Dux Prodigy 4 135ZN, Prodigy 4 135ZL, Prodigy 4 170ZN, Prodigy 4 170ZL Owner's Manual

Owner’s Manual

Models: 135ZN / 135ZL

170ZN / 170ZL

4 Star Gas Hot Water Heater

Specications and materials may change without notice.

Effective for all Prodigy 4 water heaters manufactured and sold after 1st December 2012.

For advice, repairs and service, call:

1300 365 115 (Australia)

0800 729 389 (New Zealand)

Carefully remove all packaging and

transit protection from the heater before

installation. Dispose of the packaging

responsibly using re-cycling facilities

where they exist.

Installation Details

Owner’s Information

Warranty

H3071 3071 Rev. J

Owner’s Manual – Prodigy 4

H3071 3071 Rev. J

Contents

© Dux Manufacturing Limited 2012. All rights reserved.

Welcome To Dux Hot Water 1

Installation Details 2

Specications 3

Plumbing Connections 4

Gas Connections 7

Commissioning Adjustments 10

Owner's Information 11

SystemMaintenance 13

Troubleshooting 14

Warranty 16

Other Information 19

Owner’s Manual – Prodigy 4

1

H3071 3071 Rev. J

Welcome To Dux Hot Water

Your decision to purchase a Dux Hot

Water system will reward you for many

years to come.

Since 1915, the Dux range has seen

continuous research and development,

resulting in many breakthroughs in the

efciency, reliability and longevity of hot

water systems.

Dux water heaters are manufactured

in Australia in a state-of-the-art facility,

using a Quality Endorsed Company

production system.

This is your assurance that you have

purchased the highest quality water

heater available, one that will provide

continuous hot water for all your needs

– safely, economically, and for many

years to come.

To be upfront about it, we want Dux to

be your brand of choice. So you can

depend on us to provide more than just

a hot water system.

You can rely on Dux products and

choose them with condence. We’ll

make sure you have the information, the

quality and the innovation you’re looking

for, including the latest energy-saving

alternatives. If you should ever have a

problem – and we’ll bet you won’t –

you’ll nd that we’re easy to get hold of,

friendly to talk to and quick to act. Our

service is all about providing anything

you need as soon as you need it.

Go with Dux and you’ll have a

dependable, economical, efcient hot

water system designed to perform well,

year after year. And that’s a promise.

Owner’s Manual – Prodigy 4

2

H3071 3071 Rev. J

Installation Details

Outdoor Tank Installation

The water heater must be installed

outdoors, with the minimum clearances

as shown in the gure below.

We recommend a plinth be installed

under the water heater where the

water heater is subjected to wet

conditions.

Minimum clearance around the windows

and doors must be maintained – refer to

AS 5601.

Location

The water heater should be located as

close as possible to the most frequently

used hot water outlet. Ensure that the

data label is clearly visible and that there

is adequate access for servicing the unit.

Note: All models are equipped with a

sacricial anode, accessible through the

top cover. Allow 50% of the height of

the water heater for clearance above to

replace the anode.

