Page 1

Series 1630 – Differential Pressure Switch

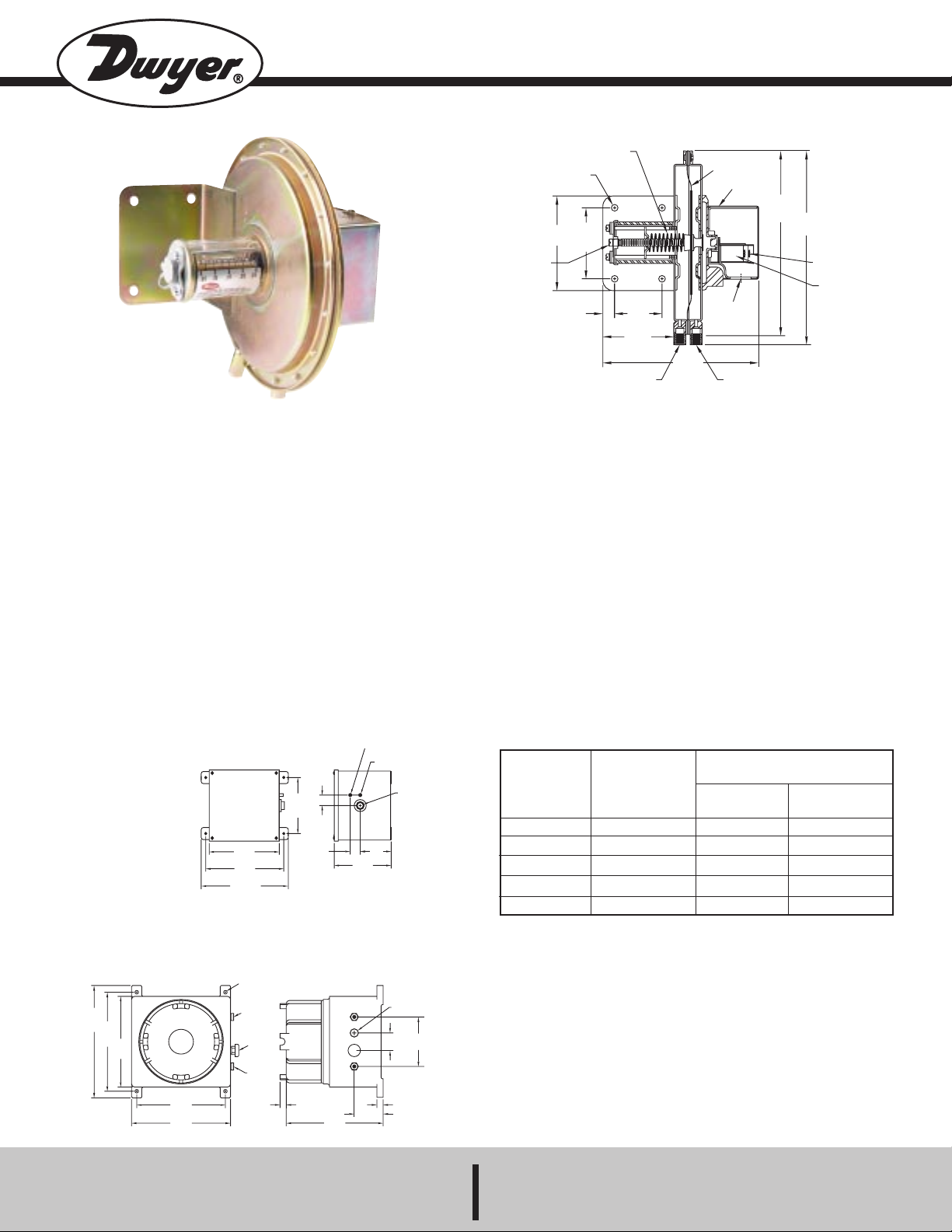

DIAPHRAGM

1/2

[12.70]

TYP.

