Page 1

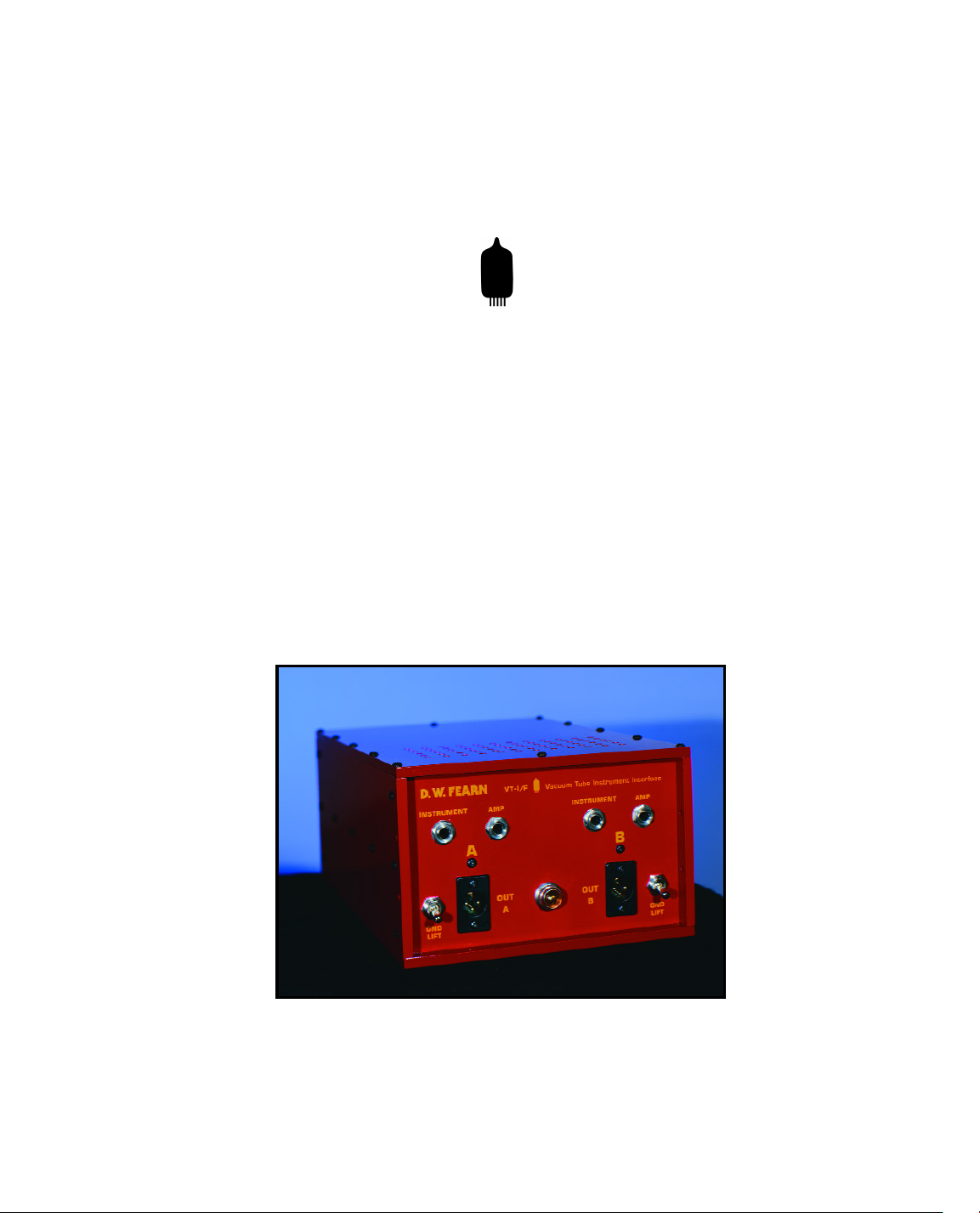

VT-I/F

Vacuum Tube

Instrument Interface

D.W

. FEARN

Operating Instructions

Page 2

How to Contact us:

Telephone: 610-793-2526

Fax: 610-793-1479

Mail: P.O. Box 57, Pocopson, PA 19366 U.S.A.

