Page 1

Gamma 60/61

Gamma 70/71

Direct Digital Ceramic

Decoration Systems

The Durst Gamma is the world‘s first

industrial-scale inkjet printer using

specially formulated, pigmented

ceramic inks to digitally decorate

ceramic floor and wall tiles, offering

significant economic benefits as well

as superior design advantages over

traditional systems.

Page 2

Compare to the limitations of conventional

tile decoration techniques and other digital

systems on the market, this new, no-touch,

digital printing technology offers unlimited

image variations, no setup costs thus eliminating the need to print minimum quantities, far superior image quality, definition

and dynamic range. It prints onto the

same glazes used with conventional screen

printing systems (does not require special

glazes to create the color), the inks are not

sensitive to environmental conditions, thus

allowing a stable production, the same inks

can be used to decorate wall and floor tiles

obtaining a large color gamut and high

densities and with just 4 colors all colors

and shades are produced.

Durst is holding various patents on this

new, innovative technology.

4 Models of your Choice

Gamma 60

Top of the line, full color version for tile

sizes up to 50 x 120 cm (20 x 48 in.)

Gamma 61

Economical 3-color version for tile sizes

up to 50 x 120 cm (20 x 48 in.), with the

possibility to fully upgrade it to the full

color Gamma 60 version.

Gamma 70

Top of the line, full color version for tile

sizes up to 60 x 120 cm (24 x 48 in.)

Gamma 71

Economical 3-color version for tile sizes

up to 60 x 120 cm (24 x 48 in.), with the

possibility to fully upgrade it to the full

color Gamma 70 version.

The Benefits

• Ultimate design exibility

(image & text)

• Drastically reduced setup time and

costs

• Economical printing of short runs

– mass customisation

• Lower production costs

• Reduced inventory and storage space

• Higher margins

The Technology

Gamma-Patented Synchronized Inline

Printing Engine

Durst has a longterm experience in

developing and manufacturing industrialscale large format inkjet printers for the

graphic, packaging and industrial market,

using heavy duty industrial piezoelectric

inkjet print heads.

For the Durst Gamma, Durst has developed

a special, patented single pass non-impact

inkjet printing technology, consisting of

four (CMYK) full width inkjet printing

arrays, fully synchronized with the

production process.

Page 3

The CMYK Printing Process

The Durst non-impact CMYK inkjet printing

technology uses droplets of ink jetted from

the small apertures (nozzles) to a specified

position on the tile to create an image.

During printing the four colors—cyan,

magenta, yellow and black, abbreviated

as CMYK—are automatically combined in

various ways to create virtually any color

required in one step.

Same glazes as for conventional printing

The specially formulated pigmented

ceramic inkjet inks for the Gamma

work with the same glazes used with

conventional screen printing equipments

and do not require special glazes to create

the color, such as other digital systems,

in addition they are not influenced by the

environmental conditions (temperature,

humidity, etc.) of the production process.

Ink Supply

The Durst Gamma features large main ink

supply tanks with a user-friendly ink refill

system.

Tile Transport System

On the Gamma the tiles are transported

on conveyor belt. The transport system is

designed for easy integration of the Gamma

into an existing production line. It features

continuous speed adjustment and quick stop

and start functions. On the printer entrance

a precise autocentering tile guiding system

assures perfect image/tile registration.

Software

Proprietary, patented Durst user software

designed for the needs of the ceramic tile

industry and built on the successful Durst

software used in over 1000 Durst Lambda

– high resolution digital laser imagers and

in more than 500 Rho’s – large format

industrial scale inkjet printers since 1994.

It features on-the-fly, full random printing

for unlimited number of different tiles from

given designs, concept printing, register

printing, sophisticated color management

control and many other interesting features.

Page 4

The Advantages

For decorating tiles, the manufacturing

companies desire faster turnaround time,

smaller runs and more flexibility in the

decorating process to minimize inventories

and maximize cash flow. The Durst Gamma

Direct Digital Ceramic Decoration System

offers the following advantages:

Ultimate Design Variation & Flexibility

(Patented Durst Random Design Printing

Technology).

With this technology endless different

tiles can be created, using several designs

at the same time and to obtain each tile

to be different. It allows to develop new

products and to offer new customized

solutions. New design samples can also be

created much faster and at lower costs.

Unique custom designs and concepts are

now possible.

Page 5

100 % Edge-to-Edge Decoration

With the Durst Gamma the entire top

surface of the tile is printed, right to the

very edge where the mould falls. No more

need to use colored glaze body to minimize

the effect of “white edges” known from

traditional decoration systems.

