T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 1

(Translation of the original instructions)

INDEX

1 DISCLAIMER ...................................................................................................................................................................................... 2

2 EU-DECLARATION OF CONFORMITY .................................................................................................................................................. 3

3 SAFETY INSTRUCTIONS AND WARNINGS ........................................................................................................................................... 4

3.1 Water draining, packing, transport and storage instructions of DTE installations. ....................................................................... 5

3.1.1 Draining water from the machine ............................................................................................................................................. 5

3.1.2 Packing, transport and storage instructions ............................................................................................................................. 7

3.2 Correct applications ....................................................................................................................................................................... 7

3.3 Application area ............................................................................................................................................................................ 7

4 GENERAL DESCRIPTION ..................................................................................................................................................................... 8

4.1 Identification.................................................................................................................................................................................. 9

5 COMMISSIONING ............................................................................................................................................................................ 10

5.1 Connecting cooling water pipes ................................................................................................................................................... 11

5.2 Connecting overflow pipe ............................................................................................................................................................ 12

5.3 Connecting power supply ............................................................................................................................................................. 12

5.3.1 Plug-in terminals ..................................................................................................................................................................... 13

5.4 Connecting external contacts ...................................................................................................................................................... 13

5.5 Water quality ............................................................................................................................................................................... 14

5.6 Filling of (external) pipes and systems CoolMaster (K) ................................................................................................................ 15

5.7 Filling of (external) pipes and systems CoolMaster (N) ................................................................................................................ 16

5.8 Filling of the system CoolMaster (K) ............................................................................................................................................ 19

5.9 Filling of the system CoolMaster (N) ............................................................................................................................................ 20

5.10 Deaerating ................................................................................................................................................................................... 21

5.11 Setting thermostat ....................................................................................................................................................................... 22

5.12 Commissioning after long standstill ............................................................................................................................................ 23

6 MEANING OF ALARMS (IF APPLICABLE) ........................................................................................................................................... 24

7 FAULT ANALYSIS .............................................................................................................................................................................. 25

8 MINIMUM INSPECTION-INTERVAL SCHEME ..................................................................................................................................... 26

9 CLEANING OF THE MACHINE............................................................................................................................................................ 27

10 CHECKS ....................................................................................................................................................................................... 27

11 SERVICE ....................................................................................................................................................................................... 27

12 GUARANTEE ................................................................................................................................................................................ 28

13 REMOVAL .................................................................................................................................................................................... 28

14 APPENDIX ................................................................................................................................................................................... 29

14.1 Options ........................................................................................................................................................................................ 30

14.2 Connection diagram filling the system ........................................................................................................................................ 31

14.3 Watertreatment .......................................................................................................................................................................... 32

14.4 Guidline for water quality in DTE installations............................................................................................................................. 33

14.5 User manual thermostat.............................................................................................................................................................. 34

14.6 Safety information sheets ............................................................................................................................................................ 37

14.7 Comments .................................................................................................................................................................................... 45

14.8 Technical information .................................................................................................................................................................. 46

* Specification list ..................................................................................................................................................................................... 46

* Machine drawing ................................................................................................................................................................................... 46

* Parts list ................................................................................................................................................................................................. 46

* Flow scheme .......................................................................................................................................................................................... 46

* Electrical scheme.................................................................................................................................................................................... 46

* User manual thermostat ........................................................................................................................................................................ 46

* Safety data sheet refrigerant ................................................................................................................................................................. 46

* Other ...................................................................................................................................................................................................... 46

ENGLISH

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 2

11 DDiissccllaaiimmeerr

The manufacturer reserves the right to change parts at any time to change, without prior or immediate notice to the customer. The contents of

this manual may also be changed without prior warning. This is an original manual, and is valid for the machine in its standard version. The

manufacturer can therefore not be held liable for any damages resulting from specifications that deviate from the standard version delivered to

you. For information on adjustments, maintenance and repair insofar as this guide does not provide it, please contact the technical department

of your supplier. This manual was drawn up with the greatest possible care, however the manufacturer cannot accept any liability for any errors

in this book or any consequences thereof. Finally, this manual is a personal and confidential communication to the user. No part of this

publication may be reproduced, copied, altered or transmitted in any form or in any manner whatsoever without written permission from Dutch

Thermal Engineering n.v.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 3

22 EEUU--DDeeccllaarraattiioonn ooff ccoonnffoorrmmiittyy

Manufacturer: D.T.E. n.v.

Address: Westerbroekstraat 18

7011 EX GAANDEREN / HOLLAND

Hereby certifies that:

The CoolMaster meets the requirements of the Machinery Directive

(Directive 2006/42/EC, as amended),

and the national legislation implementing this Directive;

Meets the provisions of the following other EU directives.

- 2014/35/EU Low Voltage Directive

- 2014/30/EU EMC directive

- 2014/68/EU Pressure Equipment Directive (PED)

And furthermore certifies that

The following (parts of) harmonised standards are applied:

- NEN-EN-IEC 60204-1:2006/C11:2010

- NEN-EN-ISO 12100:2010

- NEN-EN 378-2:2016

- NEN-EN-ISO 13857:2008

The following (parts of) national technical standards and specifications are used:

- Cooling Systems Leak Tightness Arrangement (Dutch abbreviation: RLK).

Person authorised to draw up technical documentation:

Mr T.J.H.M Ratering

(Manager Engineering)

Signed in Gaanderen on 09-12-2016

F.G.R. Geerdink

General Manager

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 4

33 SSaaffeettyy iinnssttrruuccttiioonnss aanndd wwaarrnniinnggss

Always observe the following safety instructions and warnings!

WARNING!

Warning of possible damage to the device, environment or user

WARNING!

Warning of electricity and / or current threat

WARNING!

Warning of possible entrapment hazard

Compliance with the technical manual is a prerequisite for fault-free operation and the honouring of any

warranty claims. Therefore please read the technical manual carefully before you start working with your

device! The manual must therefore be kept near the machine. The CoolMaster is under pressure with a

refrigerant, more information about this can be found in Appendix 14.6.

This user’s manual was written for types similar to DTE CoolMaster (K), (N) type machines. Therefore

certain topics may not apply to your machine. For the same reason, the images may differ slightly from

how your machine actually looks. When deviating from the standard, a machine drawing is included as

an attachment.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 5

33..11 WWaatteerr ddrraaiinniinngg,, ppaacckkiinngg,, ttrraannssppoorrtt aanndd ssttoorraaggee iinnssttrruuccttiioonnss ooff DDTTEE iinnssttaallllaattiioonnss..

These actions are general and have to been carried out, of course, if applicable for the

application by qualified personal!

33..11..11 DDrraaiinniinngg wwaatteerr ffrroomm tthhee mmaacchhiinnee

Step 1: Close the filling connection (D1)

Step 2: Drain the Water tank of the cooling system by opening the ball

valve. (See Figure 3.1) Further draining of the Water tank with a wet

vacuum cleaner. (See Figure 3.2)

Step 3: Drain the Tempering/Hot water tank by opening the

drainage/overflow valve. (See Figure 3.3)

Step 4: If present, switch on all solenoid valve by external power.

Step 5: If present, switch al 3 way-mix- regulation valve into the middle

position. (See Figure 3.4)

Figure 3.1

Figure 3.2

Figure 3.3

Figure 3.4

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 6

Step 6: Drain all connection on the machine with a wet vacuum

cleaner. (See Figure 3.5)

Step 7: Open all BVS valves if present (See flow diagram) and

remove the interior (See Figure 3.6). Drain the connection on the

outside of the machine with a wet vacuum cleaner. The interior will be

transported separately and has to be assembled before

commissioning.

Step 8: Remove all plugs of the water pumps. After this drain al pumps

with a wet vacuum cleaner. (See Figure 3.7 and Figure 3.8)

Figure 3.5

Figure 3.6

Figure 3.7

Figure 3.8

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 7

33..11..22 PPaacckkiinngg,, ttrraannssppoorrtt aanndd ssttoorraaggee iinnssttrruuccttiioonnss

Before packing, transport and storage, first follow the instructions of chapter 3.1.1 Draining water

from the machine.