Shipping Address:

West Chester, PA 19382 U.S.A.

e-mail: dwfearn@dwfearn.com

World Wide Web: http://www.dwfearn.com

182 Bragg Hill Road

Page 3

Table of Contents

History of the VT-I/F .............................................................................. 7

Specifications.......................................................................................... 9

Description..............................................................................................11

Installation ..............................................................................................13

Operation ................................................................................................17

Theory.....................................................................................................21

Maintenance............................................................................................23

List of Illustrations

Rear Panel Controls and Connections ....................................................14

Front Panel Controls and Connections ...................................................15

Block Diagram........................................................................................21

Page 4

Notice

D.W. Fearn shall not be liable for technical or editorial errors or omissions in this manual, nor

for incidental or consequential damages resulting from the use of this material.

This instruction manual contains information protected by copyright. No part of this guide

may be photocopied or reproduced in any form without prior written consent from D.W. Fearn.

Copyright ©1995 D.W. Fearn & Associates

Page 5

LIMITED 5-YEAR WARRANTY

During the warranty period, D.W. Fearn will, at no additional charge, repair or replace defective parts

with new parts.

This warranty does not extend to any VT-I/F that has been damaged or rendered defective as a result

of accident, misuse, or abuse; by the use of parts not manufactured or supplied by D.W. Fearn; or by

unauthorized modification of the VT-I/F. Vacuum tubes are excluded from the 5-year warranty, but are

warranted for a period of 90 days.

Except as expressly set forth in this Warranty, D.W. Fearn makes no other warranties, express or

implied, including any implied warranty of merchantability and fitness for a particular purpose.

Page 6

History of the VT-I/F Vacuum Tube

Instrument Interface

As far back as I can remember, taking instruments “direct” has never sounded

very good to me. There always seemed to be a lack of dynamics, and a sterile qual-

ity to sounds recorded with a direct box (or DI).

Frankly, initially I was not very excited about designing the VT-I/F. I assumed

that the lifeless sound I was accustomed to was the nature of direct sounds.

Before beginning the design of the circuit, I spoke to a number of engineers,

producers, and musicians about what they felt was lacking in DI boxes. Almost

without exception, they all said, “It’s got to have tons of headroom.” How much

headroom was enough? I spoke to a number of instrument pickup manufacturers

and got an idea of the peak output level of a variety of instruments. These figures

were confirmed with an oscilloscope placed directly across the output of various

electric guitars, basses, pianos, synthesizers, etc.

7

The first design goal was to accommodate the full dynamic range of sources

likely to be connected to the VT-I/F. Secondly, the design had to be quiet. After

that, it was just a matter of designing it to have the type of performance and pack-

aging that audio professionals have come to expect from our VT-1/VT-2 Vacuum

Tube Microphone Preamplifiers.

The decision was made early on that the output of the VT-I/F would be at micro-

phone level. Although a line-level output is not difficult to design, it would

increase the cost. Besides, everyone has mic preamps available. Although the VT-

I/F will work with virtually any mic preamp, it was designed to complement the

VT-1/VT-2 series of preamps.

We tried the first prototype on a solid-body electric guitar, and compared the

sound to several other respected DI boxes. We were astonished at first listen! It

sounded very close to the sound of the guitar through a good vacuum tube amp.

This prototype was evaluated by a number of studio friends, who made some

useful suggestions. These suggestions were incorporated into the second proto-

type, and the VT-I/F design was complete. By the way, our evaluators were very,

very reluctant to return the prototype.

