Page 1

Operating manual DÜRR X-RAY film processor XR25

1995/04

9000- 600- 04

51

Page 2

52

Page 3

CONTENTS

1. SAFETY ADVICE

1. Safety advice .......................................... 51

1.1 Electrical safety advice ................... 51

1.2 General information ......................... 51

2. Scope of XR 25 ...................................... 52

3. Model review .......................................... 52

3.1 The whole programme at a glance .. 52

4. Operation ............................................... 53

5. Changing of chemicals ......................... 54

5.1 Cleaning the roller sets....................54

5.2 Cleaning the bath ............................ 55

5.3 Before draining the chemicals ........ 56

5.4 Draining the chemicals .................... 56

5.5 Cleaning the tanks ........................... 57

5.6 Filling up with chemicals ................. 58

5.7 Inserting roller sets .......................... 58

5.8 Putting on lid .................................... 58

5.9 Switching on XR25 for operation ..... 58

6. Daylight attachment .............................. 59

7. Film storage ........................................... 59

8. Surgery breaks ...................................... 60

9. Fault finding info . ................................. 61

1.1 Electrical safety advice

Work on electrical apparatus must only be

carried out by qualified electricians (VBG 4)

or through our trained Service Technicians.

With the combination of equipment, as well

as with electrical repairs, the relevant safety

and check regulations must be observed.

(VDE 0100, or else, IEC 364, 0105 pt.1, 0701,

EN603351, VBG4, in other countries the

relevant regulations such as IEC, CEE must

be complied with). For repairs only use

original parts otherwise the guarantee and

test certification will be invalidated.

1.2 General advice

In the BRD, as well as some other countries,

used x-ray chemicals are regarded as special

waste and must be collected and disposed of

separately.

53

Page 4

2. XR 25 OUTLINE

3. MODEL SURVEY

• Automatic film developing of various film

sizes from 2x3 to max. 24x30 cm.

• A fresh mix of chemicals lasts approx. 3

weeks based on a usage rate of 10 intra-oral

and 3 panorama films per day. This

statement only refers to Durr Automat XR

Chemicals.

• Films can be fed in continuously.

• The run through time is approx. 6 mins. With

model 1702-03 (variable) it is between

3-6 mins.

• The transport of films in processing is via

roller sets.

• In the Processor the developer and fixer

solutions are warmed and kept to a constant

temperature within an accepted tolerance

range. The warm-up phase is approx 20

mins. depending upon ambient temperature.

• If the XR 25 is installed in a darkroom, no

daylight attachment is required.

XR25 X-ray film processor

Model: 1702-01 (230V)

1702-02 (110V)

1702-03 (110V, variable processing

time)

