Page 1

XR 24 NDT

Manual

EN

EN

9000-608-25/30

Page 2

EN

2

9000-608-25/30 2011/04/13

Page 3

Content

Important Informations

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Official guidelines . . . . . . . . . . . . . . . . 4

1.2 Notes . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Disposal of appliance . . . . . . . . . . . . . 4

1.4 Correct Usage . . . . . . . . . . . . . . . . . . 4

1.5 Incorrect usage . . . . . . . . . . . . . . . . . 5

1.6 Product description . . . . . . . . . . . . . . 5

1.7 Connecting peripheral appliances . . . . 5

2. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 General notes on safety . . . . . . . . . . . 5

2.2 Electrical safety instructions . . . . . . . . 5

3. Warnings and Symbols . . . . . . . . . . . . . 6

4. Delivery Contents . . . . . . . . . . . . . . . . . . 6

4.1 Special accessories . . . . . . . . . . . . . . 6

4.2 Disposable materials . . . . . . . . . . . . . 6

5. Technical Data . . . . . . . . . . . . . . . . . . . . 7

6. XR 24 NDT Functional layout . . . . . . . . . 8

7. Functional description XR 24 NDT . . . . 9

7.1 Arrangement of PCB (main board) . . . 9

Mounting

8. Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8.1 Room for set-up . . . . . . . . . . . . . . . . 10

8.2 Set up options . . . . . . . . . . . . . . . . . 11

8.3 Set up . . . . . . . . . . . . . . . . . . . . . . . 11

9. Installation . . . . . . . . . . . . . . . . . . . . . . 12

9.1 Connecting water supply . . . . . . . . . 12

9.2 Waste water connection . . . . . . . . . . 12

9.3 Connection of developer and fixer

waste hoses . . . . . . . . . . . . . . . . . . . 13

10. Commissioning and first set up . . . . . . 14

10.1 Cleaning the unit . . . . . . . . . . . . . . . 14

11. Electrical connections . . . . . . . . . . . . . 15

12. Circuit diagram . . . . . . . . . . . . . . . . . . . 16

12.1 Operating section PCB . . . . . . . . . . 16

12.2 Controller section PCB . . . . . . . . . . 16

12.3 Performance functions PCB 230 V . .17

13. Commissioning and first set up . . . . . . 18

13.1 Settings / Service operation for

the Service Technician . . . . . . . . . . . 19

13.2 Check temperature of the developer 20

14. Transport . . . . . . . . . . . . . . . . . . . . . . . . 21

14.1 Remove the drainage hoses . . . . . . 21

14.2 Protection from damage . . . . . . . . . 21

Use

15. Operation . . . . . . . . . . . . . . . . . . . . . . . . 22

15.1 Mornings or before surgery begin . . 23

15.2 In the evening or after surgery

hours . . . . . . . . . . . . . . . . . . . . . . . 24

15.3 Operation interruption . . . . . . . . . . . 24

15.4 Film recommendations . . . . . . . . . . 24

16. Maintenance . . . . . . . . . . . . . . . . . . . . . 25

16.1 Change the chemicals . . . . . . . . . . . 25

Trouble-shooting

17. Tips for operators . . . . . . . . . . . . . . . . . 32

17.1 Fault message on display with

audible signal . . . . . . . . . . . . . . . . . 33

18. Tips for technicians . . . . . . . . . . . . . . . 34

19. Tips for Troubleshooting . . . . . . . . . . . 35

19.1 Before beginning work . . . . . . . . . . 35

19.2 Remove front panel . . . . . . . . . . . . . 35

19.3 Remove rear panel . . . . . . . . . . . . . 35

19.4 Remove side panels . . . . . . . . . . . . 35

19.5 After completing work . . . . . . . . . . . 35

19.6 Service operation plan . . . . . . . . . . 36

19.7 Replacing display unit . . . . . . . . . . . 38

19.8 Check the fusing of the unit . . . . . . . 38

19.9 Replacing process heater with

PTC-sensor . . . . . . . . . . . . . . . . . . 39

EN

2011/04/13 9000-608-25/30

3

Page 4

Important Informations

1. General

1.1 Official guidelines

This product has been subject to conformity

acceptance procedures and has been found to

conform to all requirements of the European

guidelines applicable.

EN

1.2 Notes

• The Installation and Operating Instructions

constitute a part of the appliance. They must

be made available to the operator. Correct

observance of the Installation and Operating

Instructions is is a basic requirement for using

the appliance properly and safely, and new

personnel must be instructed accordingly.

These Installation and Operating Instructions

must be handed over to any subsequent

owner or operator of this appliance.

• The safety of the operator and trouble-free

operation of the appliance can only be

ensured where original engineering

manufactured parts are used. Additionally,

only those accessories listed in the Installation

and Operating Instructions may be used or

parts or accessories expressly approved by

Dürr NDT. If accessories are used

manufactured by third parties, then Dürr NDT

can no longer provide any guarantee for safe

operation or correction functioning. No liability

on the part of the manufacture will be

accepted in the case that damage arises

through the use of non-approved accessories.

• Dürr NDT cannot be held responsible for the

appliance with regard to safety, reliability and

function where installation, reset, alterations,

extension or repairs were not carried out

either by or for Dürr NDT or by a third party

specifically approved by Dürr NDT, or if the

appliance is not used and operated according

to the instructions laid down in the Installation

and Operating Instructions.

• These Installation and Operating Instructions

accord with the features of the appliance and

the level of engineering at the time of first

introduction of the model. All circuits,

processes, names, software and appliances

quoted are protected under industrial property

rights.

• This translation of the Installation and

Operating Instructions has been carried out in

good faith. Liabilty for incorrect translation will

not be accepted. The accompanying German

version of these Installation and Operating

Instructions are to be used as reference; if you

have any doubt to the correct interpretation of

the instructions please consult your dealer.

• Any reproduction of these Installation and

Operating Instructions, or parts thereof, in any

medium whatsoever including electronic is

only permitted with the prior written approval

of Dürr NDT.

• Keep original packing for possible return of

the appliance to the supplier. Do not let the

packaging fall into the hands of children. Only

the original packing ensures optimum

protection for the appliance during transport.

If, during the period of guarantee, return of the

appliance is necessary, DürrNDT will not

accept claims for damage arising from using

incorrect packaging during transport!

1.3 Disposal of appliance

EU Directive(s) 2002/96/EG - WEEE (Waste

Electric and Electronic Equipment) of 27th

January 2003 and their current application in

national law states that products covered by the

above directive within the European Union must

be disposed of as special waste.

If you have any questions concerning the

correct disposal of this product please contact

Dürr NDT.

1.4 Correct Usage

The Dürr X-ray film developer XR 24 NDT is

designed exclusively for the automatic

development of X-ray films for industrial

applications.

Correct usage of the appliance involves exact

observance of the Installation and Operating

Instructions and adhering to the conditions

concerning set up, instructions for use as well

as maintenance.

Additionally, correct usage also involves

observing any local or national regulations

currently in force concerning health and safety

at work or the disposal of chemicals.

4

9000-608-25/30 2011/04/13

Page 5

1.5 Incorrect usage

Incorrect usage is understood to mean any

usage above or beyond the specific use laid

down. The manufacturer will accept no claims

for any damage or injury arising thereby. All risks

will be borne by the operator and/or owner.

