Page 1

Theta 76

Theta 76 HS

Multi Format Lab System

The production of small and large print

sizes directly from image files is made easy

with our fully digital Multi-Lab System

Theta 76/76 HS. Please observe closely,

because the Theta 76 produces all images

continuously on RA4 roll media up to a

maximum width of 76.2 cm, thus allowing

print sizes from 9 x 13 cm (3.5 x 5 in.) to

76,2 cm x 4 m (30 in. x 13 ft). With this

enormous flexibility a multitude of new

applications and business opportunities are

opening themselves for you. Whether its

portrait or wedding photography, whether

studio or minilab – there are no jobs that

you can not accomplish at optimum

quality. Theta prints with a resolution

of 254 ppi continuous tone (which

corresponds with about 1.200 dpi) and a

linear printing speed of up to a max. of

72 cm (28 in.) per minute. This means,

that you can from now on reliably produce

standard print sizes, panorama prints, each

with or without cropping, package prints,

print series and so on, either as cut single

images or as panels up to 4 m (13 ft.).

Page 2

With many new formats to many

new businesses!

You will produce as flexible as never before! Previously almost

impossible print size requests can now be produced easily with

Theta 76/76 HS. From standard prints sized 9 x 13 cm (3.5 x 5 in.)

to 76 cm (30 in.) all the way up to 4 m (13 ft.) long panorama

prints, all poster prints, mix format orders, as well as long, double

sided print sizes for trendy “digital albums” - all that becomes

normal, daily work for you.

You are working with a production capacity of 370 prints per hour

in 20 x 25 cm (8 x 10 in.) format at maximum exposure speed on

the largest possible roll width. This corresponds with a capacity

of over 18 m

2

/hour (193 sq. ft.). Outstanding in it’s performance,

Theta 76 produces up to 1.120 prints in 10 x 15 cm format per

hour, 370 prints in 20 x 25 cm format per hour, 47 prints in

50 x 75 cm format per hour or 24 prints in 76 x 100 cm format

per hour.

With Theta 76 HS your production capacity will increase another

50 %, which equals to 27 m

2

, over 2.000 prints 9 x 13 cm

(3,5 x 5 in.) or 70 posters 50 x 70 cm (20 x 30 in.)

Convincing image quality

The 254 PPI resolution “full continuous tone” exposure of Theta

76 generates a perfect image definition from image edge to image

edge.

Superior material utilization

Theta 76 positions images side by side on panels or strips. With

it’s special auto nesting software and multiple print function an

optimal material utilization is guaranteed. Even its productivity

is increased by the connected, automatic cutting device, which

makes sure that images are cut to the correct sizes.

Javier Cruces

©

Surprising even on the

reverse side

With Theta you receive the only

digital printer, that can print on

the back of single cut images

and at side-by-side nested

images on a wider media roll.

Patrick Cointepoix

©

Page 3

Profit from the trend.

Digital photo albums

become more and more

popular as they are a creative

and attractive medium to

present memories exclusively

and individually. It does not

matter how different the

requested formats are, Theta is

well versed in all of them. Offer

your clients album sizes they

way they desire. With Theta

you can produce fast and easy

double sided albums pages for

weddings, vacations and many

other occasions.