Page 7

8

I have seen how direct boxes can be abused in the studio environment, so the

VT-I/F was built to take rough treatment. The case is machined from solid quar-

ter-inch thick aluminum plate, and finished with a tough polyurethane aircraft fin-

ish.

Why does the VT-I/F sound so good? I’m not entirely sure, but I do know that

it provides the proper load to the instrument. This is vital for an unrestricted sound.

The frequency response is flat from 10 cps to 20 kc, with -3 dB points at 0.5 cps

and 90 kc. The VT-I/F circuit is very similar to the circuit of the VT-1/VT-2, with

a different input design. The output is identical to the VT-1/VT-2 but operates at a

lower level. The power supply is virtually identical to that used in the VT-1/VT-2.

The VT-I/F has been used on electric and acoustic (with a pickup) guitars, elec-

tric and acoustic (with a pickup) bass, electric pianos, synthesizers, samplers, etc.

and it sounds great on all of them. It will not overload on any instrument, although

when driven hard, the sound becomes fatter. It has enough gain, and it’s quiet

enough, for use with very low level instruments, like finger-picked acoustic gui-

tar.

The lifeless, restricted sound I thought was part of direct recording is gone. The

VT-I/F has depth, fullness, dynamics, and excitement while remaining quiet and

under control with any instrument.

Douglas W. Fearn

November 1994

VT-I/F Vacuum Tube Instrument Interface

D.W. FEARN

Page 8

Specifications

(with 200 mV input)

9

Input 200 mV nominal

Input Load

Impedance 1 megohm minimum

Minimum

Input Level 5 mV nominal

Maximum

Input Level 2.3 volts P-P for

Gain -10 dB

Frequency

Response +/- 0.2 dB 10 cps to 20 kc

THD + Noise <0.3% 20 cps to 20 kc

Intermodulation

Distortion <0.01% SMPTE

Noise minimum 90 dB below output

Output Transformer Balanced

Output Level -30 dBm nominal

Maximum

Output Level -12 dBm

unbalanced

1% THD

-3 dB @ 0.5 cps and 95 kc

(22 cps to 22 kc bandwidth)

(matches 150 ohm input)

Crosstalk maximum -90 dB @ 20 kc

Power

Requirements 100/120/220 VAC 50/60Hz

Dimensions 8”W x 5”H x 12”D

Weight 15 lbs (6.82 kg)

NOTE: Throughout this manual, frequency is specified in cps (cycles per second) and kc (kilocycles per second). These units correspond

to Hz and kHz. Specifications and price subject to change without notice.

D.W. FEARN

25W

(20.3cm x 12.7cm x 30.5cm)

VT-I/F Vacuum Tube Instrument Interface

Page 9

10

VT-I/F Vacuum Tube Instrument Interface

D.W. FEARN

Page 10

Description

The D.W. Fearn model VT-I/F Vacuum Tube Instrument Interface is designed to

provide recording professionals with a sonically superior method for recording

electric and electronic musical instruments by direct injection (DI). Any instru-

ment designed to operate into a “guitar amp” will work perfectly with the VT-I/F.

Typical instruments include: electric bass, electric guitar, electric piano, acoustic

instruments with a pickup (piano, acoustic guitar, electric violin, etc.), synthesiz-

ers, and samplers.

The VT-I/F is a two-channel device that provides the optimum load impedance

for these instruments. It is capable of quality reproduction of a wide range of

instrument levels. The unit does not have the limitations of passive transformer-

type DIs, and has greater headroom and warmth when compared to similar solid-

state devices.

11

It is designed to operate in the professional recording or performing environ-

ment. The output level is “hot” mic level (-30 dBm nominal). The output is trans-

former-balanced, using a custom transformer built for us by Jensen Transformers,

Inc., and is designed to match 150 ohm professional mic inputs. Top-quality parts

are used throughout. The case is machined from solid quarter-inch thick aluminum

plate for ruggedness and durability. Both the filament and plate power supplies are

fully regulated.

