Page 1

Flex-Tube®Manometer

Installation & Operating Instructions

1220/1230 Series

U-Tube and Well-Type Manometers

Pressure

Bulletin D-21

Vacuum

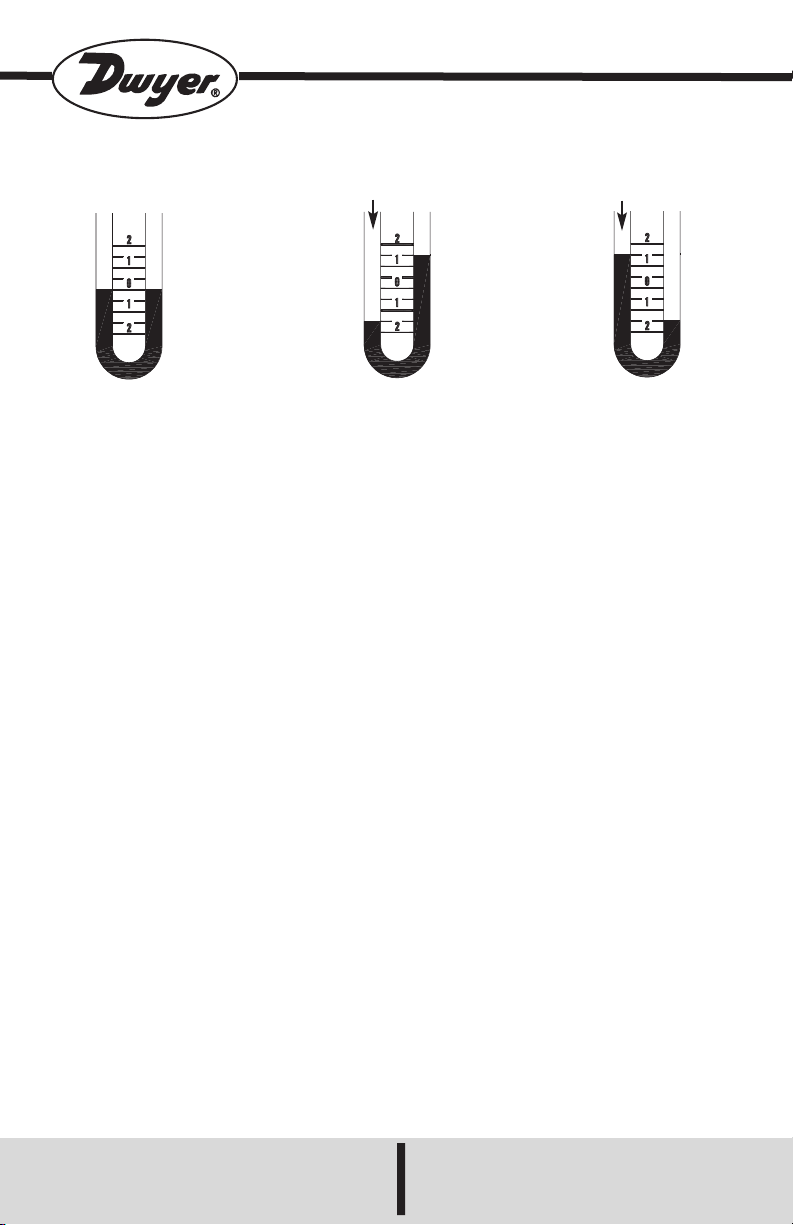

Fig. 1

With both ends of the tube open,

the liquid is at the same height in

each leg.

The difference in height, “h”, which

is the sum of the readings above

and below zero, indicates

pressure.

Measuring Pressure, Vacuum and Differential

Pressure with Dwyer®Manometers

Dwyer manometers are available in two different

styles. The W/M models use either water for

readings in inches of water or mercury for

readings in inches of mercury. The D models use

Dwyer .826 specific gravity red gage fluid for

readings in inches of water. The scales on the

two styles have different lengths, so it is

important to use the correct fluid.

Mounting Dwyer U-Tube Manometers

1221 - Mount to a vertical surface through holes

in the scale.

1222 - Attach magnets to steel surface or

remove magnets and mount through holes in

scale.

1223 - Attach magnets to steel surface or

through the hole in safety trap housing.

Fig. 2

The difference in height, “h”, which

is the sum of the readings above

and below zero, indicates the

amount of vacuum.

Fig. 3

1227 - Because of angled connections, 1227

must be filled with indicating tube at an angle.

After filling, check zero in vertical position. Clean

all fluid from the exterior of the unit to prevent

cracking of the backplate.

Note: Read vertical range on the right leg with

the manometer vertical. Incline the manometer

to zero for low range reading.

Mounting Dwyer Well Manometers

1230 - Mount to a vertical surface with flat-head

screws through the holes in the scale.

1235 - Mount behind panel cutout to show only

the tube and scale. Attach by drilling holes

through the manometer’s back-plate and

panels. Make the panel cutout for the length and

width of the tube and scale.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, IN 46360, U.S.A. Fax: 219/872-9057

Phone: 219/879-8000 www.dwyer-inst.com

e-mail: info@dwyer-inst.com

Page 2

Filling U-Tube Manometers 1221 - 1222

Open both fittings to atmosphere. Slide scale to

mid-point of travel. Add liquid to zero on scale.

Clean all fluid from the exterior of the unit to

prevent cracking of the backplate.

Filling 1223 - 1230 and 1235 Manometers

Remove large fitting from well using a 3/4˝ openend wrench. Also remove cork, disc, and O-ring.

Be sure the other side is vented to atmosphere.

Adjust zero to middle of travel. Add fluid to well

up to the zero on scale. Replace cork, disc, and

O-ring before replacing fitting. Clean all fluid

from the exterior of the unit to prevent cracking

of the backplate on 1223 models. To order red

gage fluid, order part # A-101 (1 oz). To order

fluorescein green color concentrate, order part #

A-126 (1 oz).

Operation of 1221, 1222 and 1223

Manometers

Connect either side to pressure or vacuum,

leaving the other side open to atmosphere. Add

together the readings above and below zero.

It is normal for the two sides to have different

readings and has no effect on accuracy. For

differential pressure, connect both the high and

low fittings. Add the readings above and below

zero on the scale.

Operation of 1230 and1235 Manometers

Positive Pressure: Connect the well reservoir

fitting to the pressure source, leaving the other

side open to atmosphere.

Negative Pressure: Connect the top fitting to

vacuum source, leaving well side open to

atmosphere.

Differential Pressure: Connect higher pressure

to well reservoir fitting and lower pressure to

upper fitting.

Note: When finished, close fitting to prevent

spilling or evaporation.

Maintenance

With proper care, Dwyer Flex-Tube

Manometers will continue to give accurate

readings. If cleaning is needed, remove fittings,

drain fluid, and rinse with mild soap and water. A

cleaning brush (part #A-366) may be used to

remove oxidation.

Avoid harsh soaps and solvents which may

damage manometer and void warranty.

When replacing O-rings, apply a thin coat of

petroleum jelly to assure a good seal. Do not

coat O-ring used in the overpressure safety trap.

®

Avoid using fluids other than those specified.

Corrosive fluids may damage the manometer.

If return is needed contact customer service to

receive a return goods authorization number

before shipping.

©Copyright 2013 Dwyer Instruments, Inc Printed in U.S.A. 5/13 FR# 44-440475-00 Rev. 7

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, IN 46360, U.S.A. Fax: 219/872-9057

Phone: 219/879-8000 www.dwyer-inst.com

e-mail: info@dwyer-inst.com

Loading...

Loading...