Page 1

Slack Tube®Manometers

Instructions and Operation

Slack Tube®Manometer rolled up for easy handling

and storage.

®

Dwyer

Slack Tube®Manometers are as accurate

as the finest laboratory “U” gages - yet they are

made to roll up compactly for easy carrying and to

withstand rough usage.

Simply unroll the Dwyer® Slack Tube®Manometer

and set up to read static pressure, vacuum, or

differential pressure. Magnetic clips hold it firmly to

any steel surface or hang it on a nail. Turn

connectors one revolution to open. When the

pressure is imposed, add the number of inches one

column travels up to the number of inches the other

column travels down. When reading is completed

turn connectors to seal columns, roll up

manometer into compact coil and tuck it away in its

circular metal case or a tool box. No fluid lost. No

loose caps or inserts to lose.

Dwyer® Slack Tube®Manometers cover a wide

range of pressure readings from 4-0-4 inches up to

60-0-60 inches. Use them in determining velocity

and static pressures, for leakage, fan and blower

tests, calibrating control devices, checking gas

pressure and many other applications.

Bulletin D-20

All models have flexible vinyl-plastic columns

and flexible spring steel scale calibrated in

inches of water using water, and inches of

mercury using mercury. Scale is centermounted between columns to eliminate parallax

error and has a full 2-inch sliding zero

adjustment.

All Dwyer® Slack Tube®Manometers feature

exclusive molded nylon tubing connector

assemblies with rapid shutoff design in an

unbreakable molded top (see picture, page 2).

One turn counter clockwise and the instrument

is ready for use. Another turn seals the tubes

completely. Molded all-nylon construction

makes this assembly corrosion-proof leakproof

and practically unbreakable. Tubing connectors

extend horizontally allowing 360° freedom.

Tubes will not bend or pinch off.

All models have over pressure safety traps in

the top of both columns to prevent loss of fluid

due to over range pressures or surges in

pressure.

Slack Tube®Manometers are suitable for total

pressures to 50 psi and vacuum not exceeding

20˝ Hg. (10˝ Hg absolute). Can not be used with

0.826 sp. gr. red gage fluid; use only water or

mercury.

STANDARD ACCESSORIES

Standard Accessories are metal carrying case,

magnetic mounting clips, two rapid shutoff type

molding nylon rubber tubing connectors and one

bottle of fluorescein green color concentrate

with wetting agent. Mercury is not included but

will be furnished at added cost when specified.

OPTIONAL ACCESSORIES

Optional Accessories are available in a wide

range and are in misc. section.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Phone: 219/879-8000 www.dwyer-inst.com

Page 2

FILLING

Using 1 quart distilled water, add 1 oz bottle of A126 Fluorescein green color concentrate.

Remove a tubing connector from the manometer

and pour fluid in to mid-point level. Shake to

remove air bubbles and slide scale so zero mark

is in line with the meniscus of the two fluid

columns.

For readings in inches of mercury, fill with 13.6

sp. gr. triple distilled mercury. When used with

mercury, some discoloration of the vinyl tubing

will normally occur.

READING

Connect the manometer to the source of

pressure, vacuum or differential pressure. When

the pressure is imposed add the number of

inches one column travels up to the amount the

other column travels down to obtain the pressure

reading. If the reading is desired in other units

the conversion chart may be used.

Should one column travel further than the other

column, due to minor variations in the tube I.D. or

to pressure imposed, the accuracy of the

pressure reading thus obtained is not impaired.

The U-tube manometer is a primary measuring

device indicating pressure by the difference in

the height of two columns of fluid. The fact that

one column travels further than the other does

not affect the accuracy of the reading.

CLEANING

Cleaning can best be accomplished with a little

pure soap and water. Avoid liquid soaps and

solvents. Flush thoroughly with clear water to

remove all soap. Dry completely before refilling

with mercury.