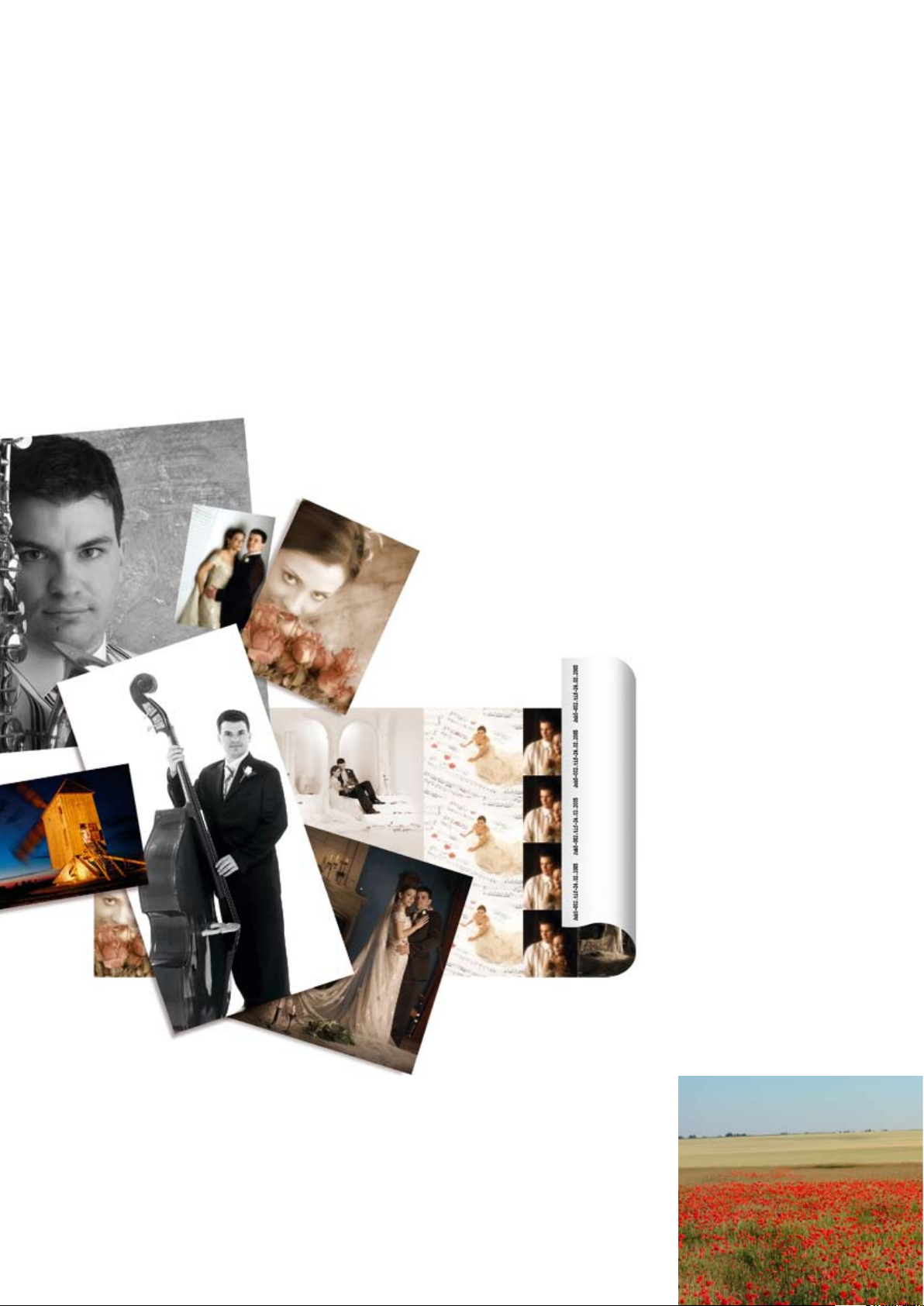

Win new customers with additional services.

Lead in print sizes - it will be worth it!

Make your customer a

desirable offer with

attractive indexprints and

professional contact sheets.

Instead of standard print sizes

you create exactly the sizes

that your customers want.

Here, even the most demanding

customer will be pleased!

Panorama images are the

show piece of any lab.

Theta produces first class

panaroma images in any

desired length just with the

push of a button. Do we have

to tell you that your image

will also expand in view of

service and competence?

Page 4

Which Theta is the right one for you?

Theta 76

Here we introduce you to the cost-efficient

versions. Equipped with a high speed digital

imager, daylight paper cassette, the connected

RA4 paper processor and a front end workstation, your daily work is improved and at

the highest standard.

Theta 76 CS

You can reach the optimum productivity and

operating comfort with our complete version,

additionally equipped with the connected cutter

& sorter station. Your everyday lab day would

conceive a significant appreciation with the

Theta 76 CS:

• minilab like operation up to the ready cut and

completely sorted print order

• shorter run-through time on all mixed format

orders

• the high print size exibility makes poster

prints and panorama images up to 4 m length

possible

• double sided album pages for weddings and

events in any image length. You satisfy your

customers wishes at lower cost and superior

quality.

At the same time, Theta 76 CS reaches a

production capacity of nearly 200 cut prints

20 x 25 cm (8 x 10 in.) per hour, or alternatively,

370 prints 20 x 25 cm (8 x 10 in.) at maximum

printing speed on strips of the largest roll width.

Theta 76 HS

Theta 76 CS-HS

Theta 76 is also available as High-Speed

version in order to match your high production

requirements, reaching 27 m

2.000 prints 9 x 13 cm (3.5 x 5 in.) or 70 posters

50 x 70 cm (20 x 30 in.)