The VT-I/F is not mass-produced. Each one is hand-made and meticulously test-

ed before shipment to the customer.

D.W. FEARN

VT-I/F Vacuum Tube Instrument Interface

Page 11

Installation

The VT-I/F is carefully packed for shipment and should survive all but the most

brutal handling. If there is any damage, keep the shipping material for use during

any claim for damage with the shipper.

Included in the box:

1) The VT-I/F Instrument Interface

2) Line cord

3) This instruction manual

Mounting

The VT-I/F is designed to be placed on the floor, counter, or table-top. In most

cases, cooling will not be a problem, but avoid placing the unit where it is tightly

confined. Do not block the cooling holes on the top. Be sure that heavy carpeting

does not interfere with air circulation through the cooling holes on the bottom. The

VT-I/F runs cool, cooler, in fact, than many solid-state devices.

13

Rack mounting is possible if a shelf is provided. If the unit must be mounted in

a rack, be certain that there is adequate support for both the front and the back of

the unit. It is heavy and could be damaged if not securely bolted in place and prop-

erly supported.

Moderate electrical and magnetic fields in the vicinity of the VT-I/F should not

cause any degradation in noise performance, due to the well-shielded construction,

but proximity to devices with motors or large power transformers (i.e. tape

machines or power amps) should be avoided.

Although the vacuum tubes in the VT-I/F are selected for minimum micro-

phonic response, it is a good practice to avoid mounting locations that subject the

unit to very high sound or vibration levels.

Page 12

14

VT-I/F

Vacuum Tube Instrument Interface

ON

OFF

POWER

0.5A 100/120V

0.25A 220V

D.W. FEARN P.O. BOX 57 POCOPSON, PA 19366 U.S.A. 610-793-2526

D.W. FEARN

1

2

Figure 1. VT-I/F Rear Panel Connections and Controls

REAR P

ANEL CONNECTIONS (See Figure 1)

AC (Mains) Power (2)

The VT-I/F is designed to operate from 100, 120, or 220 volt, 50/60 Hz power.

The unit will be shipped wired for the voltage specified in the order, but may be

changed in the field if necessary. The ground pin of the power cord is internally

connected to the chassis. This configuration is standard in professional equipment

and is required by most electrical codes. If ground loop hum is detected, a careful

check of the studio grounding scheme is needed. The VT-I/F is less susceptible to

grounding problems than many studio devices.

The Fuse is a 3AG-type 1 amp for 100/120 VAC operation, and 0.5 amp for 220

volts.

The AC input connector (2) is used with the mating line cord (supplied). For 120

VAC operation, this cord is a Belden 17250 or equivalent.

VT-I/F Vacuum Tube Instrument Interface

D.W. FEARN

Page 13

D.W. FEARN

VT-I/F Vacuum Tube Instrument Interface

15

FRONT PANEL CONNECTIONS (See Figure 2)

The VT-I/F has two identical channels, labeled A and B. They may be used indi-

vidually or simultaneously. These instructions apply to either channel.

The musical instrument output connects to the VT-I/F INSTRUMENT input (2)

via a standard 1/4 inch single-conductor (monaural) phone jack. The input is

unbalanced. Since the input cables carry very low level audio, it is important that

well-shielded cables are used. There should be no additional connectors, patch

jacks, switches, etc. between the instrument and the VT-I/F inputs. It is important

to keep the input lines as short as possible. Avoid locating the VT-I/F where it will

be subjected to high sound levels or excessive vibration (such as on a drum riser).

If desired, the musical instrument may be simultaneously connected to the input

to an external instrument (guitar) amplifier. The AMP jack (1) is a 1/4” single-con-

ductor (monaural) phone jack wired directly in parallel with the INSTRUMENT

jack.