Attention! Before transport the machine has to be protected with the also delivered cardboard

box or has to be wrapped with bubble wrap. The machine has to be transported and stored

perpendicular at all time on its fundament on the provided pallet!

The machine has to be placed perpendicular on its fundament at all time.

Attention! In no way the machine can be stacked or overturned. This during transport and storing

as well during repairs and commissioning. Even when the machine is not used it should be

perpendicular at all times.

Attention! Not following these instruction can cause big damage to the machine.

Use at all time the right equipment such as a pallet truck and a forklift truck.

33..22 CCoorrrreecctt aapppplliiccaattiioonnss

The CoolMaster (K)(N) may only be kept inside a cool, well-ventilated, frost-free building!

The minimum and maximum ambient temperature can be found in the relevant specifications list.

The CoolMaster (K) is only suitable for tap water of drinking quality.

The CoolMaster (N) is only suitable for tap water of drinking quality, mixing with appropriate antifreeze

(glycol) in suitable mixing ratio.

Information on the correct water-glycol ratio and the recommended type of glycol can be found on the

specification list corresponding to the machine.

Please consult the relevant specification list for information on the minimum and maximum

environmental temperature, the right water-glycol ratio and the recommended type of glycol.

Attention! In no way the machine can be stacked or overturned. This during transport and storing

as well during repairs and commissioning. Even when the machine is not used it should be

perpendicular at all times.

Attention! Not following these instruction can cause big damage to the machine.

33..33 AApppplliiccaattiioonn aarreeaa

CAUTION! Application is prohibited:

- In explosive atmospheres.

- In environments with hazardous oils, acids, gases, fumes, substances, radiation, etc.

- Corrosive environment.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 8

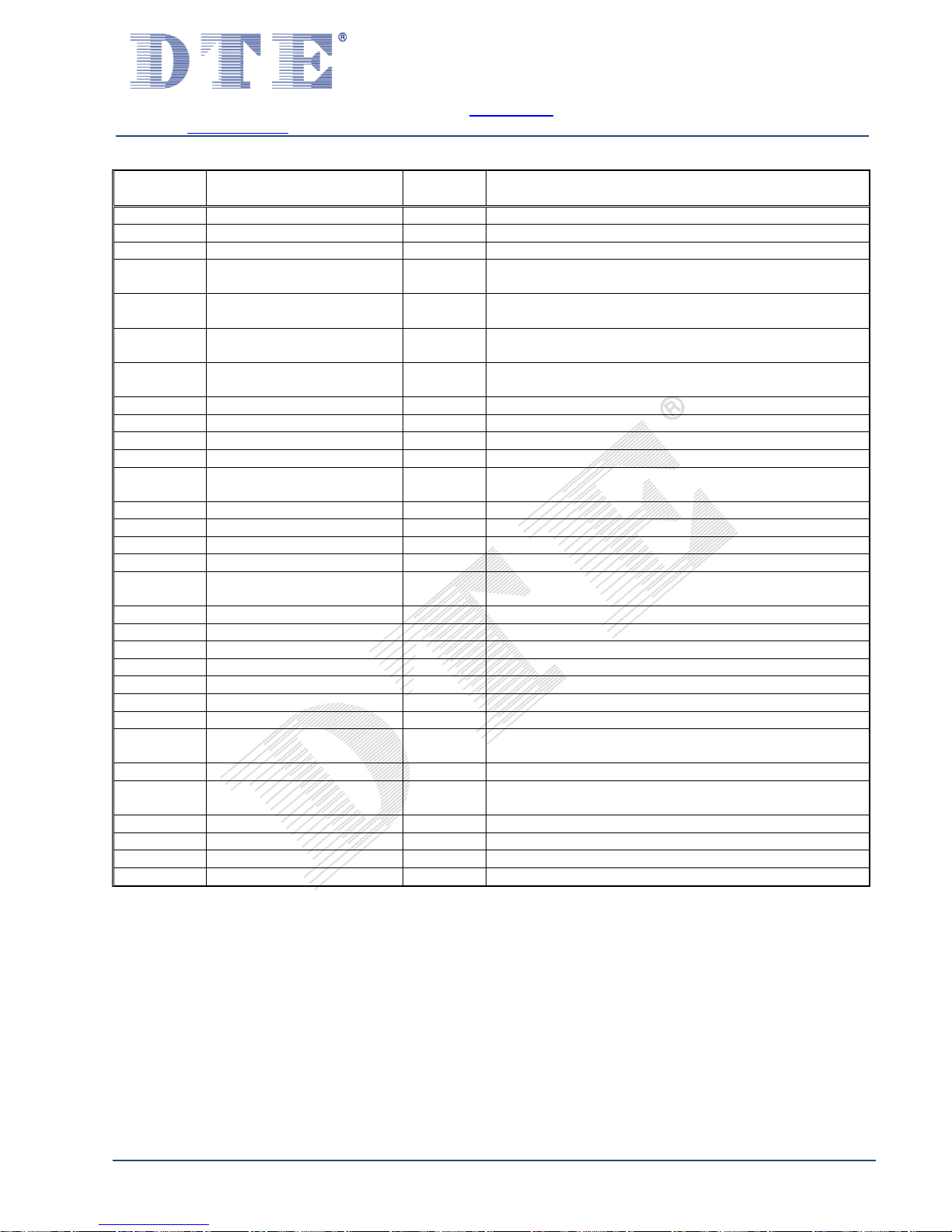

44 GGeenneerraall ddeessccrriippttiioonn

The CoolMaster is a complete plug and play water cooler with integrated water cooler tank, pump, condenser and

controls. Is built for perfect cooling in closed industrial process water systems.

A

=

Cooling water inlet, see specification list

B

=

Cooling water outlet, see specification list

C

=

Drain water tank, see specification list

D1

=

Filling water connection, see specification list

(not present in machines, specified as (N)(NF))

D2

=

Filling water facility

E

=

Overflow water tank, see specification list

F = Bushing coupling electrical supply cable

G = Control panel

H = Incoming condenser air

I = Removable cover

CAUTION! POSITION THE COVER(I) BEFORE SWITCHING ON THE

MACHINE!

J = Fixing bolts cover, 10 pieces

K = Air grille outgoing condenser air

L = Rubber legs, 4 pieces

P = Sight glass

Maximum glycol/water level

Minimum glycol/water level

S1 =

Main switch

* When deviating from the standard, a machine drawing is included as an attachment!

