Page 1

Series 160S “S” Type Pitot Tubes

Operating Instructions

Bulletin H-12

Series 160S Pitot Tubes are designed to meet the need

of the environmental testing field for an inexpensive, yet

accurate and reliable way to measure the flow of particulate-laden air or gas streams. These pitot tubes use large

5/16˝ diameter stainless steel tubing for both total and static pressures to avoid plugging. Versatile 1/8˝ female NPT

connections enable use with any type of piping or tubing.

Two barbed tubing adapters are included for use with 3/16˝

I.D. rubber or vinyl tubing.

This instrument was built to allow measurement of flows by

the procedures detailed in U.S. Environmental Protection

Agency publication 40 CFR Change 1, Application A,

Method 2. For complete information, refer to that publication and the procedures contained within.

INTRODUCTION

The total pressure of a flowing air stream in a duct or pipe

is the sum of the static or bursting pressure exerted on the

sidewalls and the velocity or impact pressure of the moving air. The difference between total and static pressure is

called velocity pressure, which can be used to determine

the linear rate of air movement expressed in FPM (feet per

minute). A pitot tube has two tubes arranged to sense both

pressures simultaneously. By connecting these two tubes

differentially to a manometer, velocity pressure is indicat-

ed directly and the corresponding air velocity can be calculated after applying the appropriate correction factor.

For maximum accuracy of ±2%, as in laboratory applications, care is required and the following recommendations

should be followed.

1. Duct diameter should be 4˝ or larger.

2. Point total pressure opening upstream facing flow

and static pressure opening downstream pointing in

the direction of the flow. The faces of both openings

must be perpendicular to the airflow.