Figure 2. VT-I/F Front Panel Controls and Connections

D.W. FEARN

VT-I/F

Vacuum Tube Instrument Interface

INSTRUMENT

AMP

INSTRUMENT

AMP

A

B

OUT

A

OUT

B

GND

LIFT

GND

LIFT

1

2

3

4

5

Page 14

16

The OUTPUT connectors (4) are XLR-3 male wired according to AES standard:

pin 1 is ground (shield), pin 2 is “high” or “+,” and pin 3 is “low” or “-.” The out-

put is transformer-balanced. The output level is a nominal -30 dBm. This is some-

what higher in level than a typical microphone.

Grounding and Shields

A full discussion of proper studio wiring schemes is beyond the scope of this

manual, but, in general, the shield should be connected to pin 1 of the output con-

nector. The shield should be connected to ground at only one end; however,

although not recommended, the shields can often be connected at both ends with-

out a problem.

VT-I/F Vacuum Tube Instrument Interface

D.W. FEARN

Page 15

OPERA TION

17

REAR P

Power switch (1)

Primary power is applied to the VT-I/F circuits when the Power switch (1) is in

the up position. The amber pilot lamp (5) on the front panel indicates that the unit

is on. It takes about twenty seconds for the Interface to start working, but it is sug-

gested that you turn on the power at least five minutes prior to use. The tubes are

often noisy until all the internal elements reach a stable operating temperature.

FR

The only controls on the VT-I/F are the GND LIFT switches. These connect or

disconnect pin 1 of the OUTPUT connectors to the unit internal ground. In most

situations, the GND LIFT switch (3) will remain in the down (pin 1 to internal

ground) position. In some situations, particularly when an external instrument

amplifier is connected to the AMP jack, a ground loop may occur. This causes a

hum or buzz in the recording equipment. Placing the GND LIFT switch in the up

position may help alleviate this.

ANEL CONTROLS (see Figure 1, page 14)

ONT PANEL CONTROLS (see Figure 2, page 15)

The musical instrument is connected to the INSTRUMENT jack (2), an option-

al guitar amp is connected to the AMP jack (1), and the external preamp (VT-1/VT-

2 or other) is connected to the OUT jack (4).

HUMS AND BUZZES

Unfortunately, it is the nature of high-impedance, unbalanced instrument output

to be highly susceptible to hum and buzz. Some of this is often unavoidable — the

instrument pickup(s) are very sensitive to the omnipresent AC fields in our envi-

Page 16

VT-I/F Vacuum Tube Instrument Interface

D.W. FEARN

18

ronment. Experiment with the orientation of the instrument to minimize this

source of noise. Most guitar and bass players will do this automatically, but with

keyboards it may be necessary to rotate and/or move the instrument to find the qui-

etest spot.

Fluorescent lights and SCR dimmers are terrible electrical noise generators.

Turn off the fluorescents. If SCR dimmers must be used, they will generally pro-

duce the least noise in their full-on (brightest) position.

Another source of these hums and buzzes is ground loops caused by the inter-

connection of various AC (mains) powered equipment. A properly-wired studio

should not create a ground loop between the VT-I/F and the studio equipment, but

often a loop is formed when the VT-I/F is connected to an instrument and guitar

amp simultaneously. In this case, use the GND LIFT (3) switch to find the proper

IMPOR

TANT

When using the VT-I/F with the D.W. Fearn VT-1 or VT-2 Vacuum

Tube Microphone Preamplifier, the VT-1/VT-2 Input switch must

be in the -20 dB position (unless the instrument level is extremely

low). With other preamps, use the input pad and/or reduce trhe

gain of the preamp.

position for minimum noise. If the guitar amp has a “Ground” switch, experiment

with it as well. Be sure to try all combinations of all switches.

The VT-I/F and the guitar amp (if used) should be on the same electrical circuit

(same circuit breaker or fuse) as the studio equipment to minimize ground loop

potential.