OFF

OFF

0

0

ON

1

S1

I

J

G

P

D2

C

F

FF

D1

A

B

E

I

H

L

K

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 9

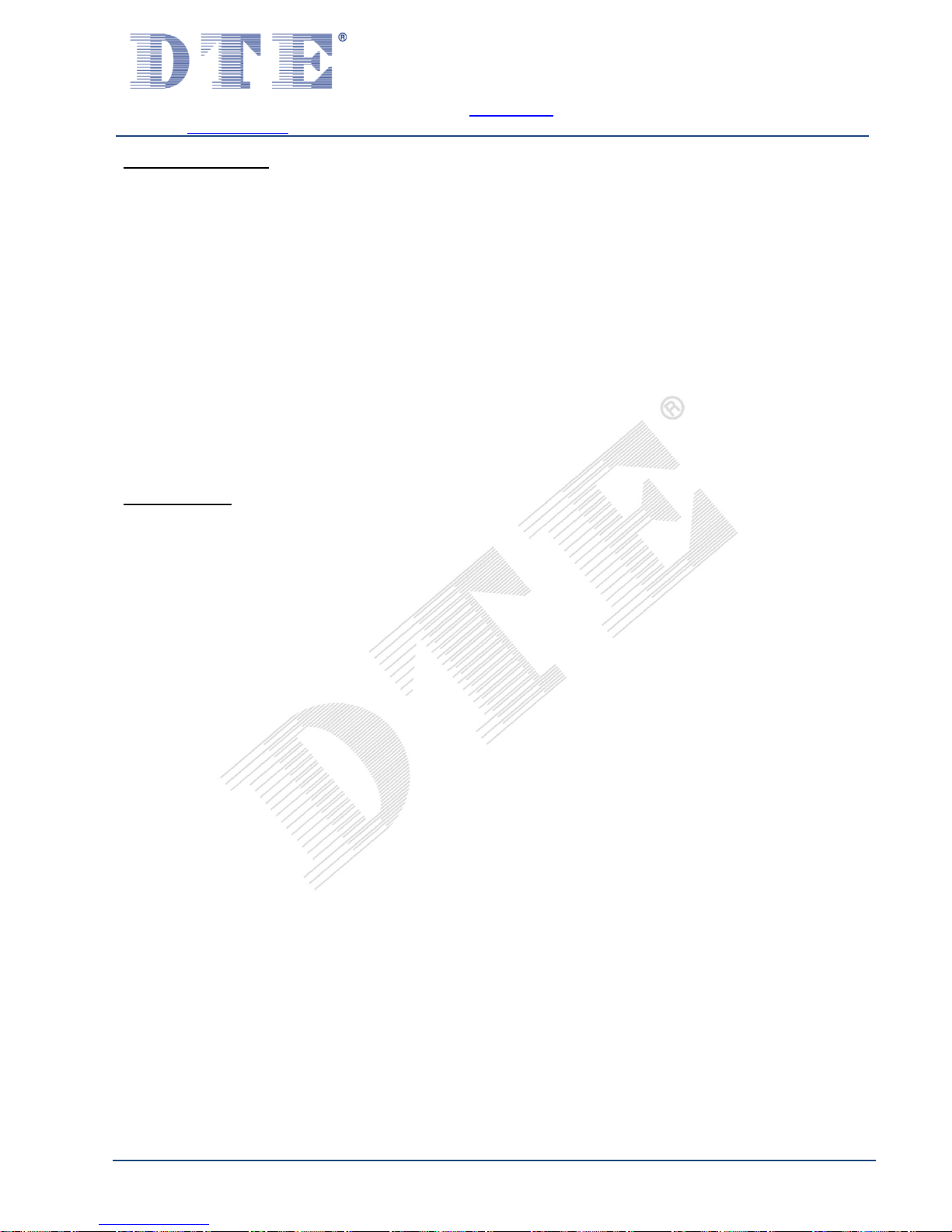

44..11 IIddeennttiiffiiccaattiioonn

The identification plate is located on the left next to the fan. (Figure 4.1)

A

=

Machine number/ serial number

Figure 4.1

B

=

Machine type

C

=

Voltage

D

=

Maximum Current

E

=

Number of phases

F

=

Frequency in Hz.

G

=

Refrigerant type

H

=

Refrigerant mass

I

=

Maximum ambient temperature

J

=

CO2 equivalent

K

=

GWP-values

L

=

Thermostat Temperature range

M

=

Maximum pressure

N

=

Compressor lubrication

O

=

Compressor oil volume

P

=

Built

Q

=

Weight

R

=

Cooling capacity

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 10

55 CCoommmmiissssiioonniinngg

See for the connections chapter 4.

CAUTION! The installation work must be carried out by a certified professional!

Place the CoolMaster at a level position and at least 1 meter from a wall. For a good functioning of the

CoolMaster we recommend keeping the distance between the CoolMaster and the user to a minimum.

The cooling water pipes between the CoolMaster and the user must be longer than 15 meters.

WARNING! The diameter of the pipes/hoses must at least match with the connections on the

CoolMaster.

The hoses MUST be reinforced with braided fibre to prevent kinking the hose.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 11

55..11 CCoonnnneeccttiinngg ccoooolliinngg wwaatteerr ppiippees

s

1

1

Let op! Before making any connections to the CoolMaster,

clean the external pipes. Dirt must be prevented from

entering the CoolMaster. It may cause serious damage to

the system and the CoolMaster.

Connect the following pipes:

- A and B: cooling water pipes between CoolMaster and the

User.

- D1: If you wish to fill automatically.

(does not apply to machinery specified as (N))

Step 1:

1. Install the ball valve (BVS-1) on the cooling water inlet (A)

2. Install cooling water pipe between CoolMaster (BVS-1) and

User. (See Figure 5.1)

The ball valve (BVS-1) must be kept closed, unless otherwise

indicated!

Step 2:

1. Install the ball valve (BVS-2) on the cooling water outlet (B).

2. Install the ball valve (BVS-3) on the T-piece (central section).

3. Install the cooling water pipe between CoolMaster

(on the T-piece) and the user. (See Figure 5.2)

The ball valves (BVS-2 and BVS-3) must be kept closed, unless

otherwise indicated!

Step 3:

1. Connect the cooling water pipes between CoolMaster and

user. (BVS-1 and BVS-3), See appendix §14.2

2. Connect D1 to a water tap if you wish to fill

automatically.

(does not apply to machinery specified as (N))

Figure 5.1

Figure 5.2

1

Ball valves are not supplied as standard.

Available by DTE with art. no. 87000090

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 12

55..22 CCoonnnneeccttiinngg oovveerrffllooww ppiippee

Connect the overflow pipe (E). To enable good outflow of superfluous water, the overflow pipe must be

able to flow out into the open sewer without any foreseeable obstructions. The length of the overflow

pipe should be kept to a minimum. The pipe should also flow downwards, from the perspective of the

CoolMaster (E).

CAUTION! For machines filled with a mixture of water and glycol (machines displaying (N)), the

excess mixture from connection (E) must not be discharged into public sewers for reasons

relating to environmental law.

55..33 CCoonnnneeccttiinngg ppoowweerr ssuuppppllyy

Attention! Work may only be carried out on the electrical installation of the CoolMaster by an

authorised, professionally competent person.

Attention! The CoolMaster must only be connected to a clockwise rotary field.

Turn off the main switch on the control panel (G).

Connect your electrical power supply cable to the appropriate terminals in the control box via the cable

entry (F). Refer to the electro-technical diagram for the connection of the cable cores. Consult the

diagram number as stated on the technical specifications sheet corresponding to the serial number of

the CoolMaster.

Consult the type plate for the correct voltage.

Attention! Ensure the voltage as stated on the type plate is also the voltage on each phase wire.

Of no less importance is the mains frequency (50 or 60 Hz) corresponding to the frequency on the type

plate. The maximum voltage deviation is +6% and –10% from the voltage indicated on the type plate.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 13

55..33..11 PPlluugg--iinn tteerrmmiinnaallss

Use a screwdriver with a 3mm wide point. Push the screwdriver

in the square recess to open the spring. (See Figure 5.3)

Figure 5.3

Place the 10mm stripped wire with cable end into the round

recess and press the wire into the terminal as deeply as

possible. (See Figure 5.4)

Figure 5.4

Remove the screwdriver. Check whether the wire is firmly

connected. (See Figure 5.5)

Figure 5.5

55..44 CCoonnnneeccttiinngg eexxtteerrnnaall ccoonnttaaccttss

Also connect the electrical cables for the external contact(s).

See for supplied wiring diagram.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 14

55..55 WWaatteerr qquuaalliittyy

CAUTION! The CoolMaster is not suitable for use with demineralized water or water containing

high levels of minerals or iron.

The filling water which is used must be of good quality. It must at least be of drinking water quality and

the water must not contain high levels of lime and/or iron, as it may cause serious damage.

You must check the water regularly.

The minimum filling pressure must be 2,5 bar.

See Appendix 14.3 for extra information.

See Appendix 14.4 for directive water quality.

CAUTION! The CoolMaster (N) are only suitable for tap water of drinking water quality mixed with

the correct ratio of a suitable anti-freeze (glycol).

