Dustless Turbo Drywall Sander User Manual

How to Order Repair Parts:

For nearest service center Call:

1-800-568-3949

or send sander to:

Love-Less Ash Company

600 South Nick Lane

Price, Utah 84501

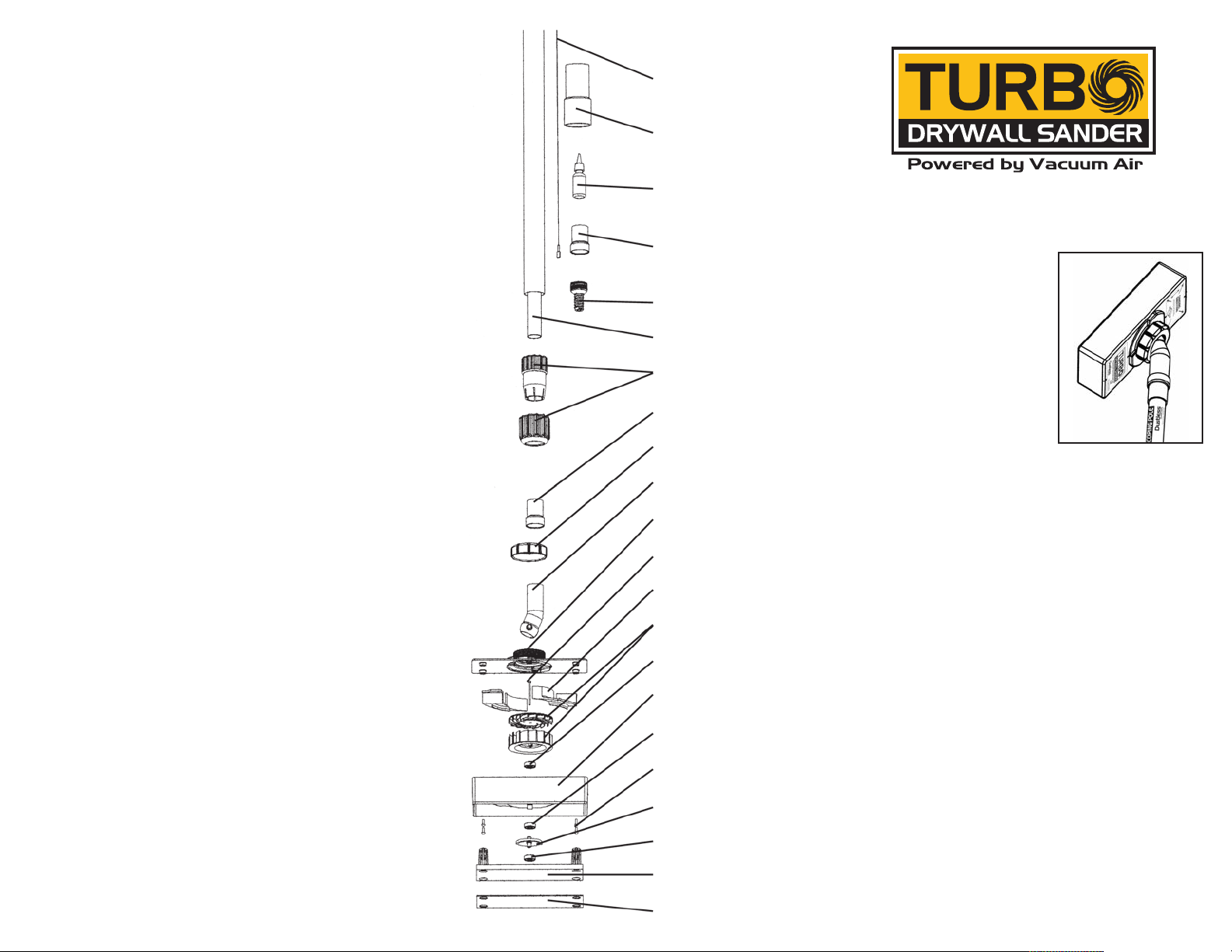

Parts List/Accessories

Item # Qty. Part # Description

1. 1 54501 Copper wire 18”