Suggestions

You have chosen to use the VT-I/F because of the superior sound it provides. To

gain the maximum benefit from your investment, it is important that you hook up

the VT-I/F so that other factors do not adversely affect the sound quality.

Page 17

1. The VT-I/F must be located near the instrument. Ten feet of cable between

the instrument and the VT-I/F should be considered the maximum.

2. Use the best quality cables you can. We don’t believe you have to use eso-

teric wire, but do use good quality, well-shielded cables. The input cable

shielding is particularly important. The output cable should be a standard

balanced mic cable designed for use with low-Z microphones. Gold-contact

phone and XLR connectors are recommended.

3. There should be no additional cables, connectors, junction boxes, patch

jacks, punch blocks, etc. between the VT-I/F output and the VT-1/VT-2

Input.

4. The outputs of the VT-1/VT-2 should be fed directly to the recorder through

the shortest practical lengths of quality cables. Avoid additional cables, con-

nectors, junction boxes, punch blocks, or patch jacks. Use gold contact con-

nectors if possible. Do not go through the mixing console unless you

absolutely need its features for the track you are cutting.

19

D.W. FEARN

4. In general, for superior sound, we recommend recording directly to the

recorder with no processing (compression, equalization, gating, etc). Any

processing can be added in the mix, if necessary. You may find that far less

processing is required when using the VT-I/F. If processing is required while

recording the track, insert the processing device after the VT-1/VT-2 and

before the recorder.

5. Feeding the VT-I/F into the studio console will negate some of the benefits

of the VT-I/F. Use a premium-quality microphone preamplifier (such as our

VT-1/VT-2). Go through the console only if it is absolutely necessary.

VT-I/F Vacuum Tube Instrument Interface

Page 18

20

Page 19

THEORY OF OPERA TION

Figure 3. VT-I/F Block Diagram

Output Stage

The output tube is the second section of the 6072/12AY7. It is operated as a

cathode follower, capacitively-coupled to the custom output transformer. A resis-

From Instrument

To Guitar Amp

Mic Level Output

to Preamplifier

This circuit description refers to only one channel. Both channels are identical,

sharing only the power supply. (See Figure 3.)

Input section

The INSTRUMENT input jack is fed directly to the grid of the first amplifier

stage, a selected 6072 or selected 12AY7. The input impedance is very high (1

megohm) for proper loading of the musical instrument.

The first stage is capacitively-coupled to the grid of the output stage.

21

Page 20

22

tive network on the secondary of the transformer provides proper loading and

matching to the input of the external microphone preamplifier.

The GND LIFT switch disconnects pin 1 of the OUTPUT connector from the

internal ground when the switch is in the up position.

ower Supplies

P

Primary power from the AC mains is connected to the VT-I/F through a stan-

dard IEC power input connector. The Power switch energizes all power supplies.

A fuse, accessible on the rear panel, protects the VT-I/F.

The Pilot lamp is a type 1820 bulb, operated far below its rated voltage of 28.

The life of the bulb is lengthened, and the light output is more compatible with

other modern studio equipment.

The power transformer is custom made for the VT-I/F and has primary taps for

100, 120, or 220 volt operation. The VT-I/F may be rewired for different mains

voltages.

Filament supply

The power transformer output is rectified by a bridge rectifier and filtered

before being regulated to 12.0 volts by a three-terminal regulator. The negative

output of this supply is grounded. Although the tube filaments are rated for 12.6

volts, utilization of 12.0 volts has no effect on the operation of the VT-I/F.

B+ supply

Two separate regulated voltages are required for the plates of the VT-I/F. The

B+ is filtered with long-life, low-leakage computer-grade filter capacitors before

being regulated and extensively bypassed and decoupled. The negative side of the

supply is grounded.

VT-I/F Vacuum Tube Instrument Interface

D.W. FEARN

Page 21

MAINTENANCE

The VT-I/F is built with only the highest quality parts and will prove to be

extremely reliable. Vacuum tubes and electrolytic capacitors, however, have a

finite useful life and must be periodically replaced.