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 15

55..66 FFiilllliinngg ooff ((eexxtteerrnnaall)) ppiippeess aanndd ssyysstteemmss CCoooollMMaasstteerr ((KK))

Step 1:

1. All the connections must be made in accordance with §5.1

2. Turn the air vent(s) in your system to “open”. (The venting

must take place at the highest point(s) in pipe(s))

CAUTION! Do not use automatic air vents!

CAUTION! CoolMaster (N) filling procedure in §5.9

3. Connecting the filling water (min. 2.5 Bar) to BVS-3.

4. Turn the valve (BVS-3) to “open”. (See Figure 5.6)

Step 2:

Excess air will be released from the pipe(s) though the air

release valve(s).

If the water spills from the air release valve(s), the external

pipes/systems are filled with water.

1. Turn the ball valve (BVS-3) to “closed”. (See Figure 5.7)

2. Turn the air release valve(s) in your system to the

"closed" position.

3. Turn the water fill line to “closed”.

4. Remove the fill water line which is mounted on BVS-3.

Step 3:

1. Turn the ball valve (BVS-1) to “open”. (See Figure 5.8)

2. Turn the ball valve (BVS-2) to “open”. (See Figure 5.9)

When these steps have been completed correctly, the entire

system will be filled with water.

Figure 5.6

Figure 5.7

Figure 5.8

Figure 5.9

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 16

55..77 FFiilllliinngg ooff ((eexxtteerrnnaall)) ppiippeess aanndd ssyysstteemmss CCoooollMMaasstteerr ((NN))

Step 1:

1. The connections must be made in accordance with §5.1.

The ball valve (BVS-1) must be kept closed, unless otherwise

indicated! (See Figure 5.10)

CoolMaster (N)

Filling set for mixture of water and glycol 2

Step 2:

See Figure 5.11 and Figure 5.12. for a complete image from

the filling set. The mixture of water and glycol will be provided

in the supplied tank.

The ratio of the mixture is indicated in the relevant specification

list.

Figure 5.10

Figure 5.11

Figure 5.12

Figure 5.13

2

The fillingset is not supplied as standard.

Available by DTE with art. no. 87000089

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 17

1. Install the cooling water pipe between CoolMaster

(on the T-piece) and the user.

The ball valve (BVS-2 and BVS-3) must be kept closed, unless

otherwise indicated! (See Figure 5.13)

2. Install the link (BVS-5) onto the ball valve (BVS-3) (Minimum

pressure 2.5 bar). (See Figure 5.14)

Step 3:

1. Turn the air release valve(s) to “open”. (It is essential

that the air release(s) takes place at the highest

point(s) in the pipe(s))

CAUTION! Do not use automatic air release valves!

2. Turn the ball valve (BVS-5) to “open”.

(See Figure 5.15)

3. Turn the ball valve (BVS-3) to “open”.

(See Figure 5.16 and Figure 5.17)

Figure 5.14

Figure 5.15

Figure 5.16

Figure 5.17

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 18

Step 4:

Excess air will be released from the pipe(s) though the air

release valve(s).

If the water and glycol mixture spills from the air release

valve(s), the external pipes/systems are filled with the water

and glycol mix.

1. Turn the ball valve (BVS-3) to “closed” (See Figure 5.18)

2. Turn the air release valve(s) in your system to the

"closed" position.

3. Turn the ball valve (BVS-5) to “closed”:

4. Remove the ball valve (BVS-5) (See Figure 5.19)

Step 5:

1. Turn the ball valve (BVS-1) to “open” (See Figure 5.20)

2. Turn the ball valve (BVS-2) to “open” (See Figure 5.21)

When these steps have been completed correctly, the entire

system will be filled with the water and glycol mixture.

Figure 5.18

Figure 5.19

Figure 5.20

Figure 5.21

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 19

55..88 FFiilllliinngg ooff tthhee ssyysstteemm CCoooollMMaasstteerr ((KK))

Fill the CoolMaster with water (fill automatically or manually):

1. Auto fill (D1) (a power supply is required; a minimum filling

pressure of 2.5 bar is required). (See Figure 5.22)

2. Manual fill (D2). (See Figure 5.23)

External systems must be filled via an external filling point.

See chapter §5.6 for instructions.

WARNING! To add any chemicals or other substances,

please consult the supplier.

Figure 5.22

Figure 5.23

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 20

55..99 FFiilllliinngg ooff tthhee ssyysstteemm CCoooollMMaasstteerr ((NN))

CoolMaster (N): Fill the CoolMaster with the mix of water and

glycol (using manual fill D2). (See Figure 5.24)

WARNING! This mixture must be prepared beforehand.

Filling with water first and adding the glycol afterwards or

vice versa is prohibited. For the mixing ratio for this

machine see the appropriate specifications list.

External systems must be filled via an external filling point. See

chapter §5.7 for instructions.

To add any chemicals or other substances, please consult the

supplier.

WARNING! To prevent the heat exchange and/or other

parts from freezing, the mixing ratio of the water and

glycol mix must be checked weekly by taking a sample

from the tank. If the mixing ratio is not correct, this may

affect the warranty.

Figure 5.24

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 21

55..1100 DDeeaaeerraattiinngg

WARNING! DO NOT START THE PUMP BEFORE IT IS

FILLED WITH LIQUID AND DEAERATED!

This machine is fitted with a bypass and will therefore

automatically be deaerated.

Figure 5.25

Figure 5.26

WARNING! Ensure the compressor is disabled when

starting up for the first time!

Step 1: Remove the removable cover from the machine (I).

(See Figure 5.25 and Figure 5.26)

Step 2: Turn on the installation and let the pump run for 10

minutes to get the system deaerated.

Step 3: The whole system is now deaerated, the cover can be

placed into place. The compressor is reactivated now

the removable cover is back into place.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 22

55..1111 SSeettttiinngg tthheerrmmoossttaatt

See chapter §4 for the specified parts.

CAUTION! COVER(I) MUST BE PLACED, BEFORE STARTING

UP THE MACHINE!

Switch on the main switch (S1) on the control panel (G).

Switch on the external start/stop.

Set the thermostat to the correct value, which is on the front of the control panel (G).

Zie appendix 14.5 for the settings.

CAUTION! It is important that the values in the specifications list are adhered to, otherwise

damage to the compressor may occur! When temperatures set incorrectly the guarantee claim

may expire!

WARNING! This machine is equipped with a bypass, which is erected between water supply and

water return pipe inside the CoolMaster. The minimum flow is already factory defined and may

not be hanged!

The CoolMaster is now ready for use.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 23

55..1122 CCoommmmiissssiioonniinngg aafftteerr lloonngg ssttaannddssttiillll

CAUTION! BEFORE OPENING MACHINE, ALWAYS

ENSURE POWER SUPPLY IS COMPLETELY

DISCONNECTED!

Figure 5.27

Figure 5.28

DTE uses reputable components in its products, whereby DTE

will reduce the risk of faults in its machines.

This also applies to the water pumps. These pumps are made

with a stainless steel fan, a high quality pump house and a

“Mechanical seal” to seal the axis. The mechanical seal is a

high quality axis seal made from polished hard metal, and all

contact surfaces are polished. This will guarantee a good

sealing even under the toughest operating circumstances. The

mechanical seal will lubricate itself by means of a thin liquid

layer of the pumped fluid.

When the machine has not been used for a long period there is

a chance that the water pump will not run. The cause of this

fault may be cohesion between the polished contact surfaces

of the mechanical seals. The seals "stick together". This

problem is easily solved by rotating the pump axis by hand. In

the Grundfos pump, it can be done by first removing the roster

by unscrewing the two screws. You can now rotate the engine

fan by hand. The sticking together has now been broken and

the machine can be started. (See Figure 5.27 and Figure 5.28)

CAUTION! MAKE SURE TO REPLACE THE ROSTER,

OTHERWISE THE PUMP ENGINE WILL NOT BE COOLED

PROPERLY!