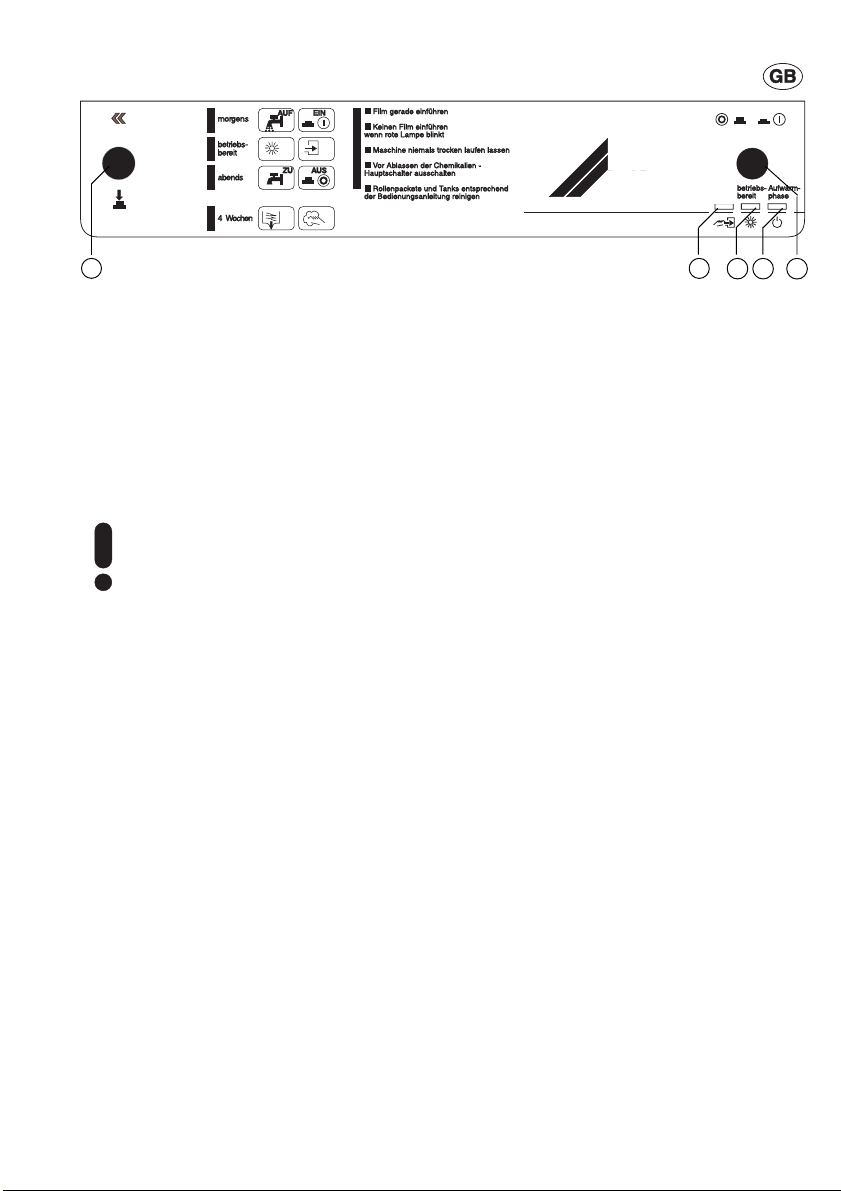

3.1 The whole programme at a

glance

Please open up left fold-in page!

Pos./Description Order n.

