TYPE 5320

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

I O M . U K . D V C . 5320. 300 6 15- R E V . B

PAGE 1

TYPE 5320

Mechanical limit switch box

TYPE 5320

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

I O M . U K . D V C . 5320. 300 6 15- R E V . B

PAGE 2

TABLE OF CONTENTS

1. Introduction

3

1.1 Purpose

3

1.2 Safety notice

3

2. Product identification

4

2.1 Marking

4

2.2 Initial inspection

4

2.3 Storage

4

3. General information

5

3.1 Type 5320 standard technical data

5

3.2 Type 5320 optional technical data

5

3.3 Internal parts / materials

5

3.4 Dimensions

6

4. Installation instructions

6

4.1 Pre-installation

6

4.2 Limit switch box mounting

6

4.3 Fitting the mounting bracket

7

4.4 Adjustment of the limit switch box

8

4.4.1 Open cam setting

8

4.4.2 Closed cam setting

8

4.4.3 Checking the switch cam setting

9

4.4.4 Wiring

9

4.4.5 Reassembly of limit switch box

9

5. Operation instructions

10

5.1 Electrical connections and preliminary test

10

5.2 Wiring

10

5.3 Operation

10

6. Maintenance

11

6.1 Maintenance

11

TYPE 5320

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

I O M . U K . D V C . 5320. 300 6 15- R E V . B

PAGE 3

1. Introduction

1.1 Purpose

This installation and operating manual explains how to install, operate and maintain Type 5320 limit

switch boxes.

1.2 Safety notice

Safety notices in his manual stating precautions the user must take to reduce the risk of personal

injury and damage to the equipment. User must read these instructions before installation,

operating or maintenance is carried out.

DANGER: Refers to personal safety. Alert the user of danger or harm. The hazard or unsafe

practice will result in severe injury or death

WARNING: Refers to personal safety. Alert user of potential danger. Failure to follow

warning notices could result in personal injury or death

CAUTION: Directs the user’s attention to general precautions that, if not followed could result in

personal injury and/or damage

TYPE 5320

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

I O M . U K . D V C . 5320. 300 6 15- R E V . B

PAGE 4

2. Product identification

2.1 Marking

The limit switch box name plate is located on the top cover casing. The name plate contains the

following:

Logo

Type number

Enclosure

Rated current

Accreditations, certifications

2.2 Initial inspection

When you receive the limit switch box, please make sure that the specifications of the limit switch

box (name plate) confirms with the customer order sheet and / or the required specifications.

Remove the packing wrap or carton box carefully. Inspect the product for any physical

damage that may have occurred during shipment or handling.

Check the product specification with your order. If something does not match the

requirements / differs from the expected, please contact us immediately for required

actions to be carried out.

2.3 Storage

Limit switch boxes must be stored in a clean, cool and dry area. The unit shall be stored with cover

installed and the conduit entries sealed. Storage must be off the floor, covered with a sealed dust

protector.

If limit switch boxes are to be stored outside before use / installation they must be stored off the

ground, high enough to prevent them from being immersed into water or covered with snow.

The conduit entries shall remain sealed until mounting of the power cable / signal cable takes

place.

TYPE 5320

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

I O M . U K . D V C . 5320. 300 6 15- R E V . B

PAGE 5

Type

3. General information and features

The DVC type 5320 limit switches are designed for the use in various types of industries together

with small size valves i.e. butterfly valve, ball valves etc. for signaling / valve position monitoring

purposes.