ADJUSTMENT

SCREW

2

[50.80]

TYP

3

[76.20]

6-1/2

[165.10]

1/8 NPT(F) LOW

PRESSURE CONNECTION

1/8 NPT(F) HIGH

PRESSURE CONNECTION

1/2

CONDUIT

CONNECTION

SPDT SNAP

SWITCH

SCREW TYPE

ELECTRICAL

TERMINALS

TYP 3 PLACES

8-3/16

[207.96]

Ø7-3/4

[196.85]

CONDUIT

ENCLOSURE

ADJUSTABLE

RANGE SPRING

Ø9/32 [7.14]

MOUNTING HOLE

TYP 4 PLACES

3

[76.20]

TYP

4

[101.60]

8-7/8

[225.43] SQ

9-3/4

[247.65] TYP

10-7/8

[276.23] TYP

1-1/4

[31.75]

7-1/8

[180.98]

3-7/8

[98.43]

1/2 NPT

ELECTRICAL

CONNECTION

1/8 NPT HIGH

PRESSURE

CONNECTION

1/8 NPT LOW

PRESSURE CONNECTION

1-5/16

[33.34]

7

[177.80]

TYP

Specifications – Installation and Operating Instructions

Model 1638 pressure switch U.L. and C.S.A. listed F.M. approved

Our highest precision conventional large diaphragm

pressure switch provides maximum dependability. In addition it incorporates a visible set point indicator for maximum

convenience. U.L. and C.S.A. listed, F.M. approved for general service, these switches are suitable for most applications in air conditioning and industrial service. Electrical

capability of 15 amps handles most small electrical loads.

Environmental (MIL) Construction. Unlisted Model 1635

can be furnished with special snap switch and silicone rubber diaphragm for high humidity and/or for government

applications. Similar to standard Model 1638 except dead

band is slightly greater. Specify Model No. 1635 (range No.)

MIL in ordering. Example: 1635-5-MIL.

HOUSINGS FOR USE WITH MODEL 1638 SWITCH

(also suitable for Models 1626, 1627 and 1640 switches)

Weatherproof Housing

16 ga. steel enclosure for

unusually wet or oily conditions. Withstands 200

hour salt spray test.

Gasketed cover. Weight,

20 lbs. Switch must be

installed at factory.

Specify “WP” in addition

to switch catalog.

Explosion-proof Housing

Killark cast alum. housing No. 4GRH with dome for No. 1638 switches and No.

GRH with flat cover for No. 1626 and 1627 switches rated for Class I, Group D;

Class II, Groups E, F and G and Class III. Approximate weight, 47 lbs. Specify

“EXPL” in addition to switch catalog number.

