Dw Drums 8000 Series, 8000B Owner's Manual

Thank you for purchasing this DW pedal. It has been designed and

manufactured to provide a lifetime of trouble-free service. Please take a

moment to familiarize yourself with the exclusive features and

operating suggestions contained in this manual in order to ensure its

optimum performance. Should you have any further questions, feel free

to contact your local authorized DW dealer.

-Don Lombardi

President, Drum Workshop, Inc

DW Pedal 5-Year Limited Warranty

For a period of ve years from the date of purchase, Drum Workshop,

Inc. guarantees the original owner when presented with proof of

purchase, that all 8000 Series Pedal cast parts are free of material and

manufacturing defects. This warranty is limited to cast parts only such

as the base casting, footboard, beater hub, sprocket, heel and cam

casting. This warranty does not include moving parts such as the

spring assembly, beater ball, hex shaft, ball bearings, etc. Moving

parts have a six month warranty from the date of purchase. If under

normal playing conditions parts covered in the limited ve year

warranty fail, they will be replaced at no charge. Return the pedal to

your authorized DW dealer, or if there is not a dealer in your area,

contact DW directly. DO NOT send pedal to DW without rst receiving

a Return Authorization (RA) number. Shipping charges to DW will be

paid by the consumer.

OWNER’S MANUAL

8000 Series Bass Drum Pedals

DRUM WORKSHOP INC.

3450 Lunar Court - Oxnard, CA 93030 USA

www.dwdrums.com

www.dwdrums.com

to loosen the chemical lock holding these screws, you may rst need to heat them with a heat gun or hair dryer for 2-3 minutes.

Note: Some of the screws on the pedal have been treated with a chemical lock to prevent unwanted loosening during playing. In order