1.6 Product description

The exposed film travels through several zones

or stages within the Dürr X-ray film developer

XR24 NDT: developer / fixer / rinsing and drying

zones.

After switching on the unit the developer and

fixer baths are heated up to the set temperature

of the baths, e.g. 28 °C (at 0.5 °C / min). After

this is complete the unit is ready for use and will

start automatically as soon as a film is inserted

and the film will be transported through the unit.

As soon as the blinking display "MACHINE IN

OPERATION" is extinguished a new film or 2

new films alongside each other can be inserted.

Once the film transport process is complete the

unit switches off automatically and goes into

Stand By mode.

1.7 Connecting peripheral appliances

Appliances may only be connected together or

connected to parts of other units where it has

been absolutely established that such

connections will not endanger the safety of the

operator and the environment will not be

affected in any negative way. If it is not clear

from the appliance documentation that such

connection is possible then the operator /

owner must establish this beyond reasonable

doubt, e.g. by contacting the manufacturer or

another expert, to ensure that the required

safety of the operator and the environment are

not put at risk.

2. Safety

2.1 General notes on safety

This appliance has been designed and

manufactured by Dürr NDT so that correct

usage will result in no danger to operator or

patient. However, we feel it is important to

describe the following safety measures in order

to remove any likelihood of danger.

• When operating this appliance all local and

national rules and regulations must be

observed! This appliance must not be

converted or altered in any way. Dürr NDT

accepts no liability claims where an appliance

has been converted or altered in any way. In

the interests of safe usage of the appliance

both operator and owner are responsible for

seeing that all relevant appliance are

observed.

• Installation must be carried out by a technical

expert.

• The operator must carefully check the

appliance for safety of function and the proper

working condition before every use.

• The operator must be trained in the correct

operation of the appliance.

• This product is not to be operated in an area

at risk through explosion, or an area with a

combustible atmosphere.

2.2 Electrical safety instructions

• The appliance may only be connected to a

correctly installed electrical socket.

• Before connecting to the electricity supply the

appliance must be inspected and checked

that the supply voltage and the supply

frequency correspond to that of the local

electrical supply.

• Before initial use and start-up the appliance

and all supply lines must be checked for any

signs of damage. Damaged supply lines and

connections must be replaced immediately.

• When using the appliance observe all the

relevant electrical safety procedures.

EN

2011/04/13 9000-608-25/30

5

Page 6

3. Warnings and Symbols

In the operating instructions the following

warnings and symbols have been used:

Information including preventative

measures to protect injury to

persons or damage.

Warning for high voltage.

Extra information concerning economic

usage of the appliance and other

EN

instructions.

CE-labeling without Notified Part

Number

Observe Installation and Operating

Instructions

Electrical supply switch ON / OFF

/ select parameters

confirm selection

Switch on supply

4. Delivery Contents

X-ray film developer XR 24 NDT

model 1734-08 (230 V ~, 50-60 Hz)

accessories, complete 1700-001-00

4.1 Special accessories

The following parts are not supplied as part of

the Delivery Contents clean.

Please order as required!

Water hose with Aqua-Stop ......... 1330-001-51

Regenerationunit (230 V) .............. 1734-820-00

Container, 20 liter for developer .... 1416-021-00

Container, 20 liter for fixer ............ 1416-011-00

Fuse 230 V, T 6.3A ....................... 9000-115-25

4.2 Disposable materials

NDT Starter-Set,

2x1.5 l developer, 2x1.5 l fixer .....CXB312A9940

NDT Fixer-Set, 4x1.5 liter ...........CXB313A5740

NDT Developer-Set, 2x6 liter ......CXB310A7540

NDT Fixer-Set, 2x6 liter ..............CXB310A7540

XR CLEANER NDT, 2 x Pack,

spray cleaner for

transport rollers ......................... CCB810C5540

Switch off supply

Mornings - open water tap

Evenings - close water tap

28 x 24 h every 4 weeks change

chemicals

drain chemicals

clean unit

6

9000-608-25/30 2011/04/13

Page 7

5. Technical Data

X-ray film developer XR 24 NDT

Model 1734-08

Voltage (V) 230

Frequency (Hz) 50-60

Current consumption (A) 4.0

Fusing (A) T 6.3

Output(W) 950

Heating

Bath heating (W) 400

Drying (W) 450

Warm-up time (min) ca. 20 (0.5 °C/min)

Film processing time (min) 5:30 - 10:00

Bath circulation process

Developer (l/min) ca. 1.8

Fixer (l/min) ca. 2.0

Water flow rate (l/min) 2

Water pressure (bar)

min. water pressure 2

max. water pressure 6

Tank volumes (l)