((1) XR25 X-ray film processor

230V, 50Hz .....................................1702-01

or

XR25 X-ray film processor 110V, 50-

60Hz ............................................... 1702-02

or

XR25 X-ray film processor 110V, 50-60Hz

(variable)........................................1702-03

(2) Darkroom light ...................... 1482-000-00

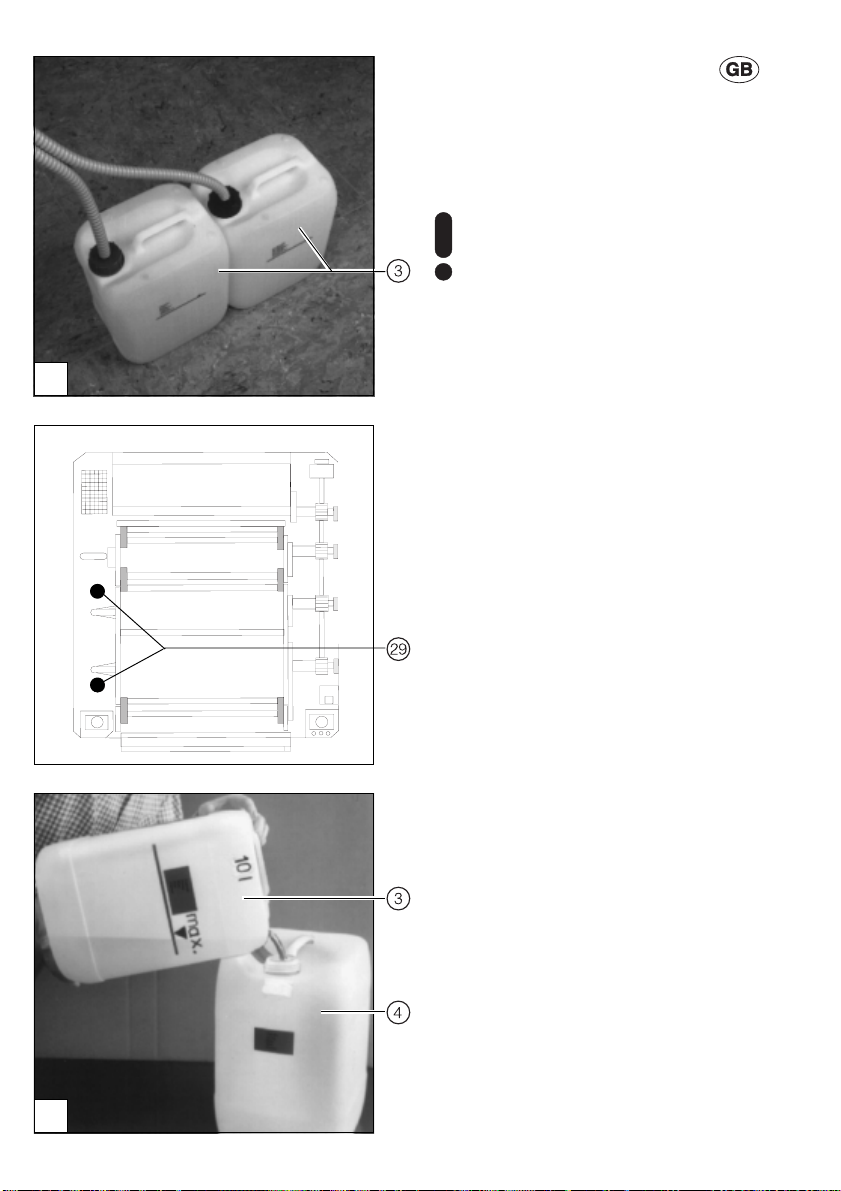

(3) *Collecting container

for Developer ........................ 1700-062-00

Collecting container

for Fixer ................................. 1700-061-00

(4)* Storage container

for Developer ....................... 1700-060-00

Storage container

for Fixer ................................. 1700-070-00

(5) Daylight attachment DL24

with filter pane ...................... 1700-910-00

Darkroom attachment

DA 24 ..................................... 1700-930-00

suitable for commonly used dental films

e.g. 2x3 up to 18x24 or 15x30 cm films

(6) Daylight attachment DL26

with filter pane ...................... 1700-920-00

suitable for film sizes up to 24x30

* It is possible to order a Collection system

consisting of:

1 Collecting container and

3 Storage containers

Collection system for Developer .. 1700-060-00

Collection system for Fixer .......... 1700-070-00

54

Page 5

XR25

DÜRR

DENTAL

FilmTransport

A

4. OPERATION

MORNING: Open water tap

EVENING: Close water tap

Never let machine run when dry and

never without D/F roller in situ. Pull out

power plug on emptied machine.

Morning

• Open water tap

• Mains switch (G) ON

Warming up phase begins (approx,

20mins.)

Yellow indicator light (D) shines

Ready for use

The correct processing temperature

(28°C) is reached as soon as the green

indicator (C) lights up.

Film transport

• Film transport switch (A) ON

Red light indicator (B) lights up

Advice: Insert DURR cleaningfilm, order no.

1410-007-00- before starting the day’s

processing by feeding in film at the

film entrance.

• Feed in film at film entrance.

Advice: Always feed in films straight and do

not have them overlapping, to avoid

bending or blocking the transportation.

• When the last film in a sequence has

been processed, switch OFF transport

switch (A).

Red light (B) goes out.

B C D G

(A) Film transport switch ON/OFF

(B) Film transport ON

RED indicator lights up

(C) Ready for use

Green indicator lights up

(D) Warm up phase

Yellow indicator lights up

(G) Mains switch ON/OFF

55

Page 6

5. CHANGING CHEMICALS

Chemicals should be changed every 3

weeks.

Advice: The 3 weekly chemical change

G

1

5.1 Cleaning the roller sets

▲▲

▲

▲▲

▲

▲▲

▲▲

2

▲▲

▲

▲▲

▲▲

▲

▲▲

Advice: Any hard particle deposits can

Left and right fold-in pages:

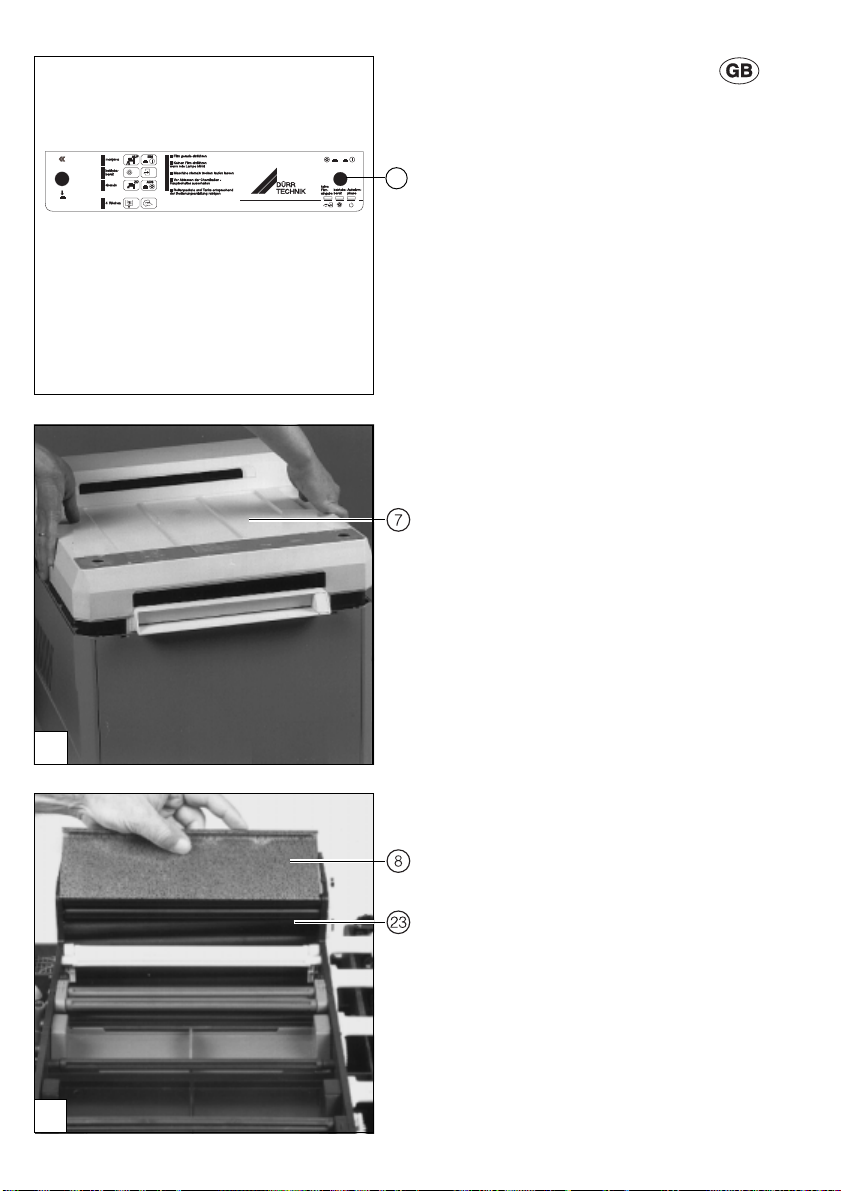

• Mains switch (G) off, see fig. 1

• Pull out mains plug.

• Lift off lid (7) and put to one side.

• Open all latches (25) and catches (24),

• Remove guide plate (8) from dryer set.

• Tilt dryer set (23) backwards and then lift out.

• Remove water roller set (26) and film

specifically refers to:

a) The use of „DURR Automat XR

chemicals“.

b) A daily max. film throughput of 10

intra-oral and 3 panoral films.

In the BRD, as well as some other

countries, used x-ray chemicals are

regarded as special waste and

must be collected and disposed of

separately. We recommend the use

of a DURR Collection & Storage

system, see left fold-in page (3) and

(4).

safely and easily be removed with

the special DURR Spray Cleaner

WR 200 (P/N CCB800C55..). For

Cleaning the roller racks periodically

(3-6 mos) please use DURR

Cleaning Bath set (P/N 1700-007-

00).

see right fold-in page.

entrance set (28).