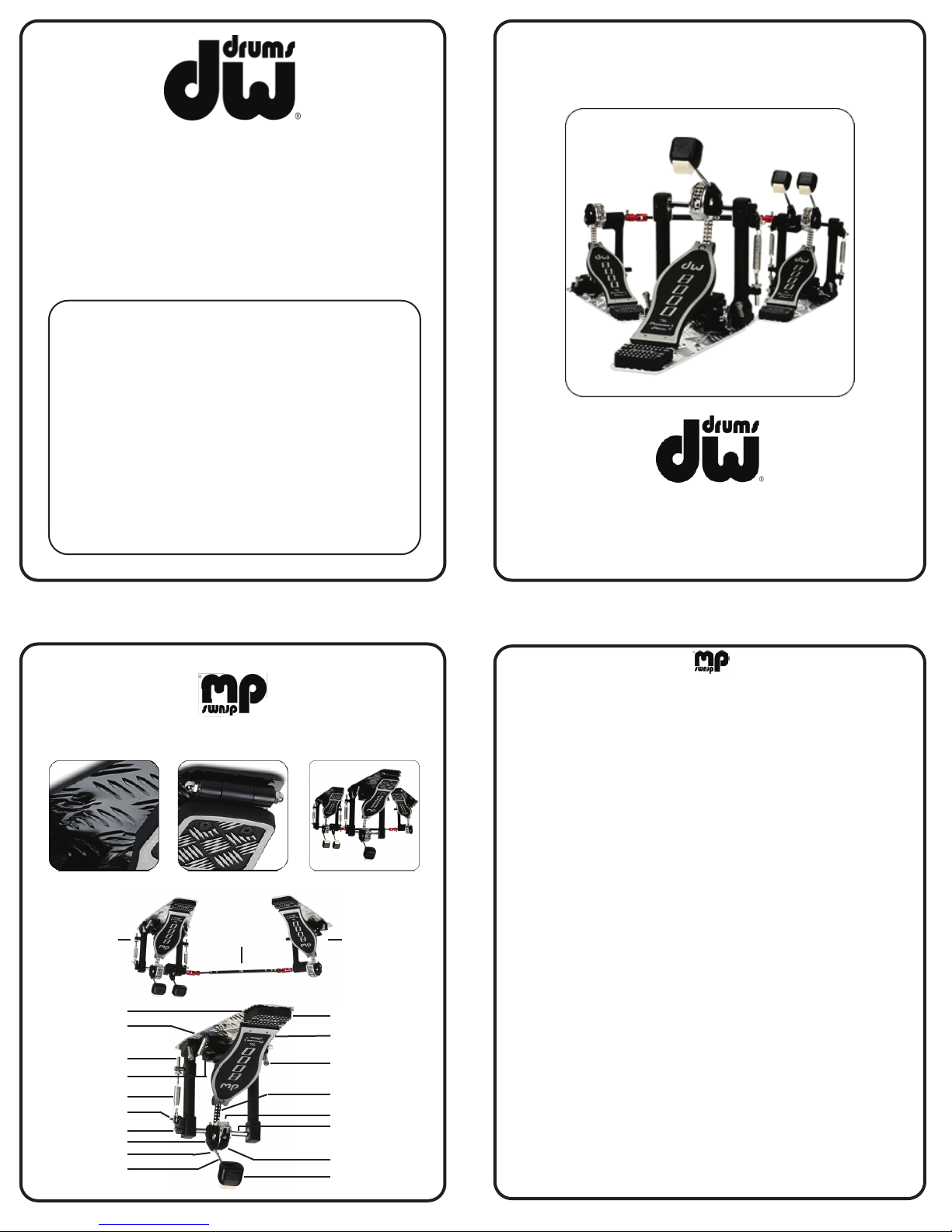

pedals

Diamond Base Plate

8000B Pedals feature a Black

Hinge design identical to 9000

State-of-the-art Ball Bearing

footboards.

and 8002, but with power

the same features as the 8000

The 8000B pedals include all of

- 8000B Solid Footboard Pedals

Heel Plate

Footboard

Hex Shaft

Double Chain

Adjustment Screw

Innate Torque

Adjustable Cam

Doube Chain Drive

Two-Way Beater

Auxiliary Pedal

Primary Pedal

Screw

Hoop Clamp Wing

Adjustment Nut

Spring Tension

Adjustment

Hoop Clamp Height

Spring

Rocker Hub

Stroke Adjustment

Linkage

Pedal Plate

Spur

Beater Hub

Beater Memory Lock

Beater Shaft

time you set up.

position, then retighten the key screws. Set the linkage memory lock to maintain the desired distance every

screws on the middle section of the linkage and adjust the length and angle of the linkage to the desired

playing position, attach the linkage and tighten the auxiliary side key screw. Loosen the two sets of key

tightening the key screw. Rotate the beater, casting and hex shaft on the auxiliary pedal to the correct

Use the provided drum key or any standard drum key to secure the linkage to the primary pedal by

Attaching and adjusting the linkage assembly (Double Pedals)-

footboard height then re-tighten the screw to lock it in place.

screw on top of the beater hub and slide the chain strap forward or backward to acheive the desired

desired position is acheived, retighten the screw. To adjust the footboard height and angle, loosen the key

underside of the rotor and slide the bar forward or backward to change the shape of the cam. Once the

feel. To adjust the torque use the short end of the 3-way drum key provided to loosen the hex screw on the

the stroke. The concentric setting maintains a direct relationship to provide a solid, powerful and consistant

between the beater and footboard which increases the speed and sensitivity by shortening the length of

(Accelerator) and concentric (Turbo). Choosing an eccentric setting creates an in-direct relationship

drummers. However, the 8000 drive can be adjusted to a variety of torque positions between eccentric

The factory settings are recommended for most general playing situations and preferred by many

Torque & Footboard Angle Adjustment-

to prevent bass drum crawl.

All DW Bass Drum Pedals include built in adjustable spurs and non-skid Velcro on the bottom of the pedals

Non-Skid Spurs and Velcro-

to avoid damage to the bass drum hoop.

the center of the hoop and tighten the side wing screw securely. Use the provided rubber hoop protector

and then rotate the knurled nut to narrow or widen the gap. Retighten the set screw. Position the pedal on

the hoop clamp for your bass drum, use the allen wrench provided to loosen the set screw on the clamp

The DW Toe Clamp is designed to t a wide variety of manufacturers’ bass drum hoops. To set the space of

Side/ Dual Adjusting Hoop Clamp-

desired tension, then release the hex nut and retighten the knurled nut to lock in the adjustment.

and pull down on the spring to release the locking hex nut. Tighten or loosen the lock nut to create the

To increase or decrease the spring tension, loosen the round knurled nut at the base of the spring assembly

DW drum pedal springs feature an internal noise reduction damper as well as a tension locking mechanism.

Spring Tension-

plastic side for a brighter attack, much like wood, but without the weight.

The standard Two-Way Beater has both a curved, medium felt side for a warmer attack and a at, hard

Beater Playing Surface-

achieved, secure the beater shaft by tightening the beater hub key screw.

should hit the center or an area 1-2 inches above the center of the drum. Once the desired height is

The length of the beater shaft can be adjusted to achieve the desired feel and impact area. The beater

Beater Height-

screw forward.

slightly heavier (longer) stroke move the screw towards the back, for a lighter (shorter) stroke move the

The stroke adjustment can be used to vary the distance the beater travels before hitting the drum. For a

Stroke Adjustment-

Loading...

Loading...