Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

2006/03

DÜRR XR 24 PRO

X-RAY FILM DEVELOPING APPLIANCE

Page 2

2

Page 3

CONTENT

Important information

1. Instructions ............................................. 4

1.1 EU - Labelling ................................... 4

1.2 Guidelines .........................................4

1.3 General Instructions ......................... 4

1.4 General Safety Instructions.............. 4

1.5 Use of additional apparatus ............5

1.6 Use of orthocromatic (green-

sensitive) films ..................................5

1.7 Safety instructions for electric power

protection .......................................... 5

1.8 Warning instructions and symbols .. 6

2. Product information .............................. 6

2.1 Use in accordance

with regulations ................................. 6

2.2 Use not in accordance

with regulations ................................. 6

2.3 Product information ..........................6

3. Extent of Supply ..................................... 7

3.1 Special accessories ......................... 7

3.2 Consumables.................................... 7

4. Technical data......................................... 7

5. Functional principle XR 24 PRO ..........8

6. Functional description of the

XR 24 PRO ...............................................9

6.1 Arrangement of plates ......................9

Mounting and assembly

7. Setting up ..............................................10

7.1 Area in which machine

is to be set up .................................10

7.2 How to set up machine ................... 11

7.3 Setting up the machine ................... 11

8. Installation ............................................ 12

8.1 Mains water supply ........................12

8.2 Wastewater connection .................. 12

8.3 Connection for developer and

Fixer outflow pipe ............................ 13

9. Before operating machine

for first time ..........................................14

9.1 Cleaning the machine ..................... 14

10. Power point (mains) ............................15

11. Circuit diagram ..................................... 16

12. First time operation .............................18

12.1Settings / Servicing work for

technician ........................................ 19

12.2Checking developer temperature and

carrying out acceptance test ......... 20

13. Transporting the machine ..................21

13.1 Removing the outflow pipes ...........21

13.2 Protection against damage ............21

Usage

14. Operation ............................................... 22

14.1 Procedure to be followed every

morning or before beginning work 23

14.2 Procedure to be followed every

evening or after finishing work .......24

14.3 Every week ..................................... 24

14.4 Every 4 weeks ................................24

14.5 1x a year ......................................... 24

14.6 When practice is closed ................. 24

14.7 List of reccomended films for Dürr

XR 24 PRO developing machine. ..25

15. Maintenance .......................................... 26

Troubleshooting

16. Tips for the user.................................... 32

17. Tips for Technicians .............................34

18. Troubleshooting tips........................... 35

18.1 Before beginning work ................... 35

18.2 Removing front covering ................35

18.3 Removing rear covering ................. 35

18.4 Removing lateral coverings ............ 35

18.5 After work has ended ..................... 35

18.6 Plan for carrying out service work . 36

18.7 Changing the display .....................38

18.8 Checking appliance fuses ............. 38

18.9 Replacing flow heating unit with

PTC sensor .....................................39

18.10 Checking the water valve ............39

18.11 Replacing the water valve ........... 39

18.12 Cleaning the water level sensor ..40

18.13 Changing the light barrier ............ 40

Disposal

19. Disposing of unit ................................. 40

3

Page 4

IMPORTANT INFORMATION

1. INSTRUCTIONS

1.1 EU - Labelling

The product carries EU labelling in

accordance with the Council’s guideline on

medicinal products (EU 93/42) and complies

with the basic requirements contained in

appendix 1 of this guideline.

1.2 Guidelines

• The requirement for electromagnetic

capability related to electric medical

appliances has been complied with.

1.3 General Instructions

• The instructions for mounting and using the

appliance are an integral part of the

machine. They must always be stored

close to the machine. These instructions

must be strictly complied with so that the

machine can be used and correctly

operated in accordance with the relevant

regulations. New employees must be

acquainted with the instructions for

mounting and using the machine

• So that the machine may be operated safely

and in a trouble-free manner, original parts

must be used. In addition, only

accessories mentioned in the technical

documentation or expressly released by

Dürr Dental for this purpose may be used.

• No warranty claims shall be made for

damage caused by the use of accessories

or consumables manufactured by external

companies. Dürr Dental can give no

warranty for the safe operating and

functioning of the machine.

• With regard to safety, reliability and

functionality, Dürr Dental shall only be

responsible if the machine has been

mounted, assembled, altered, enlarged or

repaired by Dürr Dental or by a specialist

authorised by Dürr Dental, and if the

machine was used and operated in

accordance with the instructions for

mounting and use.

• The XR 24 PRO developing appliance fulfils

the basic norms on safety and technology.

All rights of protection are reserved for the

circuits, procedures, names, software

programs and appliances mentioned in the

documentation.

• The technical documentation, or parts

thereof, may only be reprinted with the prior

written permission of Dürr Dental.

1.4 General Safety Instructions

The appliance was developed and designed

in such a way that dangers associated with

use in accordance with the relevant

regulations are largely ruled out. However,

we are obliged to list the following safety

measures so that residual dangers can also

be ruled out..

• When the machine is being operated, the

laws and regulations applying in the place

of use must be complied with. It is illegal to

reconstruct or alter the machine in any way;

contravention of this regulation shall lead to

expiry of the permit. If an altered machine

is operated, the operator shall be liable to

prosecution. When the machine is being

operated, the laws and regulations applying

in the place of use must be complied with.

It is illegal to reconstruct or alter the

machine in any way; contravention of this

regulation shall lead to expiry of the permit.

If an altered machine is operated, the

operator shall be liable to prosecution.

• The original packaging must be stored in

case the appliance has to be returned. The

packaging must be kept out of the reach of

children. Only the original packaging can

guarantee that the machine is protected in

the optimum manner while it is being

transported. If the machine has to be

returned during the warranty term, then Dürr

Dental shall not be liable for any damage

which occurred as a result of faulty

packaging while the machine was being

transported.

• The machine complies with the relevant EU

guidelines and may only be used by

qualified persons who are capable of

operating it in the appropriate manner.

4

Page 5

• Before using the machine, the user must

always check its functional safety and that

it is in proper condition..

• The user must be familiar with the

operating instructions for the machine.

• The machine must not be operated in

medical rooms where explosions are likely

to occur. Explosions may occur in areas

where combustible anaesthetics, skin

cleaning agents, oxygen and skin

disinfectants are used. The machine is not

suitable for operation in a combustible

atmosphere.

1.5 Use of additional apparatus

• Machines may only be used together or with

parts from other systems if a guarantee

exists that the safety of the patient, the user

and the surrounding area is not adversely

affected by his or her doing so. If the user

is unable to tell from the available technical

data whether or not safety is adversely

affected by coupling machines or using

parts from other systems, he or she must

enquire of the manufacturer or a suitably

qualified person in this regard..

1.6 Use of orthocromatic (green-

sensitive) films

To prevent incorrect exposure, the luminous

power of the darkroom light must be reduced

when green-sensitive films are being used.

A qualified technician must carry out the

necessary work in all such cases..

1.7 Safety instructions for electric power protection

• The developing machine may only be

connected to an earthed plug which has

been properly installed.

• Before the machine is connected an

inspection must be made to ensure that the

mains voltage and mains frequency

indicated on the appliance match the

values for the supply network.

• No extension leads may be used for

feeding the current.

• Before it is operated for the first time, the

machine and its leads must be checked to

ensure that they are not damaged in any

way. Damaged leads, plugs and sockets

must be replaced immediately..

• The machine may only be operated, i.e.,

connected to the mains, when sealed

(coverings must be attached and lid put

on).

• In accordance with IEC 601, the machine

should not be operated when patients are

present.

5

Page 6

1.8 Warning instructions and symbols

The following designations and symbols are

used for particularly important information in

the instructions for mounting and usage:

Information, requirements and

prohibitions on preventing personal

injury and extensive damage to

propert.

Warning about dangerous electrical

voltage

Special information concerning the

economic and profitable use of the

appliance, and other instructions.

EU labelling without Notified Body

Number

Comply with instructions for mounting

and usage

Mains button on / off

/ Select parameters

Confirm selection tigen

2. PRODUCT INFORMATION

2.1 Use in accordance with regulations

The Dürr XR 24 PRO X-ray developing

machine is to be used exclusively for the

automatic development of extra-oral and

intra-oral X-ray films in accordance with Dürr’s

recommended list of films.

Use in accordance with the regulations

includes compliance with the instructions for

mounting and usage as well as compliance

with the provisions on setting up, installing

and operating the machine, and on warranty.

Use in accordance with the regulations also

includes compliance with all legal provisions

in force in the place where the machine is

being used, with regard to work safety and

the disposal of chemicals.

2.2 Use not in accordance with regulations

If the machine is used for a purpose other

than the one stated in the regulations, the

manufacturer shall not be legally liable for any

damage arising as a result of same. In such

cases, the user shall incur the risk.

Switch on mains button

Switch off mains button

Open bibcock - every morning

Close bibcock - every evening

28 x 24 h

Change chemicals every 4 weeks

Allow chemicals to drain off

Clean machine

6

2.3 Product information

The exposed film passes through different

zones within the Dürr XR 24 PRO X-ray

developing machine: the developing, fixing,

rinsing and drying zones.