Developer, fixer je 5

Temperature ranges

Environmental conditions

for unit in operation +10 to +28 °C

Optimum image quality up to max. +28 °C

Storage and transport -10 to +60 °C

Relative humidity

for unit in operation max. 80 %

Storage and transport max. 95 %

Dimensions D=51 cm, W=42 cm, H=44 cm

Weight (kg) 25

Protection category IP20

Protection class I

Over voltage category II

Conformity certification CE-labeling

EN

2011/04/13 9000-608-25/30

7

Page 8

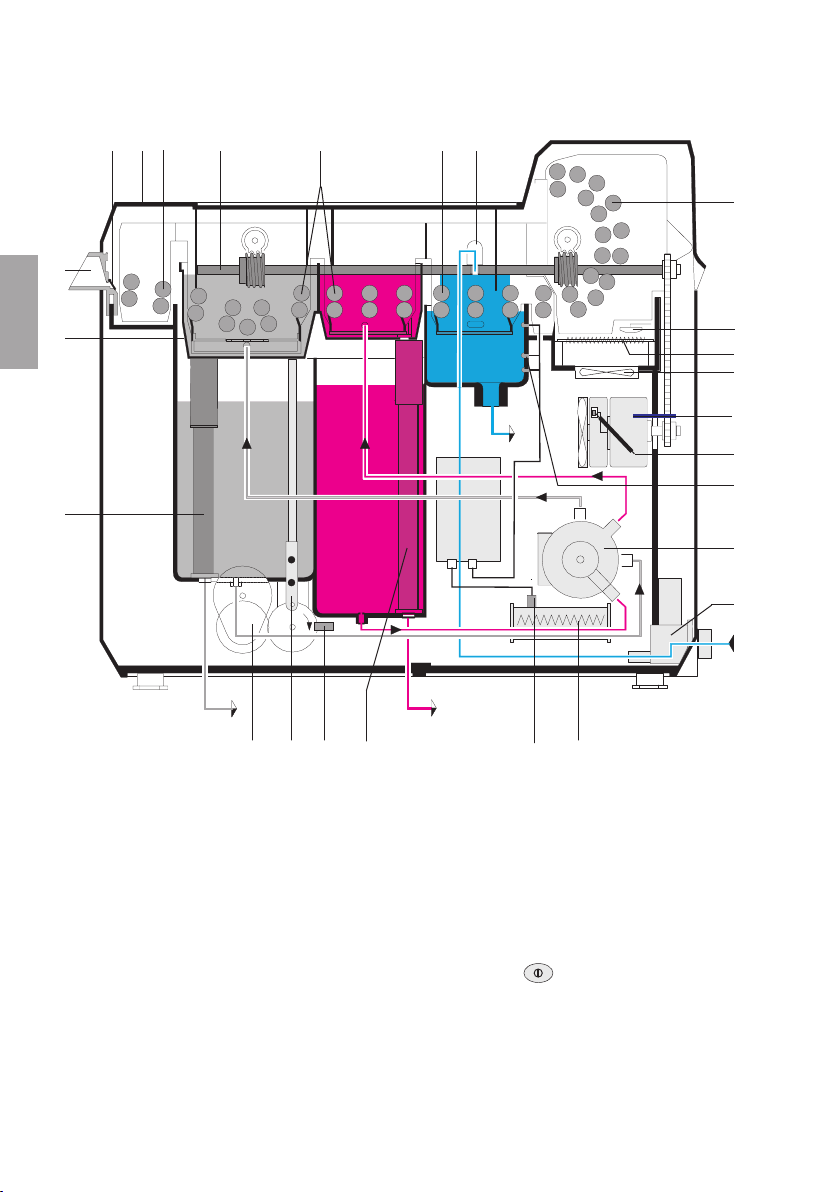

6. XR 24 NDT Functional layout

2 A 3 4 5 6 7

1

Stand By Position

8

EN

22

W

D

21

20 19 19a 18 17 16

1 Film insertion slot

2 Film feed flap

3 Film insertion slot roller set

4 Transport drive

5 Developer/fixer roller set

6 Rinse roller set

7 Water inflow

8 Dryer roller set

9 Safety switch for “dryer”

10 Dryer heater

11 Ventilation fan

12 Drive motor

12a RPM controller

13 Level indicator sensor “water”

14 Rotary pump (for developer and fixer)

15 Water intake valve

16 Process heater

17 PTC-sensing device

8

F

18 Overflow for fixer with drainage plug

19 Lifter

19a Light barrier for lifting bath

20 Lift motor

21 Overflow for developer with drainage plug

22 Lifting bath

D Developer bath

F Fixer bath

W Water bath

A Supply switch on display

9

10

11

12

12a

13

14

15

9000-608-25/30 2011/04/13

Page 9

7. Functional description XR 24 NDT

The display panel will light up once the main

power switch has been pressed

.The warming-up phase for the developer and

fixer baths will now begin. The waiting time until

the correct temperature is reached will be

displayed: "WAITING TIME . . MIN" (display

blinks). The unit will not unit during this warming

up period.

The bath circulation process runs in parallel to

the bath heating. The circulation precess

involves the rotatory pump (14) transporting the

chemicals from the developer and fixer baths

(tank volume of 5 liters each) to the lifting bath

(22).

Once the set temperature has been reached the

display lights "MACHINE FREE", i. e. the unit is

on "Standby"

As soon as the temperature falls by more than

0.5 °C below the set temperature, the process

heater and the rotary pump (14) switch on

again.

Insertion of a film causes the film feed flap (2) to

open and the display blinks: "MACHINE

OPERATING"

At the same time a signal is activated to lower

the lifting bath (22) and the water intake valve

(15) opens; the dryer heater (10), drive motor

(12) and rotatory pump (14) (for developer and

fixer bath circulation) start.

The processing time can be checked using the

RPM controller (12a).

Lifting and lowering of the lifting bath is

controlled by the rotation of the disc (driven via

the lift motor (20)) and is monitored by the

infrared light barrier (19a).

(mind.2 s)

If the waste water drainage becomes blocked, a

level indicator sensor (13) activates an audible

signal and the water intake valve (15) closes and

the flow of water is interrupted.

After complete insertion of a film the film feed

flap (2) closes. As soon as the blinking display

"MACHINE IN OPERATION" is extinguished a

new film or 6 intraoral films alongside each other

can be inserted.

If no further films are inserted after the film

process cycle (audible signal) then the lifting

bath (22) rises (Stand By Position) "MACHINE

FREE".

The drive motor (12), water intake valve (15) and

dryer heater (10) are switched off. In the Stand

By Position the developer and fixer roller sets (5)

are completely submerged in the chemicals.

This means that the build up of deposits on the

rollers can largely be avoided.

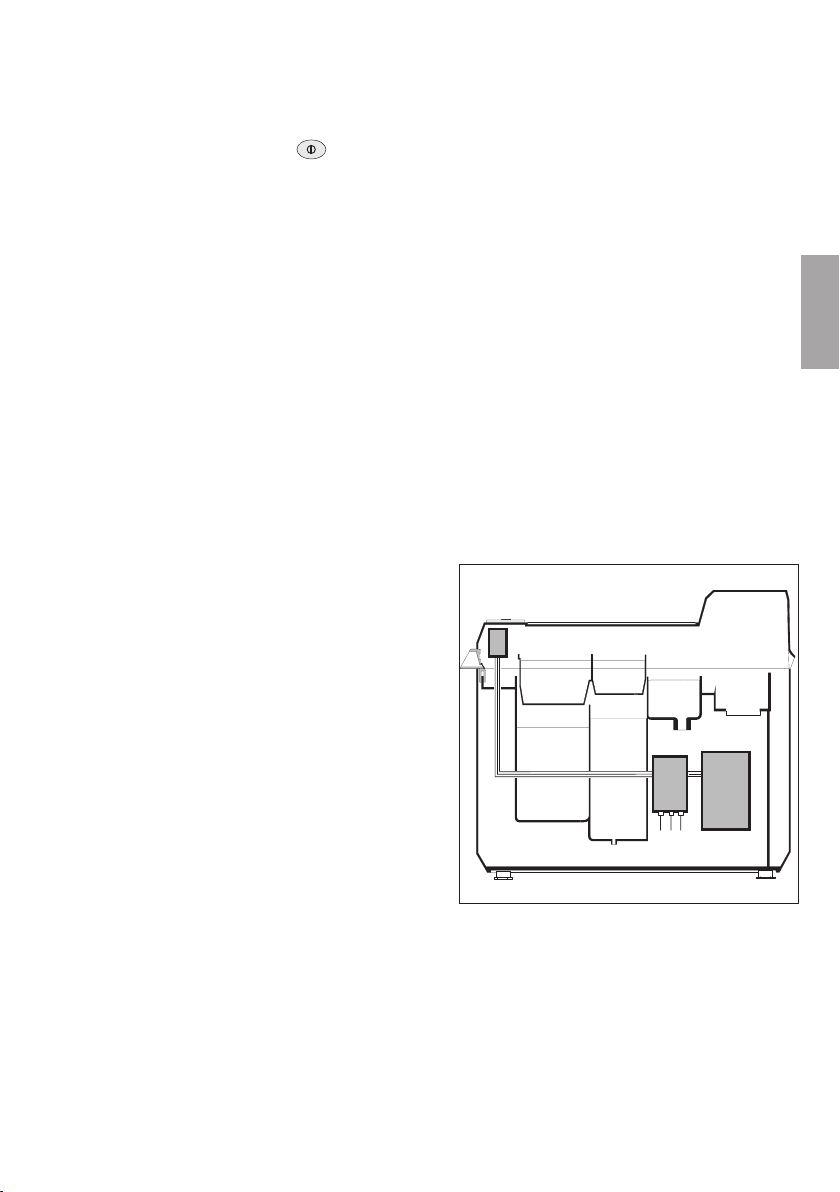

7.1 Arrangement of PCB (main board)

23 A Operating section

23 B Control functions

23 C Performance functions

23 A

23 B 23 C

EN

When the lifting bath (22) is lowered the film

passes between the rollers through the

developer and fixer baths, then through the

rinsing and the drying zones (8) at the set

processing time.