A = 500mm B=300mm min

For further details, refer to

AS 5601 – Gas Installation Code

Owner’s Manual – Prodigy 4

3

H3071 3071 Rev. J

Specifications

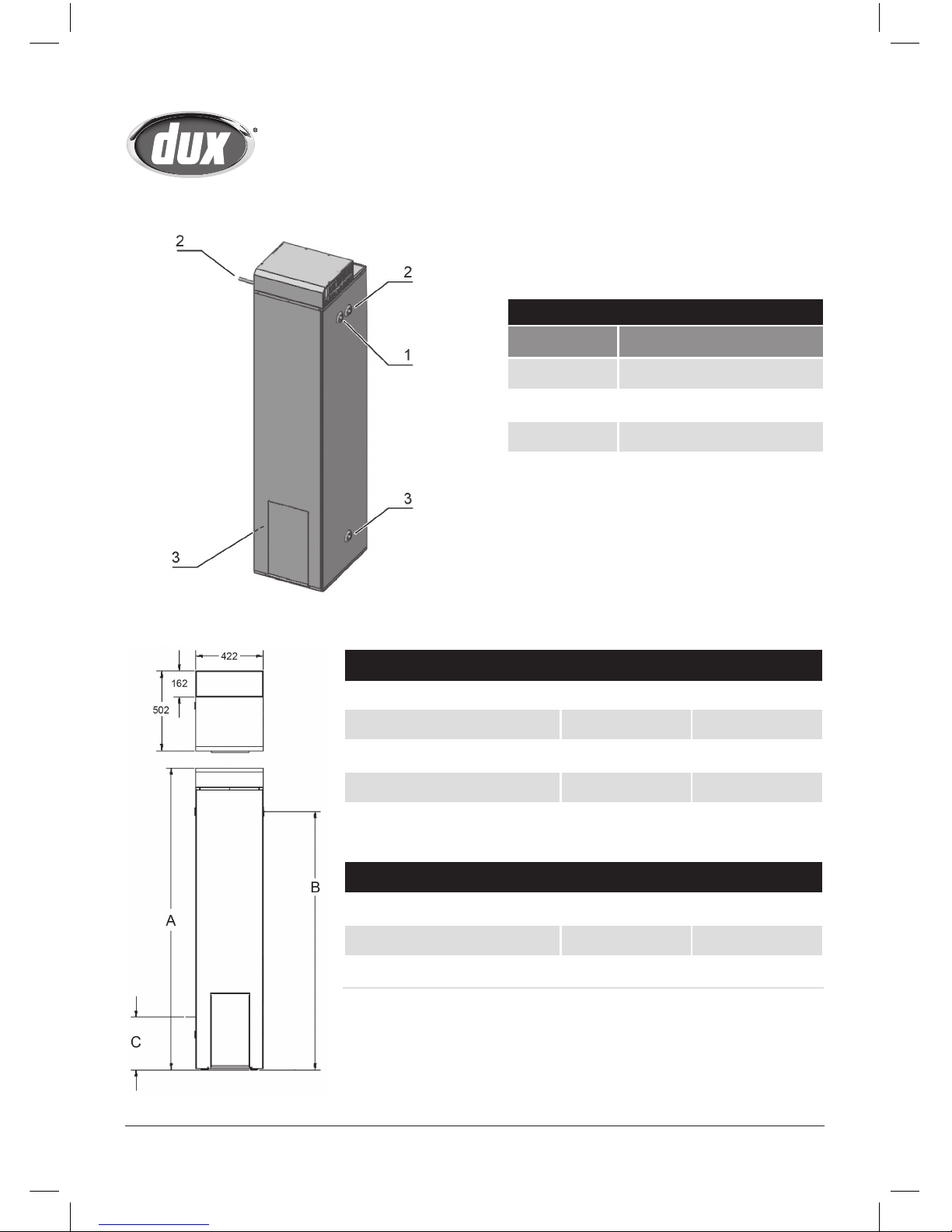

System Components

Component Description

1 PTR Valve

2 Hot Water Outlet To House

3 Cold Water Inlet

Tank Specifications

Model Numbers 135ZN / 135ZL 170ZN / 170ZL

Capacity (L) 135 170

Net Weight Empty (kg) 72 86

Relief Valve Pressure (kPA) 1400 1400

Gas Consumption 135ZN: 23.5 MJ/h

135ZL: 22.5 MJ/h

170ZN: 27 MJ/h

170ZL: 26 MJ/h

Dimensions (mm)

A – Height 1600 1895

B – Hot Water Outlet 1325 1620

C – Cold Water Inlet 220 220

Owner’s Manual – Prodigy 4

4

H3071 3071 Rev. J

Installation Requirements

This water heater must be installed

by a licensed tradesperson, and in

accordance with:

• AS/NZS3500.4 “National Plumbing

and Drainage Code Hot Water

Supply Systems – Acceptable

Solutions”.