When the machine has been switched on, the

developing bath and the fixing bath are

heated to the set bath temperature (e.g.

28°C) at a rate of 0.5°C/min. The machine is

then ready to be operated. It starts operating

automatically when a film is slid inside. The

film is transported through the machine. As

soon as the message “MACHINE LOADED”

stops flashing on the display, another film can

be introduced, or up to 6 intra-oral films, can

be introduced together. When the film has

passed through the whole of the machine, it

switches automatically to stand-by.

Page 7

3. EXTENT OF SUPPLY

4. TECHNICAL DATA

XR 24 PRO X-ray developing machine

Model 1700-08

Model 1700-09 (100-110 V ~, 50-60 Hz)

Accessories, complete1700-001-00

(230 V ~, 50-60 Hz)

3.1 Special accessories

The following parts are not part of the extent

of supply.

They should be ordered if required!

XR-Cleaning Set for cleaning rack,

Content:

1 x cleaning tray,

2 x universal cleaner,

2 x sponges 1700-007-00

Cleaning films DÜRR clear100 1410-007-00

Water hose with Aqua-Stop 1330-001-51

Replenishing unit (230 V) 1700-820-00

Collecting tray, 20 litres

for developer 1416-021-00

Collecting tray, 20 litres

for fixer 1416-011-00

DL 24 daylight attachment

with filtering disc 1700-910-00

suitable for following film sizes:

2 x 3 cm up to max. 15 x 30 cm

DL 26 daylight attachment 1700-920-00

suitable for current film sizes

up to max. 24 x 30 cm

DA 24 darkroom attachment 1700-930-00

suitable for following film sizes:

2 x 3 cm up to max. 24 x 30 cm

suitable for following film sizes:

for model 1700-08, 230 V

T 6,3A 9000-115-25

for model 1700-09,110 V

T 10A 9000-115-50

(110 V) 1700-830-00

3.2 Consumables

DÜRR-AUTOMAT XR

Developer and fixer concentrate

for 2 applications CXB140C99..

Universal cleaner for cleaning

roller packets, two packets CCB600C55..

WR 2000, Spray Cleaner for

carrier rolls, six packets CCB800C55..

XR 24 PRO X-ray developing machine

Model 1700-08 (230 V)

Model 1700-09 (110 V)

Model 1700-08 1700-09

Voltage (V) 230 100-110

Frequency (Hz) 50-60 50-60

Power consumption (A) 4,0 9,2

Fuse (A) T 6,3 T 10

Heating capacity (W) 950

Heizleistung

Bath heating (W) 400

Drying (W) 450

Normal heating time (min) approx.20(0,5°C/min)

Time it takes film

to pass through (min)

normal 2:45 - 20

Bath circulation (l/min)

Developer approx. 1,8

Fixer approx. 2,0

Water through-flow (l/min) 2

Water pressure (bar)

min. water pressure 2

max. water pressure 6

Tank volume (l) both 5

Developer, Fixer

Temperature range

Environmental conditions

for machine in operation +10 to +28 °C

Optimal photo quality up to max. +28 °C

Storage and transport -10 to +60 °C

Air humidity

Machine in operation max. 80 %

Storage and transport max. 95 %

Dimensions T=51 cm, B=42 cm, H=44 cm

Weight 25 kg

Protection category IP20

Class of protection I

Overvoltage category II

Certificate-

of conformity EU-Labelling

7

Page 8

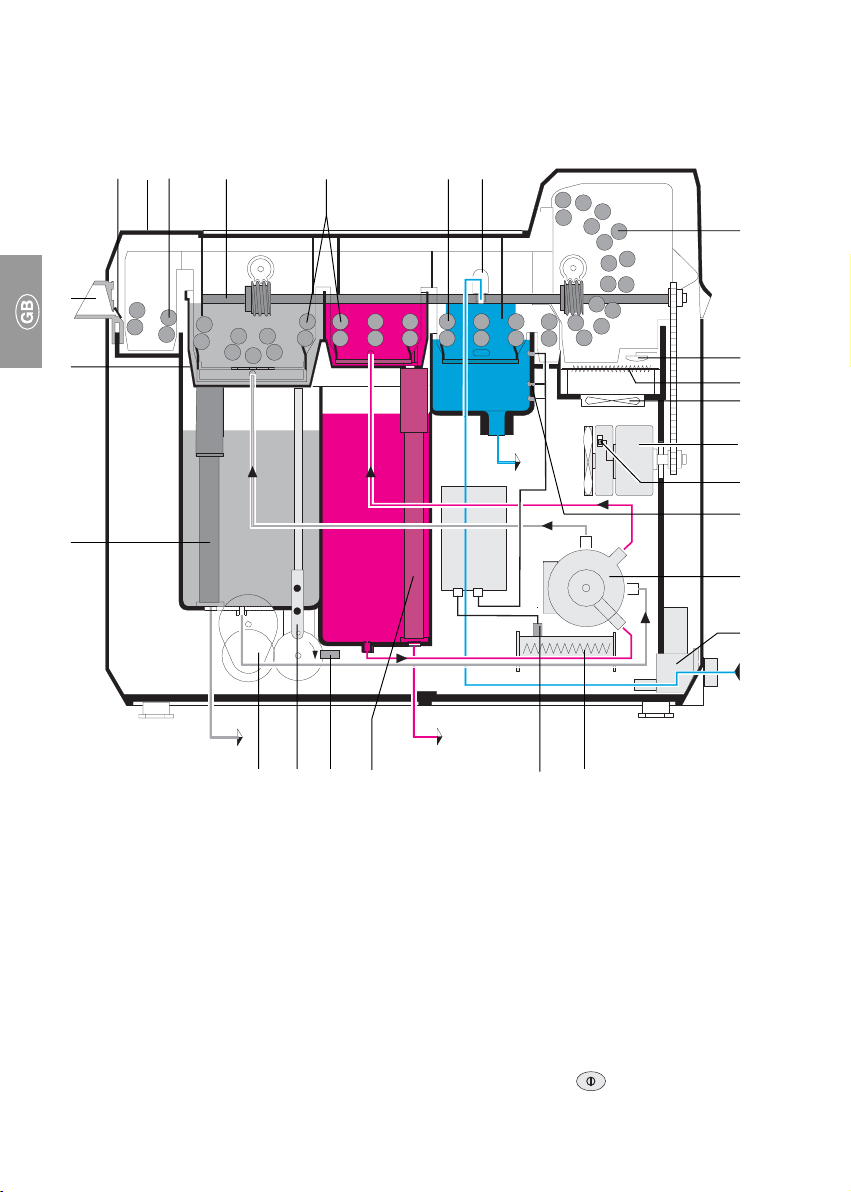

5. FUNCTIONAL PRINCIPLE XR 24 PRO

2A3 4 5 6 7

1

Stand By Position

8

22

DD

D

DD

21

20 19 19a 18 17 16

1 Film inlet

2 Start flap

3 Roller packet, film inlet

4 Drive shaft

5 Roller set, developer/fixer (D/F)

6 Roller set, water

7 Water inlet

8 Rollen set, drier

9 Safety switch for drier

10 Drier heater

11 Ventilator

12 Drive motor

12a Tachometer generator

13 Level sensors (for water)

14

Circulation pump (f. developer and fixer)

FF

F

FF

WW

W

WW

15 Water valve

16 Continuous heater

17 PTC-sensor

18 Overflow pipe with discharge plug (fixer)

19 Lifting rod

19a Light barrier, lifting tank

20 Lifting motor

21 Overflow plug (developer)

22 Lifting tray

D Developing bath

F Fixing bath

W Water bath

A Mains button on display

9

10

11

12

12a

13

14

15

8

Page 9

6. FUNCTIONAL DESCRIPTION

OF THE XR 24 PRO

When the mains button

(min. 2 sec.)

heating-up phase for the developing bath and

the fixing bath begins. The time remaining

until the correct temperature is reached is

displayed in the following manner: “WAITING

TIME… MIN” (display flashes). The machine

does not start at this point.

The bath begins to rotate when it is being

heated up.

place, the chemicals are pumped from the

developing tank and the fixing tank (volume of

5 litres for each tank) into the lifting tray (22)

via the circulation pump (14).

When the set temperature is reached, the

display lights up. The “MACHINE EMPTY”

message appears, indicating that the

machine is now ready to be operated.

As soon as the set temperature falls below

more than 0.5°C, the continuous heater and

the circulation pump (14) are switched on

again.

When a film is slid into the machine, the

start flap (2) opens and the “MACHINE

EMPTY” message flashes on the display

At the same time, a signal for lowering the

lifting tray (22) is triggered and the water

valve (15) opens. The drier heating unit (10),

drive motor (12) and circulating pump (14)

(for rotating the developing bath and the

fixing bath) start up.

The time it takes the film to pass through

the machine is controlled by a tachometer

generator (12a). The lifting tank’s rising and

falling movements are controlled by the disc’s

and the light barrier’s (19a) rotational speed.