3.1 Type 5320 standard technical data

Enclosure Rating Weatherproof IP67 & NEMA 4 & 4X

Enclosure High grade aluminum alloy

Ambient Temperature -20oC ~ + 80oC

Conduit Entries 2x M20

Travel Angle 90 degree +/- 10%

Position Indicator open: green, close: red

Switch Mechanical 2 x SPDT - Rating: 250VAC/16A, 125VAC/16A,

250VDC/0,3A, 125VDC/0,6A, 30VDC/10A

Terminal Strip 8 point

External Coating Chromate polyester powder coating

3.2 Type 5320 optional technical data

Enclosure Rating IP68

Enclosure High grade aluminum alloy

Conduit Entries 2x PF 1/2”, PT 1/2”, NPT 1/2”, PG 13,5

Switches Proximity switches

Indication Three way dome indication

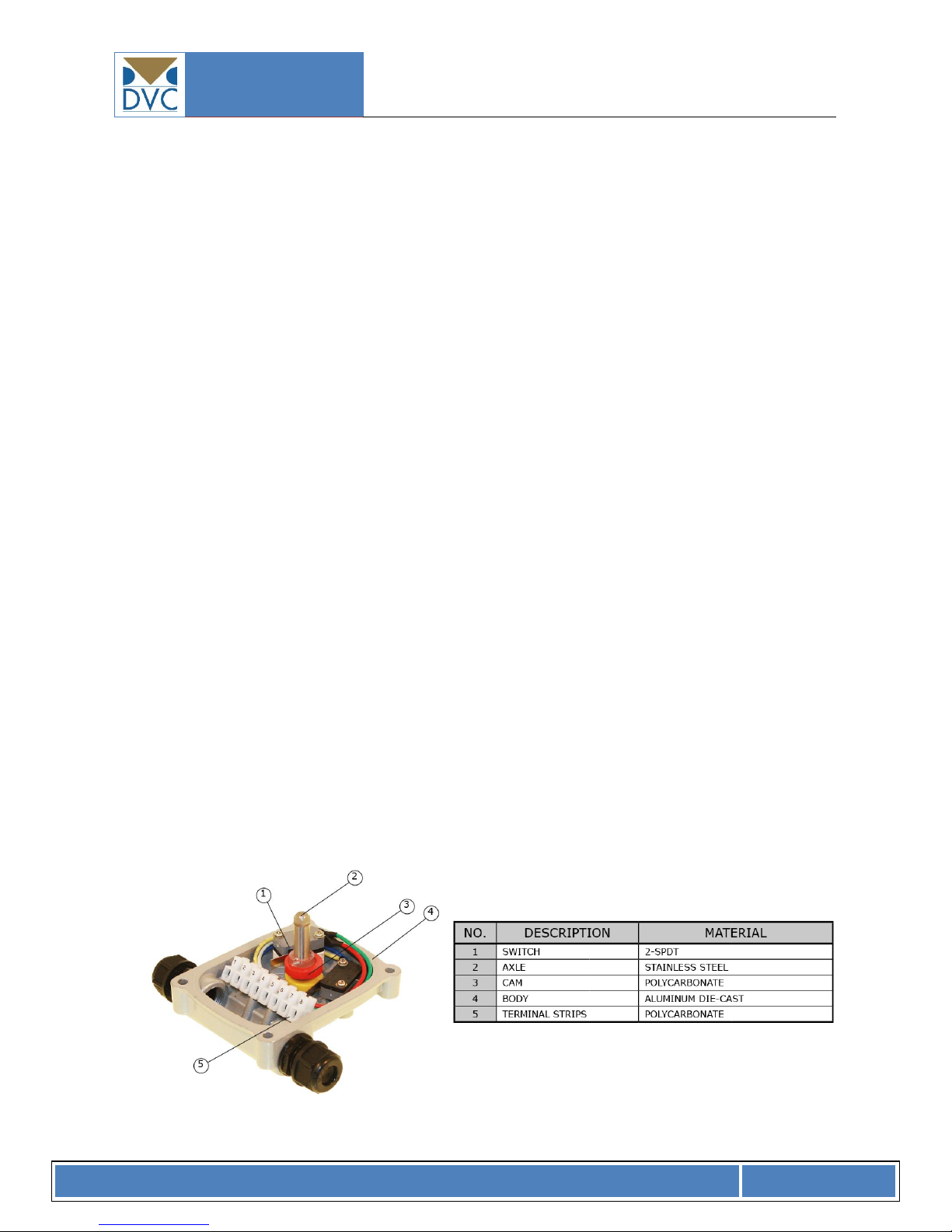

3.3 Internal parts/materials

TYPE 5320

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

I O M . U K . D V C . 5320. 300 6 15- R E V . B