56

3

Page 7

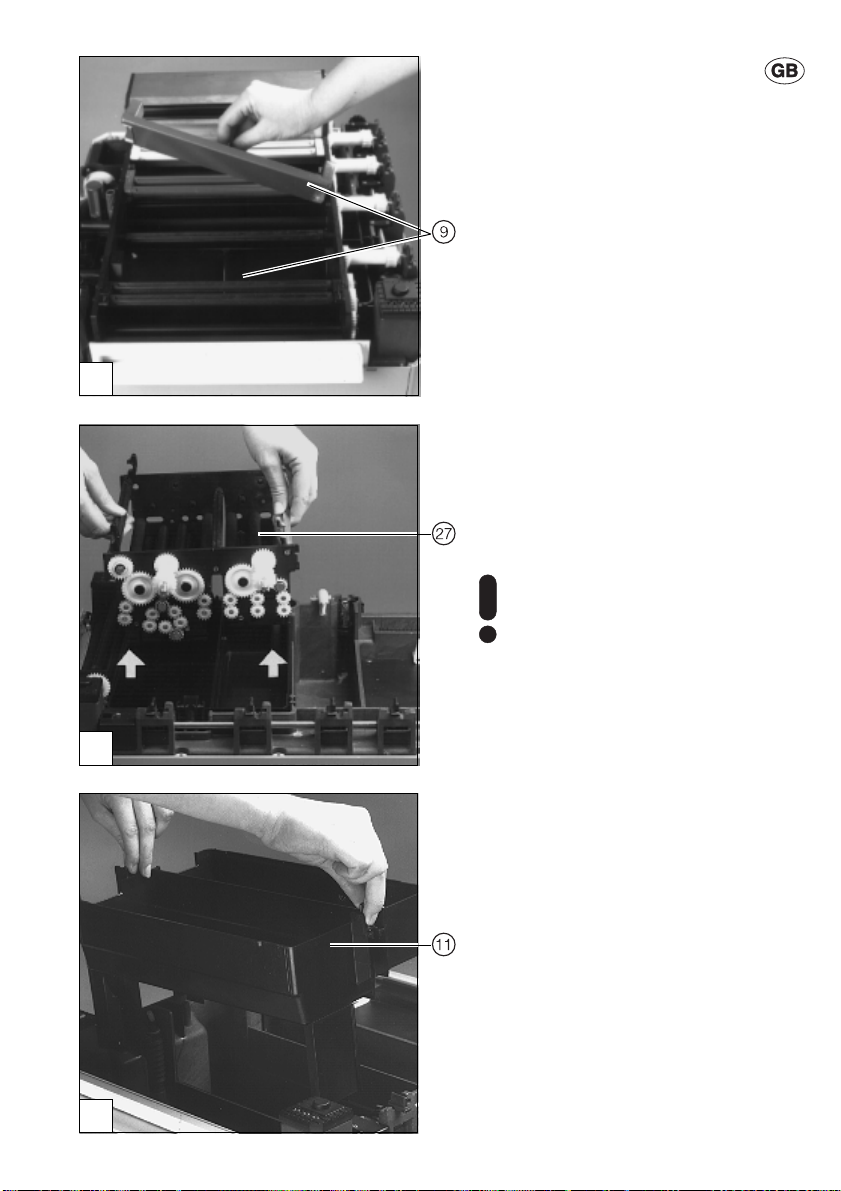

• Remove both bath covers (9) (only on model

1702-03 variable) from the developer and

fixer bath, let drip off and then lay aside.

4

• Take out Developer/Fixer roller set (27).

Firstly, lift the roller set vertically with both

hands, then carefully pour the remainder of

the chemicals into the baths over the front

side of the roller set.

• Clean all roller sets under warm water

(approx.40°C).

When cleaning the roller sets use the

correct coloured sponge.

Fixer - red

Developer - black

To disregard this advice could cause

contamination of fresh chemicals.

5

5.2 Cleaning the bath

• Lift bath (11) with both hands. Pour remaining

chemicals back into the tanks of the XR25.

• Rinse empty bath with warm water using the

appropriate sponges provided.

6

57

Page 8

5.3 Prior to draining the chemicals

Please observe the following:

If collection vessels (3) are present,

check whether they are empty.

Otherwise empty the chemicals from

them (4).

To avoid overflow it is important that the

vessels (3) are previously emptied.

Sobald die Chemiekalien vom Entwicklungsgerät abgelassen werden, fließen

sie in die Auffangbehälter.

7

5.4 Draining the chemicals

• Unscrew the red and black plugs (29).

58

8

With collection vessels (3) in position, the

used chemicals flow into them.

• Decant the collected and used chemicals

from the collection vessel (3) into the storage

containers (4).