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 24

66 MMeeaanniinngg ooff aallaarrmmss ((iiff aapppplliiccaabbllee))

Fault

Possible cause

Check and solution

1. Level Alarm

1.1. Water level is too low

1.1. Check the water level

on the gauge glass, refill

if necessary

1.2. Check whether the machine

refills automatically

(if connected)

1.3. Check water inlet

1.4. Check valves

1.5. Check for leaks

2. Compressor

Alarm

2.1. Thermal alarm or short-circuit

compressor(s)

2.1. Check for short-circuit

2.2. Check for overload of

compressor(s)

3. Condenser

Alarm

3.1. Thermal alarm or short-circuit

fan(s)

3.1. Check for short-circuit

3.2. Check for overload of

fan(s)

4. Water pump

Alarm

4.1. Thermal alarm or short-circuit

water pump(s)

4.1. Check for short-circuit

4.2. Check for overload of

pump(s)

5. Filling

5.1. Filling system

5.1. Check liquid level

5.2. Refill manually if necessary

5.3. In the event of malfunctions please

contact the supplier

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 25

77 FFaauulltt aannaallyyssiiss

Have all checks and repairs performed by a certified technician!

Fault

Possible cause

Check and solution

1. Unit does not start

1.1. Faulty wiring

1.2. Components down to earth

1.3. Faulty main switch

1.4. Controls incorrectly set

1.5. Removable cover not

correctly placed on machine

1.1. Check wiring and connections

1.2. Check and replace

1.3. Check and replace

1.4. Check, see electric diagram

1.5. Place removable cover

2. Fan(s) run but

compressor will not

start

2.1. Faulty wiring

2.2. Faulty relay, or security

2.3. Faulty compressor

2.1. Check wiring and connections

2.2. Check components

2.3. Check and replace

3. Compressor starts but

no air is delivered over

the condenser

3.1. Fan loose on shaft

3.2. Faulty fan motor

3.3. Faulty wiring

3.4. Blocked air flow

3.1. Tighten fixing screw

3.2. Check and replace

3.3. Check wiring and connections

3.4. Clean the condenser

4. Compressor switches

off

4.1. Electricity supply

4.2. Faulty thermostat

4.3. Faulty relay, or security

4.4. Internal security activated

4.1. Check electricity supply

4.2. Check and replace

4.3. Check and replace

4.4. Water and/or ambient temperature

too high. Check cleanliness of

condenser and clean it

5. Unit does not cool

5.1. Shortage of freon

5.2. Faulty compressor

5.3. Faulty thermostat

5.4. Faulty pump

5.1. Refill

5.2. Check and replace

5.3. Check and replace

5.3. Check and replace

6. Water pump gives

no water

6.1. Water pump not de-aerated

6.2. Impeller of water pump is stuck

6.3. Faulty relay, or security

6.1. De-aerate water pump

6.2. See: chapter 5.12

6.3. Check components

7. Shortage of freon

7.1. Leak in the system

7.1. Check the system for leakage and

repair

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 26

88 MMiinniimmuumm IInnssppeeccttiioonn--iinntteerrvvaall sscchheemmee

Inspection interval

Inspection points

Weekly

monthly

Every

6 months

Every

12 months

Every

24 months

Mechanical

Visual check on damage outside of

the unit

X

Visual check fans on damage

X

Visual check fan on prevalence

X

Visual (and auditive) check on

defects

X

Visual check of wiring/cabling

X

Cleaning condenser by using with

compressed air or vacuum cleaner

X

Cleaning fan blade(s) to prevent

imbalance

X

Check the hermetical system leaks

X

Pressure temperatures and

refrigeration installation check

X

Cleaning the compressor with damp

cloth.

X

Retracing hose clamps

X

Check mixing ratio water/glycol (only

for CoolMaster (N))

X

Check water quality

X

Electrical

Check all potential indicators and

earthings

X

Power consumption check

X

Check wiring main switch for damage

X

Visual check electrical components

and contactors

X

Torque for hose clamps

Hose ø 13mm.

10 N/m

Hose ø 19mm.

12 N/m

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 27

99 CClleeaanniinngg ooff tthhee mmaacchhiinnee

CAUTION! ONLY APPLIES TO THE EXTERIOR CASING!

Before cleaning the machine, make sure you completely disconnect the power supply.

To clean the machine use a soft brush, with lukewarm water with a non-aggressive cleaner. Then

rub the machine dry with a soft, dry cloth. Unless explicitly stated otherwise the machine must

not be cleaned with a high-pressure cleaner and/or other powerful water jets!

1100 CChheecckkss

We recommend carrying out the following checks every week:

- Check the fan motor(s) and fan blade(s) for pollution and operation.

- Ensure the water pump(s) has no leaks.

- Check the water and glycol mixture. (if applicable)

We recommend carrying out the following checks every month:

- Clean condenser plates with compressed air and/or vacuum cleaner.

- (Caution: The condenser plates can be sharp!)

- Check all wiring and connections.

- Ensure the hermetical system has no leaks.

- Check water level of the water tank at the gauge glass (P).

- Check the flow of the by-pass.

1111 SSeerrvviiccee

If a problem and/or advise is needed from our technical staff, please always mention:

- Serial number

- Ambient temperature

- What is shown at the display of the thermostat

- What is the setpoint of the thermostat

- Which alarm signals are given

By mention these points, a quick solution of the problem can be given.

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Tel.: +31(0)315-328311

E-mail: service@dte.eu

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 28

1122 GGuuaarraanntteeee

One or more components in this CoolMaster are sealed.

Breaking these seals or adjusting components which are not sealed, may void your guarantee.

Always contact your supplier. When claiming one or more components under the guarantee, these

components must be returned to the supplier uncleaned and in their original state.

Otherwise, the guarantee conditions on this machine apply as described in the general conditions of

delivery and payment. These were deposited at the Chamber of Commerce in Arnhem on 05-06-1989, a

copy of which is available upon request.

1133 RReemmoovvaall

The CoolMaster consists primarily of stainless steel, copper, brass and aluminium. The CoolMaster is

also compressed with a refrigerant which is specified in the “specification list” and the relevant safety

data sheet.

Removal of the CoolMaster must be carried out in accordance with local or national legislation. Contact

your government for instructions.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 29

1

1

4

4

A

A

p

p

p

p

e

e

n

n

d

dii

x

x

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 30

1144..11 OOppttiioonnss

Options Part list

Part

Article no.

K2 Connectingset (SP)

87000087

K2 Control box sealing + Heating

87000065

K2 Control box sealing

87000064

K2 Connectingset

87000055

K2 Manifold with control valve for connection of 3 machines

87000011

K2 Manifold with control valve for connection of 2 machines

87000010

K2 Black blow function for emptying the forms

87000009

Tag numbers

87000006

K2 wire numbers

87000005

K2 Wheels (1 pair fixed, 1 pair castoring) stainless steel

87000004

K2 Manometer (installed in the supply line external to

machine)