PAGE 6

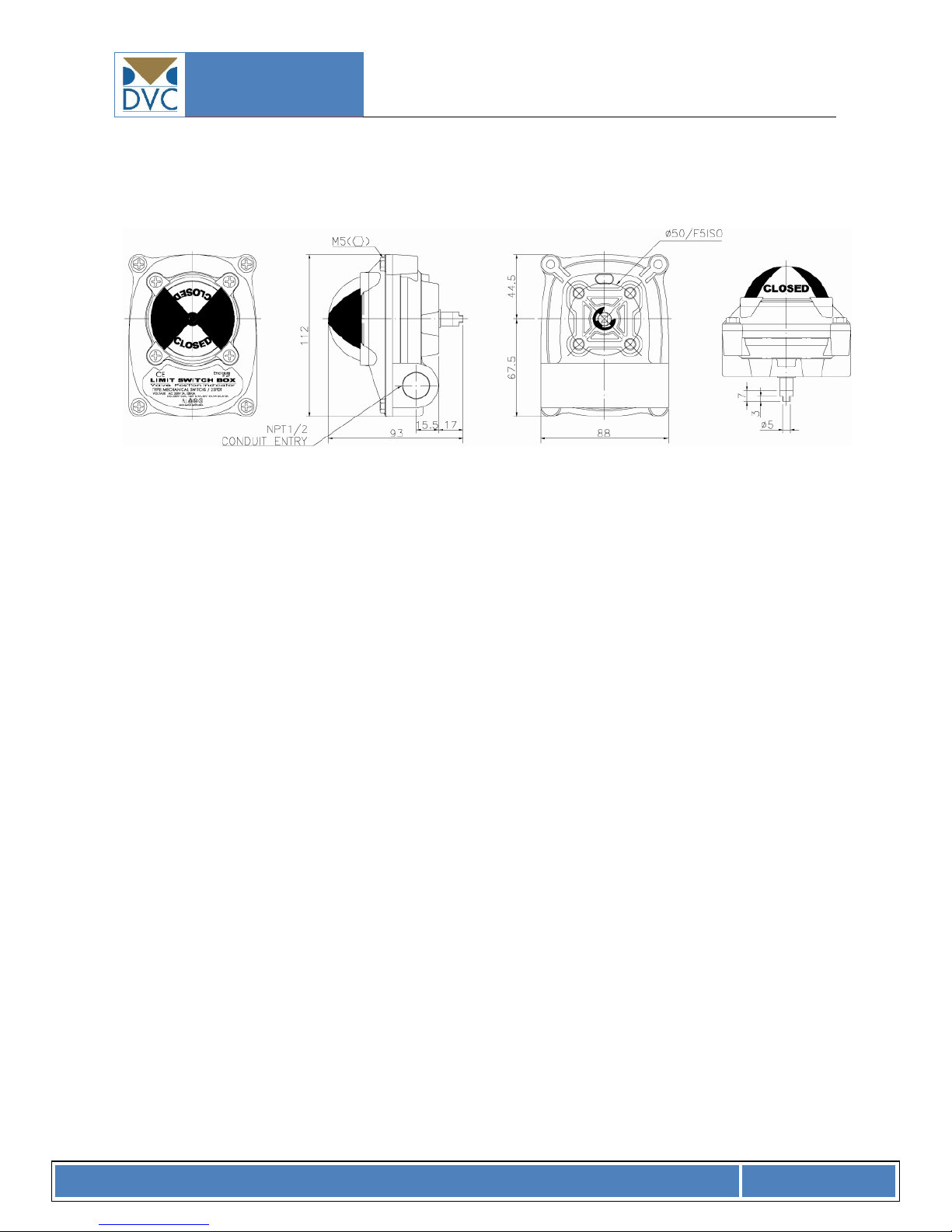

3.4 Dimensions

4. Installation instructions

4.1 Pre-installation

Verify that the nameplate of the limit switch box match the specifications needed – correct model

number, voltage and enclosure type - before installation and use.

Wiring connections should be in accordance with the diagram attached to the inside of the

top casing cover.

The two conduit cable entries shall be sealed in a proper manner until cable works is

finalized.

Position indicator and switch box covers are sealed by use of o-rings. Please take care of o-

ring in order not to cause any damage to the o-rings during disassembly or reassembly.

The position of the limit switches / cams have not been adjusted at the factory. Therefore a

final adjustment of those is needed before use.