Full Relief Decoration

When decorating uneven tiles (with

medium & strong reliefs), it assures

perfect definition of all parts. Since

the decoration of high and low reliefs

are decorated simultaneously, it ensures

designs with greater continuity and

more realism.

Higher Print Quality and Richer Colors

Extraordinary definition in terms of details,

colors, dynamic range and decorations,

obtaining tiles with a more natural look.

Delivers superior printing quality to

conventional techniques. Integrated color

management system to match the colors of

the design originals.

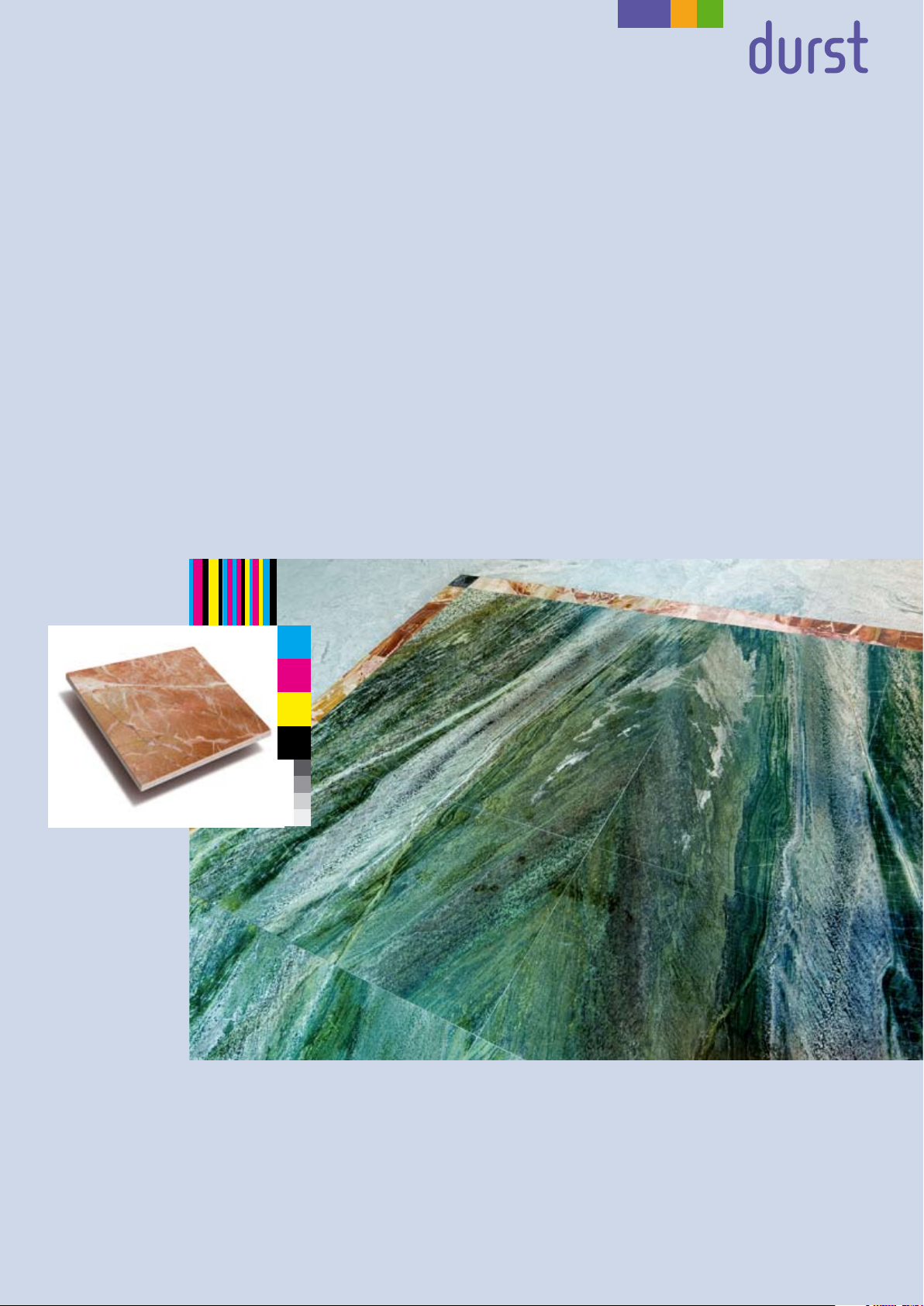

“Open Book“ Natural Stone Imitations

On Demand Printing & Trials

Since with this technology there is no

physical setup and color change needed,

the printing quantity or square meters

have no influence to the production cost

and setup-time. To facilitate on-demand

printing, the Gamma features very fast

production changeover and new model

start-up (it is sufficient to change the

printing file) in addition to no down time

between jobs.