During film development water is fed along the

water inflow (7) into the rinse zone. The water

flows out to the waste water system. There is a

continuous flow of water at a rate of ca. 2 l/min,

at a pressure of 2 bar.

2011/04/13 9000-608-25/30

9

Page 10

EN

Mounting

8. Set-up

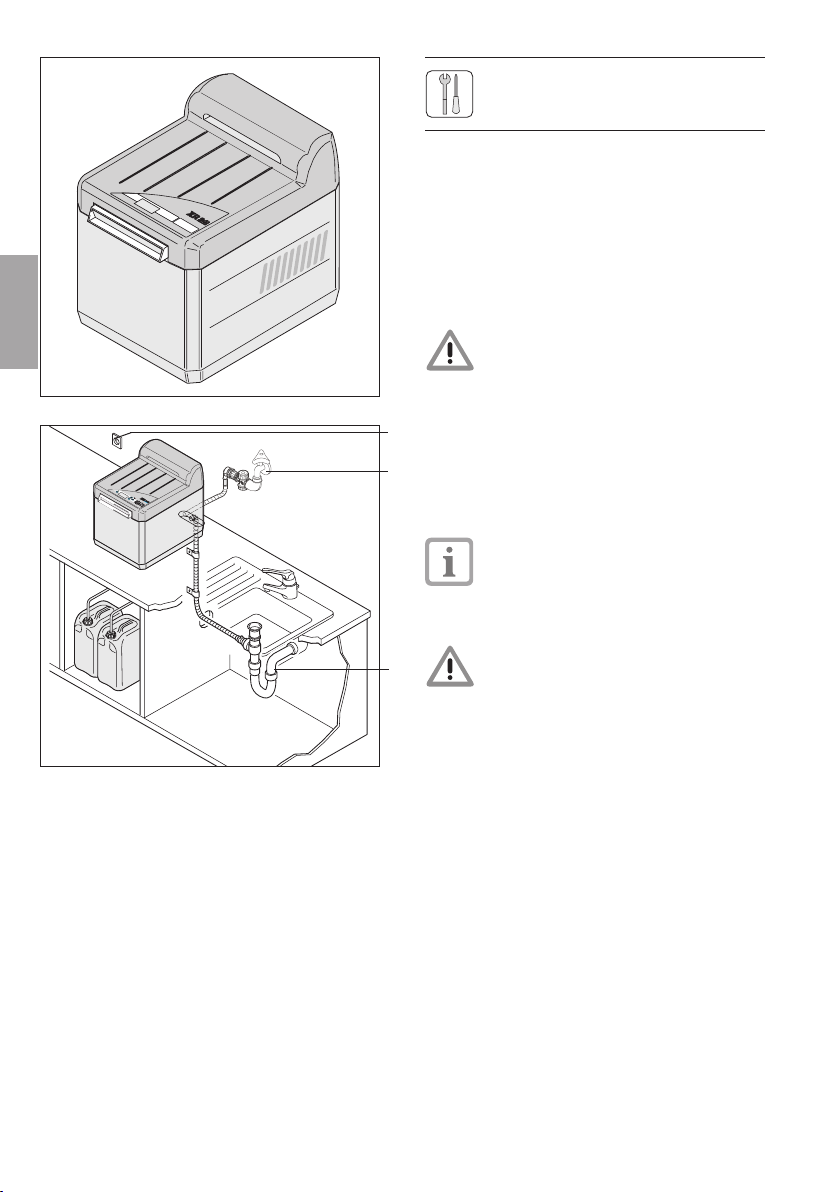

8.1 Room for set-up

• The developer unit XR24NDT may only be

set up in a dry, well-ventilated room.

• The room temperature in winter must not fall

below +10 °C or exceed +28 °C in the

summer

Do not set up the appliance in

direct sunlight! Danger of chemicals

1

26

27

28

2

overheating or premature exposure

of the film.

• The room for set up must be fitted with a

water tap (27) R3/4" with pipe ventilation,

waste water drainage (28) with ventilated

plastic siphon and an electrical safety socket

(26). It is also useful to have a wash basin or

sink near the developer unit.

Both the water tap (27) and the

electrical safety socket (26) should be

easily accessible for personnel.

• We strongly recommend set up of the

XR24NDT in a darkroom.

Interference

Portable radio transmitter/receiver

appliances (of rated power 2 W or

above) must not be operated within

a distance of 2 m of the XR 24 NDT

developer unit.

10

9000-608-25/30 2011/04/13

Page 11

D

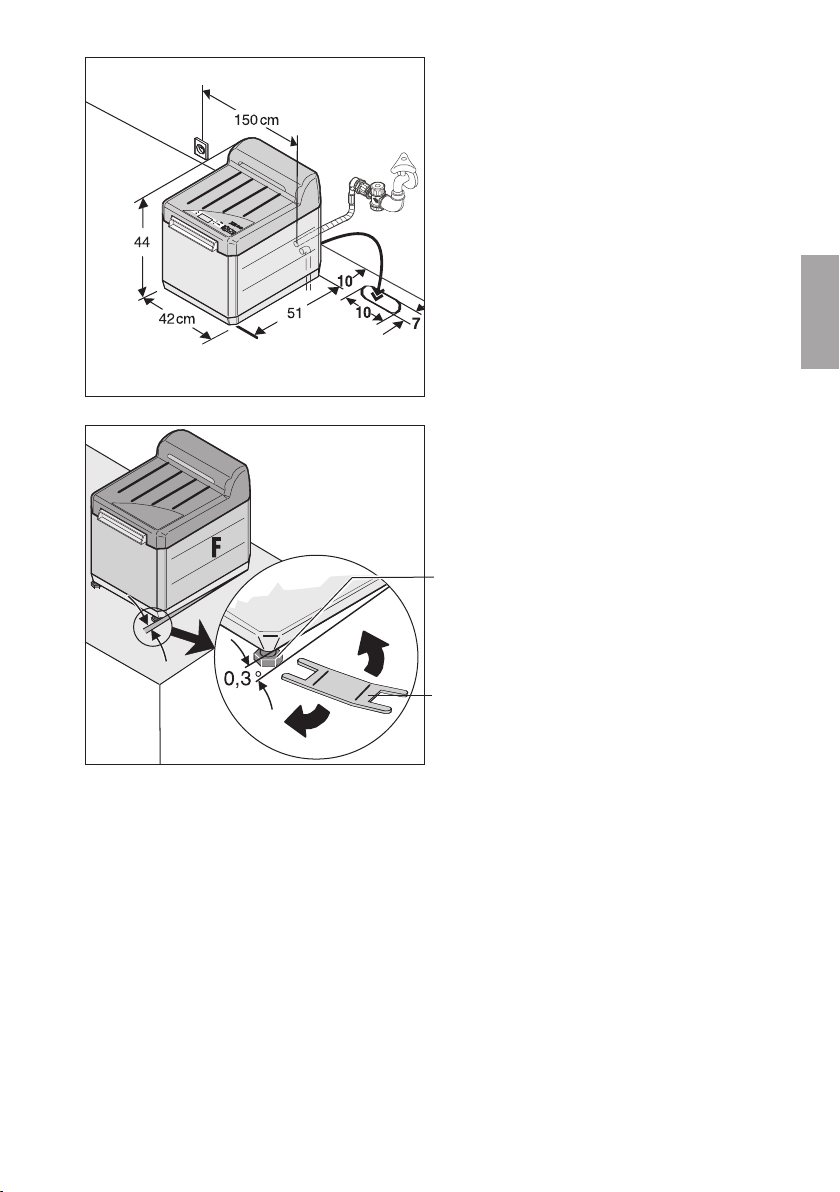

8.2 Set up options

• Set up the developer unit on a horizontal,

stable and smooth, flat working surface at a

suitable working height.