Do not use in areas where explosion proof equipment is required. These types of limit

switches are designed as weatherproof types – not explosion proof types.

4.2 Limit switch box mounting

TYPE 5320

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

I O M . U K . D V C . 5320. 300 6 15- R E V . B

PAGE 7

Note:

Prior to mounting of the limit switch box the item must be checked for any

damage

Damaged parts must be replaced by original spare parts

Mounting is most easily done with the actuator shaft pointing vertically upwards. But mounting is

also possible in any other position.

The limit switch box may be mounted in any position.

It is mandatory that the limit switch box is firmly secured t a sturdy mounting bracket High tensile

bolts or studs with spring locking washers must be used.

The limit switch box output shaft must be in line with the actuator shaft to avoid side-loading the

shaft. To avoid any backlash no flexibility in the mounting bracket or mounting should be allowed.

Caution: Make sure to cut off the electrical power before working on the limit switch box for

assembly, mounting etc.

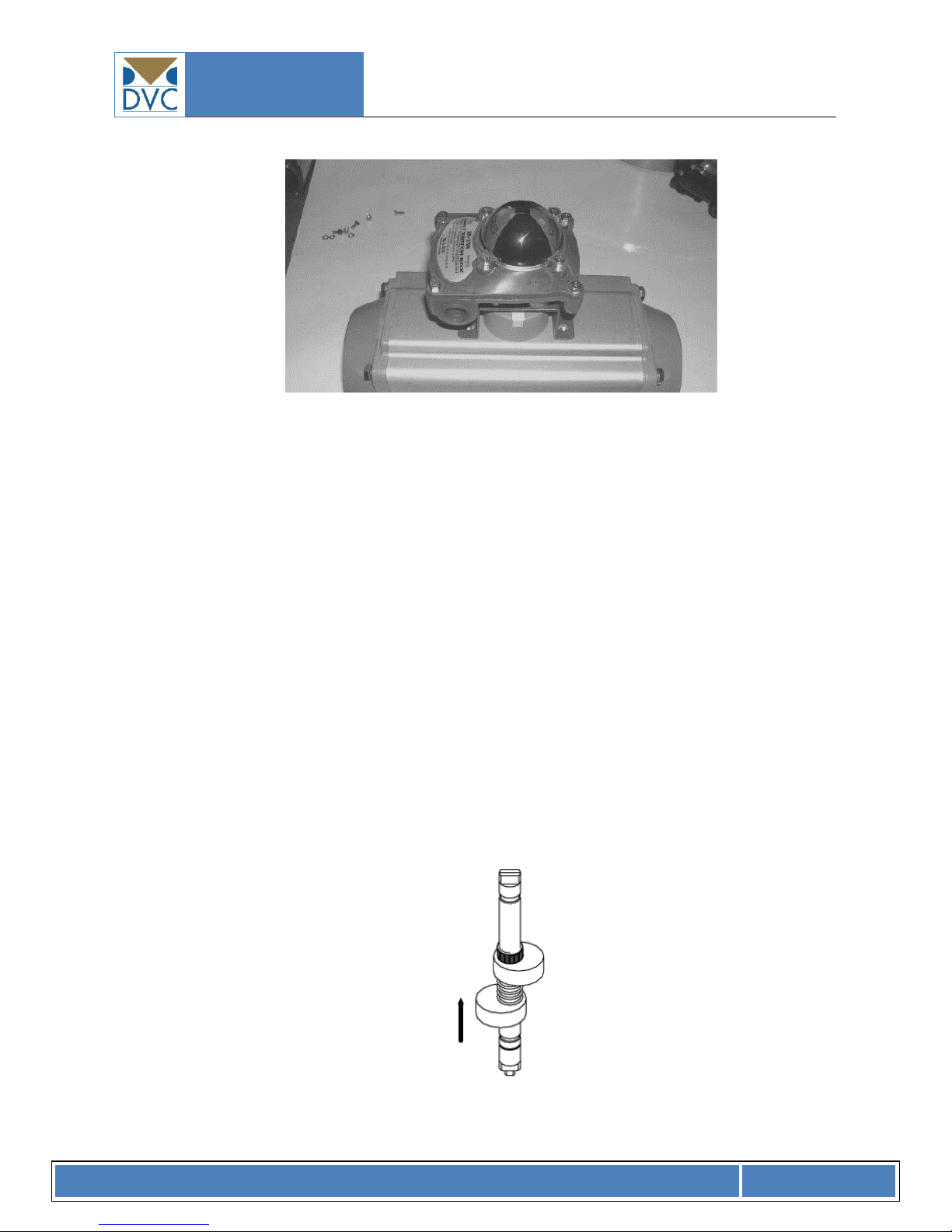

4.3 Fitting the mounting bracket

Two types of standard DVC mounting brackets are available

NAMUR VDE/VDI 3845 size 30x80

NAMUR VDE/VDI 3845 size 30x130

Fixed mounting bracket on top of actuator

The mounting bracket is fixed onto the top of the actuator by use of correctly sized high tensile

bolts and spring washers.

TYPE 5320

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

I O M . U K . D V C . 5320. 300 6 15- R E V . B

PAGE 8