9

Page 9

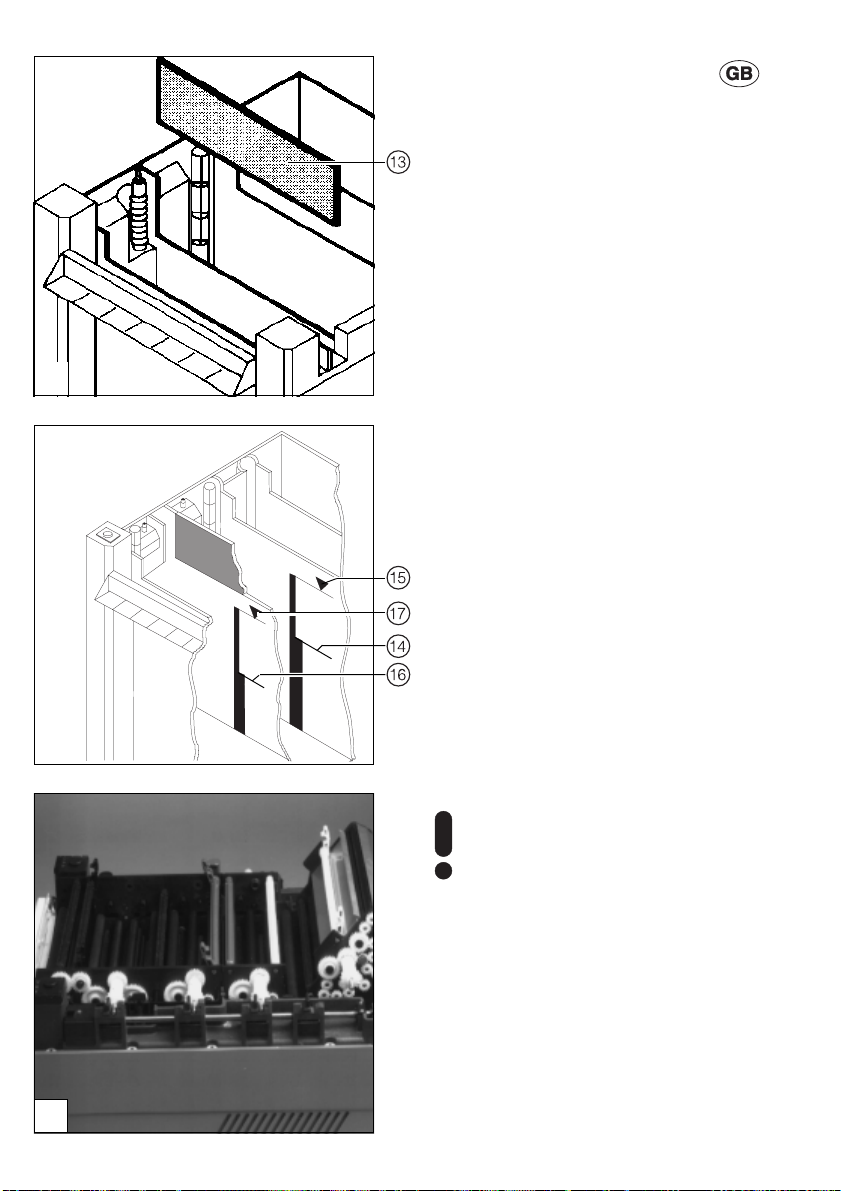

5.5 Cleaning the tanks

• With the appropriate wet sponge, wipe both

Tanks (13)(Developer-black, Fixer-red).

• Screw in red and black plugs (29), see fig.8.

9

10

• Fill both tanks up to the mark (14) with warm

water (approx.40°C).

• Insert Developer/Fixer roller set, close latches

and catches (24), see right fold-in page.

Never let Processor run when dry.

If there are no chemicals or water in the

tanks and the mains switch is activated,

this can lead to a technical defect.

If the Developer/Fixer roller set is not

inserted, the water will spurt upwards

as the conduit for the solution is not in

place.

• Replace lid (7) again, see fig.2.

• Insert mains plug.

• Mains switch (G) ON, see p. 5.

• Film transport switch (A) ON, let XR25 run for

approx. 10 mins. The remaining chemicals

are removed from the hoses and circulation

pump.

• Mains switch (G) OFF

• Pull out mains plug.