• AS5601/AG601 “Gas Installations”.

• Local authority regulations.

• Outside Australia, please refer to

local plumbing and building codes

and regulations.

• Notice to Victorian customers

from the Victorian Plumbing

Industry Commission – this water

heater must be installed by a

licensed person as required by the

Victorian Building Act (1993). Only

a licensed person will give you a

compliance certicate, showing

that the work complies with all

the relevant Standards and only a

licensed person will have insurance

protecting their workmanship for 6

years.

Water Supply Pressure

This water heater is designed for direct

connection to water supply pressures of

no greater than:

All Models – 1120kPa

Where the mains pressure can exceed

or uctuate beyond the pressure

shown above a pressure limiting device

(complying with AS1357) must be

tted in the cold water inlet supply.

This device must be installed after

the isolating valve and set below the

pressure shown above. Note during

periods of lower demand water pressure

may increase.

Pool Heating

This water heater must not be used for

pool heating.

Plumbing Connections

Owner’s Manual – Prodigy 4

5

H3071 3071 Rev. J

Plumbing Connections

Pressure & Temperature Relief

Valve

The Pressure & Temperature Relief Valve

is supplied loose with the water heater.

The valve rating is:

All Models – 1400kPa

The PTR valve must be installed directly

into the top socket marked “RELIEF

VALVE”. The drain line from this valve

must run in a continuously downward

direction in a frost-free ambient position

with the discharge end left open to

atmosphere permanently.

The PTR Valve is not intended to enable

connection of the water heater to

supplementary energy sources such as

solar panels or slow combustion stoves

(refer AS/NZS 3500.4 for guidance on

these types of installations).

The PTR Valve must not be tampered

with or removed. The water heater must

not be operated unless this valve is

tted and in working order.

The PTR Valve should be checked for

adequate performance or replaced at

intervals not exceeding 5 years, or less

in areas where local regulations apply.

Important: The PTR Valve and its

drain outlet pipe must not be sealed or

blocked. It is normal for the PTR valve

to leak a small amount of water during

heating cycles.

Danger: Failure to operate the relief

valve easing lever at least once every six

(6) months may result in a problem with

the water heater and in some cases the

tank may explode.

Warning: A separate drain line must be

run for this relief valve. It is not permitted

to couple drain lines from relief valves

into a single common drain line.