87000002

K2 Check valve 3 wc, mounted external to machine

87000001

Filling Unit, water/glycol

87000089

Filling Set for external system

87000090

Table 1: Order list options

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 31

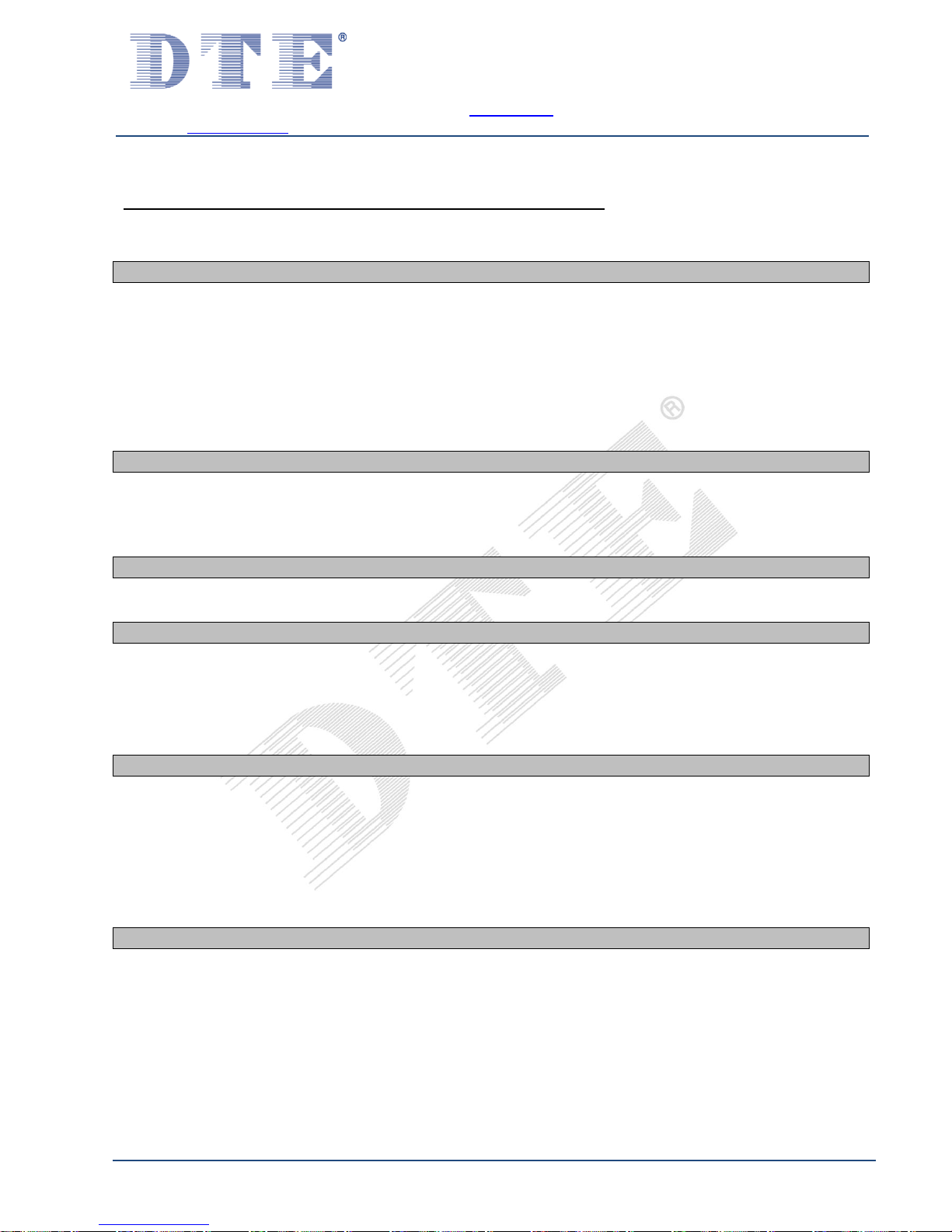

1144..22 CCoonnnneeccttiioonn ddiiaaggrraamm ffiilllliinngg tthhee ssyysstteemm

Figure 14.1

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 32

1144..33 WWaatteerrttrreeaattmmeenntt

INTRODUCTION

Semi-closed and closed cooling systems are used in many processes.

An efficient and effective cooling system is needed for a process to function without problems.

Generally such cooling systems contain between 0.5 and 5.0 m³ water,

which is normally topped up with tap water. The tap water available is often, technically speaking, of poor quality:

contains limescale and/or

is corrosive

The system may contain many different materials with which the cooling water comes into contact. Such as:

steel/cast iron

copper/brass

aluminium

synthetics/sealants

PROBLEM DEFINITION

Corrosion problems can occur in cooling systems, which have different causes.

The presence of different materials can result in galvanic corrosion, which is where the least precious metal is

dissolved. The action of oxygen on iron and steel causes oxygen corrosion and the formation of iron oxide or silt.

Natural silt accumulation can lead to “under deposit corrosion”. High flow-speeds can lead to erosion corrosion.

The quality of the cooling water plays a significant role in this.

GENERAL MEASURES

Contamination

Measure

Mechanical contamination caused by iron oxides or silt

Install filters, depending on contamination

High hardness

Soften water via ion exchange

Minor contamination caused by presence of oxides

and hardness

Use water treatment in the form of hardness stabilisation

and corrosion inhibitors

Biological contamination caused by presence of algae

and slime bacteria

Use water treatment in the form of biocides

WATER TREATMENT

Specific water treatment should be used if one or more values cannot be maintained or achieved.

Water treatment products can be used for a wide variety of applications in this case. DTE has a water treatment in the form of

PollutionMaster. This product can optionally be supplied. If the temperature of the water exceeds approx. 40°C, (partial) water

softening must in general be applied.

A complete water treatment proposal can be drawn up after the water quality has been assessed on site.

CLEANING

If the cooling system is already very contaminated, we recommend cleaning the system with a suitable cleaning product. The

cleaning solution can be pumped around using the system pump or an cleaning pump.

For the best cleaning result, at least some flow should be established across all components. The cleaning progress can be

monitored through visual inspection and using pH test strips.

Systems with considerable biological contamination should be rinsed thoroughly first. A bio-dispergator can also be used for this

purpose.

The cleaning method and costs will be assessed and determined per situation.

Note: You can contact DTE anytime.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 33

1144..44 GGuuiiddlliinnee ffoorr wwaatteerr qquuaalliittyy iinn DDTTEE iinnssttaallllaattiioonnss

Water quality for use in all DTE installations is prescribed in this general guideline. Water quality used in DTE

installations should meet this standard at all times.

Standard values for water quality:

- Acidity: PH 7 < PH 9,5

- Chloride: < 50mg / L

- Conductivity: 150 µS < 350µS

- Bicarbonate (HCO3): 80mg/L < 100mg/L

- Hardness: 2dH° < 8dH°

This directive is a general directive which also applies to systems in which water with a percentage of glycol is

used.

In cases where a water-glycol mixture is to be applied, the quality of water must first be analysed to be ensured the

water quality is within the norm values. Subsequently, a water-glycol mixture may be prepared that must be tested

on mixing ratio before use.

In the system the absorption of oxygen must prevented to keep the hydrogen carbonate (HCO3) level within the

acceptable range. In case of doubt, this should be tested with a sufficient frequency.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 34

1144..55 UUsseerr mmaannuuaall tthheerrmmoossttaatt

KLT12ID:

SETPOINT CHANGE

Push “SET” once (set point will be displayed flashing).

Change the set point by pressing “UP” and “DOWN”.

Confirm the changed set point with “SET”.

Parameter programming

(These parameters are factory set. Do not change them!)

1. To enter the parameters push the ‘’SET’’-button for at least 8 seconds. Value ‘’00’’ will appear, flashing.

2. Enter the correct code by pressing “UP” and “DOWN”. (this is factory-set to ‘’00’’)

3. Press ‘’SET’’ to confirm the code. If this is correct, the label of the first parameter will appear.

4. Using the “UP” and “DOWN” button, select the desired parameter.

5. Press ‘’SET’’ to see the value.

6. Change the parameter by pushing “UP” and “DOWN”.

7. Confirm with "SET".

8. To change more parameters, repeat step 4, 5 and 6.

9. The controller will return to its normal condition after 60 sec, or just press the ‘’SET’’ + ‘’DOWN’’ button.

Parameter list

Parameter

Description

Factoryvalue

Comment

‘’SET’’

Set point

15

Change possible between US and LS

r0

Set point differential

2

Differential on/off controller, this parameter may not be

changed!!

r1

Minimum set point

5

Sets the minimum acceptable value for the set point

r2

Maximum set point

20

Sets the maximum acceptable value for the set point

r3

Normal or differential

adjustment

Nor

r4

Diff. For diff. mode

0.1

r5

Diff. setpoint

0.0 r6

Fan operation

con d0

Cold or Hot control

re

Re=Cold, in=Hot

d1

End of defrost. temp

80 d2

Max. defrost time

0 d3

Defrost when connecting

No d4

Delay first defrost

0.0

h-m

d5

Display on defrosting

Off d6

Display return limit

15 d7

Compressor drip time

0 d8

Interval between defrost

0 d9

Fan works with defrost

No d10

Fan drip time

0 d11

Manual defrost sync.