• When feeding hoses downwards, the

working surface needs to have an opening

of ca. 7 x 10cm.

• Take into consideration the room required for

maintenace procedures and for adequate

ventilation of the unit:

at least 10 cm to the rear, ca. 50 cm free

space to left and right.

EN

4

8.3 Set up

• Set the box upright and cut loose the plastic

packing ties.

• Remove all small parts.

• Grasp the unit from the sides and set up as

appropriate.

• Set up the unit near the water supply, waste

29

water drainage and electrical safety socket

(max.1.5 m distant).

• Set up the unit with a very slight tilt, ca.

0.3°, towards the fixer bath (fig. 5).

Adjust the unit legs (29) using the spanner

(30) provided as necessary.

30

5

2011/04/13 9000-608-25/30

11

Page 12

EN

9. Installation

27

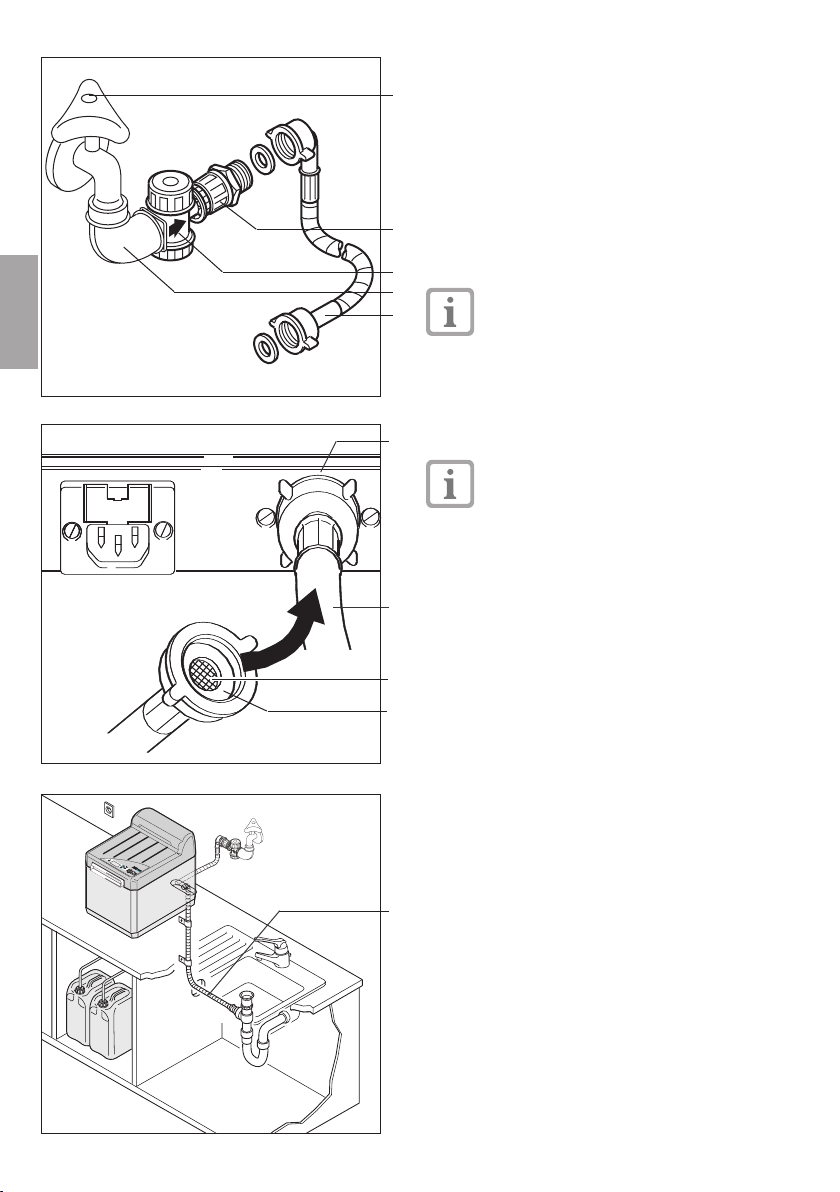

9.1 Connecting water supply

• Check firstly that clear, clean water is issueing

from the water tap (27)

When installing for the first time, let the water

flow thoroughly first!

• Because of the great differences in the

31

regional quality of water, a fine filter (32) must

first be installed between the water tap (27)

32

and water hose (34).

33

34

7

35

34

The fine filter (32) protects the flow

regulator of the water intake valve of the

appliance from impurities

• Close the water tap (27)

• Connect an elbow piece, 90° (33), to the

water tap (27), then fine filter (32) (arrow in

direction of flow) and insert double nipple

piece (31)

Check whether the coarse filter (34a)

and both seals (34b) are present in the

threaded connection piece of the water

hose (34).

• Connect the water hose (34) to the water

inflow connection (35) of the appliance

(threaded connection including coarse filter) and

fix to the double nipple piece (31).

12

34a

34b

8

9.2 Waste water connection

• Waste water connections must include a

siphon trap.

• Lay the waste water hose (36) with a

continuous incline to the siphon trap:

cut the hose to the correct length

36

9

9000-608-25/30 2011/04/13

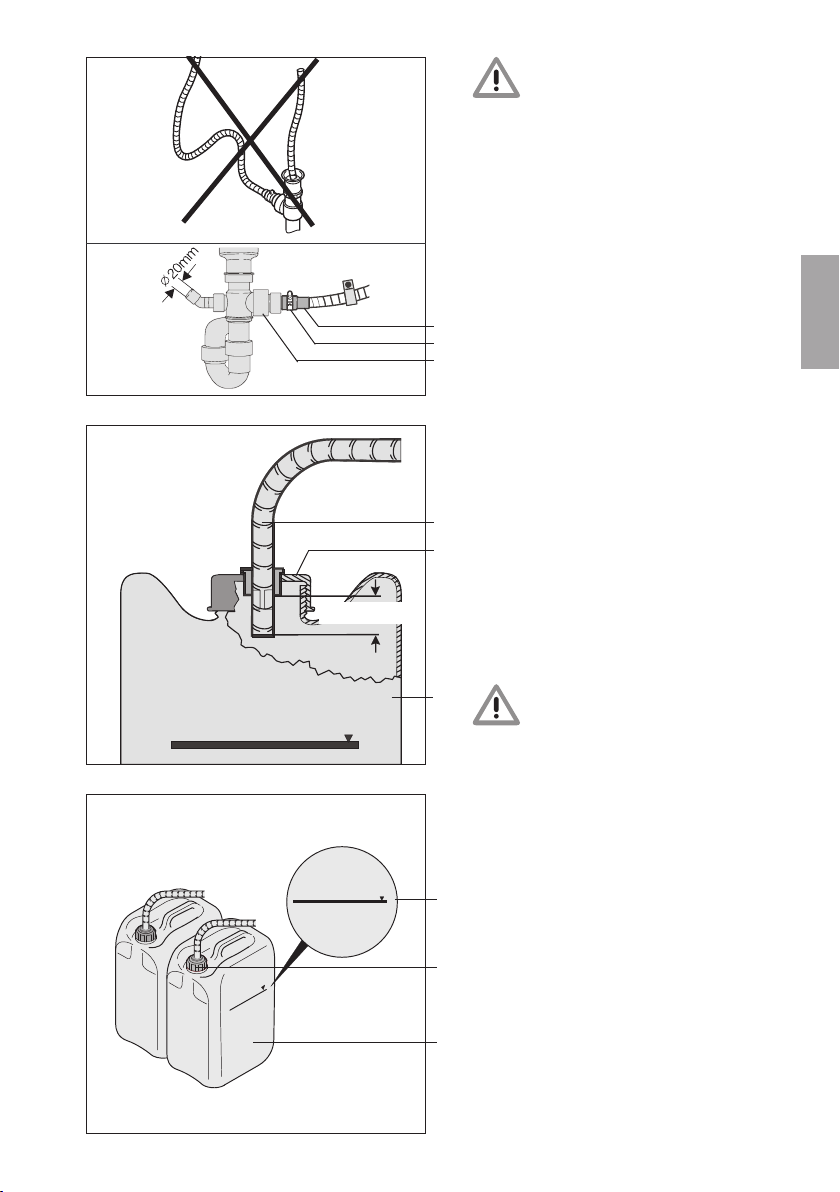

Page 13

10

11

max. 3 cm

When laying the waste water

conections please be sure to

check the following:

- Avoid hoses from sagging!

- Avoid constriction or reduction

of hoses!

• Coat the ends of the hoses on the outside

with UHU-Plast

• Fix the screw socket (37) onto the hose and

onto the siphon trap (25) using hose clamp

(38)

• Secure the waste water hose with hose

clamp, screw and dowel.

37

38

9.3 Connection of developer and

25

fixer waste hoses

• Set the 10l-collecters (39) for developer

(black level indicator marker) and fixer (red

level indicator marker) under the appliance

so that they are clearly visible but free from

any possible spillage or knocking

• Lay the hoses (40) with continuous fall

40

• Cut the hoses to the correct length.

41

• Lead the hose for developer (black

markings) through the black lid (41).

• Securely screw the lid (41) onto the collecter

(39) for developer

• Secure the hose for fixer (red markings) in

the same way to the collecter for fixer

39

Empty the collecters when they

reach the level indicator marker

(43) - danger of overflow!

When disposing of developer and

fixer observe regional rules and

regulations!

In Germany, and in several other

countries, x-ray chemicals must

be disposed of as special waste.

EN

12

2011/04/13 9000-608-25/30

Fixer

43

41

39

13

Page 14

EN

11

13

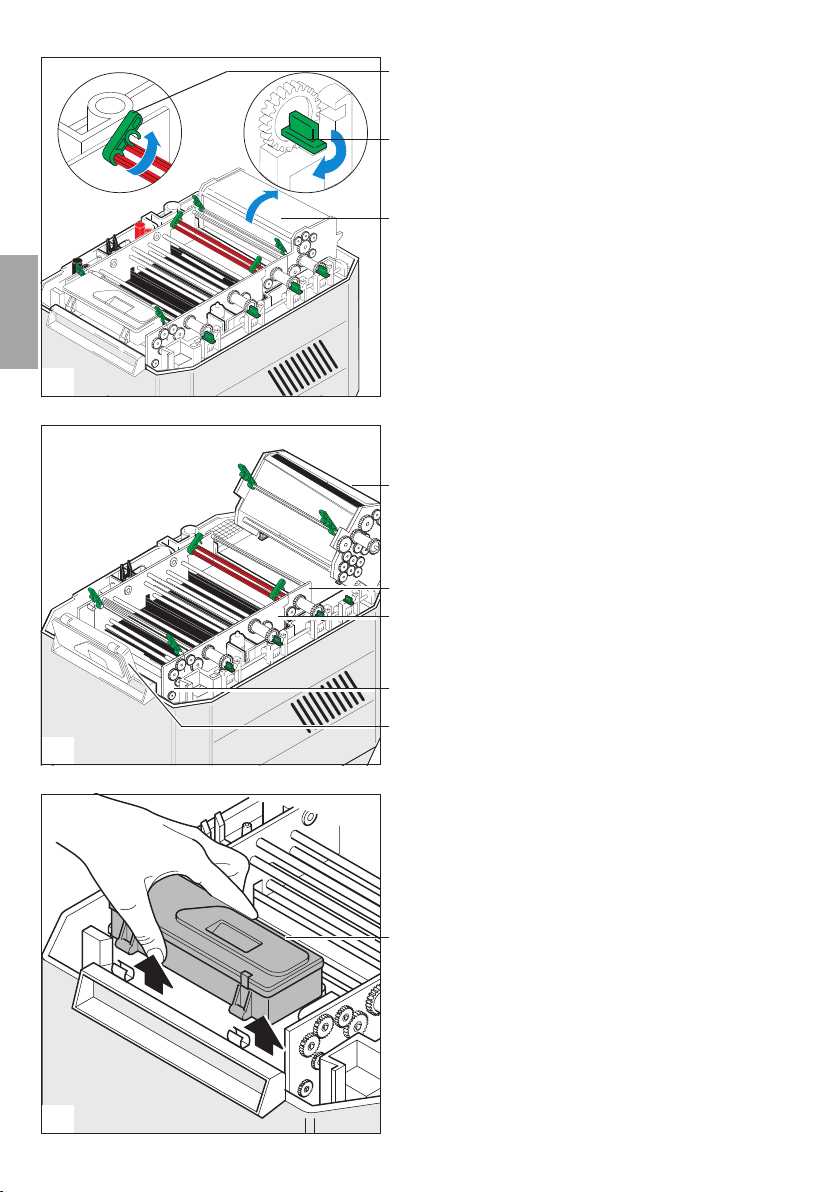

10. Commissioning and

44

first set up

10.1 Cleaning the unit

45

• Remove the lid.

• Remove the floating covers from the

developer and fixer baths

8

• Open the green catches (44) and stop clips

(45)

• Swivel the dryer packet (8) towards the rear.

• Remove the roller sets for water (6) and

developer/fixer (5).

8

• Swivel the display (90) upwards.

6

5

14

15

14

3

90

• The display can also be lifted upwards and

then to moved the left.

• Remove the roller set to the film insertion slot

(3).

90

9000-608-25/30 2011/04/13

Page 15

16

17

• On the side press the lever and remove the

lifting bath (22)

• Clean the roller sets, lifting bath and tanks

22

with a wet sponge.

"set up of chemicals"

and

"set up of roller sets"

see section USAGE

11. Electrical connections

This appliance is designed for

a supply voltage of 230 V (see

model identification plate). Before

connecting the mains power cable it

is absolutely vital to check that the

required supply voltage is available,

otherwise the connection could be

damaged. Use the Dürr mains cable

supplied.

The unit may only be operated when

it is closed - with sides and cover

in position - and connected to the

61

mains supply.

• Plug in the unit at the socket (61) in the unit

and the mains supply socket.