2

, equal to over

Page 5

Durst Fiber Optic (DFO) Technology

The DFO technology is the heart of our system. Monochrome

LED’s (red, green, blue) produce light which is projected as pixels

over glass fiber cable and optics line-by-line with 254 ppi printing

resolution/256 levels onto photo sensitive material.

The DFO technology becomes unique through its media calibration

system consisting of densitometer, scanner and the corresponding

software whereby the majority of materials are calibrated to

an optimum. The DFO technology features an LED light source

with an extremely long life time of close to 100.000 hours,

thus combining proven Durst image quality at extremely low

maintenance costs.

Digital, automatic workflow

The image data is automatically “retrieved” from the data server.

The scaling also occurs automatically – and without further

manual intervention, the ICC conversion, printing, processing,

cutting and sorting takes place. All this together really leads to

a fully automatic, digital workflow.

External

image data

entry

Scanning with the Sigma 67

Job preparation

with the Durst

Print Terminal

Job preparation

or auto spooling

with the Theta

76 Workstation

CD-Robot System

Theta 76/76 HS

Simultaneous printing/processing

Optional cutting

and sorting with

the Fotoba In-Line

Y Cutter/Sorter

up to 30 x 45 cm

(12 x 18 in.)

Optional cutting

with the Fotoba

In-Line Y Cutter

up to 50 x 70 cm

(20 x 30 in.)

Page 6

The “Brain” of your Theta 76 – The software

The special programmed Theta 76 software

is the intelligent pre-condition for save

and trouble-free processes. The software

runs on a high-performance Windows XP

Professional Workstation and accomplishes

all important work such as:

• Automatic image correction with

TM

I2E

-software

• Automatic le scaling

• Automatic le rotation,

• Automatic sharpening

• Color Management

• Auto-Nesting, Multiprints

• Index Prints

Our software works with high speed - and

therefore lowers significantly the waiting

time of the printer. An important part in

the workflow is also the multi tasking,

whereby jobs are prepared at simultaneous

printing of already prepared jobs.

Spooling without any breaks

The description “spooling“ means the fully

automatic and continues loading of files

from the server station whereby already

spooled jobs are printed simultaneously.

