16) must match the

address number used by the host computer.

bAUd (Option 992, 993, Serial Communications) Communication Baud

Rate: Select 300, 1200, 2400, 4800, 9600, or 19200. This number

must match the baud rate used by the host computer.

nAt (Option 992, 993, Serial Communications) No Activity Timer: Set

from OFF or 1 to 99 minutes.

1 - 99 Maximum time between host computer accesses. If timer

counts to 0, CHEC/LorE will be displayed.

OFF No Activity Timer function is disabled.

December, 1998 Page 21 of 28 949-1270

Page 22

DISPLAY

DIAGNOSTIC ERROR MESSAGES

MEANING

SP OUTPUTS

ACTION REQUIRED

No

display

lighted

FAIL

tESt

CHEC

SP1,

CHEC

SP2

CHEC

SPL

or

CHEC

SPH

Display is blank. Instrument is not getting power, or the

supply voltage is too

low.

Fail test appears

upon power up if the

internal diagnostics

detect a failure. This

message may occur during operation

if a failure is detected. Displays flash.

This message will

appear upon power

up if SP1, SP2, or

#SP1 is set outside

of the SPL or SPH

values.

This message appears at power up if

SPL or SPH values

are programmed

outside the input

range ends.

Set point

outputs inactive

Alarm inactive

Set point

outputs inactive

Alarm inactive

Set point

outputs inactive

Alarm active

Set point

outputs inactive

Alarm inactive

Check that the power supply is

on, or that the external fuses

are good.

The display alternate between

FAIL tESt and one of the following messages: FACt dFLt:

Memory may be corrupted.

Press the ENTER key and the

DOWN ARROW key to start

the factory default procedure.

Recheck controller programming. rEt FACt: Unrecoverable error, return to factory for

service.

Correct the SP1, etc. or adjust

the SPL or SPH values by

programming new values.

Correct the SPL or SPH values by programming new values.

CHEC

LorE

ArEA

(Alter-

nates

with PV)

ArEA

This message appears if the Serial

Communications

has timed out.

This message appears

when the ambient temperature of the control

approaches unacceptable ambients.

This message appears

if the ambiient temperature of the control is

out of range or RJC

sensor is broken.

Set point

outputs active

Alarm inactive

Set point

outputs active

Alarms active

Set point

outputs active

Alarms active

Restore the communications

line and switch the LorE to

LOC.

Correct the ambient temperature

conditions. Ventilate the area of

the cabinet or check for clogged

filters. If RJC broken, return to

factory for service.

Correct the ambient temperature

conditions. Ventilate the area of

the cabinet or check for clogged

filters. If RJC broken, return to

factory for service.

949-1270 Page 22 of 28 December, 1998

Page 23

DISPLAY

DIAGNOSTIC ERROR MESSAGES

MEANING

SP OUTPUTS

ACTION REQUIRED

UFL

or

OFL

bAd

InP

OPEn

InP

SEnC

bAd

CHEC

CAL

Underflow or Overflow: Process value

has exceeded input

range ends.

UFL or OFL will sequence to display

one of these messages if the InPt is

set for a time value.

For RTD inputs RTD

is open or shorted.

For THERMOCOUPLE inputs thermocouple is open.

Sensor Rate of

Change exceeded

the programmed limits set for SEnC.

Check calibration appears as an alternating message if the

instrument calibration nears tolerance

edges.

Set point

outputs active

Alarm active

Set point

outputs

inactive

Alarm active

Set point

outputs

inactive.

Alarm Active

Set point

outputs active

Alarm active

Input signals may normally go

above or below range ends. If

not, check input and correct.

To reset use the INDEX &

ENTER keys. When InPt (in-

put fault timer) has been set

for a time, the outputs will be

turned off after the set time.

Setting the time to OFF causes the outputs to remain active, however UFL or OFL will

still be displayed.

Correct or replace sensor. To

reset use the INDEX & EN-

TER keys.

Check for the cause of the

error. The value setting may

be too slow for the process, or

the sensor is intermittent.

Correct the problem and press

INDEX and ENTER to reset.

Remove the instrument for

service and / or recalibration.

To reset use the INDEX &

ENTER keys.

Check calibration appears as a flashing

message if the instrument calibration exceeds specification.

Set point

outputs

inactive

Alarm active

Remove the instrument for

service and / or recalibration.

To reset use the INDEX &

ENTER keys.

December, 1998 Page 23 of 28 949-1270

Page 24

SPECIFICATIONS

Selectable Inputs: Thermocouple, RTD, DC Voltage, or DC Current

selectable.

Input Impedance:

Thermocouple = 3 megohms minimum. RTD current = 200 µA.

Current = 10 ohms. Voltage = 5000 ohms.

Sensor Break Protection: De-energizes output(s) to protect system after

customer set time. (See InPt in Secondary Menu.)

Set Point Range: Selectable (See Range Chart Page 26).

Display: Two 4 digit, 7 segment 0.3" high LEDs.

