Durst PICTOCER HD BROCHURE

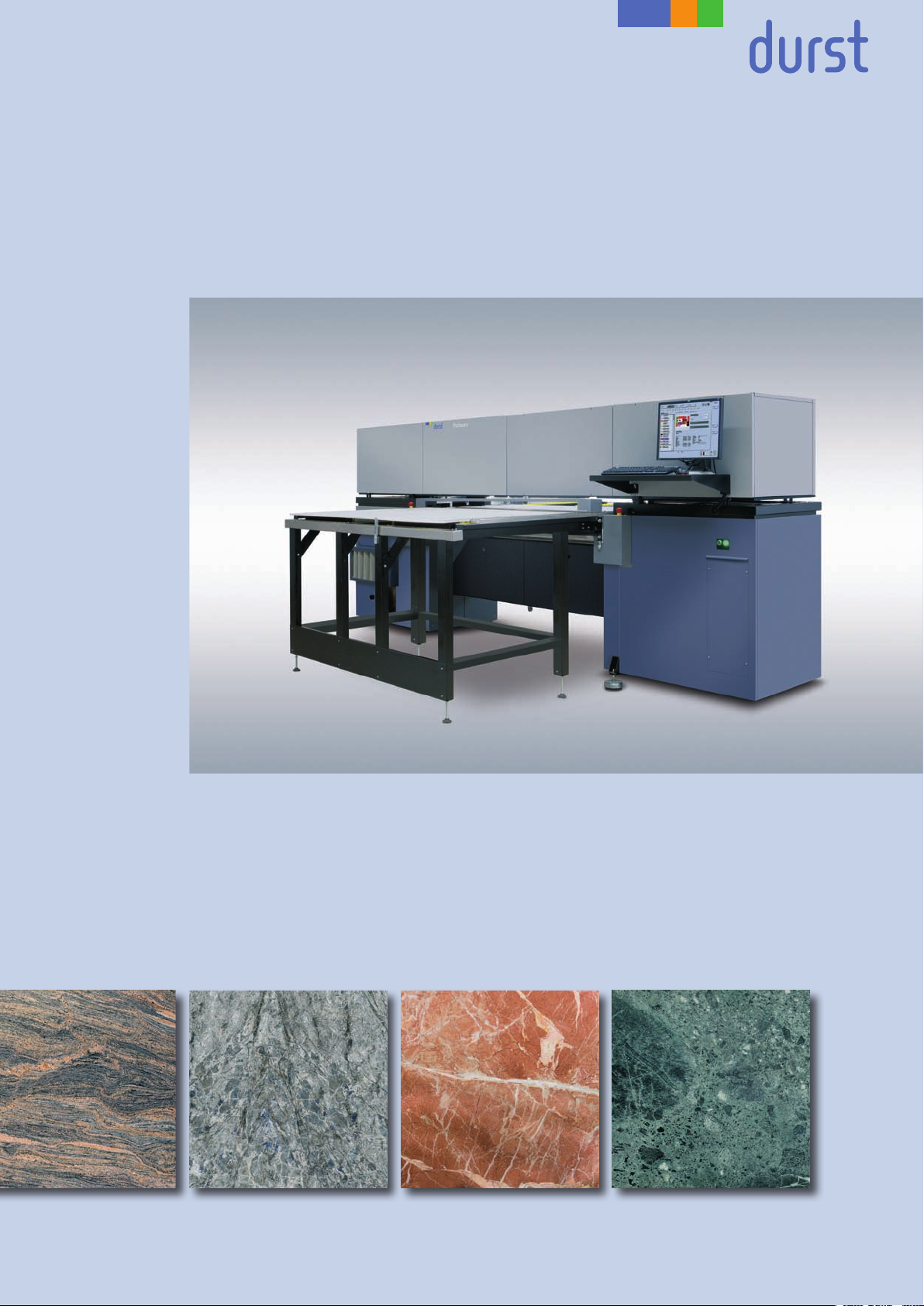

Pictocer HD

Ceramic Lab Printer

Durst Pictocer HD is a compact digital ceramic inkjet printer which uses pigmented ceramic inks for firing

temperatures up to 1250°C and therefore the ideal printer for different small run printing applications, such as:

• Developing new ceramic tile designs at design bureaus and ink manufactures

• In-house developing and testing new designs/products at ceramic tile manufacturing companies with

High-Performance Digital Printers (such as Durst Gamma) in operation at their main stream factories.

• Third re applications (ceramics and glass decoration)

• Printing small runs and custom products, photoceramics, etc.