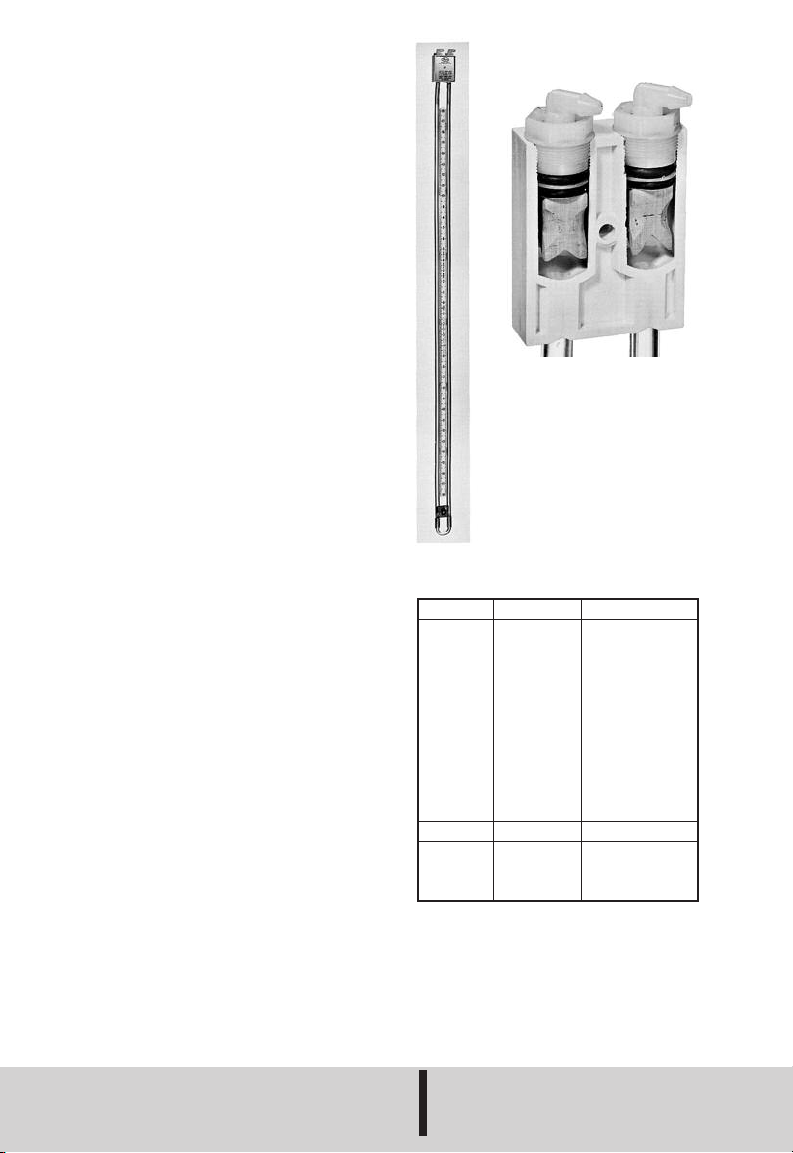

Slack Tube®Manometer extended

with cross-sectional view of molded

unbreakable Acrylic plastic top,

connectors and over pressure traps.

OPERATING RANGES

Model

1211-8

1211-12

1211-16

1211-24

1211-30

1211-36

1211-48

1211-60

1211-72

1211-120

Metric

1211-50

1211-100

1211-200

Range, In.

4-0-4

6-0-6

8-0-8

12-0-12

15-0-15

18-0-18

24-0-24

30-0-30

36-0-36

60-0-60

Range,CM

25-0-25

50-0-50

100-0-100

Hg Req’d (oz.)

6

7

9

12-1/2

15

17-1/2

22-1/2

27

32

57

Hg Req'd (oz.)

11

18-1⁄2

35

Page 3

Manometros Enrollables

Instrucciones de Montaje y Operación

Manometros enrollables para fácil manejo y

almacenaje.

Bulletin D-20

Todas los modelos, tienen columnas de plasticovinyl flexible y escala en metal calibrada en

pulgadas de agua usando agua, y pulgadas de

mercurio usando mercurio. La escala esta

montada en el centro de las dos columnas para

eliminar el hacer lecturas erróneas, y tiene

ajuste a cero.

Todos los manometros Dwyer® Slack Tube

tienen conectores para tubo de nylon exclusive

de Dwyer® los cuales permiten desconectarios

rápidamente, una vuelta en sentido de las

manecillas del reloj y el instrumento esta listo

para usarse. Otra vuelta y quedan sellados los

tubos. Su construccion a base de nylon los hace

a prueba de corrosión, fugas y casi irrompibles.

Los conectores se extienden horizontalmente

para así poder girar 360°.