This assures also shorter production time

from creation to final decorated tile.

Reduced ink Management & Storage

costs

Since the digital system automatically

creates all required colors and tonal

shades with just 4 colors, it eliminates

all activities relating to preparation,

management, control and storage of

colors, fixatives, solvents, etc., and

obviates the need for printing drums and

screens. The process is also ultimately

more flexible, because the quantity of

ink always corresponds perfectly to the

production requirements, thus reducing

stock.

Easy Operation – Remote Diagnostics

The Gamma features a user guided touchscreen operation and remote access

diagnostics and servicing via network.

No Special Glazes Required – Stable

Production

The system uses pigmented, ceramic

CMYK inks to print onto the same

glazes as used for traditional decoration

systems. The colors are not influenced by

the environmental conditions of the

production processes.

Page 6

Technical Data

General Specifications

Power Supply:

230/400 V AC 3-phase

Configuration:

System can be configured for right or left hand

operation.

Dimensions (L x W x H)

Gamma 60/61: 509 x 230 x 270 cm

(200 x 91 x 107 in.)

Gamma 70/71: 577 x 230 x 285 cm

(227 x 91 x 112 in.)

Weight

Gamma 60/61: Approx. 4000 kg (8800 lb)

Gamma 70/71: Approx. 4500 kg (9900 lb)

Safety Standards:

complies with currently valid guidelines

Printing Specifications

Printing System:

Patented Durst Synchronized Inline Printing

System (SIPS)

Resolution:

200 - 924 dpi

Colors:

Gamma 60/61: 4 colors CMYK

Gamma 70/71: 3 colors at your choice

Inks:

Special, Patented Pigmented Ceramic Inks for

decorating floor and wall tiles, as well as third

fire applications.

Ink Supply:

Ink supply system designed for continuous, nonstop operation with user-friendly refill system.

Software:

Proprietary and patented 64 Bit LINUX based

Durst Gamma software with intuitive workflow

and sophisticated, powerful job preparation and

print controls for fast and easy operation.

Native File Format:

CMYK-TIFF

Image Processing:

Patented Durst Print Engine with on-the-fly

image processing and random image variation

control with multiple choices for ultimate tile

variability and very fast operation

Tile Specifications

Tile Type:

• Wall and oor tiles

(ceramic and porcelain tiles) in form of

Green tile bodies (monocottura – fired once)

and fired bisque (bicottura – fired twice)

• Ceramic border tiles – Listello

(terzo fuoco – third fire)

Tile Width (un-fired)

Gamma 60/61: 10 – 56.9 cm (3.9 – 22.4 in.)

Gamma 70/71: 10 – 71.5 cm (3.9 – 28 in.)

Tile Length (un-fired)

Gamma 60/61: 10 – 130 cm (3.9 – 51.2 in.)

Gamma 70/71: 10 – 135 cm (3.9 – 53 in.)

Tile Thickness:

5 to 20 mm (0.2 – 0.8 in.)

Greater thickness on special request

Environmental Requirements

Temperature Range:

+5°C to +40°C (+41°F to 104°F)

Relative Humidity:

25-80 % non condensing

Durst Phototechnik

AG

Industrial Printing Division

Vittorio-Veneto-Straße 59

I-39042 Brixen, Italy

Telefon +39/0472 81 01 11

Telefax +39/0472 83 09 80

www.durst-online.com

info@durst.it

Printing Speed: (Belt Speed)

• 1 – 64 m/min. (1 – 210 ft/min.)

• 1 – 32 m/min. (1 – 105 ft/min.)

at maximum resolution of 924 dpi

Copyright © 1994- 2006 Durst

Phototechnik AG, Brixen/Italy

All Rights Reserved - Patents and

Patents Pending for Soft- and Hardware

Durst, Durst Gamma, Durst Rho, Durst

Lambda, Durst Epsilon and Durst

Autocutter are trademarks of Durst

Phototechnik AG. All other trademarks

or registered trademarks are the

property of their respective owners.

Descriptions, illustrations and

specifications subject to change

without notice.

Durst Phototechnik AG, 09/2008

©

IX22005

Loading...

Loading...