EN

2011/04/13 9000-608-25/30

15

Page 16

12. Circuit diagram

12.1 Operating section PCB

12.2 Controller section PCB

(see also section 23 C under section 7)

EN

23 B

16

23 A

12.1 12.2

R1 Temperature Sensor "Bath Temperature"

X5 "Water" level indicator sensor

U1 Cover light barrier

U2 Cover light barrier

U3 Lifting bath light barrier

1734-215-50

1700-221-00

M1 RPM regulater

U4 Film insertion slot-flap light barrier

9000-608-25/30 2011/04/13

Page 17

12.3 Performance functions PCB 230 V

(see also section 23 C under section 7)

23 C

EN

M1 Roller drive

M2 Ventilation fan

M3 Rotary pump

M4 Motor to lifting bath

R1 Bath heating

12.3

1734-216-50

2011/04/13 9000-608-25/30

R2 Dryer heater

Y1 Water intake valve

X1/X2 Appliance sockets

X3 Regeneration unit

17

Page 18

13. Commissioning and first set up

The developer unit XR 24 NDT has

3processing time alternatives, and is factory

set as follows:

10:00 min - Program REG. GRAIN

8:00 min - Program MTID. GRAIN

5:30 min - Program FINE GRAIN

Please note: X-ray films are not suitable for

archiving at this processing time.

When using film types which require a different

processing time, set the values according to

EN

the type of film being used.

- developer / fixer bath temperature 28°C

- dryer performance 30%

Films should emerge dry from the unit. The

dryer performance should be set according to

film type.

Program overview, see section Usage

The unit may only be operated when

it is closed - with sides and cover

in position - and connected to the

mains supply.

Every time the unit is switched on at the

main power switch the program "REG.

GRAIN" is automatically started, i.e.

after switching off there is an automatic

default selection of "REG. GRAIN"

Instructions concerning the operation

and display for the operator can be

found in section "USAGE", section 15.

A complete plan for service operation

can be found under Maintenance,

section 19.6.

Before developing the first film

the lifting tank of the developer

and fixer baths must be filled to

the overflow level, otherwise the

film development quality may be

impaired.

Always use cold water when making

up the chemicals.

The developer unit must never be

operated without its roller sets!

Without the roller sets it is possible that

the developer and fixer fluids will be

placed under pressure and will splash

vertically upwards out of the developer

unit.

Chemicals attack eyes and skin and

there is the possibility of severe

injury to the eyes.

Without the developer and fixer roller

sets there can be no circulation of

chemicals in the baths.

There is the danger of mixing of

chemicals.

Never operate the developer unit

without fluids (chemicals, water),

as this can lead to the heating

controller breaking down.

18

9000-608-25/30 2011/04/13

Page 19

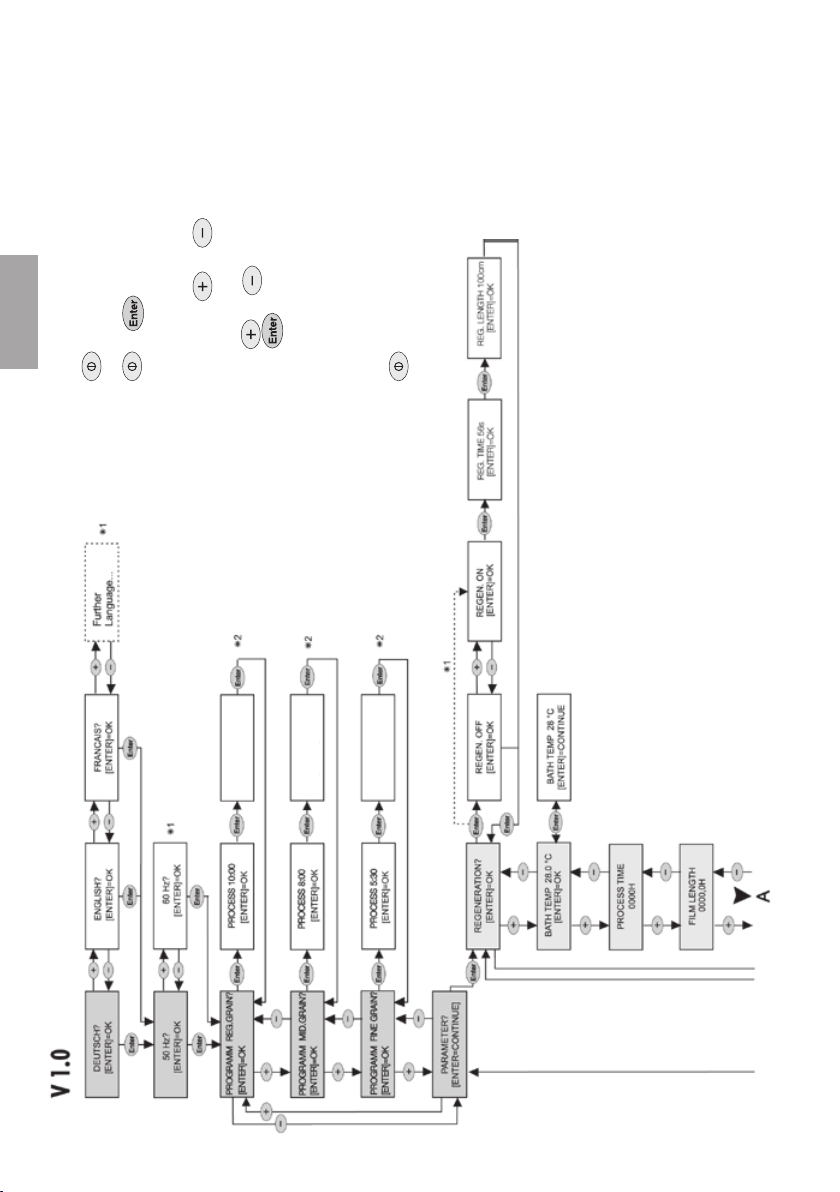

13.1 Settings / Service operation for the Service Technician

• Open the water tap.

• Check the unit and all connections for signs of

leakages

• Start the service operation

+ at the same time pressing (min. 4 s)

unit in service mode

• Select the service function

use button

to select service function

• Change settings

alter parameter values with

or

use 1 s to confirm new values

• *1 First to appear when switching on are set

language, frequency or value

*2 Factory settings

V 1.0

• End service function

Switch off unit using

power switch (press min. 2 s)

• Parameters such as language, electrical

frequency, etc. on the display can be set

according to the program plan :

EN

2011/04/13 9000-608-25/30

Change values using and in

5 and 5% steps, confirm with

DRYER 30%

[ENTER]=OK

DRYER 30%

[ENTER]=OK

DRYER 30%

[ENTER]=OK

19

Page 20

EN

21

13.2 Check temperature of the developer

The following procedure is applicable for

Germany. In other countries different

regulations may apply!

• Switch on the unit and wait for the

developer bath to raech operating

temperature, see also "Section 15.1 morning

or before surgery opening"

• In order to check the temperature of the

developer, switch off the unit.

• Unplug at the mains and remove all power.

• Close the water tap .

• Remove the lid.

• Measure the temperature of the developer

(front left at a depth of ca. 20 cm).

The temperature of the developer must be

+28 °C +/- 0,5 °C.

• Replace lid, plug in at the mains, open water

tap,

switch on unit so .

20

9000-608-25/30 2011/04/13

Page 21

22

14. Transport

Before transporting the developer unit please

note the following points:

27

31

39

63

The developer unit must only be

transported with completely empty

baths.

• Press the power switch to turn the unit off.

• Close the water tap (27)

• Unplug at the mains and remove all power.