,,

, the display is illuminated. The

,,

While this process is taking

is pressed

Should the outflow pipe be blocked, a signal

is sounded via a level sensor (13). The

water valve (15) closes and no more water is

fed into the machine.

When the film has been slid into the

machine, the start flap (2) closes. As soon as

the message “MACHINE LOADED” flashing

on the display goes out, another film can be

introduced, or up to 6 intra-oral films, can be

introduced together.

If no other film is slid into the machine when a

particular film has passed through it (this is

signalled by a sound) the lifting tray (22)

moves upwards (to stand-by position),

indicating that the machine is now empty.

The drive motor (12), water valve (15) and

drier heater (10) are switched off. When the

machine is in stand-by position, the

developer’s and fixer’s roller packets are

completely immersed in the chemicals. This

prevents deposits from forming on the rollers.

6.1 Arrangement of plates

23 A Operating part

23 B Control part

23 C Power part

23 A

When the lifting tray (22) is lowered, the film

is carried between the rolls through the

developing bath and the fixer bath, as well as

through the rinsing and drying zones (8)

within the time set for same.

While the film is being developed, water is fed

into the rinsing zone via water inlet (7).

The water is discharged via the outflow pipe.

Water flows through continuously at a rate of

2 l/min., with water pressure of 2 bar.

23 B 23 C

9

Page 10

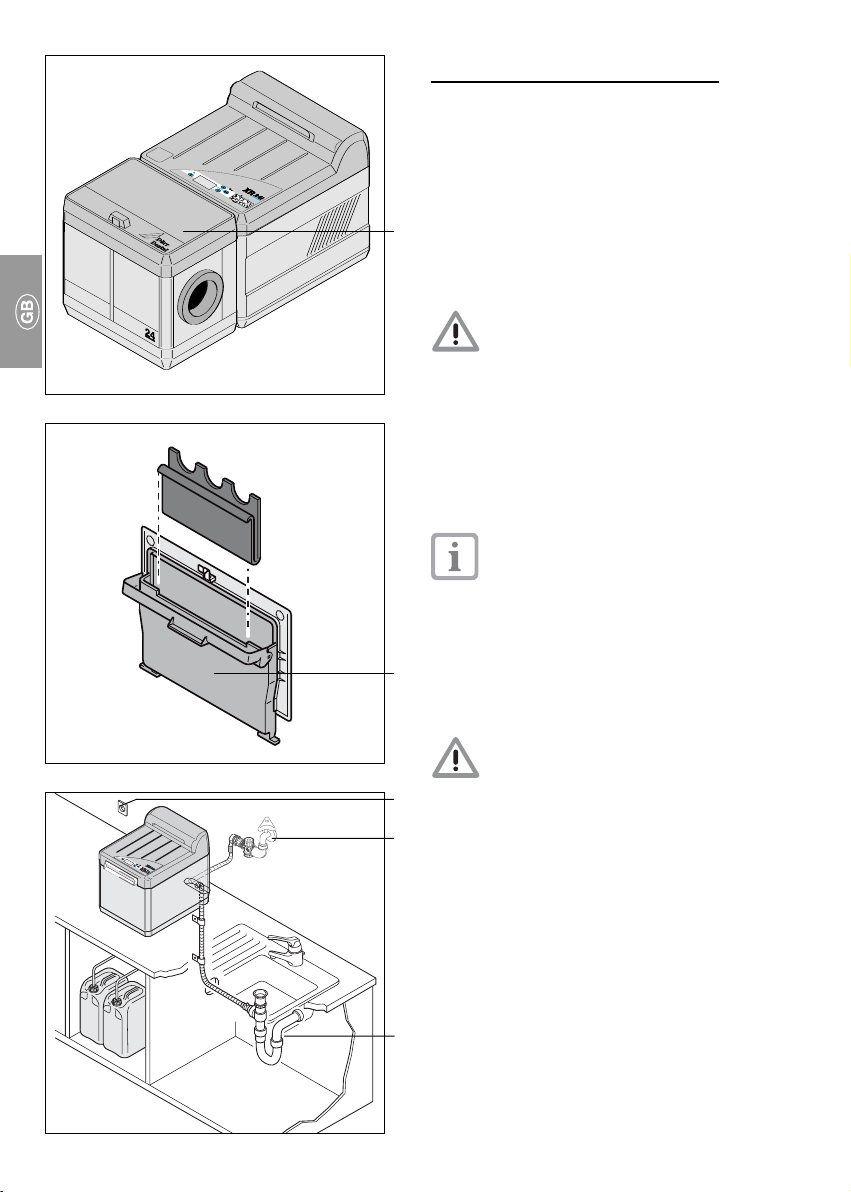

MOUNTING AND ASSEMBLY

7. SETTING UP

7.1 Area in which machine is to be set up

• The XR 24 PRO developing machine should

only be set up in a dry, well-aired room.

24

• In winter, the room temperature should not

fall below +10°C; in summer it should not

rise above +28°C.

Danger. The appliance should not

be directly exposed to the sun’s

rays. There is a danger that the

1

25

2

26

27

chemicals may overheat or that the

films might be pre-exposed.

• The room in which the machine is being set

up must contain a R3/4” bibcock (27) with a

ventilation pipe, an outflow pipe (28) with a

ventilated plastic trap, and an earthed plug

(26). Ideally, a washbasin should also be

situated close to the machine.

The operating staff must have easy

access to the bibcock (27) and the

earthed plug (26)..

• We recommend that the XR 24 PRO be set

up in a darkroom. If the machine is

up in a darkroom, a daylight attachment

(24) (DL24 or DL26) must be fixed to it.

• The following should be taken into

consideration if the machine is being used

with a daylight attachmentwith a daylight attachment

with a daylight attachment:

with a daylight attachmentwith a daylight attachment

Danger. Films should never be

stored in the vicinity of an X-ray

room

Danger. When films are stored in

the daylight attachment’s film

storage part (25), there is a danger

that pre-exposure can occur due to

stray radiation in the appliance.

If necessary, a partition with a lead screen

may be inserted.

notnot

not set

notnot

10

28

3

Page 11

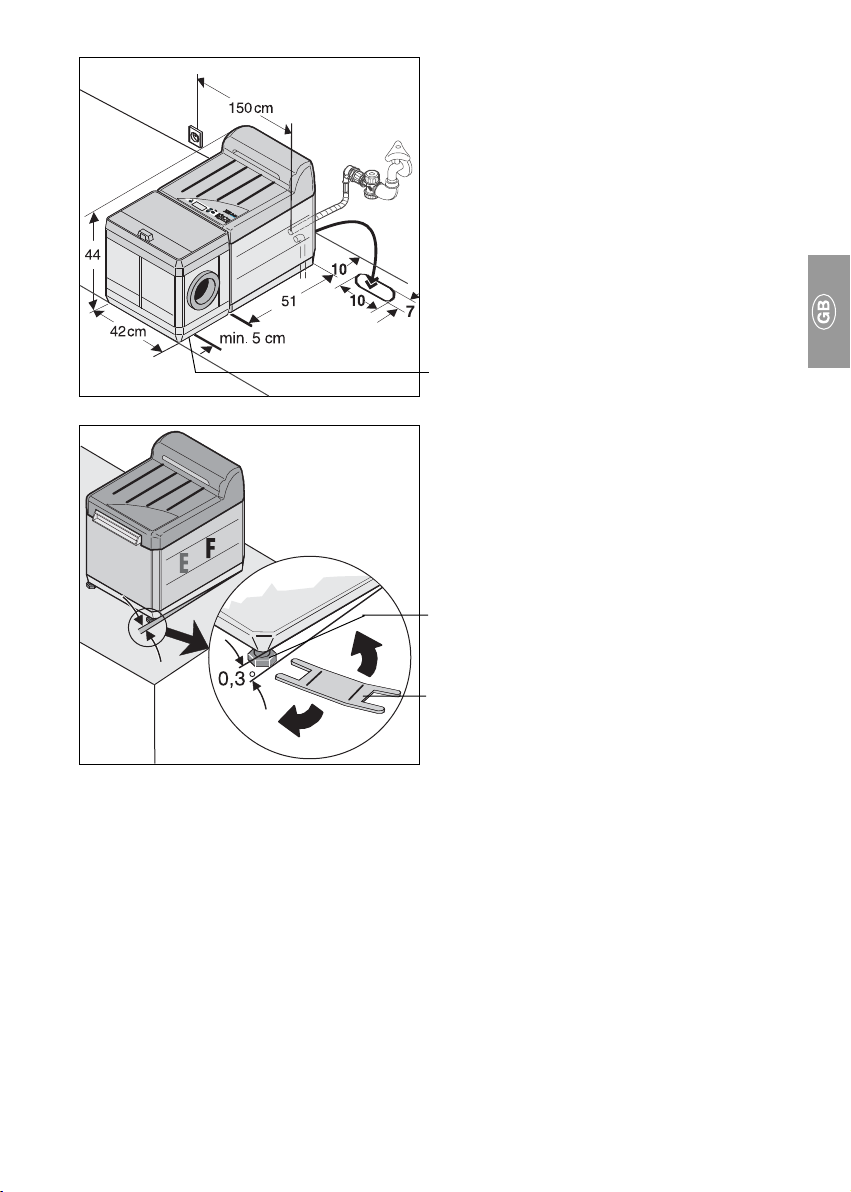

7.2 How to set up machine

• Set the machine up on a horizontal, stable,

even board at working height.