Output Action: Fully programmable to allow output(s) to energize or de-

energize above or below set point(s).

On - Off Differential: Adjustable 1° F, 1° C, or 1 count to full scale in 1° F,

1° C, or 1 count steps.

Accuracy: ±0.25% of span, ±1 least significant digit.

Resolution: 1 degree or 0.1 degree, selectable.

Line Voltage Stability: ±0.05% over the supply voltage range.

Temperature Stability: 4µV/°C (2.3 µV/°F) typical, 8 µV/°C (4.5 µV°F)

maximum (100 ppm / °C typical, 200 ppm / °C maximum).

Common Mode Rejection: 140 db minimum at 60 Hz.

Normal Mode Rejection: 65 db typical, 60 db at 60 Hz.

Isolation:

Relay and SSR outputs: 1500 Vac to all other inputs and outputs.

SP1 and SP2 Switched Voltage outputs: 500 Vac to all other inputs

and outputs, but not isolated from each other.

Process Output (934, 936): 500 VAC to all other inputs and outputs.

Supply Voltage: 100 to 240 Vac, nominal., +10 -15%, 50 to 400 Hz. single

phase; 132 to 240 Vdc, nominal., +10 -20%.

Supply Voltage (Option 9502): 12 to 24 Vdc, Vac 40-400 Hz, ±20%.

Power Consumption: 5VA maximum.

Operating Temperature: -10 to +55 °C (+14 to 131 °F).

Storage Temperature: -40 to +80 °C (-40 to 176 °F).

Humidity Conditions: 0 to 90% up to 40 °C non-condensing 10 to 50% at

55 °C non-condensing.

Memory Backup: Nonvolatile memory. No batteries required.

949-1270 Page 24 of 28 December, 1998

Page 25

Output Ratings:

AC SSR: 2.0 A @ 240 Vac at 25 °C (77°F). Derates to 1.0 A @ 55° C

(130°F).

DC SSR: 1.75 A @ 32 Vdc maximum.

Relay: SPST, 3 A @ 240 Vac resistive; 1.5A @240 Vac inductive;

Pilot duty rating 240 VA, 2 A @ 120 Vac or 1 A 240 Vac.

Switched Voltage (isolated): 15 Vdc @ 20 mA.

Panel Cutout: 45 mm x 45 mm (1.775" x 1.775").

Depth Behind Mounting Surface: 121.6 mm (4.79"), maximum.

Weight: 220 g (8 oz).

Agency Approvals: FM, CE.

Front Panel Rating: IP66, (NEMA4X).

December, 1998 Page 25 of 28 949-1270

Page 26

Input Ranges (Field Selectable)

Thermocouple T ypes

Input

Type

Range

1°F

1°C

Input

Type

Range

1°F

1°C

Input

Type

Range

1°F

1°C

Type J or L*

-100 to +1600

-73 to +871

Type R

0 to 3200

-17 to +1760

Type N*

-100 to +2372

-73 to +1300

Type K*

-200 to +2500

-129 to +1371

Type S

0 to 3200

-17 to +1760

* These Input Types can be set for 0.1° display.

If temperature goes above 999.9° or less than

-199.9° the display will return to whole degree

resolution.

Type T*

-350 to +750

-212 to +398

Type B

+75 to 3308

+24 to 1820

Type E*

-100 to +1800

-73 to +982

Type C

0 to 4208

-17 to 2320

RTD Types

Input

Type

Range

1°F

1°C

100 Ohm

Platinum

0.00385 DIN

Curve*

-328 to +1607

-200 to +875

100 Ohm

Platinum

0.00392 Nist

Curve*

-328 to +1607

-200 to +875

120 Ohm

Nickel

0.00628 US

Ind. Curve*

-112 to +608

-80 to +320

1000 Ohm

Platinum

0.00385 Nist

Curve*

-328 to +1607

-200 to +875

Process Input Types

The 0 to 20 mAdc, 4 to 20 mAdc, 0 to 10 Vdc, 2 to 10 Vdc, and -10 to +10

mVdc inputs are fully scalable from a minimum of 100 counts span placed

anywhere within the within the range of -1999 to +9999. Decimal point

position is adjustable from the zero place (9999), tenths (999.9), hundredths (99.99), thousandths (9.999), or ten thousandths (.9999).

949-1270 Page 26 of 28 December, 1998

Page 27

December, 1998 Page 27 of 28 949-1270

DIMENSIONS

L

LM

LM

All dimensions in millimeters (inches). Panel cut out is 45 +0.6 (1.77 +0.02) square.

RESET

FM

®

Page 28

LOVE CONTROLS DIVISION

Dwyer Instruments, Incorporated

®

PO Box 338 Michigan City, IN 46361-0338

(800) 828-4588 (219) 879-8000 FAX (219) 872-9057

949-1270 Page 28 of 28 December, 1998

m

m

www.love-controls.com

m

Loading...

Loading...