• Remove lid (7).

• Take out developer/fixer roller set (27), see

fig.5.

• Unscrew red and black plugs (29). The water

will flow into the empty collection vessels (3).

• Empty vessels (3) again.

11

59

Page 10

12

13

▲▲

▲

▲▲

EE

E

EE

EE

E

EE

FF

F

FF

FF

F

FF

▲▲

▲

▲▲

5.6 Filling with chemicals

• Screw in red and black plugs (29), see right

fold-in page.

• Insert separating plate (13) between Fixer

tank „F“ and Developer tank „E“, black side

towards developer, red side towards fixer.

1.Filling up tank F-fixer (red):

• Pour in large red bottle A and top up with

cold water to the lower mark (14).

• Now pour in small red bottle B and top up

with cold water to the upper mark (15).

2.Filling up tank E-developer (black):

• Pour in large black bottle A and top up with

cold water to the lower mark (16).

• Now pour in small black bottle B and top up

with cold water to the upper mark (17).

• Take out separating plate (13), clean it and

store it.

• Replace bath (11), see fig.6.

5.7 Insert roller sets

see right fold-in page and fig.14.

• Firstly, lift all latches (25) ready to receive

roller sets.

• Insert roller sets. Secure all latches (25) and

catches (24).

5.8 Replace lid

see fig.2 (7).

The lid should fit easily. If not, check

that all catches (24) and latches (25)

are properly closed.

60

5.9 Making XR25 ready for use

• Insert mains plug

• Power switch (G) ON, see p.5.

Yellow indicator (D) lights up, warm up phase

begins (approx.20mins.) As soon as the

green indicator (C) lights up, the correct

temperature has been reached and the XR25

is ready for use.