• When the tubes are being passed under,

the board must have an opening measuring

ca. 7 x 10 m

• Ensure that additional space is available so

that servicing work can be carried out and

so that the machine is adequately

ventilated:

There must be at least 10 cm of free

space behind the machine and ca. 50 cm

free space left and right.

At the front there must be enough space in

case a daylight attachment (24) has to be

24

4

fixed to the machine. If necessary, detach

the installation feet at the front and screw

them on to the back.

7.3 Setting up the machine

• Undo the plastic bands attached to the

cardboard packaging.

• Take out all small parts.

• Grip the sides of the machine and place it

in suitable position.

• Set it up close to a mains water supply, an

29

outflow pipe and an earthed pipe (max.

distance 1.5 m)

• Set up the appliance so that it has a slight

tilt, ca. 0.3 ° to the fixer bath (fig. 8).

30

Adjust the feet of the appliance (29) using

the spanner provided (30) as required.

7

11

Page 12

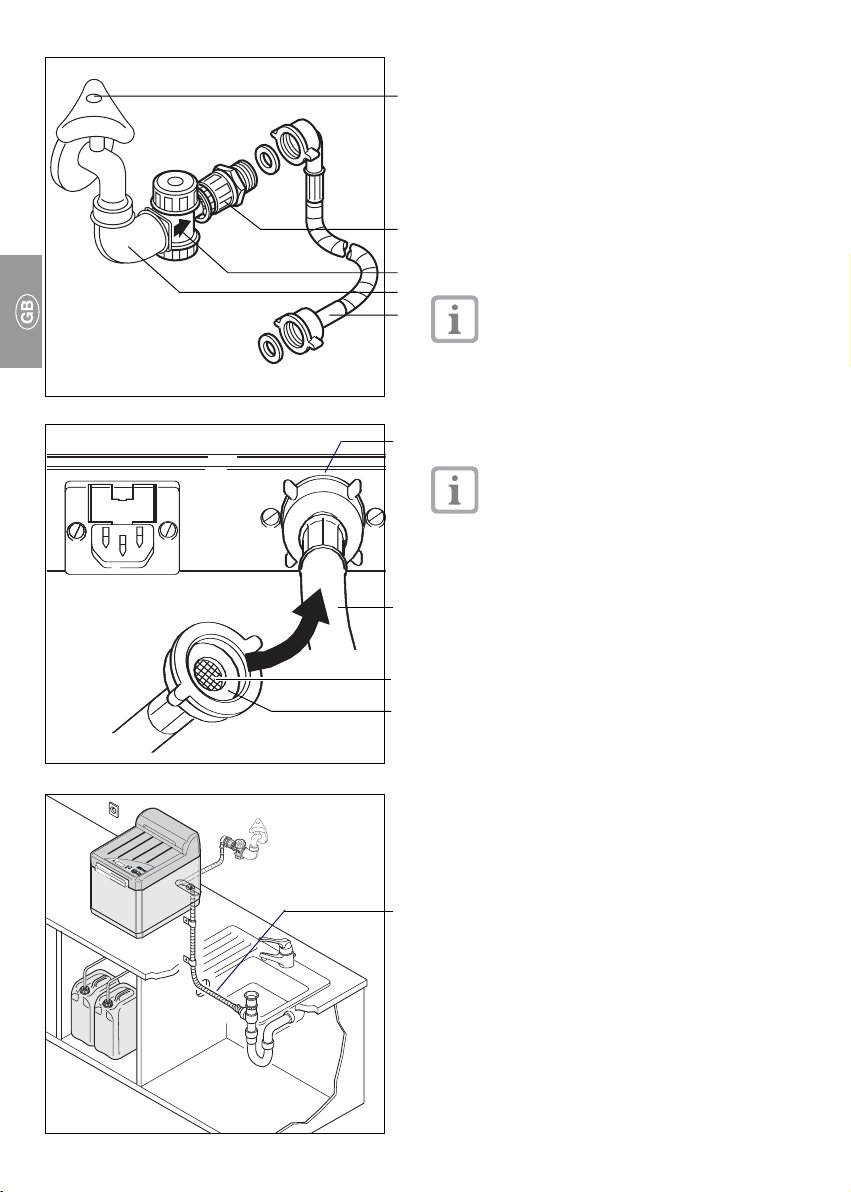

8. INSTALLATION

27

8.1 Mains water supply

• Check whether or not pure water is flowing

out of the bibcock (27). When the machine

is being installed initially, rinse the

pipelines thoroughly!

• Because the water quality can vary greatly

31

from region to region, a fine-mesh filter (32)

must be inserted between the bibcock (27)

32

and the water pipe (34).

33

34

7

35

34

The fine-mesh filter (32) protects the

flow-through limiter in the appliance’s

water valve from impurities

• Close the bibcock (27).

• Connect the 90º bow to the bibcock (27).

Attach the fine-mesh filter (32) (arrow in flow

direction) and double nipple (31) to the

bibcock

Check whether the strainer (34a) and

both seals (34b) are present in the

water pipe’s (34) threaded joints.

• Connect the water pipe to machine’s water

intake point (35) (threaded joint with

strainer) and to the double nipple (31).

12

34a

34b

8

8.2 Wastewater connection

• The wastewater connection may only be

connected via a ventilated siphon.

• Move the outflow pipe (36) to the siphon at

a continuous slant. Shorten the pipe to the

36

correct length.

9

Page 13

10

11

max. 3 cm

Fixierer

When moving the outflow pipe,

avoid sagging, constrictions and

reductions.

• Cover exterior of end of pipe with UHU

plaster

• Screw screwed fitting (37) to pipe and

attach to siphon’s (25) muff using pipe clip

(38).

• Secure outflow pipe using pipe clips,

screws and pins.

• The washing basin’s outflow point must be

open!

37

38

8.3 Connection for developer and

25

40

41

39

43

Fixer outflow pipe

• Set up the collecting tray (39) for the

developer (black level marking) and the

fixer (red level marking) beneath the

appliance so that it is clearly visible and

stable

• Move the pipes (40) at a continuous slant

• Shorten the pipes to the correct length.

• Feed the pipe for the developer (black

marking) into the black lid (41).

• Screw the lid (41) to the collecting tray (39)

for the developer

• Secure the pipe for the fixer (red marking)

to the collecting tray for the fixer in the

same way

When the full level marking has

been reached, empty the collecting

tray (danger of overflow). When

disposing of the developer and the

fixer, regional regulations must be

complied with. In Germany and in

several other countries X-ray

chemicals are classified as special

waste, and are disposed of

accordingly.

12

41

39

13

Page 14

11

13

9. BEFORE OPERATING

44

MACHINE FOR FIRST TIME

45

9.1 Cleaning the machine

• Take lid off.

• Remove floating lid from developing bath

and fixing bath

8

• Open green stop flaps (44) and seals (45).

• Swivel drier packet (8) backwards.

• Remove roller packets for water (6) and

developer/fixer (5).

8

• Swivel display (90) upwards.

6

5

14

3

90

14

The display may also be removed and

moved to the left.

• Remove roller packet film inlet (3).

90

15

Page 15

16

17

➘

➘

➘

• Actuate lateral lever and remove lifting tank

(22).

• Clean roller packets, lifting tray and tanks

22

with damp sponge

Adding chemicals Adding chemicals

„

Adding chemicals „

Adding chemicals Adding chemicals

and

and inserting roller packets and inserting roller packets

„

and inserting roller packets „

and inserting roller packets and inserting roller packets

see chapter on USE, Pt.15.1.3

10. POWER POINT (MAINS)

The machine is designed for use

with a mains voltage of 230 V or

100-110 V/50-60 Hz (see nameplate).

Before connecting the mains cable

check whether the required mains

voltage is available; otherwise the

appliance may be damaged. Use

the Dürr mains cable supplied with

the machine. The machine may only

be connected to the supply network

when it has been shut down and

when the lateral coverings have

61

been attached and the lid replaced.

• Plug the mains plug (61) into the machine

and the mains socket.