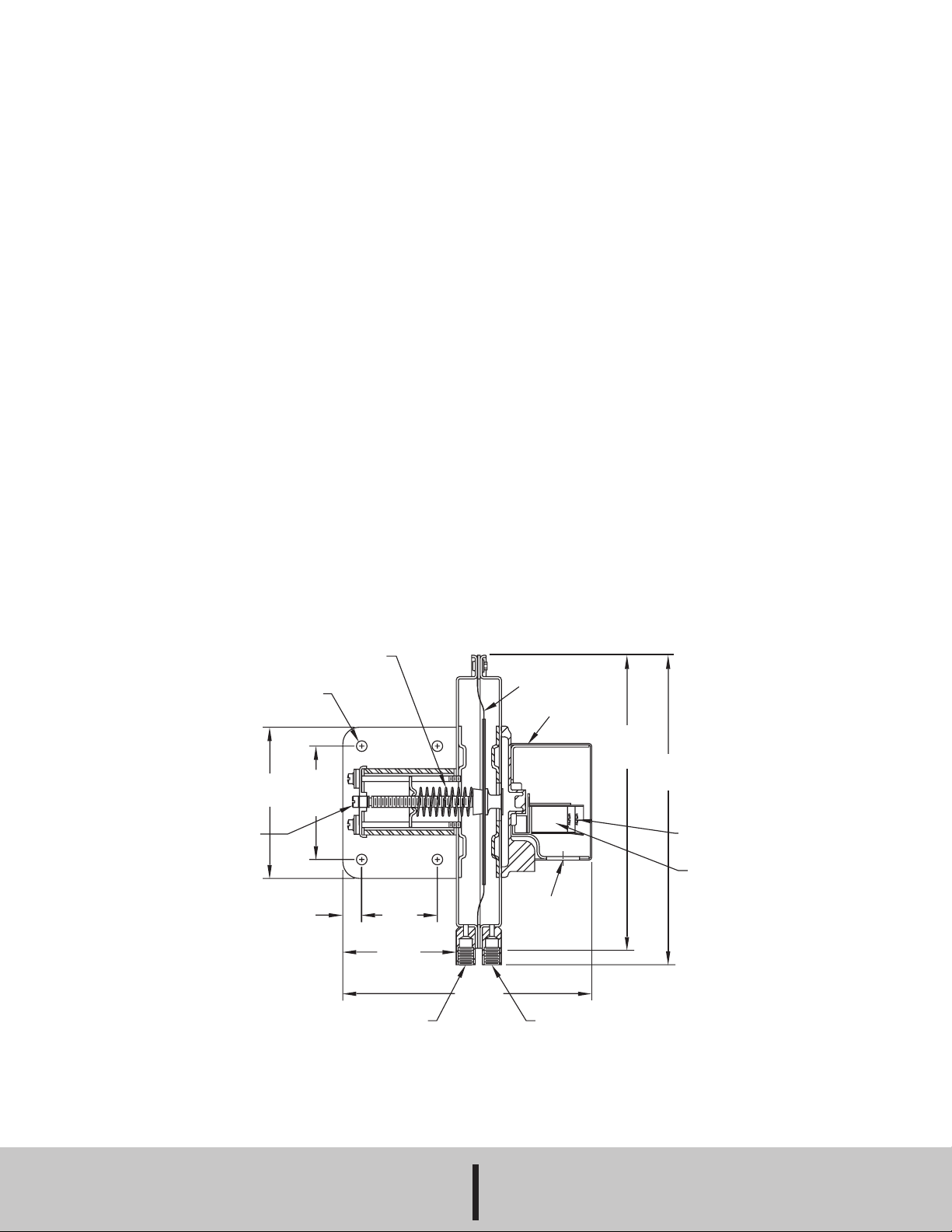

13-5/8

[346.08]

12

TYP

[304.80]

TYP

11

[279.4]

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361 U.S.A.

10-3/4

[273.05]

TYP

12

[304.80]

Ø3/8 [9.53]

MOUNTING HOLES TYPE 4 PLACES

1/8 NPT HIGH

PRESSURE

CONNECTION

BREATHER

1/8 NPT LOW

PRESSURE

CONNECTION

3/4

[19.05]

TYP

[88.90]

[298.45]

3-1/2

11-3/4

3/4 NPT

ELECTRICAL

CONNECTION

2-1/8

[53.98]

3/4

[19.05]

TYP

6

[152.40]

Bulletin E-52

PHYSICAL DATA

Temperature Limits: -30°F (-34.4°C) for dry air or gas to 110°F

(43.3°C). (Consult factory for higher temperature applications.)

Maximum Surge Pressure: 25 psig.

Rated Pressure: 10 psig.

Pressure Connections:

Electrical Rating: 15 amps, 120-480 volts, 60 Hz. A.C.

Resistive

1

/8H.P. @ 125 volts, 1/4 H.P. @ 250 volts, 60 Hz. A.C.

1

/8″ NPT(F).

Wiring Connections: 3 screw type, common, normally open

and normally closed.

Set Point Adjustment: Screw type with enclosed scale.

Housing: 16 ga. steel, zinc plated, dichromate dipped for 200

hour salt spray test.

Diaphragm: Silicone rubber.

Calibration Spring: Stainless steel.

Weight: 4 lbs., 14 oz. (2.21 kg).

Installation: Diaphragm vertical.

MODEL 1638:

Operating Ranges, Dead Bands and Ratings.

U.L. and C.S.A. Listed, F.M. Approved.

Approximate

Dead Band

At Min.