14

Page 11

15

16

▲▲

▲

▲▲

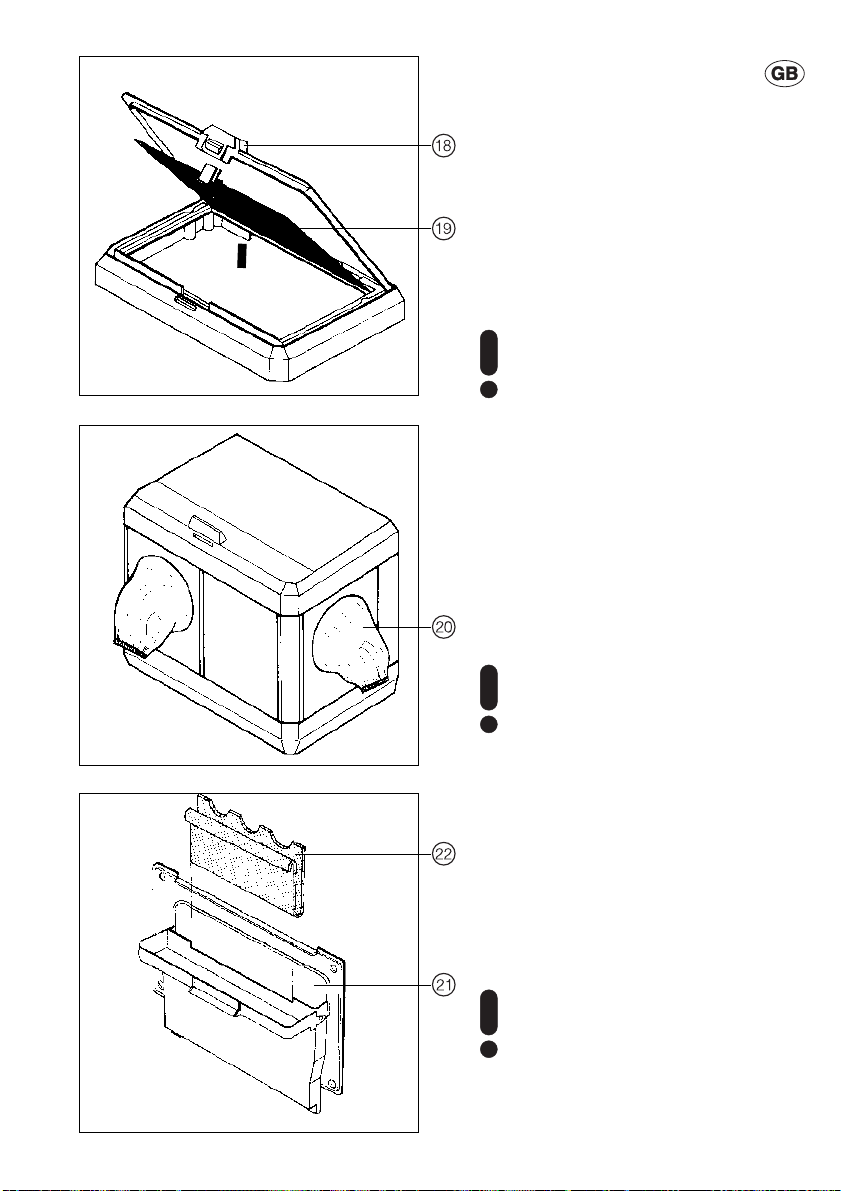

6. DAYLIGHT ATTACHMENT

If no darkroom is present, two daylight

attachments, DL24 und DL26, are available to

choose from, see left fold-in page, fig.(5) and

(6). The order no. as well as the recommended

max. film size for each is on p.4 under pt. 3.1.

„The whole programme at a glance“ can be

seen. For easier handling of wrapped intra-oral

films, the lid (18) can be lifted whilst the filter

pane (19) remains closed.

When processing thin coated (Extraoral) RP films, the lid must be

definitely closed. Otherwise the film

will be pre-exposed.

When necessary, individual elements of the

daylight attachment can be altered. Through

this, the arm sleeves (20) can be adjusted to

suit individual requirements.

7. FILM STORAGE

In the film compartment (21) which is situated

in the daylight attachment, a max. of 10

extraoral films can be stored.

When storing films in the compartment it is

important to observe the following:

When using the film storage

compartment always use up the films

before refilling. This will prevent films

being stored too long which, if

ignored, will cause ‘veiling`of the

films.

• Films 12x30, 13x18 and 15x30 place in film

holder (22).

- Hang film holder in storage compartment

- Lay films in film holder.

• Films 24x30 and 24x18 do not require the film

holder

- Lay films directly into film compartment

- The 24x18 films are stood upright in the film

compartment.

Close film compartment (21) each time

after taking out a film. If the film

storage area is not closed there is

always the danger of exposing the

films whenever the lid is lifted.

17

61

Page 12

8. SURGERY BREAKS

The max. lifespan of the chemicals in the tanks

is 4 weeks. If this period is exceeded during a

Surgery break,e.g. holidays, the chemicals

should be drained beforehand. The tanks and

roller sets cleaned with warm water (approx.

40°C) and then left standing empty. The

procedure as under pt.5 „CHANGING THE

CHEMICALS“.

62

Page 13

9. FAULT FINDING INFO.

Condition

1. Film too light

2. Films too

dark

3. Yellow/Green

veiling on the

film

4. Dark veiling

on films

Possible causes

• Developer temperature too

low

• X-ray exposure time too short

• Developer solution exhausted

• Developer temperature too

high

• X-ray exposure time too long

• Film not properly fixed

• Light getting into darkroom,

e.g. through keyhole

• Darkroom light wrongly

positioned

• Film has been affected by

Processor control lights

• Lid of daylight attachment not

properly closed

Remedy

Set temperature to 28°C

If possible, longer exposure time

Drain chemicals and mix fresh solutions.

Set temperature to 28°C

Shorten x-ray exposure time

Test whether Fixer solution is OK: Swish

film to and fro for approx. 40 secs. If the

film is transparent, the fixer is fine.

Should veiling persist: Drain chemicals

and mix fresh ones.

Check darkroom for light leakage and

seal off source.

Only indirect light allowed

Check all control lights and if necessary

dim them

When inserting extraoral and panoral

films the cover of the filter pane must be

closed.As films are light sensitive, the

lid must be properly closed.

5. Increased

background

veiling on the

film

6. Brownish

veiling on the

film

• Films out of date

• Film falsch gelagert.

• Film not properly washed

Check sell-by date

Store films in a cool place. Films should

not be kept near the x-ray machine.

(Scattered radiation)

Open water tap.

Safety switch in water bath has

switched off water inlet valve - Check

water drain..

63

Page 14

64

Loading...

Loading...