15

Page 16

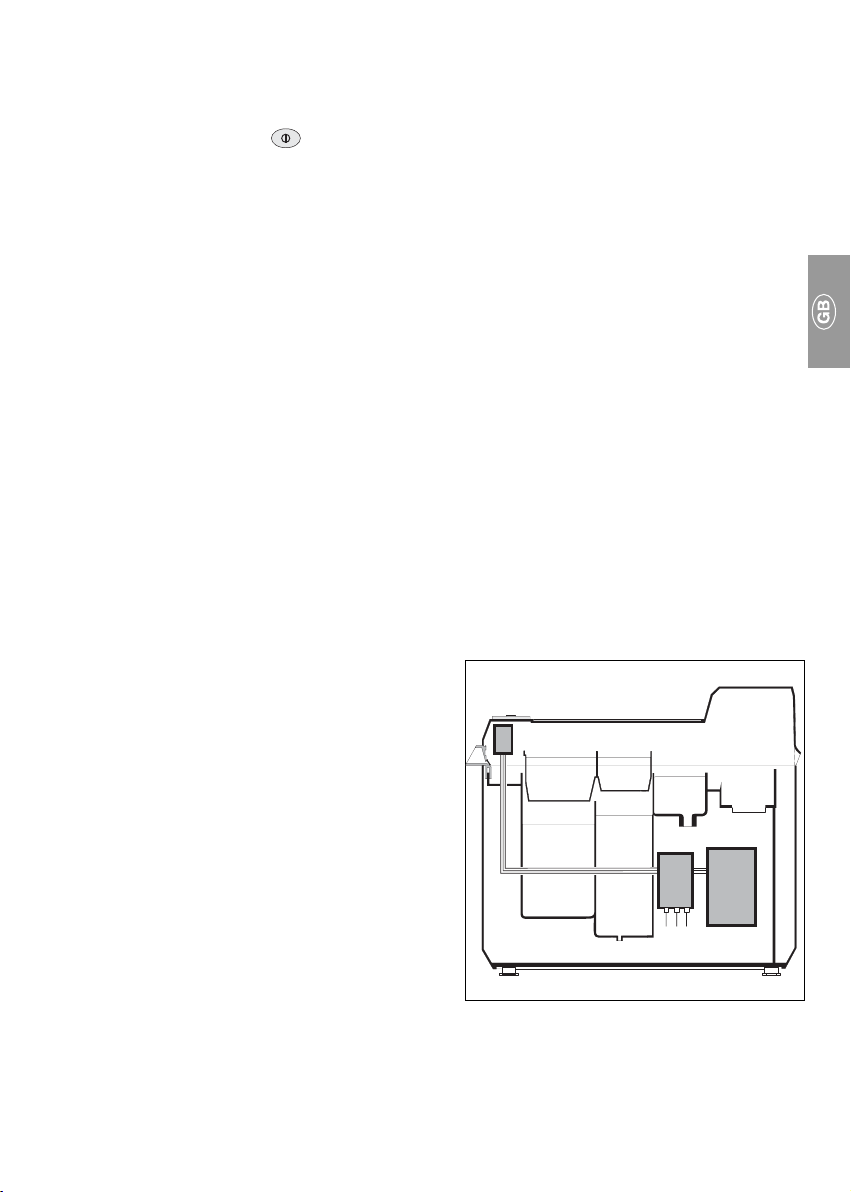

11. CIRCUIT DIAGRAM

11.1 Printed circuit board, operating part / 11.2 Printed circuit board, control

(see also pos. 23 A and 23 B under Pt. 6)

23 B

U1 Photo-electric barrier cover

U2 Photo-electric barrier cover

U3 Photo-electric barrier, lifting tray

U4 Photo-electric barrier, film inlet flap

R1 Bath temperature temperature sensor

23 A

11.1 11.2

16

X5 Water level sensor

M1 Tachometer generator

Page 17

11.3 Printed circuit board,

power part 230 V

(see also pos. 23 C under Pt. 6)

23 C

11.3

M1 Roller drive

M2 Ventilator

M3 Circulating pump

M4 Lifting tray motor

R1 Bath heating unit

R2 Drier heating unit

Y1 Water valve

X1/X2 Appliance plug

X3 Replenishing unit

17

Page 18

12. FIRST TIME OPERATION

The XR 24 PRO developing machine has

three settings which determine the amount of

time it takes a film to pass through the

machine. The following values are set for the

machine “ex works”:

Intra-oral films 6 min. (INTRA program)

Extra-oral films 4 min. (EXTRA program)

Endodontal films 2.45 min. (ENDO prog.)

Note: It is not possible to archive X-ray films

which pass through the machine during this

short period of time).

- Developing bath and fixing bath

temperature: 28 ºC

- Drier capacity: 30%

When films with different drier capacities,

and which pass through the machine in

longer or shorter periods of time, are used,

the values can be changed in accordance

with the films which are to be processed.

In this context, see the list of films, point 14.7.

For a program overview, see the chapter on

USAGE

The machine may only be

connected to the supply network

when it has been shut down and

when the lateral coverings have

been attached and the lid replaced!

The operating instructions on the

display for the user

the chapter on USAGE, point 14

Detailed instructions on how to

service the machine are listed under

maintenance, point 18.6.

• The developing machine must

never be used without roller

packets!

If no roller packets are used, the

developing and fixing fluids can

spurt up and out of the developing

unit when placed under pressure.

Chemicals irritate the eyes and

skin. Serious injuries can be

incurred.

• If no developing and fixing roller

packets are used, the chemicals

cannot be directed into the tanks

There is a danger of the chemicals

being mixed together.

• The developing machine should

never be operated without fluids

(chemicals, water). This can lead

to malfunctioning of the heating

control system.

are contained in

Whenever the machine is switched on

using the mains button, the “INTRA”

program is started, i.e., whenever the

machine is switched off it is reset to

“INTRA”.

18

Page 19

12.1 Settings / Servicing work for technician

• Open the bibcock.

• Check leak tightness of machine and

connections

• Start servicing operation

+ +

+

press at same time (min. 4 s).

+ +

Machine now in service mode

• Select service function

Select with buttons and service

funktion

• Change settings

Change with or parameter value

With 1 s, confirm new value

*1 Selected language, frequency or value

appears at first by switch on

*2 Particular values by manufactoring

V18

• End servicing mode

Switch off machine using mains

button (press for min. 2 sec.)

• Parameters such as language, mains

frequency, etc. may be changed on the

display if the instructions are followed:

DEUTSCH?

[ENTER]=OK

50 Hz?

[ENTER]=OK

PROGR. INTRA?

[ENTER]=OK

PROGR. EXTRA?

[ENTER]=OK

PROGR. ENDO?

[ENTER]=OK

PARAMETER?

[ENTER=OK]

ENGLISH?

[ENTER]=OK

60 Hz?

[ENTER]=OK

PROCESS 6:00

[ENTER]=OK

PROCESS 4:00

[ENTER]=OK

PROCESS 2:45

[ENTER]=OK

FRANCAIS?

[ENTER]=OK

1

Change value with and in

5er and 5% steps, confirm with

DRYER 30%

[ENTER]=OK

DRYER 30%

[ENTER]=OK

DRYER 30%

[ENTER]=OK

Further

Language...

2

2

2

1

19

Page 20

21

12.2 Checking developer temperature

and carrying out acceptance test

The following procedure is only valid

for, e.g., Germany. Users in other

countries should comply with the

relevant local regulations!

• Switch on the machine and wait until

the heating phase for the bath has ended

(see also point 14.1, “in the morning or

before beginning work”).

• In order to check the developer

temperature, switch off the machine.

• Pull out the mains plug.

• Close the bibcock.

• Take off the lid.

• Measure the developer temperature (to the

front and left at a depth of ca. 20 cm).

In accordance with the list of films, the

developer temperature must amount to,

e.g., +28 ºC, +/- 0.5.

• Record the temperature in the acceptance

log and the constancy test log.

• Replace the lid, plug in the mains plug,

open the bibcock and switch on the

machine.

• Insert test film and carry out acceptance

test in accordance with ordinance on Xrays. Record the test results in the test log.

Store the test film in the archives.

Inform operating staff that constancy tests

must be carried out on a regular basis.

20

Page 21

22

13. TRANSPORTING THE MACHINE

Before carrying the developing machine,

27

please note the following:

The developing machine may only

31

39

63

be transported when the tanks are

empty.

• Switch off the machine by pressing the

mains button.

• Close the bibcock (27).

• Pull the mains cable out of the earthed

socket and the machine.

• Unscrew the water pipe (31) from the

machine and the bibcock (27).

• Empty the chemicals out of the collecting

trays (39) into the corresponding trays (63).

• Allow the chemicals to flow out of the tanks

into the collecting trays (39). See point

15.1.

• Clean the machine (see point 9.1)

23

24

13.1 Removing the outflow pipes

• Remove the outflow pipe (35).

• Disengage the pipe from the collecting tray

(39) for the developer and the fixer. Make

sure that no chemicals drip out.

35

13.2 Protection against damage

• Protect the machine against mechanical

stress and damage

• Ensure that the machine cannot move about

when it is being transported.

• Instruct staff charged with transporting the

machine.

39

21

Page 22

USAGE

Mains button

Confirmation button

, „Browsing through menu“

Program overview

The intra, extra and endo programs are set

to particular values when the machine is

being manufactured (see below).

However, each of them can be adapted by the

technician using the list of films.