Set Point

0.04

0.04

0.06

0.07

0.11

At Max.

Set Point

0.05

0.06

0.08

0.25

0.30

Model

Number

1638-0

1638-1

1638-2

1638-5

1638-10

Operating

Range

Inches,

W.C.

0.05 to 0.25

0.20 to 1.0

1.0 to 3.0

2.0 to 6.0

3.0 to 12

Suggested Specification

Differential pressure switches shall be diaphragm operated

to actuate a single pole double throw snap switch. Motion

of the diaphragm shall be restrained by a calibrated spring

that can be adjusted to set the exact pressure differ ential at

which the electrical switch will be actuated. Motion of the

diaphragm shall be transmitted to the switch button by

means of a direct mechanical linkage. Set point adjustment

shall be screw type with set point indicated on a visual

scale. Switches shall be Dwyer Instruments, Inc. Catalog

No. 1638-_____ for the required operating ranges.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-by-Fax: 888/891-4963

Page 2

INSTALLATION

1. Select a location free from excessive vibration where oil

or water will not drip on the switch and where ambient temperature will be within a range of -30°F (-34.4°C) (dry air or

gas) to 110°F (43.3°C). See special housing for unusual

requirements and MIL option for high humidity.

Bulletin E-52

Page 2

ment screw, counter-clockwise to increase the pressure

setting or clockwise to decrease the setting. Note that the

indicated calibration is correct only if the switch is mounted

with the diaphragm assembly in a vertical plane. If mounted

in any other position, the switch must be recalibrated as follows:

2. MOUNT THE SWITCH WITH THE DIAPHRAGM IN A

VERTICAL PLANE. The switch is position sensitive so it

must be recalibrated for each change in operating position.

3. Connect switch to source of air pressure differential.

Metal tubing with 1/4″ O.D. is recommended, but any tubing system which will not restrict the air flow is satisfactory.

4. Electrical connections for all switches are marked

Common, Normally Open and Normally Closed. Be certain

connections are properly made and that no mechanical load

can be transferred from the wiring to the snap switch.

ADJUSTMENT AND CALIBRATION

1. The calibration or actuation point of the switch is indicated on the scale secured to the transparent range spring

enclosure. Recalibration to another setting within the range

of the switch is readily accomplished by turning the adjust-

a. Using a “T” assembly with three rubber tubing leads, all

as short as possible and offering minimum flow resistance,

run one lead to the pressure switch and the second lead to

a manometer of appropriate range and known accuracy.

Apply pressure through the third tube, preferably by successively pinching the tube tight with the fingers. Pinch off

the tube and make the final approach to the set point slowly. Check the set point by listening for the click of the switch

or by using a volt meter.

b. Note that the manometer and pressure switch will have

different response characteristics due to their different internal volumes, lengths of tubing, fluid drainage, etc. Be certain that the switch is checked in the position it will assume

in use, or preferably, that it is installed in its final location and

then checked. When pressure reading has been established, replace scale to proper position, relating set point

indicator to markings on scale.

Ø9/32 [7.14]

MOUNTING HOLE

TYP 4 PLACES

ADJUSTMENT

SCREW

4

[101.60]

[12.70]

ADJUSTABLE

RANGE SPRING

3

[76.20]

TYP

1/2

TYP.

1/8 NPT(F) LOW

PRESSURE CONNECTION

2

[50.80]

TYP

3

[76.20]

DIAPHRAGM

CONDUIT

ENCLOSURE

Ø7-3/4

[196.85]

8-3/16

[207.96]

SCREW TYPE

ELECTRICAL

TERMINALS

TYP 3 PLACES

SPDT SNAP

SWITCH

1/2

CONDUIT

CONNECTION

6-1/2

[165.10]

1/8 NPT(F) HIGH

PRESSURE CONNECTION

©Copyright 2001 Dwyer Instruments, Inc. Printed in U.S.A. 1/01 FR# 23-440200-00 Rev.1

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000 www.dwyer-inst.com

Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Lit-by-Fax: 888/891-4963

Loading...

Loading...