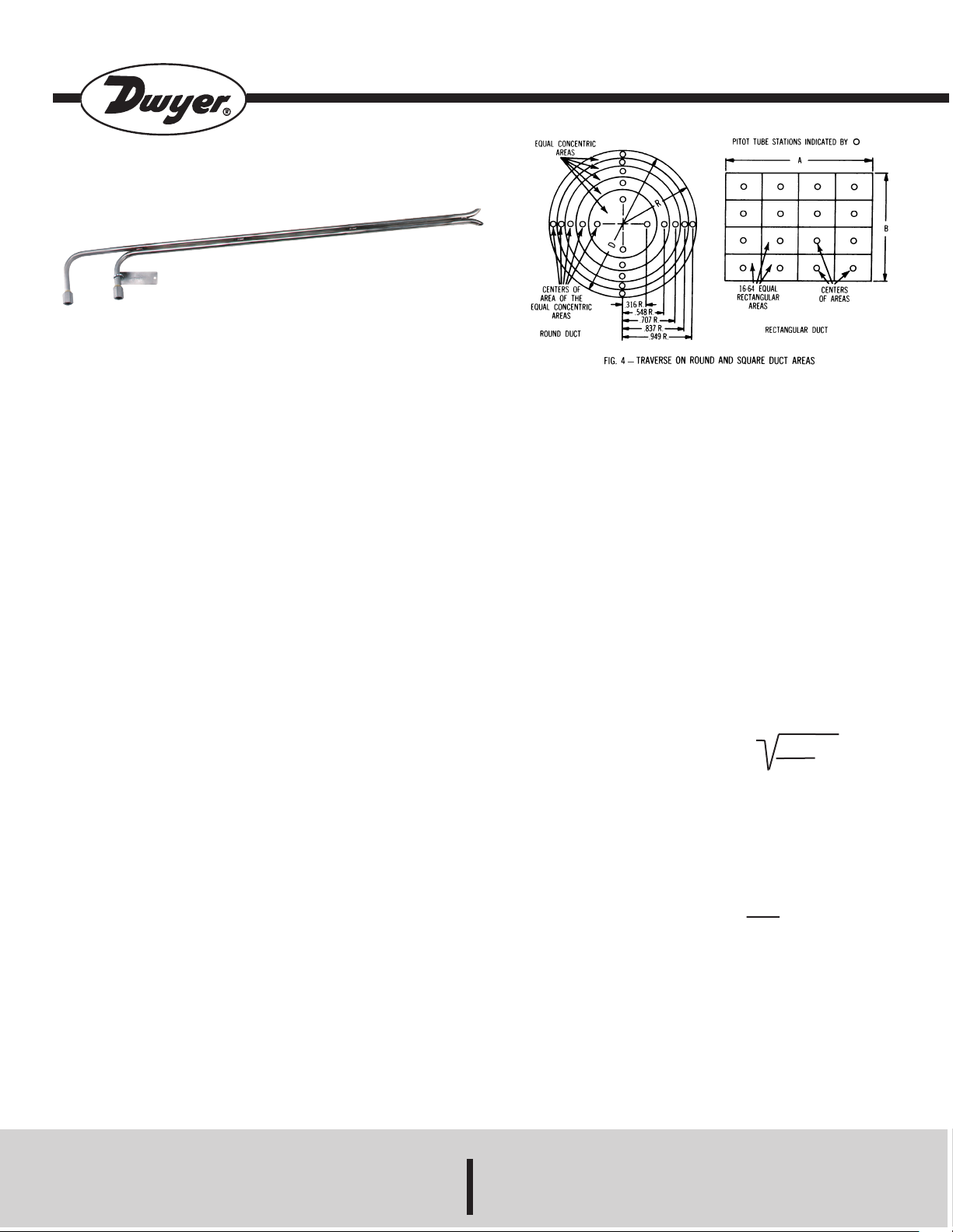

3. Make an accurate traverse per drawings; calculate the

the velocities at each point and average them.

4. Take readings in a smooth, straight duct section a

minimum of 82 duct diameters in length upstream

and 12 diameters downstream from the pitot tube.

5. Provide an egg-crate type straightener upstream from

the pitot tube.

TAKING AIR VELOCITY READINGS

To measure air velocity with a Series 160S Pitot Tube, make

a 13/16˝ (20 mm) opening in side of duct. Permanentmount models require a 1˝ female NPT opening. Note: permanent mounting is not recommended with insertion

lengths over 24˝ (61 cm) due to risk of excessive deflection.

Connect tubing from total pressure port to high pressure

side of manometer and from static pressure port to the low

pressure side. If reading is negative, reverse connections.

Make a series of readings traversing the duct in horizontal

and vertical planes. Using velocity pressures recorded at

each location, calculate velocities and average them for

final velocity value. If circumstances do not permit or

require an accurate traverse, center the pitot tube in the

duct, determine the pressure differential (velocity pressure),

calculate actual center velocity, and multiply this value by

0.9. Tests run in this manner should be accurate within

±5%.

CALCULATING VELOCITY

Air Velocity = 1096.2 (Cp) P

where:

P

= Sensed pressure difference (velocity

v

pressure) in inches of water column

D = Air density in lbs./ft.3(dry air = .075)

Cp = Pitot tube coefficient: 0.84

Air Density = 1.325 X

PB = Barometric pressure in inches of

mercury

T= Absolute Temperature (Indicated

Temperature in °F plus 460)

Flow in cubic feet per minute equals duct cross sectional

area in square feet x air velocity in feet per minute.