2. 1 14311 11/ 2” Soft Hose Adapter

3. 1 53351 1/ 2 oz Bearing Oil with spout

4. 2 56611 Sander Adapter for hand handing

5. 1 56112 Acme Thread Adapter

6. 1 57101 Extension Pole

7. 2 57102 Pole Locking Mechanism (2 parts)

8. 1 56631 Cap

9. 1 56621 Goose Neck

10. 1 56641 Power Head Block Cover

11. 1 51201 Turbine Screw 11/ 8”

12. 2 56651 Air Inserts

13. 2 55151 Turbine (2 parts)

14. 2 52251 Shielded Bearing

15. 1 53101 Power Head Block

16. 1 52101 Sealed Bearing

17. 4 51151 Sander Screws 3/ 8” (4)

18. 1 55131 Sander Counter Weight

19. 1 53131 Sanding Pad (Hard with Stand offs)

20. 1 53341 Velcro Pad

Sand Paper Qty Number Qty Number

220 Grit 5 54301 25 54302

180 Grit 5 54201 25 54202

120 Grit 5 54101 25 54102

100 Grit 5 54501 25 54502

80 Grit 5 54401 25 54402

1. 54501

2. 14311

3. 53351

4. 56611

5. 56112

6. 57101

7. 57102

4. 56611

8. 56631

9. 56621

10. 56641

11. 51201

12. 56651

13. 55151

14. 52251

15. 53101

16. 52101

17. 51151

18. 55131

14. 52251

19. 53131

20. 53341

INSTRUCTION MANUAL

Congratulations on your

purchase of this contractor

quality Turbo Drywall Sander.

Important:

Please read these instructions

completely and carefully before

operating your new Turbo Drywall

Sander. Keep this instruction

sheet for future reference.

Limited Warranty

Your Turbo Drywall Sander is warranted in normal use;

provided that use is in accordance with the Owner’s

Manual and the safety rules listed within, against original

defects in material and workmanship for a period of 30

days. Please note this warranty is limited to and applies

only to the original purchaser. Love-Less Ash Company is

not responsible and will not be held liable for statements

made by any person(s) as to operation of this unit that vary

from the terms of this limited warranty. Please read this

manual carefully for limitations. There are no warranties

express or implied written or verbal, which extend beyond

the description in this manual.

Simply return the complete unit or part, (transportation

prepaid), to Love-Less Ash Company, 600 South Nick Lane,

Price, Utah 84501. Love-Less Ash Company assumes no

responsibility for damage or faulty performance caused by

misuse or careless handling, or where repairs have been

made or attempted by others. Proof of purchase date is

required. This warranty gives you specific legal rights and

you may also have other rights, which may vary, from

state to state.

Model 50001

Important Safety Instructions:

1. Use Safety Glasses and Hearing Protection – Protection

for eyes and ears is always recommended.

2. Guard against electric shock- This tool is supplied with a

grounding strip inside the extension pole. Never use this

tool with out the grounding strip in place. This sander

does not have an electrical cord but the vacuum you will

use with it does. Always protect electrical cords and use

an appropriately grounded vacuum.

3. Observe OSHA Rule Avoid Power lines by 10 feet.

4. Use right tool –Don’t use tool for purpose not intended.

5. Don’t force tool – It will do the job better and safer at

the rate for which it was intended. Use a light touch.

6. Don’t overreach – Keep proper footing and balance at

all times.

7. Maintain tools with care – Keep tools clean for better

and safer performance. Follow instructions for

lubricating and changing sandpaper. Inspect tools

periodically and if damaged, have repaired by

authorized service facility.

8. Replacement parts – when servicing use only identical

replacement parts.

9. When extending or contracting the extension pole –

always have vacuum source turned off.

Additional Safety Rules

1. This Turbo Drywall Sander is specifically designed to

work with the Love-Less Ash Company Model 16004 QV

“Dustless” Drywall Vacuum. Love-Less Ash Company is

not responsible for the performance of this sander with

any other wet/dry vacuum.

2. Hold the tool firmly

3. Keep hands away from rotating parts or pinch points.

4. Do not leave the tool running when not in use.

5. Operate the tool only when hand-held.

SAVE THESE INSTRUCTIONS.