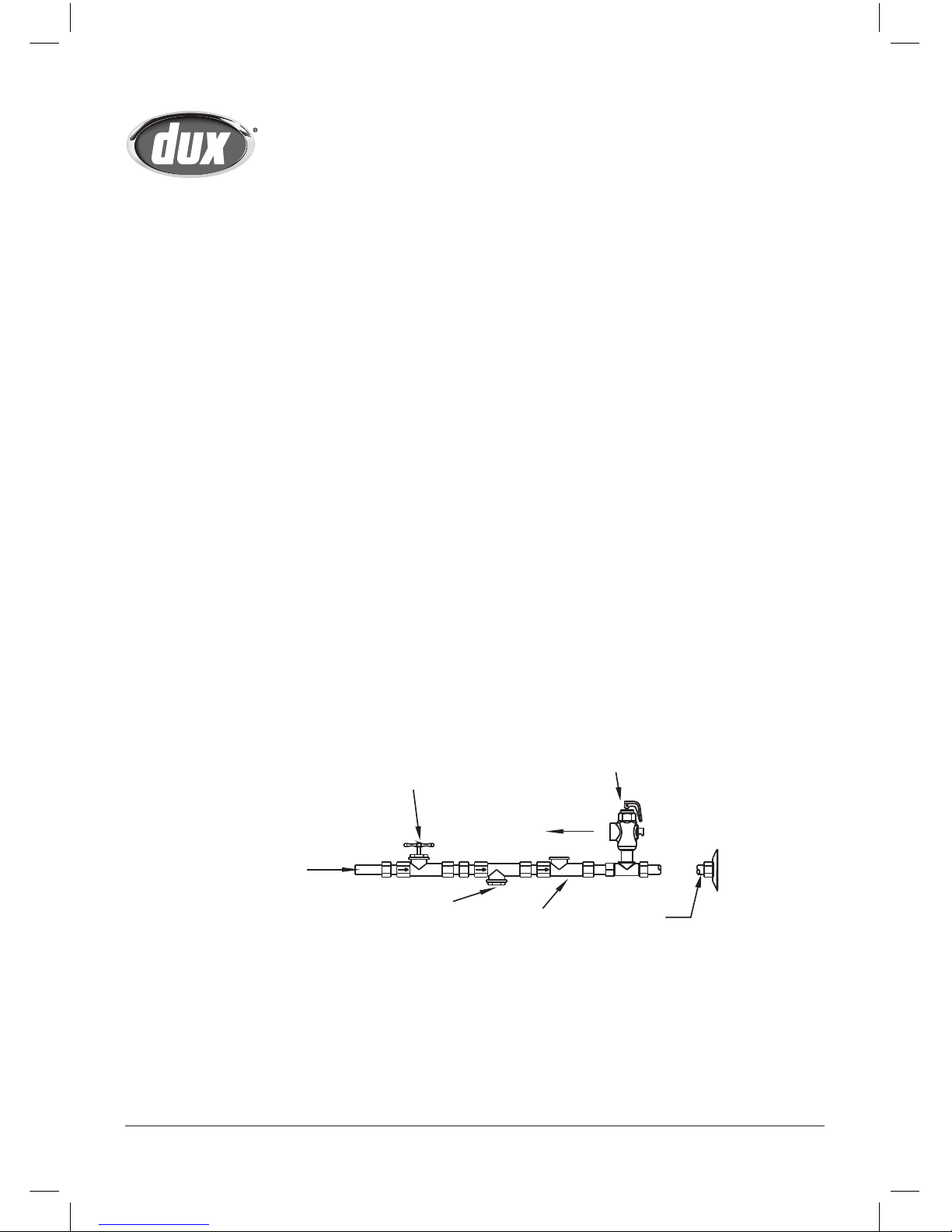

Cold Water Connection

An approved isolating valve, non

return valve, line strainer (optional but

recommended), and union must be

tted between the supply main and

either of the RP¾/20 sockets marked

“INLET” at the bottom of the water

heater. All ttings must be approved by

the relevant Authority. See the diagram

on page 5 for details.

Note: Brass plugs are supplied with

the water heater to plug off the unused

ttings. Ensure that a sealing material is

applied to the plugs to prevent leaking.

Note for S.A. and W.A.: It is a state

requirement that a Expansion Control

Valve be tted on the cold water supply

line between the non return valve and

the water heater. See the diagram on

page 6 for details.

Owner’s Manual – Prodigy 4

6

H3071 3071 Rev. J

Hot Water Connection

The hot water pipe should be connected

to either of the RP¾/20 sockets marked

"OUTLET" at the top of the unit. Please

check local regulations regarding the

use of hot water supply pipework that is

not made of copper.

Insulation of Pipes

For the most economical operation of

the water heater, it is recommended

that all hot water lines are insulated.

Where the hot water pipes are installed

outdoors, the insulation should be UV

stabilised.

Note: a combined isolating valve/non-return valve/line strainer may be used.

Expansion Control Valve only required where local regulations demand although it is

recommended in areas where the water saturation index is above 0.40 (see page 11).

Union

Connection

Non-return

Valve

Line

Strainer

Cold Water

Inlet

Drain

Expansion

Control Valve

Isolating Valve

(Spindle Vertical)

Inlet Connections

Temperature Protection

Water heaters can produce very hot

water. To reduce the risk of scald injury,

it is mandatory under the requirements

of Australian Standard AS/NZS3500.4

that a suitably approved temperature

control device be tted to the hot water

supply to outlets used primarily for

personal hygiene. This valve should be

checked at regular intervals to ensure its

operation and settings remain correct.

Plumbing Connections

Loading...

Loading...