Insert the shaft of the limit switch box correctly into the drive slot on the top of the actuator drive

shaft – use correctly sized high tensile bolts and spring washers for fastening the box to the bracket.

4.4 Adjustment of the limit switch box

By use of screw driver loosen the captive bolt on the cover and lift off top cover.

Each switch has its own independent cam arrangement. Follow the procedures bellow for

adjustment.

4.4.1 Open cam setting

Lift the bottom cam up and turn it until the switch is activated (clicks) – then release the cam.

The spring will force the cam back into the splines on the shaft ensuring the correct position

of the cam.

Lift up and release

TYPE 5320

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

I O M . U K . D V C . 5320. 300 6 15- R E V . B

PAGE 9

4.4.2 Closed cam setting

Push the top cam down and turn it until the switch is activated (clicks) – the release the cam.

The spring will force the cam back into the splines on the shaft ensuring the correct position

of the cam.

Push down and release

NOTE: It should be kept in mind that an incorrect setting of the cam position may/will

result in incorrect signaling to external control systems.

4.4.3 Checking the switch cam setting

Operate the actuator from full open to full closed in both directions several times to check

that the switch cams are operating correctly – preferably with a detection of the output

signal from the limit switches (if possible)

4.4.4 Wiring

The correct wiring diagram is attached onto the inside of the top casing cover. Please follow

the instructions carefully. If in doubt – please contact DVC.