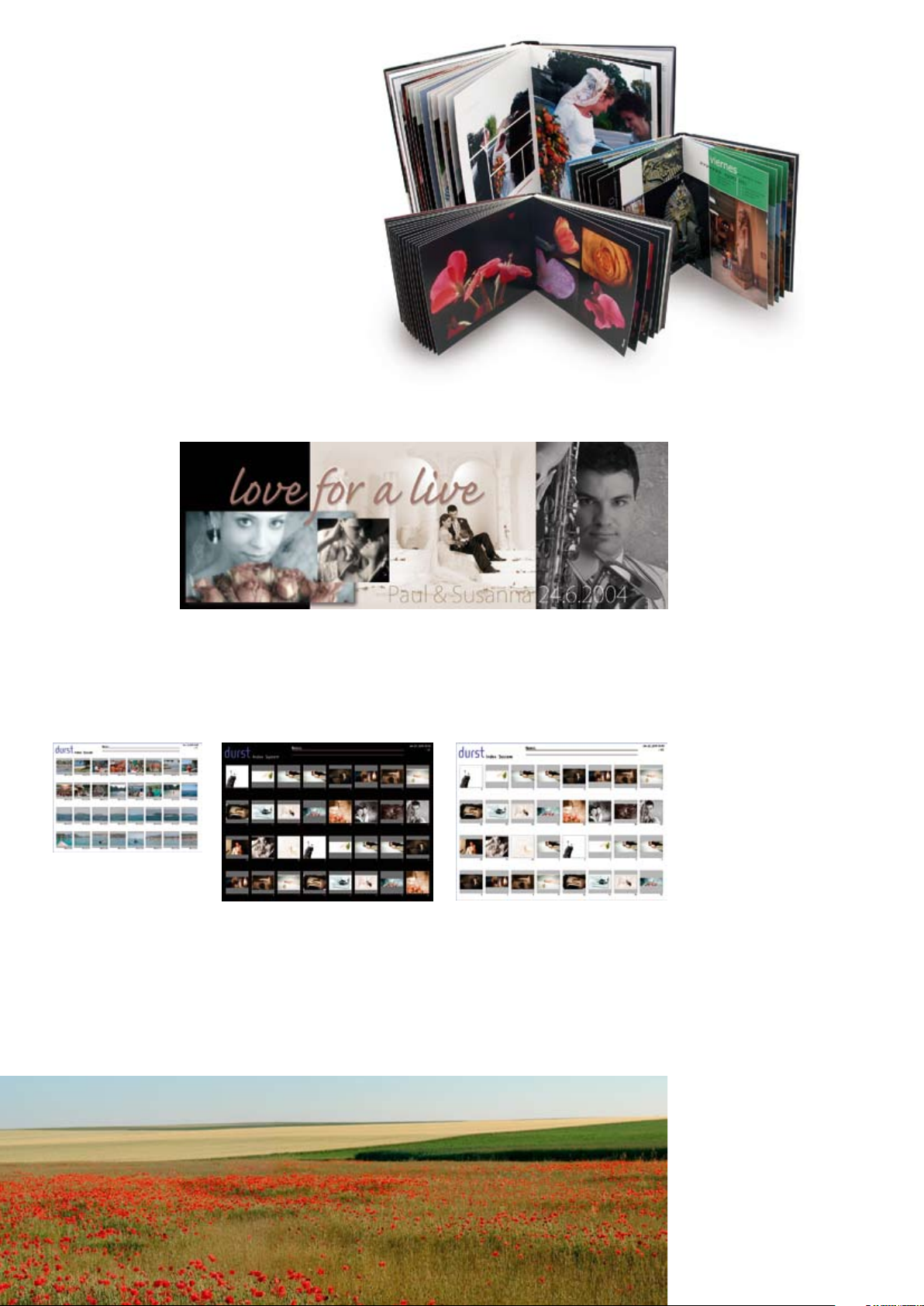

Direct correction with “soft proofing“

New is also the “Soft proong“ function,

allowing a direct correction of single

images or multiple images in thumbnail

size on the screen. A deciding advantage

is the operation safety which results in

improved image quality.

Here we convert colors correct: the color

management software

The fully automatic Color-Management

Workflow converts TIFF, JPEG, BMP and

PPM files with:

• Choice of desired ICC input prole with

rendering intents

• automatic recognition of embedded ICC

profiles

• Automatic selection of the correct

output profiles assigned to the paper

channel.

Page 7

The paper cassette:

functional and practical.

The 100 % light tight and wheel mounted

paper cassette can be easily loaded from

the front side of the imager. The cassette

allows full daylight use and accepts media

roll widths from 20.3 cm (8 in.) up to

76.2 cm (30 in.) at a max. length of

175 m (530 ft.). For printing, the paper is

transported out of the cassette and in

case of a cassette or material change

pulled completely back into the cassette.

Using this technique unnecessary material

loss is avoided.

Facts of the RA4 paper

processor

Designed for RA4 and compatible

processes, our roller transport paper

processor is directly connected to the

Theta 76 imager. It can be operated as

desired with either chemical or flowing

wash. The processor contains everything

that you expect from a professional device:

integrated bath replenishment and bath

heating, bath level monitoring and a high

performance IR dryer. The processor runs

with a transport speed of 52 meters

(170 ft.) per hour.

Can it be anymore

comfortable?

If you want to make it even more easy for

yourself in handling the Theta 76, then you

should decide right away for the external

automatic cutter/sorter station. Here, the

auto nesting software arranges all images

in strips whereby all print sizes are

produced on the largest media roll,

resulting in maximum flexibility and

productivity. And after processing, the

cutter&sorter station cuts single images

and sorts them to orders. You profit from

the simplicity of operation which comes

close to a minilab, because you receive

ready cut and according to the order

sorted pictures.

For even larger sizes there is a larger

Y-cutter 50 available, that can cut sizes

up to 50 x 70 cm (20 x 30 in.)

Page 8

DFO - Technology with LED

light source and fibre optic

DFO - Print head

Print buffer

Back printer

Daylight loading cassette for roll widths up to 30 inch

Page 9

Infra Red Drier

The printing unit

At Durst no drums are used as in other systems.

Therefore you have the advantage of image sizes

up to 4 meter (13 ft.) length – ideal for panorama

prints in any length. And this is the procedure:

Our patented LED fiber optic light source exposes

continuously onto photo paper in rolls. Prints

are cut according to the selected print size prior

to feeding it into the paper processor. Customer

and lab information is printed on the back of the

image with the back printer.