23

TOP C

head bolts must be removed.

V

used. This is the low-noise industrial version of the 12AY7.) There can be as much

as a 15 dB difference in noise level among an assortment of tubes, and the tube

used in the VT-I/F should be carefully chosen to maintain low noise. Selected low-

noise tubes are available from D. W. Fearn.

Catastrophic tube failure is rare with this type of device, but a gradual increase in

noise or distortion, or a reduction in headroom, should indicate the need for

replacement. It is recommended that you periodically perform a quick noise and

distortion check on the VT-I/F and compare the results to previous measurements.

OVER REMOVAL

Removing the top cover allows access to the vacuum tubes. Twelve 6-32 allen-

acuum Tubes

A single 12AY7 tube is used in each channel of the VT-I/F. (A 6072 may be

Tube life is difficult to predict, but it will probably be measured in years.

Tubes also sometimes develop a microphonic response — they will respond to

ambient noise and vibration. This can be an insidious problem since measurements

in a quiet room will indicate perfect performance. Gently tapping the tube shields

while listening to the output at a normal monitor level should reveal nothing more

than a slight “clank.” On a peak reading meter connected to the VT-I/F output, any

microphonic response above -55 dBm is excessive. Replacement is indicated

unless the VT-I/F always operates in a quiet and vibration-free environment.

D.W. FEARN

VT-I/F Vacuum Tube Instrument Interface

Page 22

24

Although you could purchase a batch of 12AY7s and select the quietest one(s),

it may be cost effective to buy a low-noise tube from the us. Current prices are

$35.00 for a selected low-noise 6072/12AY7. We test the tubes in a VT-I/F after a

burn-in period and grade them according to noise, microphonic response, and

other characteristics. A low-noise tube from us will meet the original VT-I/F spec-

ifications.

The base pins of vacuum tubes supplied by D.W. Fearn have been chemically

treated for low contact resistance and oxidation prevention. When handling these

tubes, care should be taken to avoid removing or contaminating the treatment. Use

a lint-free cloth or paper towel to avoid direct contact between any part of the tube

and your fingers.

Remember that vacuum tubes may be quite hot during operation. Protect your

fingers during tube replacement. The VT-I/F should be turned off before removing

tubes. Allow at least one minute for the filter capacitors to discharge before tube

removal or insertion.

Tubes are made of glass and will break if dropped or even bumped in a critical

area. Handle with care.

Electrolytic Capacitors

The VT-I/F is designed and built to last for a long, long time, and it is possible

that some components (e.g. electrolytic capacitors) may reach the end of their life

long before the equipment becomes obsolete. The electrolytic capacitors used in

the VT-I/F typically will last at least twenty years. If there is a measurable and/or

audible increase in 120 cps noise, the filter capacitors should be suspected. They

should be replaced with new capacitors of equivalent capacitance and voltage rat-

ing, and the replacements should be specified for a minimum ten-year service life.

Electrolytic capacitors are also used as plate and cathode decouplers. In choos-

ing a replacement, the same considerations as with the filter capacitors should be

followed.

VT-I/F Vacuum Tube Instrument Interface

D.W. FEARN

Page 23

TROUBLESHOOTING

Most problems will be traced to defective vacuum tubes. However, if normal

tests do not easily reveal the problem, feel free to call the factory for assistance. If

you lack access to a qualified service technician with vacuum tube equipment

repair experience, you may return the VT-I/F to the factory for repair. Call first,

however, for shipping information.

ARRANTY REPAIR

W

If the VT-I/F should develop a problem during the five-year warranty period,

call the factory for return shipping instructions. We will repair and return your VT-

I/F quickly. Note that the warranty does not cover vacuum tubes, which must be

periodically replaced.

25

D.W. FEARN

VT-I/F Vacuum Tube Instrument Interface

Loading...

Loading...