Los manometros enrollables “Slack Tube” de

Dwyer® son tan buenos como los mejores

manometros de laboratorio, y además están

hechos para enrollarse y transportarse

fácilmente, aun en uso rudo.

Simplemente desenrolla el manometro “Slack

Tube” de Dwyer® y prepárate para medir presión

estática, vacio o presión diferencial. Sus clips

magnéticos lo sostienen firmemente en cualquier

superficie acero, Abre sus conectores y cuando

se presente la presión, suma el numbero de

pulgadas que la otra columna baja. Cuando

termine de hacer sus lecturas, cierre los

conectores para sellar las columnas, enrolle

nuevamente su manometro y póngalo en su

estuche circular metálico o caja de herramientas.

No habrá derrame de liquido ni piezas que se

pierdan.

Los Manómetros Dwyer® Slack Tube cubren un

amplio rango de mediciones, desde 4-0-4

pulgadas, hasta 60-0-60 pulgadas. Úselos para

determinar velocidad y presiones estáticas, para

determinar velocidad y presiones estaticas, para

hacer pruebas de fugas, ventiladores y

quemadores, calibrar equipos de control y

revisar presiones de gas, asi como en muchas

otras aplicaciones.

Todos los modelos tienen trampas de seguridad

en la parte superior de cada columna para

prevenir perdidas de fluido debido a sobre

presiones.

Los manometros Slack Tube, se pueden usar

para presiones absolutas de hasta 50 psi y vacio

que no exceda 20˝ de mercurio. Estos

manometros no pueden usar fluido rojo 0.826 de

gravedad especifica, use únicamente agua o

mercurio.

Assesorios Incluidos: Estuche metálico, clips

magnéticos de montaje, dos conectores rápidos

para tubo de plástico y una botella de colrante

verde. El mercurio no esta incluido, pero se

puede suministrar con un cargo adicional.

Accesorios Opcionales: Están disponibles

gran variedad de accesorios.

Page 4

Llenado:

Usando 1 litro de agua destilada, agregue 1 oz.

del concentrado verde fluorescente (A-126).

Quite un conector del manometro y vierta el

liquido hasta el punto medio. Agite para quitar

las posibles burbujas y asegurese que el fluido

este en la marca de cero en las dos columnas.

Para mediciones en pulgadas de mercurio,

realice lo mismo pero con este liquido, puede

decolorarse un poco el equipo, esto es normal.

Lecturas:

Conecte el manometro a la fuente de presión

diferencial. Cuando surja la presión, sume el

numero de pulgadas que una columna sube al

numero de pulgadas que la otra baja, para asi

obtener la lectura de presión. Si la lectura se

requiere en otras unidades, se puede usar una

tabla de conversión.

Debe alguna columna avanzar mas que lo otra,

debido a pequeñas variaciones en el tubo

indicador, o a la presión suministrada, sin esto

empeorar la exactitud de la medición de la

lectura. El manometro tip “U” es un elemento

primario de medición de presión por diferencia

en la altura de dos columnas de fluido. El hecho

de que una columna avance mas que la otra, no

afecta la exactitud de la lectura.

Limpieza:

La limpieza se puede realizar acompañada de

agua y jabón. Evite solventes, enjuague bien con

agua para quitar todos los residuos de jabón.

Seque completamente antes de rellenar el

manometro con mercurio (Cuando se use este).

Slack Tube®Manometer extended

with cross-sectional view of molded

unbreakable Acrylic plastic top,

connectors and over pressure traps.

OPERATING RANGES

Model

1211-8

1211-12

1211-16

1211-24

1211-30

1211-36

1211-48

1211-60

1211-72

1211-120

Metric

1211-50

1211-100

1211-200

Range, In.

4-0-4

6-0-6

8-0-8

12-0-12

15-0-15

18-0-18

24-0-24

30-0-30

36-0-36

60-0-60

Range,CM

25-0-25

50-0-50

100-0-100

Hg Req’d (oz.)

6

7

9

12-1/2

15

17-1/2

22-1/2

27

32

57

Hg Req'd (oz.)

11

18-1⁄2

35

©Copyright 2013 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

Printed in U.S.A. 5/13 FR# 45-440214-00 Rev. 12

Phone: 219/879-8000 www.dwyer-inst.com

Loading...

Loading...