INTRA -Processing time: t=6min

EXTRA - Processing time: t=4min

ENDO -Processing time: t=2min45sec

- Bath temperature: T=28 °C

- Drier capacity: 30%

- Bath temperature: T=28 °C

- Drier capacity: 30%

- Bath temperature: T=28 °C

- Drier capacity: 30%

Whenever the machine is switched

on using the mains button, the

“INTRA” program is started, i.e.,

whenever the machine is switched off

it is reset to “INTRA”.

Service- / and error messages

See point 16.1, error messages on display,

indicated by signal

SERV. INTERVAL

REACHED!

Only when acivated

by the technician!

22

BEFORE OPENING

MAIN PLUG PULL

ERROR

WATER TO LOW!

ERROR

WATER TO HIGH!

ERROR

ROLLER DRIVE

14. OPERATION

Before operating the machine, please note

the following:

• The developing machine must

never be used without roller

packets.

If no roller packets are used, the

developing and fixing fluids can spurt

up and out of the developing unit when

placed under pressure.

Chemicals irritate the eyes and

skin. Serious injuries can be

incurred.

• If no developing and fixing roller

packets are used, the chemicals

cannot be directed into the tanks.

There is a danger of the chemicals

being mixed together.

• The developing unit should never

be operated without fluids

(chemicals, water). This can lead

to a malfunction in the heating

control system.

In order to guarantee that the films be

of a consistently high quality, the

machine must be switched on every day.

Care must also be taken to ensure that the

temperature in the area surrounding the

machine is not higher than the temperature of

the developing bath!

Standby-Mode

When in the stand-by mode, the machine is

ready to be operated. A film may now be

inserted into it

Before inserting a film, check the program

selection!

Page 23

14.1 Procedure to be followed every morning or before beginning work

• Open the bibcock.

• Switch on the machine:

Press the mains button for ca.

2 sec. until the signal sounds

>> DURR DENTAL<<

✳ ✳

✳ XR 24 PRO V ..

✳ ✳

WARM UP PHASE

WAITING .. MIN

<INTRA> 6:00

M. FREE

▼▼

▼

▼▼

<INTRA> 6:00

M. TAKEN

<INTRA> 6:00

REMAIN TIME ..MIN

<INTRA> 6:00

M. TAKEN

<INTRA> 6:00

M. FREE

Changing the program:

▼▼

▼

▼▼

see next page

➞➞

➞

▼▼

▼

▼▼

➞➞

➞➞

➞

➞➞

➞➞

➞

➞➞

➞➞

➞

➞➞

➞➞

➞

➞➞

➞➞

➞

➞➞

➞➞

➞

➞➞

✳✳

✳

✳✳

1 The display lights up. The lifting tray

automatically moves to the corresponding

position, ca. 30 sec.

2 The machine is heated until the correct

temperature for the developing bath is

reached. Heating time: 0.5°C/min. The

“WAITING TIME… MIN” message flashes

on the display while this process takes

place.

3 As soon as the set temperature is reached,

the display lights up.

The machine is ready to be operated.

A film can be introduced.

The INTRA program has been pre-set; if

another program is to be used, select

EXTRA or ENDO using the button .

4 Once a film has been introduced into the

machine, the display message “MACHINE

LOADED” begins to flash. When the

message stops flashing, another film can

be introduced into the machine.

Up to six intra-oral films can be

introduced between the markings into

the machine together (see next

page).

5 The remaining time that the film spends in

the machine is displayed (automatic

counter).

A signal sounds when the film leaves the

machine.

6 If no other film is introduced, the lifting tray

moves to stand-by position

7 When the machine is in stand-by mode, the

“MACHINE EMPTY” message is displayed

Films which have not been

developed must not be laid on the

machine because they may be

incorrectly exposed due to the LCD

display.

23

Page 24

Changing the program

INTRA

M. FREE

6:00

PROCESS 6:00

[ENTER]=END

BATH TEMP. 28.0°C

[ENTER]=END

DRYER 30%

[ENTER]=END

EXTRA

M. FREE

ENDO

M. FREE

4:00

2:45

PROCESS 4:00

[ENTER]=END

PROCESS 2:45

[ENTER]=END

For error messages, see point

16.1 “error messages on the

display”.

25

• Up to six intra-oral films can be introduced

into the machine between the markings. If

2 x 3 films are being introduced, ensure that

they are not inserted crossways and that

the marking point in the developing

machine is respected.

• In order to acquire a check photo quickly

when the endo program is being used (e.g.,

when root canals are being treated) (short

processing time, 2.45 min.), change.

See list of recommended films (point 14.7).

14.2 Procedure to be followed every

evening or after finishing work

• Switch off the machine by pressing

the mains button.

• Close the bibcock.

BATH TEMP. 28.0°C

[ENTER]=END

BATH TEMP. 28.0°C

[ENTER]=END

DRYER 30%

[ENTER]=END

DRYER 30%

[ENTER]=END

14.3 Every week

• Using at least weekly cleaning films, e.g.

"DÜRR clear100" before starting work

order no. 1410-007-00

• Carry out a constancy test in accordance

with the ordinance on X-rays:

- Expose the film with the set parameters

for the constancy parameters.

- Measure the temperature.

- Develop the film.

- Compare the test results with the film for

the acceptance test and record the

results in the test log.

- Archive the test film.

14.4 Every 4 weeks

or according to requirements,

• Change chemicals, see para. 15.1

14.5 1x a year

• Clean the roller packets with chemicals in

the roller tray using the XR Cleaning Set;

order no. 1700-007-00; includes instructions

on use.

• Check light tightness of darkroom.

14.6 When practice is closed

for more than 2 weeks:

• Drain off chemicals.

Clean tanks and roller packets and allow to

dry (see point 15.1)

24

Page 25

14.7 List of reccomended films for

Dürr XR 24.. developing machine.

Intraorale Films

Bath temperature 28 °C

Processing time 6 min

Drier capacity 30 %

Filmtypes

Kodak Ultra Speed 2,2x 3,5 cm

Kodak Insight 2,2x 3,5 cm

Agfa Dentus M2

When taking certain examination films

(e.g. before root canal treatment) for

developing in the „ENDO“ program, bitte

please note the following:

During this short period of time, Xrays films may not be archived.

If the film is to be archived, it must be

fixed and rinsed for 30 sec. as soon

as possible after the diagnosis has

been made.

Comfort

3,1x 4,1 cm

2,7x 5,4 cm

5,7x 7,6 cm

3,1x 4,1 cm

2,4x 4,0 cm

2,7x 5,4 cm

5,7x 7,6 cm

2 x 3 cm

3 x 4 cm

5 x 7 cm

Extraorale Films

Bath temperature 28 °C

Film formats bis max. 24 x 30 cm

Filmtypes Processing Drier-

time capacity

Kodak

X-OMAT K 6min 30 %

T-MAT L/RA 4min 20 %

T-MAT G/RA 4min 20 %

Ekta Vision L 6min 30 %

Ekta Vision G 6min 30 %

Agfa

Dentus RP 6 6 min 30 %

Dentus Ortholux 6 min 30 %

The processing times for other types

of films must be checked against the

Dental Sensitivity Index, and adapted

accordingly.

25

Page 26

15. MAINTENANCE

Every 4 weeks

Change chemicals without using

replenishing unit (91) (see paragr.15.1 below)

Chemicals should be changed every

4 weeks if a maximum amount of 10

intra-oral and 3 extra-oral films are

used on a daily basis.

The instructions on how to clean the apparatus

should be kept close to the machine and

should be displayed in poster (A3) format.

Every 3 months

Change chemicals using replenishing unit

(91) (see paragraph 15.1 below).

1 x a year

Clean the roller packets using the

XR Cleaning Set

60

61

The tanks do not have to be cleaned

with chemicals. Only the roller

packets need to be cleaned using

chemicals using the XR Cleaning Set

(cleaning tray, accessories and

instructions for use).

Order no: 1700-007-00.

26

27

28

15.1 Changing the chemicals

15.1.1 Drain off the chemicals

• Switch off the machine using the mains

button.

• Pull the earthed socket out of the mains

91

plug (61).

• Remove the lid (60).

• Check if the collecting tray (39) is empty; if

necessary, empty into main tray (63).

39

63

It is important that the collecting tanks

be empty; if they are not, there is a

danger that they will overflow if the

chemicals are drained out of the tanks.

• Remove floating lid from developing bath

and fixing bath. Drain and put to one side

• Unscrew small plugs from lifting tanks, then

unscrew large plugs from tanks

• Empty collecting tray

• Unscrew lid from collecting tray. Hang pipe

ends in neutral tray

This prevents water from getting into

the collecting tray and the main tray

when cleaning is being carried out.

Page 27

11

29

15.1.2 Cleaning tanks and roller packets

44

• Open green stop flaps (44) and seals (45).

• Swivel drier packet (8) backwards

45

8

• Swivel display (90) upwards. If a daylight

attachment is being used, the display must

be removed and moved to the left

• Remove insertion packet for water (6) and

film (3)

6

30

31

3

• Remove roller packets for water (6) and

developer/fixer (5); tilt sideways to allow

chemicals to drain off

5

27

Page 28

➘

32

33

➘

➘

• Place roller packets in washbasin. Spray

with, e.g., WR 2000 Spray Cleaner and

allow to work in for ca. 10 min.