No

d12

Defrost probe

SD1 d14

Units to count defrost cycle

Rt

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 35

Parameter list

Parameter

Description

Factoryvalue

Comment

A0

Set point

2.0

Degrees

A1

Max. Alarm temperature

85

Alarm high value

A2

Min. alarm temperature

5.0

Alarm low value

A3

Alarm exclusion time during

continuous cycle

0.0

Minutes

A4

Alarm exclusion time

After defrost

0.0

Minutes

A5

Alarm exclusion time after

opening door

0.0

Minutes

A6

Alarm exclusion after

connection

0.0

Minutes

A7

Alarm verification time

0.0

Minutes

A8

Ext. alarm verification time

0.0

Minutes

F0

Fan stoppage temperature

0.0 F1

Fan works with door open

Yes

c0

Min. stoppage time

compressor

1

Minimum interval between the compressor start and stop

(value in minutes)

c1

Continuous cycle time

0.0

Minutes

c2

ON-time of fault cycle

0

Minutes

c3

OFF-time of fault cycle

999

Minutes

c4

Min. ON-time

0

Minutes

c5

Min. time between 2

ignitions of compressor

0

Minutes

P0

Temperature scale

°C

°C or °F

P1

Ambient probe calibration

-1.0

Allows to adjust possible offset of the thermostat probe

P2

Defrosting probe calibration

0

Allows to adjust possible offset of the thermostat probe

P4

Decimal point

Yes

Display point on/off

P5

Probe to be displayed

SD1 P6

Number of probes used

1 E0

Digital input

off

Digital input not used

H0

Selection to record a

configuration

0

H1

Keypad protection

No

H2

Service cut due to digital

input

No

H3

Delay time on connecting

0

Minutes

H4

Address for serial comms

0 H5

Keyboard code

0 H6

Type of probe

NTC

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 36

DISPLAY MESSAGE:

In normal operation the probe temperature selected by P5 will be displayed. But the following messages may also

appear:

- ‘’Err’’ - Memory reading error

- ‘’Erp’’ - Probe error, not viewed in display

- ‘’Eri’’ - Internal parameter error. In this case, enter the above DTE-configuration

- ‘’ALH’’ - High temperature alarm

- ‘’ALL’’ - Low temperature alarm (temperature is 5 degrees lower then ‘’SET”)

- ‘’ALE’’ - External alarm

- ‘’AEL’’ - High and external alarm

- ‘’000’’ - Probe open

- ‘’---‘’ - Probe short-circuited

- ‘’DON’’ - Defrosting activated

- ‘’DOF’’ - Defrosting de-activated, or cannot be done

- ‘’CON’’ - Continuous cold cycle

- ‘’COF’’ - Continuous cold cycle de-activated, or cannot be done

- ‘’-d-‘’ - Thermostat on defrosting

- ‘’OFF’’ - Thermostat switched OFF, can be switched on by pressing the ‘’UP’’ and ‘’DOWN’’-button

simultaneously for at least 8 seconds

MAINTENANCE

- Cleaning

Clean the surface of the controller with a soft, damp cloth. NEVER use abrasive detergents, alcohol or

solvents

- Repairs/Programming

All repairs and the programming of the thermostat must be carried out by authorised professional.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 37

1144..66 SSaaffeettyy iinnffoorrmmaattiioonn sshheeeettss

The refrigerant safety data sheet is sent separately as an attachment!

MONOPROPYLENE GLYCOL USP

1. IDENTIFICATION OF THE PRODUCT AND THE COMPANY

Substance name:

MONOPROPYLENE GLYCOL USP

Substance type:

Raw material

Supplier:

BREUSTEDT CHEMIE BV

POSTBUS 721

7300 AS APELDOORN

THE NETHERLANDS

Tel.

055-5332844

Fax.

055-5429072

2. COMPOSITION OF AND INFORMATION ON THE INGREDIENTS

Official substance name:

MONOPROPYLENE GLYCOL USP

CAS no.:

Annex 1 no.:

3. DANGER IDENTIFICATION

Not a dangerous product according to guideline 67/548/EEG

4. FIRST AID MEASURES

Swallowing:

No harmful effects are expected in case of this type of exposure

Eyes:

Rinse extensively with water

Skin:

Rinse skin with plenty of water or shower

Inhaling:

No harmful effects are expected in case of this type of exposure, in association with the correct

professional usage.

5. FIRE FIGHTING MEASURES

Risks:

Stability:

Stable under normal circumstances

Preventative measures:

Extinguishing agents:

Water spray, carbon dioxide, foam and extinguishing powder

Fire:

Incomplete incineration may lead to the formation of carbon monoxide and propionaldehyde

6. MEASURES IN CASE OF UNWANTED RELEASE

Personal precautions

Swallowing

Do not eat, drink or smoke during work

Eyes

Safety glasses with side protection

Skin

Prevent skin contact, wear gloves

Inhaling

Ventilation, wear breathing protection if limit is exceeded

Environmental precautions/cleaning methods

Cleaning/waste

If possible, recover or re-use, or dispose of waste in accordance with the applicable legislation.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 38

7. HANDLING AND STORAGE

Storage

In a ventilated, dry space, separate from strongly oxidizing substances

8. EXPOSURE MANAGEMENT/PERSONAL PROTECTION

Swallowing

Do not eat, drink or smoke during work

Eyes

Safety glasses with side protection

Skin

Prevent skin contact, wear gloves

Inhaling

Ventilation, wear breathing protection if limit is exceeded

Exposure details

ppm

mg/m3

ceiling value

Absorption through

skin?

MAC-TGG 8 hours

50

10

No No

MAC-TGG 15 min

No

WGW values

No

WGD recommended

values

No

BGW values

No

9. PHYSICAL AND CHEMICAL CHARACTERISTICS

Description

MONOPROPYLENE GLYCOL USP

Blacklist substance?

No

Physical form

Liquid

Colour

Colourless, clear

Appearance form

Liquid

Odour

None Molecular mass

Not available

Odour threshold

Not available

ppm

Vapour pressure (mbar)

0.3 mbar

Boiling point/pathway

188

°C

Vapour pressure (bar)

Not available

bar

Melting point/pathway

Not available

°C

Density (water=1)

1.04 g/cm3

Sublimation

point/pathway

Not available

°C

Vapour density (air=1)

2.62 g/cm3

Flash point

103

°C

Water solubility

Completely

Auto-ignition temp.

371

°C

Soluble in

Not available

Dissolution temperature

Not available

°C

pH

N/a

Lower explosion

threshold

2.6

Vol%

Viscosity

Not available

Upper explosion

threshold

12.5

Vol%

As a standard temperature and standard pressure 20 °C and 1 atm. (=103,325 kPa) apply unless stated

otherwise

Other details

Anti-freeze

10. STABILITY AND REACTIVITY

Reactivity

Dangerous reactions: with caustic potash and caustic soda (T<200 C), oxidizing

substances

Stability

Stable under normal circumstances

Preventative measures

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 39

11. TOXICOLOGICAL INFORMATION

Carcinogenic

No

Reprotoxic (for the reproduction of poisoning)

No

Sensitising

No

Special indication

Mutagenic

No

Inhaling

Coughing, headache, sore throat

Skin

Redness, pain

Eyes

Redness, pain

Swallowing

Abdominal pain, nausea

Ingestion via

Swallowing and inhaling, no hazardous effects are expected

Other toxicological details

LD50 oral, rat: > 5000 mg/kg

LD50 dermal, rabbit: > 10000 mg/kg

Skin irritation rabbit: not irritating, irritation of eyes rabbit: not irritating

Sensitisation: causes no skin conditions

12. ECOLOGICAL INFORMATION

LC50 vis, 96 h: 4600-54900 mg/l

EC50 Daphia Magna, 48h: 4850-34400 mg/l

Biological degradation, 28 days 86% (BOD 28 > 60%)

No long-term negative effects are expected in a watery environment

13. POINTS OF ATTENTION FOR REMOVAL

Cleaning/waste

If possible, recover or re-use, or dispose of waste in accordance with the applicable legislation.