TYPE 5320

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

I O M . U K . D V C . 5320. 300 6 15- R E V . B

PAGE 10

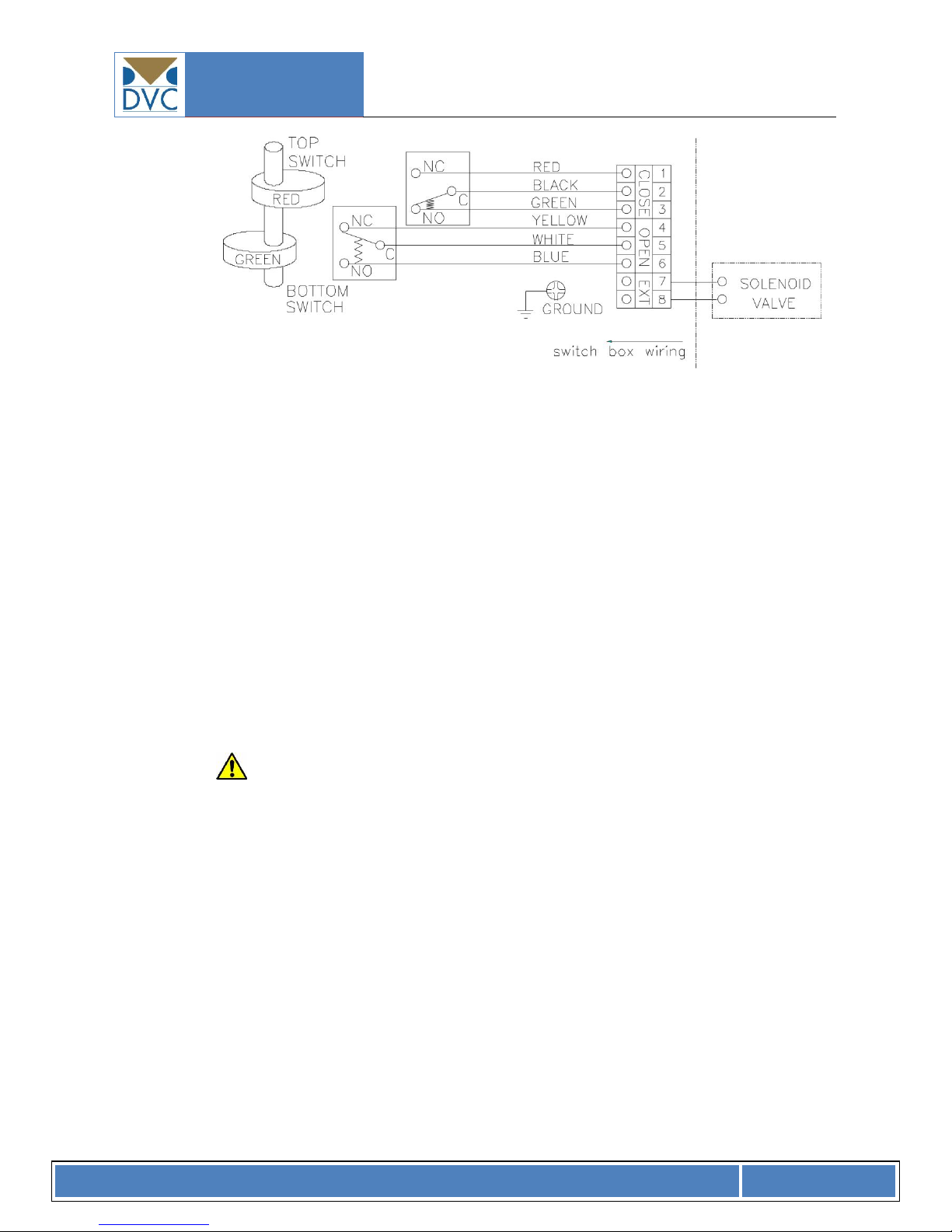

Standard electrical diagram

Important: Earth wire cable shall be use in bicolor combination green/yellow

4.4.5 Reassembly of limit switch box

Carefully mount the top cover onto the bottom part of the casing – taking care not to

damage the o-ring.

5. Operation instructions

5.1 Electrical connections and preliminary test

WARNING:

Work on the electrical system or equipment must only be carried out by a skilled

electrician himself or by specially instructed personnel under the control and

supervision of such an electrician and in accordance with the applicable electrical

engineering rules

Cable gland or conduit entries shall be controlled by qualified engineers to ensure

correct protection against water damages etc.

Treat limit switch casing top with care. Gap between limit switch box housing parts

may lead to unexpected damages. Do not jam cover during fitting.

TYPE 5320

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

I O M . U K . D V C . 5320. 300 6 15- R E V . B

PAGE 11

5.2 Wiring

Please refer to the enclosed wiring diagram or contact us for further details.

If the enclosed diagram is not followed/neglected – the guarantee will no longer be valid.

5.3 Operation

As to the fact that the limit switch are fully controlled/operated by the actuator shaft no manual

operation is necessary.

6. Maintenance

6.1 Maintenance

Caution:

Turn off all power services before attempting to perform service on the limit switch box.

Before removing or disassembling the limit switch box ensure that the valve or other

actuated device is isolated and not under pressure.

When/if replacing any part use only original DVC spare parts.

All though no real maintenance is necessary on the limit switch box, regular maintenance

checks should, under normal conditions, be carried out with intervals of maximum six

months. But if service conditions are severe more frequent inspections may be advisable.

Ensure limit switch box / actuator alignment

Ensure wiring insulation is intact, connected and terminated properly

Ensure all screws are present and tight

Ensure cleanliness of internal electrical parts / devices

Ensure conduits connections are installed properly and dry

Check enclosure o-ring seals and verify that the o-ring is not pinched between

flange

Visual inspect during open/close cycle

Inspect identification labels for wear and replace if necessary

TYPE 5320

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

I O M . U K . D V C . 5320. 300 6 15- R E V . B

PAGE 12

WARNING:

Before starting work on the limit switch box, please check all conditions of the limit

switch box, other related equipment and site for safety purposes.

Loading...

Loading...