22

• Actuate lateral lever and remove lifting tank

(22).

Rinse using the sponges; black for

developing and red for fixing tank

• Rinse the lifting tank (22) with warm water

(min. 40 °C) and clean thoroughly using the

appropriated spongs as above.

• Rinse tanks (22) with suitable sponges

under warm water

• Rinse roller packets with suitable sponges

under warm water

• Screw large plugs (18, 21) into tanks

• Fill developing (E) and fixing tanks (F) to

marking (54) with 40 ºC warm water.

• Starting the developer and fixer packets

18

21

54

60

61

1

The developing machine must never

be used without roller packets. If

no roller packets are used, the

developing and fixing fluids can

spurt up and out of the developing

unit because the water is not being

redirected into the tanks! Chemicals

irritate the eyes.

• Close green stop flaps and seals

• Swivel display back into place

• Replace lid (60)

• Plug in mains plug (61). Switch on machine

by pressing mains plug.

• Start up machine. Insert 3 x 4 films into layin point (1) until start flap is actuated.

Leave films lying in this position for about 4

min.

• Allow machine to run for ca. 10 min. (pipes

and circulatory pump are thus automatically

cleaned).

• 10 min. later, switch off machine by

pressing mains button and pull out mains

plug (61).

• Remove lid (60)

• Swivel display upwards

• Open green stop flaps (44) and seals (45).

28

34

Page 29

35

• Remove roller packets for water (6) and

developer/fixer (5); tilt sideways to allow

water to drain off.

• Unscrew large plugs for developer (21) and

fixer (18); allow water to drain off from these.

15.1.3 Pouring in chemicals

The information on pouring in the

chemicals refers to the

54

52

“DÜRR AUTOMAT XR” chemistry.

• Screw the large plugs for the developer

(21) and the fixer (18) into the tanks (see

pg. 28)

• Reconnect developer and fixer pumps to

collecting trays

• Place partition (52) between developing

and fixing tank.

The partition prevents chemicals from

mixing together when they are being

poured in.

Chemicals can cause damage to

health. They irritate eyes and skin.

Danger of serious injury to eyes

exists. Irreversible injuries may be

caused.

Wear protective gloves and glasses

when pouring in chemicals.

If chemicals get into eyes, wash

thoroughly with water and consult

doctor.

Clean hands under running water

when work has been carried out.

36

For further information on safety

measures, see following internet site:

http://www.duerr.de.

Dürr Dental has converted from the

two-part to the one-part

“DÜRR AUTOMAT XR” chemistry

(pict. 35 and 36). The advantages are:

- These are easier to handle and

- result in a more constant

development quality

1. Filling the fixing tanks (F) (Picture 35)

Carefully pour into large red bottle (avoid

splashes so that chemical do not mix

together) and fill with water (max. 20 ºC) to

upper marking (54).

2. Filling the developing tanks (E) (Pict. 36)

Carefully pour into large black bottle (avoid

splashes) and fill with water (max. 20 ºC) to

upper marking.

29

Page 30

38

• Insert lifting tray (22)

• Screw small plugs into lifting tray

15.1.4 Inserting roller packets

60

59

6

5

58

3

22

44

8

45

Danger. The developing machine

must never be used without roller

packets.

If no roller packets are used, the

developing and fixing fluids can spurt

up and out of the developing unit

when placed under pressure.

Chemicals irritate the eyes and

skin. Serious injuries can be

incurred.

If no developing and fixing roller

packets are used, the chemicals

cannot be directed into the tanks.

There is a danger of the chemicals

getting into the eyes or being mixed

together.

• Insert drying packet (8) and swivel

backwards

• Insert, one after the other, roller packets for

water (6), developer/fixer (5) and film lay-in

(3).

Make sure that conduits interlock. If

necessary, rotate driving toothed wheel (58)

until it meshes with the worm on the drive

shaft

• Swivel drier packet (8) forwards

• Close green stop flaps (44) and seals (45)

• Insert floating lid (59) for developing bath

and fixing bath

• Swivel display backwards, or insert.

• Replace lid (60). Ensure that the bottom

edge of the lid meshes completely with the

conduits in the casing coverings.

• Plug in mains plug.

30

Page 31

31

Page 32

TROUBLESHOOTING

16. TIPS FOR THE USER

If faults cannot be remedied by using the following information, the Dental Depot

technician should be contacted for further technical assistance.

Error

1. Completely out

of order

2. Films too bright

3. Films too dark • Set correct exposure time on camera

4. Yellow-green

veil on film

5. Dark veil on

film

Possible causes

• Mains cable not correctly

plugged in

• Lid not replaced

• Mains button pressed for too

short a time

• Developer run down

• Film exposure time for

camera too short

• Developing bath temperature

too low

• Film exposure time for

camera too long

• Developing bath temperature

too high

• Film not completely fixed

• Film developed in ENDO

program (with processing

time of 2.45 min.)

• Lid of daylight attachment

open.

• Light entering into darkroom,

e.g., via keyhole

• Darkroom light incorrectly

attached or light travelling in

wrong direction

Remedying faults

• Plug mains cable into back of machine

and into earthed socket

• Replace lid correctly

• Press mains button for min. 2 sec.

• Change chemicals (see point 15.1).

• Set correct exposure time on camera

(if possible)

• Have technician check and, if

necessary, set same.

(if possible)

• Have technician check and, if

necessary, set same.

• Check whether fixer is still in working

order. Wave intra-oral films about for

ca. 40 sec. in the fixer. If the film is

transparent, the fixer is in working

order. If veils are still present, change

the chemicals (see point 15.1).

• Select program with longer processing

time. Monitor time it takes film to pass

through machine (see list of

recommended films, point 14.7).

• When orthochromatic (green-sensitive)

films are being processed, lid must be

closed; otherwise films will be preexposed

• Check light tightness of darkroom; if

necessary, seal room

• Lamp should only emit rays indirectly

6. Greenbrownish veil

on film

32

• Chemicals exhausted • Pour in new chemichals

Page 33

Error

Possible causes

Remedying faults

7. Increased

basic veil on

film

• Film concealed

• Film incorrectly stored

• Developing bath temperature

too high as room temperature

is too high

16.1 Error messages on display with signal tone

Display reading

BEFORE OPENING

MAIN PLUG PULL

SERV. INTERVAL

REACHED!

ERROR

WATER TO LOW!

ERROR

WATER TO HIGH!

further message

follows ...

At beginning and/or

during developing

process.

Once machine has

been switched on

After a film has been

laid in with a delay of

ca. 35 sec.

At beginning and/or

during developing

process.

possible causes

Securing relais on

PCB is defect

Servicing interval

has been reached.

Water feed for water

bath is interrupted

- Water outflow

pipe choked up,

incorrectly laid or

not ventilated

- Electrical bridging

caused by calcified level sensors.

• Check expiration date

• Check storage provisions, expiration

date or manufacturer’s data on film

packaging.

Do not store films near

camera. Pre-exposure of films

can result due to stray

radiation.

If necessary, a partition with a

lead screen may be inserted.

• Lower room temperature

Remedying faults

Arrange maintenance work by

contacting customer service

staff. Machine can still be

operated.

Before opening main plug pull

Arrange maintenance work by

contacting customer service

staff. Machine can still be

operated.

Check whether bibcock is

open and/or feed pipe is

connected

Unblock pipes; check

whether if water outflow pipe

is correctly laid (water

pockets).

Further work may be carried

out once fault has been

remedied

ERROR

ROLLER DRIVE

At beginning and/or

during developing

process

Rotational signal

from motor

interrupted; cable

or plug defective

Arrange maintenance work

by contacting customer

service staff.

Faults which occur when films are

being developed; film is only

carried in shortest processing time

(2.45). Inadequate fixing

33

Page 34

17. TIPS FOR TECHNICIANS

also see pt.18. Trouble Schooting Tips

Error

1. Completely out

of order

2. No fresh water

being fed into

machine

3. Incorrect

developing

temperature

4. Films too

bright

5. Films too dark • Replace flow heating unit and/or PTC

6. Yellow-green

veil on film

Possible causes

• Fuses in house defective

• Fuses in appliance defective

• Water valve blocked or

defective

• Water feed blocked

• Level sensors calcified

(electrical bridging).

• Flow heating unit defective

• Air in system, circulating

pump not ventilated. (If

machine is filled with water or

chemicals at 20ºC, the

machine starts without being

heated up.)

• Developing temperature too

low

• Flow heating unit defective

• No chemicals in roller packets

for developer and fixer (bath

level too low).

• Chemicals not being

circulated

Remedying faults

• Check fuses; replace if necessary

• Check fuses; replace if necessary

(see point 18.8)

• Check water valve; replace if

necessary (see point 18.10)

• Clean fine-mesh filter and strainer in

water pipe

• Clean level sensor (see point 18.2).