BAGA

KCA/KGA

14. INFORMATION WITH REGARD TO TRANSPORT

Transport

This product has been classified as non-hazardous in accordance with international transport

regulation

UN no.

Packaging group

GEVI no.

Other transport

codings

Class

No.

Edge

no.

TEC no.

Sheet

no.

EMS

MFAG no.

NFPA-code

Road

ADR/VLG

Water

ADN

ADN(R)

IMDG

Rail

RID/VSG

Air

IATA/ICAO

15. INFORMATION WITH REGARD TO REGULATION

Chem. Identity

MONOPROPYLENE GLYCOL USP

EC no.

Contains

Safety datasheet (VIB) according NEN-ISO 11014:2009

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 40

16. OTHER INFORMATION

Comments

Liability

This safety data sheet (SDS) was drawn up in accordance with the NEN-ISO 11014:2009 guidelines. It was

drawn up with the utmost care and the data is based on current knowledge and experience.

However, the responsibility for using this SDS rests with the employer.

But we cannot accept liability for damage of any kind arising from the use of this data or use of the product.

The safety data sheet describes products for their safety requirements. This

information is no guarantee for product properties. It is the duty of the user to use this product with care and

to comply with the applicable laws and regulations.

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 41

MONO ETHYLENE GLYCOL

1. IDENTIFICATION OF THE PRODUCT AND OF THE COMPANY

Substance name

MONO ETHYLENE GLYCOL

Substance type

Raw material

Application

Frost protective additive for liquid extinguishing agents

Supplier

BREUSTEDT CHEMIE BV

POSTBUS 721

7300 AS APELDOORN

THE NETHERLANDS

Tel.

055-5332844

Fax.

055-5429072

2. COMPOSITION OF AND INFORMATION ON THE INGREDIENTS

Official substance name

MONO ETHYLENE GLYCOL USP

CAS no.:

Annex 1 no.

3. RISKS

The vapour mixes well with air. Reacts strongly with oxidation agents and oxidising acids. The substance can be absorbed into the

body through inhalation and swallowing. The substance is an irritant to eyes and skin. The substance has an effect on the nervous

system. Liver, kidney, and brain damage may occur. In serious cases there is a risk of unconsciousness.

Flammable substance: avoid open fire. Use in explosive safe environment, ensure there are earthing and spark-free tools.

Do not consume any food or drink when using or processing, and do not smoke.

4. FIRST AID MEASURES

Swallowing

Symptoms: Diarrhoea, stomach cramps, headache, dizziness, vomiting, sleepiness. Have

mouth rinsed, try to avoid vomiting and immediately transport to hospital

Skin and eye contact

Symptoms: Redness. Rinse or shower with plenty of water. Rinse eyes for long time (if

possible, remove contact lenses) Warn a doctor

Inhaling

Symptoms: Headache, dizziness, sleepiness. Take the victim into the fresh air and allow

him/her to rest

5. FIRE FIGHTING MEASURES

Suitable extinguishing agents

Powder, alcohol proof foam, water spray, carbon dioxide

Specific extinguishing methods

None

Specific exposure dangers

None

Protection in case of fire fighting

Wear chemical-resistant clothing and respiratory protection

6. MEASURES IN CASE OF UNWANTED RELEASE

Personal precautions

Wear chemical-resistant clothing and respiratory protection. Wear safety gloves and glasses.

Remove contaminated clothing and follow first aid measures

Environmental measures

Dam in spilt product and carefully vacuum it up, clear it up. Absorb it with absorption grains

Cleaning methods

Remove residuals with water

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 42

7. HANDLING AND STORAGE

Handling

Use personal protection equipment

Storage

In a ventilated, dry space, separate from strongly oxidative substances

8. EXPOSURE MANAGEMENT/PERSONAL PROTECTION

Swallowing

Do not eat, drink or smoke during work

Eyes

Safety glasses with side protection

Skin

Prevent skin contact, wear gloves

Inhaling

Ventilation, wear breathing protection if limit is exceeded

Threshold value/MAC value

10 ppm / 26 mg/m3 in droplets (maximum not to be exceeded)

Protected breathing

Extraction. Filter mask A. processing or use in well-ventilated space

Protection of hands

Safety gloves

Protection of eyes

Safety glasses

Protection of skin

Protective clothing

9. PHYSICAL AND CHEMICAL CHARACTERISTICS

Description

MONO ETHYLENE GLYCOL

Blacklist substance?

No

Physical form

Liquid

Colour

Colourless, clear

Appearance form

Liquid

Odour

None

Molecular mass

Not available

Odour threshold

Not available

pp

Vapour pressure (mbar)

0,12 @ 25 °C

mbar

Boiling point/pathway

179

°C

Vapour pressure (bar)

Not available

bar

Melting point/pathway

-13

°C

Density (water=1)

1.1 g/cm3

Sublimation

point/pathway

Not available

°C

Vapour density (air=1)

2.1 @ 25 °C

g/cm3

Flash point

116

°C

Water solubility

Completely

Auto-ignition temp.

413

°C

Solubility in water

Fully soluble

Dissolution temperature

Not available

°C

pH

N/a

Lower explosion

threshold

3.2

Vol

%

Viscosity

Not available

Upper explosion

threshold

28

Vol

%

As a standard temperature and standard pressure 20 °C and 1 atm. (=103.325 kPa) unless stated otherwise

Other details

Anti-freeze

10. STABILITY AND REACTIVITY

Circumstances to be avoided

Keep separate from food

Substances to be avoided

Reacts strongly with oxidation agents and oxidising acids.

Hazardous degradation

products

T h e N e t h e r l a n d s

w w w . d t e . e u

Dutch Thermal Engineering n.v.

Westerbroekstraat 18

7011 EX Gaanderen

Phone : +31(0)315-328311

E-mail : info@dte.eu

Specialist in:

Industrial ….Cooling

….Heating

….Tempering

….Heat Recovery

V00-08-2017 Page 43

11. TOXICOLOGICAL INFORMATION

Carcinogenic

No

Reprotoxic (for the reproduction of poisoning)

No

Sensitising

No

Special indication

Mutagenic

No

Inhaling

Coughing, headache, sore throat

Skin

Redness, pain

Eyes

Redness, pain

Swallowing

Abdominal pain, nausea

Ingestion via

Swallowing and inhaling, no hazardous effects are expected

Other toxicological details

LD50 oral, rat: > 5000 mg/kg

LD50 dermal, rabbit: > 10000 mg/kg

Skin irritation rabbit: not irritating, irritation of eyes rabbit: not irritating

Sensitisation: causes no skin conditions

12. ENVIRONMENTAL INFORMATION

Exotoxicity

LC goldfish: > 5000 mg/l

Persistence/degradation

BOD: 0.47; COD: 1.24

13. POINTS OF ATTENTION FOR REMOVAL

Cleaning/waste

If possible, recover or re-use, or dispose of waste in accordance with the applicable legislation.

14. INFORMATION WITH REGARD TO TRANSPORT

Transport

UN no.

Packaging group

GEVI no.

Other transport

codings

Class

No.

Edge

no.

TEC no.

Sheet

no.

EMS

MFAG no.

NFPA-code

Road

ADR/VLG

Water

ADN

ADN(R)

IMDG

Rail

RID/VSG

Air

IATA/ICAO

15. INFORMATION WITH REGARD TO REGULATION

Chem. Identity

MONO ETHYLENE GLYCOL

EC no.

Contains

T h e N e t h e r l a n d s