Never again trouble with

the latent image

A sensitive subject: The latent image. We

have solved the problem without the usual

productivity loss and related loss of time as it

occurs at other manufactures. And this is how

we did it: The exposed material is continuously

transported through a “Print Puffer”, where

the latent image is stabilized prior to the transfer

to the processor. This results in a homogeneous

image production with a high repeat accuracy.

You receive images of highest quality without

any color drift.

• In-line Y-Cuttter for print sizes up

to 30 cm (12 in.) width

• In-line Y-Cuttter for print sizes up

to 50 cm (30 in.) width

RA4 Paper Processor

In-line Y-Cuttter for print sizes up

to 30 x 45 cm (12 x 18 in.).

Page 10

Technical data

1.0 General Specifications

Input voltage:

• 3 Phase + N 230 /400V

(+/-10 %) 50 Hz; Max Ampere

per Phase: 10 A

• 3 Phase 208 V (+/-10 %) 60 Hz;

Max Ampere per Phase: 12 A

Power consumption:

6 KVA

Dimmensions:

Lenghts: 320 cm (126 in.)

Width: 140 cm (55 in.)

Height: 188 cm (74 in.)

Space requirement:

250 x 400 cm (158 x 217 in.)

Weigth:

approx. 1.500 Kg (3.300 Ibs)

Safety standard:

CE

2.0 Imaging Specifications

Printing technology:

RGB - LED-Fiberoptic

Linear output speed:

• Theta76

variable speed from 40 cm/min.

(16 in./min) on maximum roll width

up to 72 cm/min (28 in./min) on

minimum roll width

• Theta 76 HS

variable speed from 60 cm/min.

(24 in./min) on maximum roll

width up to 80 cm/min (32 in. /min)

on minimum roll width

Resolution:

254 PPI

File formats:

Tiff, JPEG, BMP, PPM, PS, PDF

3.0 Media Handling

Media feed system:

1 universal, daylight loading media

cassettes

Loading capacity:

175 m (530 ft.)

Suitable media:

RA4 Reflective

Print sizes:

(cut sheets from roll media)

• min. 20 x 13 cm (8 x 5 in.)

• max. 76 x 400 cm (30 x 157 in.)

• panels/panorama prints up

to 4 m (13 ft. )

4.0 Printing capacity

Printing capacity with max. media

width 76 cm (30 in.), printing in

Multiple-Print mode or AutoNesting mode:

Theta 76 Theta 76 HS

9 x 13 cm = 1.528 2.200

(3,5 x 5 in.)

10 x 15 cm = 1.121 1.600

(4 x 6 in.)

13 x 18 cm = 778 1.100

(5 x 7 in.)

20 x 25 cm = 370 550

(8 x 10 in.)

30 x 45 cm = 108 160

(12 x 18 in.)

Printing capacity with format

matched roll media in print repeat

mode:

Theta 76 Theta 76 HS

20 x 13 cm = 332 500

(8 x 5 in.)

20 x 25 cm = 198 290

(8 x 10 in.)

30 x 45 cm = 84 180

(12 x 18 in.)

50 x 76 cm = 47 70

(20 x 30 in.)

76 x 100 cm = 24 36

(30 x 40 in.)

5.0 Image Computer

Workstation: Pentium IV – 2 GHz

(or higher)

Operating system:

Windows XP Professional

RAM:

2 GB

Monitor:

19” LCD color monitor – Resolution

1280 x 1024

Hard disc:

80 GB internal hard disk

6.0 Paper processor

Tank volume:

Dev. = 23 L; Bx. = 23 L,

Wash = 3 x 16 L

Speed:

52 m/h, (170 ft/h)

Agitation:

Via circulation pumps and

chemistry filters.

Wash:

Equipped for plumbed and

non-plumbed operation

Replenishment:

Automatic, proportional

Drier:

High efficient IR drier

7.0 Ambient conditions

Temperature range:

+15 °C to +30 °C (+59 °F to +86 °F)

Relative humidity:

20 - 90 %

Durst Phototechnik

AG

Social/Portrait Division

Vittorio-Veneto-Straße 59

I-39042 Brixen, Italy

Telefon +39/0472 81 01 11

Telefax +39/0472 83 09 80

www.durst-online.com

info@durst.it

Printing capacity with file

rendering and CMS of unique files

in Autospooling mode:

reaches approx. 90 % of „print

repeat” capacity

The latest technical developments

are constantly being incorporated

into Durst products. Illustrations and

descriptions are therefore subject to

modification. All rights reserved on

images and illustrations.

Durst Phototechnik AG, 02/2006

©

IX 37015

Loading...

Loading...