Set Up Instructions:

Attaching Abrasive Hook & Loop Sandpaper

Always make sure the sander is off before removing

sandpaper. The Turbo Drywall Sander is equipped with a

hook and loop sandpaper system. Align one edge of the

loopbacked sandpaper with the hook- topped sander pad.

Then align the opposite edge of the sandpaper and sander

pad. Push down and press paper firmly along the length of

the sandpaper until sandpaper is smooth and flat.

Note: Other types of regular or peel and stick

sandpaper will not work with this system.

Grounding

Due to static electricity that could build up from normal

sanding in dry conditions, this sander has been supplied

with a grounding strip. This grounding strip is installed

at the factory before shipping. It is located inside of the

gooseneck and extends down the inside of the

extendable pole.

NOTE: If static electric shock should occur, the

grounding strip may need to be reinstalled.

Extendable Pole – The extendable pole has a twist

and lock feature that allows the pole to be shortened or

lengthened for use. Twist the handle lock clockwise to

loosen, counter clockwise to tighten.

Vacuum Hose Adapter – A soft black 1-1/2” vinyl

hose adapter, part # 14311, is provided for connecting the

Turbo Drywall Sander to Model 16004QV “Dustless”

Wet/Dry Vacuum manufactured by Love-Less Ash Company. This adapter has left handed treads for connecting

to a 1-1/2” diameter hose. The non threaded end slips over

the end of the extendable pole.

Acme Thread Adapte – This is supplied so the exten-

sion pole may be used for universal purposes ie paint roller

or broom handle. Part # 56112

Lubricating Oil – This specially designed lubricating oil

will not attack plastic surfaces. It will evaporate and not

create buildup on the high-speed turbine. Minimum of 3-4

drops of oil should be applied every 30 minutes of actual

sanding. Apply oil while vacuum is on and attached to

sander. This will draw the oil into the sander bearings.

Oil Hole – Make sure the oil hole is facing away from

adjoining surfaces so clean air is drawn into the sander.

Helpful Hints:

1. The lubrication hole located on the side of the sander

must at all times be kept away from working surfaces

or walls. This allows the hole to breathe clean air and

reduces the amount of dust drawn into the bearings.

Do not cover the hole as it must remain open

at all times.

2. Use a light touch. This will allow the sander to sand and

not get bogged down. You can still move the power head

and help the sander to sand faster just use a light touch.

3. If the sander, with new sandpaper, is hard to maneuver

on the wall, simply turn off the sander and then rub

the sandpaper and sander 2-3 short swipes across a

concrete floor. This knocks off the high uneven edges

that may exist on new sandpaper.

4. The cap and gooseneck may be removed and the

gooseneck reinstalled in a different rocking position.

This allows the power head to rock at different angles

as needed.

5. With the hand adapter Part #56611 the power head

may be removed from the extension pole and used as a

hand sander for tight locations where the pole may be

cumbersome, ie halls or closets.

6. For best operation keep sander flat against the wall.

TROUBLE SHOOTING:

Hard to maneuver sander up and down the wall –

1. Pushing too hard. Sanding too hard will hinder the

sanding vibration. A light touch is needed.

2. New sandpaper (refer to Helpful hints #3)

3.Wrong angle of sander for working direction.

(refer to Helpful hints #4)

Chattering –

1. Pushing too hard. Sanding too hard will remove

the sanding vibration. A light touch is needed.

2. New sandpaper (refer to Helpful hints #3),

3. Wrong angle of sander for working direction,

(refer to Helpful hints for solution #4)

Sander stops working –

1. Bearings may be frozen up. Lubricate sander every 30

working minutes of use with minimum of 3-4 drops of

lubricating oil Part #53351. A large particle of material

may be lodged in the turbine. Remove cap and goose

neck and see that the turbine spins freely. Turbine

screw may have worked loose.

2. No Suction – Check suction on wet/dry vac. Hose may

be plugged – check for obstructions, check filters.

Dust is in the air –

1. Check wet/dry vac. Make sure the wet/dry vac is a

“Dustless” system.

OPERATION: Connect the sanding power head to

the gooseneck. The cap threads onto the block and holds

the gooseneck in place. Thread the gooseneck onto the

extension pole. Use the soft 11/2” adapter to connect the

end of the pole to the vacuum hose. Turn on your vacuum

and the sander power head will vibrate.

Loading...

Loading...