Page 1

Series 160 Stainless Steel Pitot Tubes

Specifications - Installation and Operating Instructions

Bulletin H-11

The total pressure of an air stream flowing in a duct is the sum of

the static or bursting pressure exerted upon the sidewalls of the

duct and the impact or velocity pressure of the moving air. Through

the use of a pitot tube connected differentially to a manometer, the

velocity pressure alone is indicated and the corresponding air

velocity determined.

For accuracy of plus or minus 2%, as in laboratory applications,

extreme care is required and the following precautions should be

observed:

1. Duct diameter to be 30 times pitot tube diameter, or

greater.

2. Make an accurate traverse per sketch at

right, calculate the velocities and average

the readings.

3. Provide smooth, straight duct sections

a minimum of 8 1/2 diameters in length

upstream and 1 1/2 diameters downstream from the pitot tube.

4. Provide an egg crate type straightener

upstream from the pitot tube.

In making an air velocity check select a location as suggested

above, connect tubing leads from both pitot tube connections to

the manometer and insert in the duct with the tip directed into the

air stream. If the manometer shows a minus indication reverse the

tubes. With a direct reading manometer, air velocities will now be

shown in feet per minute. In other types, the manometer will read

velocity pressure in inches of water and the corresponding velocity

will be found from the curves in this bulletin. If circumstances do

not permit an accurate traverse, center the pitot tube in the duct,

determine the center velocity and multiply by a factor of .9 for the

approximate average velocity. Field tests run in this manner should

be accurate within plus or minus 5%.

The velocity indicated is for dry air at 70°F., 29.9˝ Barometric

Pressure and a resulting density of .075#/cu. ft. For air at a

temperature other than 70°F. refer to the curves in this bulletin. For

other variations from these conditions, corrections may be based

upon the following data:

Air Velocity = 1096.2

√

Pv

D

where Pv = velocity pressure in inches of water

D = Air density in #/cu. ft.

B

Air Density = 1.325 x

P

T

where P

B

= Barometric Pressure in inches of mercury

T = Absolute Temperature (indicated temperature °F plus 460)

Flow in cu. ft. per min. = Duct area in square feet x air velocity in

ft. per min.

AIR VELOCITY

CALCULATOR

Computes velocity based on

air density corrected for

conditions of temperature and

pressure. Eliminates tedious

calculations. Ranges from .01

to 10˝ water corresponding to

400 to 20,000 FPM.

Furnished with each pitot

tube.

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

STAINLESS STEEL PITOT

TUBES

Test confirmed unity coefficient

and lifetime construction of No.

304 stainless steel. Inch

graduations show depth of

insertion for traversing. Model 160

is designed to meet ASME “Fluid

Meters” 6th Ed, ANSI/AMCA 21099, ANSI/ASHRAE 51-1999, and

British Standard 1042. Sizes 12˝

to 60˝ long. Hand or fixed

mounting types.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Page 2

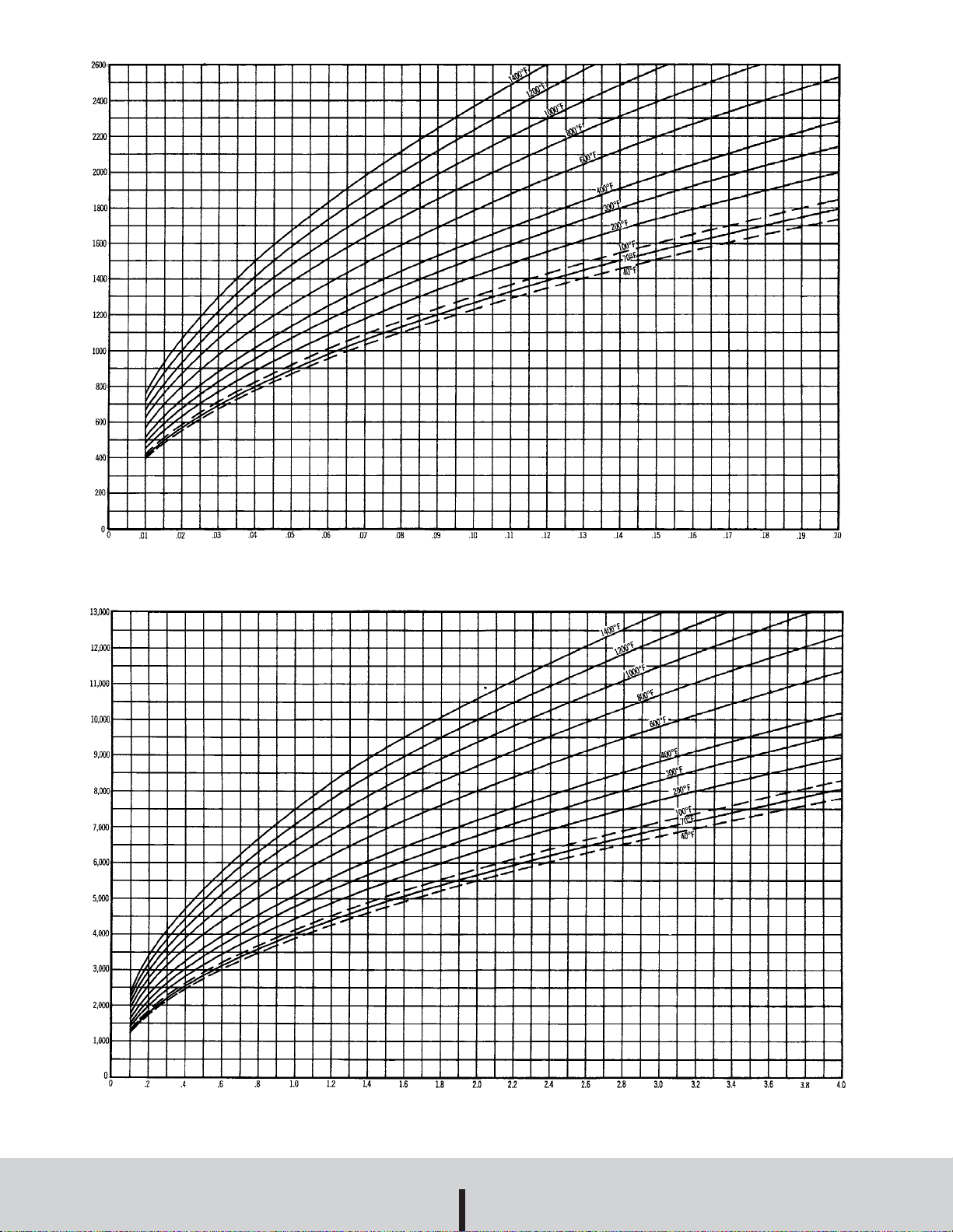

AIR VELOCITY IN FEET PER MINUTE

GAGE READING WITH PITOT TUBE (VELOCITY PRESSURE) IN INCHES OF WATER

AIR VELOCITY IN FEET PER MINUTE

GAGE READING WITH PITOT TUBE (VELOCITY PRESSURE) IN INCHES OF WATER

©Copyright 2005 Dwyer Instruments, Inc. Printed in U.S.A.8/05 FR# 440226-00 Rev. 8

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Loading...

Loading...