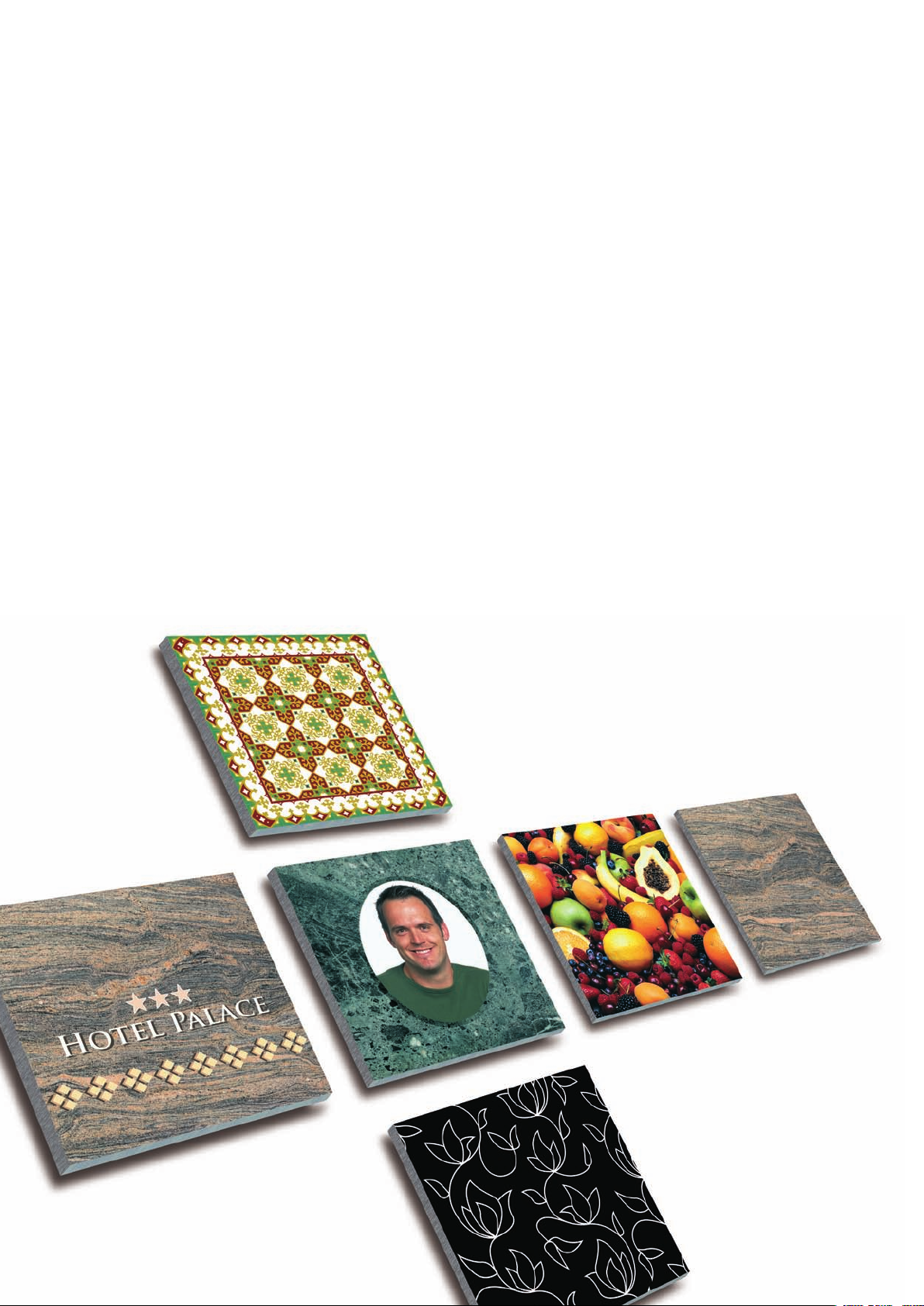

Digital ceramic inkjet print

Durst Pictocer HD uses exactly the same pigmented ceramic inks as used with Durst Gamma,

the new standard for the digital decoration of ceramic tiles and used by all the leading ceramic

tile manufactures in the world.

By using the same inks Durst Pictocer HD can simulate the final ceramic tile, such as floor

and wall and tiles (porcelain, single and double re) as well as decorative listellos produced

afterwards with Durst Gamma and anticipate the production costs.

The unique continuous tile transport system allows to decorate different type of ceramic

products and tiles from very small decorative trim pieces (listellos/photoceramics, etc.)

without any size limitations and up to a max. thickness of 50mm.

To assure a reliable, long-term operation the Durst Pictocer HD features a permanent ink

recirculation in the ink circuits and print heads with automatic maintenance cycles, proven

in more than 100 Durst Gamma printers in operation.

Key Advantages/Benefits:

• Continuous transport system with hand fed manually

pre-loaded trays to easily handle small and larger

parts without size restrictions and limitations

• Max. printing width of 155cm (61 in.) by any length

• Maximum tile or trim piece thickness: 50mm (1.98 in.)

• Main ink tank capacity of 1.5 Liters (0.4 US gal) to

assure always fresh ink also with small runs and

sporadic operation

• Same ink set as Durst Gamma

• Permanent ink recirculation in all ink circuits and the

print heads with automatic maintenance cycles for

long-term reliability

• Productivity of approx. 7-10 m

• Patented „Ringaround“ function for fast and

automated testing for new designs and when

repeating jobs, thanks to the Durst proprietary and

patented On-the-y image processing technology

• Integrated ink cost and ink consumption calculation

per design and sqm to anticipated the production

costs for a new product prior to start production

2

per hour

Loading...

Loading...