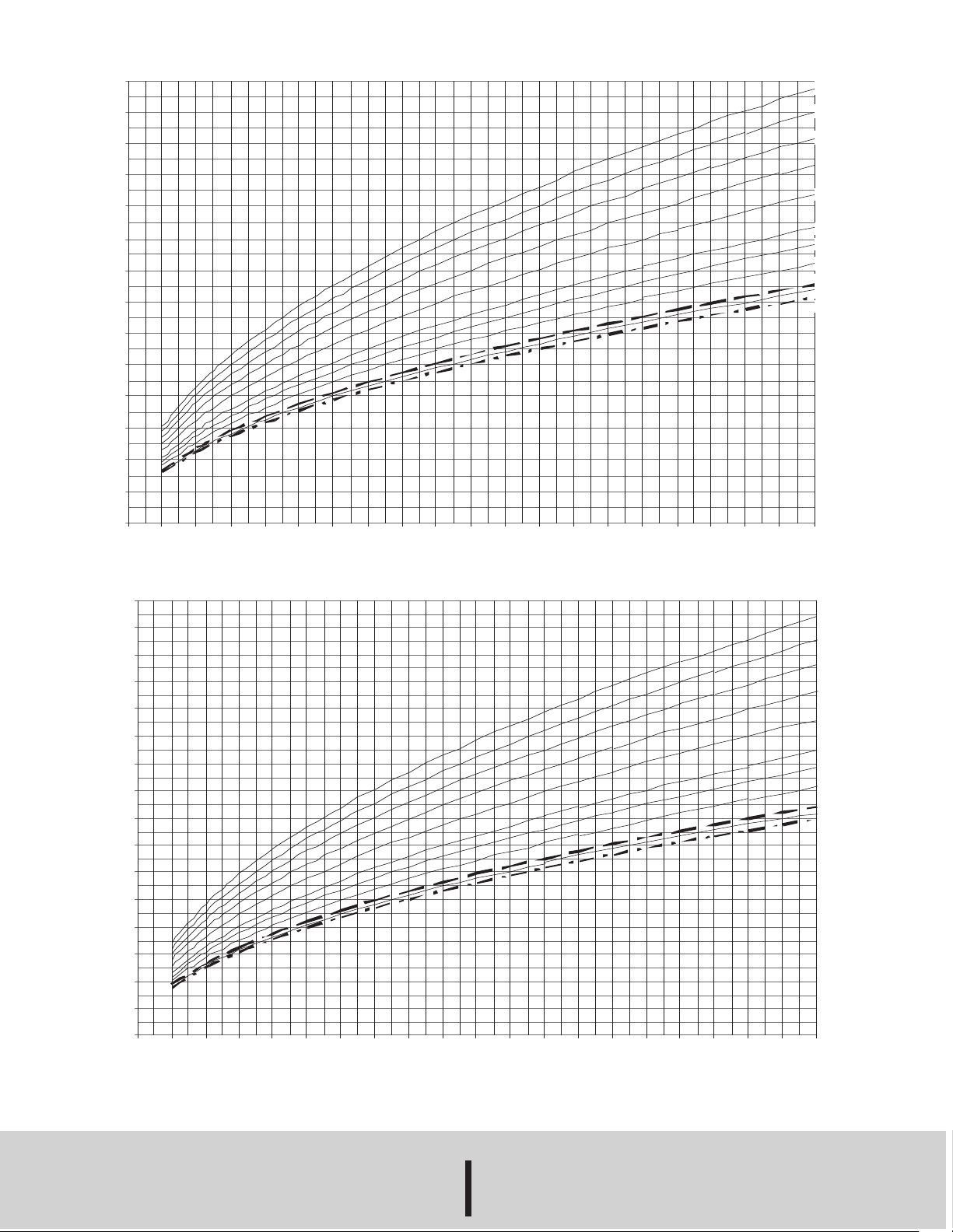

With dry air at 29.9 inches of mercury, air velocity can

be read directly from temperature correction charts on

reverse.

P

v

D

B

T

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

70ºF

40ºF

100ºF

200ºF

300ºF

400ºF

600ºF

800ºF

1000ºF

1200ºF

1400ºF

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

10,000

11,000

12,000

13,000

14,000

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0

GAGE READING WITH 160S PITOT TUBE (VELOCITY PRESSURE) IN INCHES OF WATER

AIR VELOCITY IN FEET PER MINUTE

1400ºF

1200ºF

1000ºF

800ºF

600ºF

400ºF

300ºF

200ºF

100ºF

40ºF

70ºF

0

200

400

600

800

1,000

1,200

1,400

1,600

1,800

2,000

2,200

2,400

2,600

2,800

3,000

3,200

0.00 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.16 0.17 0.18 0.19 0.20

GAGE READING WITH 160S PITOT TUBE (VELOCITY PRESSURE) IN INCHES OF WATER

AIR VELOCITY IN FEET PER MINUTE

©Copyright 2003 Dwyer Instruments, Inc. Printed in U.S.A. 9/03 FR# 72-440778-00 Rev. 5

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...