• Replace flow heating unit and PTC

sensor (see point 18.9).

• Ventilate the circulating pump, so that

the machine is repeatedly started in

succession. Mains switch ON /OFF.

• Measure the temperature and key it

into the service menü „CALIBRATION ?“

sensor (see point 18.9).

• Check sealing lip profile and roller

packet; replace if necessary.

• Check circulating pump for possible

air in pipe

7. Greenbrownish veil

on film

8. Film not

completely

dried

• Film not rinsed • Level sensor in water bath has switched

• Drier capacity incorrectly set

• Ventilator defective

• Heating unit defective

16.1 Error messages on display with signal tone

see 16.1

34

off water valve; check water outflow

pipe and, if necessary clean and lay in

accordance with regulations (see 8.2)

• Further possibilities: see remedying

faults, pt.17.2 (no feeding of fresh water)

• Set drier capacity in accordance with

list of recommended films (see pt. 14.7)

• Change ventilator

• Check temperature-locking device

Page 35

40

18. TROUBLESHOOTING TIPS

18.1 Before beginning work

60

••

Switch off machine using mainsSwitch off machine using mains

•

Switch off machine using mains

••

Switch off machine using mainsSwitch off machine using mains

buttonbutton

button

buttonbutton

• Pull out mains plug (61)

61

• Remove lid (60)

• Remove casing coverings required for

carrying out work

18.2 Removing front covering

• Swivel display upwards

• Open green stop flaps (44) on film insertion

packet (3)

• Remove film insertion packet (3)

• Unscrew two grey rapid seals (68) from the

44

front covering (56)

• Unscrew 3 Philips screws (57) and remove

front covering (56)

45

18.3 Removing rear covering

• Open stop flaps (44) and seals (45) on drier

8

packet (8)

• Swivel drier packet (8) backwards and

remove

• Unscrew 3 Philips screws (57) and remove

rear covering (67)

1141

42

3

18.4 Removing lateral coverings

• Remove front (56) and rear (67) covering;

pull lateral covering upwards and outwards

57

18.5 After work has ended

55

• Reattach casing coverings in accordance

with regulations (see also point 9.5)

57

67

55

68

56

Never operate appliance if casing

coverings have not been correctly

attached and screwed on. The

machine is live; danger of electric

shocks exists.

• Replace lid (60). Plug in mains plug

35

Page 36

36

A

V18

DEUTSCH?

[ENTER]=OK

50 Hz?

[ENTER]=OK

PROGR. INTRA?

[ENTER]=OK

PROGR. EXTRA?

[ENTER]=OK

PROGR. ENDO?

[ENTER]=OK

PARAMETER?

[ENTER= ]CONTINUE

ENGLISH?

[ENTER]=OK

60 Hz?

[ENTER]=OK

PROCESS 6:00

[ENTER]=OK

PROCESS 4:00

[ENTER]=OK

PROCESS 2:45

[ENTER]=OK

REGENERATION?

[ENTER]=OK

18.6 Plan for carrying out service work

FRANCAIS?

[ENTER]=OK

1

DRYER 30%

[ENTER]=OK

DRYER 30%

[ENTER]=OK

DRYER 30%

[ENTER]=OK

REGEN. OFF

[ENTER]=OK

Further

Language...

2

2

2

1

REGEN. ON

[ENTER]=OK

1

• Start service operation

Switch off machine using mains

button (press for min. 2 s)

+ +

+

+ +

Machine now in service mode

• Select service unction

Select buttons and service function with

and

• Change settings

Change with

With

*1 The language, frequency or value

settings selected appear first when

switched on again

*2 Factory default settings

• End servicing mode

Switch off machine using mains button

(press for min. 2 sec.)

REG.TIME

[ENTER]=OK

press at same time

or parameter value

1s, confirm new value

(min.4 sec)

BATH TEMP 28.0 °C

[ENTER]=OK

PROCESS TIME

FILM LENGTH

0000H

0000,0H

BATH TEMP 28 °C

[ENTER]=CONTINUE

Page 37

A

1

BACK

[ENTER]=OK

BACK

[ENTER]=OK

INPUTS

[ENTER]=OK

LIGHT BARRIER

LIFTING PAN ON/OFF

LIGHT BARRIER

FILM FLAP ON/OFF

SERV.INTERVAL?

WATER VALVE OFF

[ENTER]=CONTINUE

WATERVALVE ON

[ENTER]=CONTINUE

[ENTER]=OK

CALIBRATION?

[ENTER]=OK

COMP.TEST?

[ENTER]=OK

WATER VALVE?

[ENTER]=OK

SERVICE OFF SERVICEON

[ENTER]=OK

VALUE 28.0 °C

[ENTER]=CONTINUE

START MANUEL

[ENTER]=OK

START MANUELOFF

[ENTER]=OK

START MANUELON

[ENTER]=OK

REGEN.PUMP?

[ENTER]=OK

REG.PUMPOFF

[ENTER]=CONTINUE

REG.PUMPON

[ENTER]=CONTINUE

[ENTER]=OK

ROLLER DRIVE?

[ENTER]=OK

DRIVE OFF

[ENTER]=CONTINUE

DRIVE ON

[ENTER]=CONTINUE

LIFTING PAN?

[ENTER]=OK

LIFTING PAN DOWN

[ENTER]=CONTINUE

LIFTING PAN TOP

[ENTER]=CONTINUE

0490H

DUE

SERVICE RESET

BATH HEATER?

[ENTER]=OK

BATH HEATER OFF

[ENTER]=CONTINUE

BATH HEATER ON

[ENTER]=CONTINUE

VENTILATOR?

[ENTER]=OK

VENTILATOR OFF

[ENTER]=CONTINUE

VENTILATOR ON

[ENTER]=CONTINUE

SERVICE (TARGET)

0500H

CIRCULAT.PUMP?

[ENTER]=OK

CIRCULAT.PUMP OFF

[ENTER]=CONTINUE

CIRCULAT.PUMP ON

[ENTER]=CONTINUE

DRYER?

[ENTER]=OK

DRYER OFF

[ENTER]=CONTINUE

DRYER ON

[ENTER]=CONTINUE

37

WATERTO HIGH

ON/OFF

WATERTO LOW

ON/OFF

Page 38

43

18.7 Changing the display

91

• Pull the display cable’s (92) plug out of the

plate (86) and pull through openings (91)..

92

86

93

• Pull display (90) upwards.

• Attach new display in reverse sequence.

90

38

44

45

18.8 Checking appliance fuses

• Open flap (64) on rear of unit by applying

slight pressure with screwdriver.

64

• Press spring together and pull out fuse

65

holder (65).

• Check fuse; replace if necessary. For order

number, see point 3.1, special accessories

62

Page 39

46

18.9 Replacing flow heating unit with PTC sensor

• Remove all coverings.

• Allow chemicals to drain out (see point

15.1.1)

• Pull out plug (93, photo 43) on plate.

16

• Twist screw on circulating pump holder and

17

raise circulating pump.

79

• Pull both plugs out of the circulating pump

and pull plug on flow heating unit (16) out.

80

• Remove flow heating unit from holder and

15

pull out pipes.

81

• Insert new flow heating unit in accordance

with regulations.

34

• Put up all plugs on circulating pump and

flow heating unit.

Check for 230 V or 110 V plug connection.

• Put plug (93, photo 43) back up on plate

(86)..

• Reattach casing coverings in accordance

with regulations.

18.10 Checking the water valve

If the water valve has not been switched on:

• Start servicing mode (see point 18.6).

Select “Individual Test” menu and then

“Water Valve”..

• If the valve is not switched on despite the

presence of voltage, replace the whole

valve (15) (see point 18.11, “Replacing the

water valve”)

18.11 Replacing the water valve

Firstly, check water valve (see point 18.10);

replace if defective.

• Close bibcock

• Remove water pipe carefully from water

feed (34).

• Pull mains cable (80) out of valve

• Pull internal water pipe (79) carefully out of

valve at rear

• Unscrew Philips screws (81) beside water

feed and replace complete valve

39

Page 40

48

18.12 Cleaning the water level sensor

• Close bibcock.

• Remove lid.

• Open green stop flaps and seals

• Swivel drier packet backwards.

• Remove water roller packet.

• Clean level sensors (82 and 83) so that no

calcified bridges can form.

• In order to check functionality, operate

machine without water roller packets.

82

• Simulate laying-in of film; the message

“WATER LOW” will appear on the display

83

• If a bridge forms between both level

sensors (82 and 83), the message

“WATER HIGH” will appear on the display;

the sensors are now clear. The cleaning

process has ended. If deviations occur,

see

troubleshooting, point 16.1.

18.13 Changing the light barrier

For this purpose, use light barrier spare

parts kit (order no: 17000-993-00).

A description can be found in the spare part

kit.

40

DISPOSAL

19. DISPOSING OF UNIT

The built-in electronic plate and components

must be disposed of in the same way as

electronic scrap metal.

The remaining structural components can be

disposed in accordance with the relevant

local regulations.

Loading...

Loading...