• Unscrew the water hose (31) from the unit and

water tap (27).

• Empty the chemicals from the collecters (39)

into appropriate canisters (63).

• Drain the chemicals from the baths into

collecters (39), see section 16.1.1

• Clean the unit, see section 10.1

EN

23

24

2011/04/13 9000-608-25/30

14.1 Remove the drainage hoses

• Remove waste water hose (35).

• Loosen the hose from collecter (39) for

developer and fixer. Ensure that no drops of

chemicals spill or are splashed.

35

14.2 Protection from damage

• Protect the developer unit from any physical

load bearing and damage

• Ensure that the unit cannot move freely during

transport.

• Inform transport personnel.

39

21

Page 22

Power - switch

Confirm - key

, "Search menu

EN

Use

Program overview

The programs FINE GRAIN, MID. GRAIN and

REG. GRAIN are factory set (see below); your

Service Technician can set them, however, to

your individual requirements.

REG. GRAIN - Process time: t=10min

- bath-temperature: T=28 °C

- dryer performance: 30%

REG. GRAIN - Process time: t=8min

- bath-temperature: T=28 °C

- dryer performance: 30%

REG. GRAIN - Process time: t=5min

- bath-temperature: T=28 °C

- dryer performance: 30%

Films should emerge dry from the unit. The

dryer performance should be set according

to film type.

Every time the unit is switched on at the

main power switch the program "MID.

GRAIN", is automatically started, i.e. after

switching off there is an automatic

default selection of "MID. GRAIN"

Service / Fault message

see section 17.1 Fault message on display with

audible signal

SERVICE INTERVAL

REACHED!

Only when activated

by the Service

Technician!

22

BEFORE OPENING

DISCONNECT FROM

MAINS

FAULT WATER TOO

LOW!

FAULT WATER TOO

HIGH!

FAULT

ROLLER DRIVE

15. Operation

Before operation please note the following

points:

The developer unit must never be

operated without its roller sets!

Without the roller sets it is possible that

the developer and fixer fluids will be

placed under pressure and will splash

vertically upwards out of the developer

unit.

Chemicals attack eyes and skin and

there is the possibility of severe

injury to the eyes.

Without the developer and fixer roller

sets there can be no circulation of

chemicals in the baths.

There is the danger of mixing of

chemicals.

Never operate the developer unit

without fluids (chemicals, water),

as this can lead to the heating

controller breaking down. Regulate

the heating.

The unit should be switched on every

day in order to maintain constant image

quality.

Ensure that the ambient temperature of the

environment does not exceed that of the

developer bath!

Standby-Modus

Once the film exits the unit the Standby-Mode is

activated.

In Standby-Mode the unit is still operational and

simply awaits the next insertion of a film.

Before inserting a film check the program

selection!

9000-608-25/30 2011/04/13

Page 23

15.1 Mornings or before surgery begin

• Open the water tap.

• Switch on the unit:

•

Press the power on switch ca. 2 s

until an audible signal is heard

>> DURR NDT<<

T XR 24 NDT V.. T

WARM-UP PHASE

WAITING TIME .. MIN

<MID. GRAIN> 8:00

MACHINE FREE

t

<MID. GRAIN> 8:00

MACHINE BUSY

1 LED on display lights up. Lifting bath

automatically begins to move into the correct

position, ca. 30 s.

2 The unit initiates the warming-up phase until

the correct temperature of the developer bath is

reached. Warm-up time: 0.5 °C/min. During this

warm-up time a message blinks on the display

"WAITING TIME .. MIN"

3 As soon as the set temperature has been

reached the display panel lights up The unit

is ready for operation. A film can be

inserted.

The program MID. GRAIN is automatically

selected, where a different program is desired

then use key to change program to REG.

GRAIN or FINE GRAIN.

4 Before commencing developing every day run

two cleaning films through the unit.

5 Once a film has been insered the display

blinks: "MACHINE in OPERATION", as soon

as this message stops blinking then the next

film(s) can be inserted.

Two films can be inserted alongside

each other but within the markings, see

fig. 25.

EN

<MID. GRAIN> 8:00

REMAINING TIME ..MIN

<MID. GRAIN> 8:00

MACHINE BUSY

<MID. GRAIN> 8:00

t

MACHINE FREE

Changing the program:

see next page

2011/04/13 9000-608-25/30

t

6 The remaining developing time for the film(s) in

the unit is displayed (automatic countdown). An

audible signal is heard when the films exit.

7 If no further film is inserted the lifting bath

moves to the "Stand by"-Position

8 Unit in "Stand by"-Position message:

"MACHINE FREE" appears on display

Film material which has not been

exposed must not be placed on the

unit as the LCD-Display may lead to

incorrect exposure.

23

Page 24

Changing the program:

EN

DRYER 30%

[ENTER]=OK

DRYER 30%

[ENTER]=OK

DRYER 30%

[ENTER]=OK

If there is a fault message see

section 17.1 "Fault message on

display"

25

26

24

• 2 Films can be inserted together side by side.

Ensure that the marking goes into the

developer unit last.

• To obtain a fast control image change to

program "FINE GRAIN" (short process time:

5:30min).

15.2 In the evening or after surgery

hours

• Turn off the unit at the main power

switch.

•

Close the water tap.

15.3 Operation interruption

of more than 1 week:

• Drain off the chemicals.

• Clean baths and roller sets and leave to dry.

See 16.1.1

15.4 Film recommendations

Temperature of the bath(s): 28 °C

Dryer performance: 30 %

Manufacturer

Agfa Structurix D2, D3 Film 8

Agfa Structurix D3SC Film 8

Agfa Structurix D4-D8 Film 8

Kodak INDUSTREX AA400 Film 10

6

Kodak INDUSTREX DR50 Film 10

Kodak INDUSTREX High Speed

Kodak INDUSTREX M100 Film 10

Kodak INDUSTREX MX125 Film 10

3

Kodak INDUSTREX T200 Film 10

Fujifilm FUJI IX-25, FUJI IX-50 8

Fujifilm FUJI IX-80, FUJI IX-100 8

Fujifilm FUJI IX-150 8

Film type

HS800 Film

9000-608-25/30 2011/04/13

Processing

time

10

Page 25

27

28

16. Maintenance

60

Every 2 months

Change the chemicals,

Clean baths and roller sets,

make up chemicals

61

see section 16.1

• Check darkroom for stray lighting!

16.1 Change the chemicals

16.1.1 Drain the chemicals

91

• Press the power switch to turn the unit off.

• Remove the mains plug (61) from the electrical

safety socket.

• Remove cover (60).

• Check whether the collecter (39)

is empty, if necessary pour into the collection

canister (63)

It is extremely important that the

39

63

collecter is empty, otherwise there is the

dager of overflow, when the chemicals

are drained from the baths.

• Remove the floating covers from developer

and fixer baths, leave to dry and place to one

side.

• First remove the small plug from the lifting

bath, then the large plugs from the baths.

• Empty the collecter.

• Unscrew the lid of the collecter, hang the hose

ends in a neutral container.

This will prevent water from entering

either the collector or the canister

during cleaning.

EN

2011/04/13 9000-608-25/30

25

Page 26

EN

11

29

44

45

8

6

Cleaning and making up of chemicals

for the developer unit are based on the

use of DürrXR24NDT chemicals.

When using chemicals from third party

suppliers be sure to observe the

manufacturer's instructions!

16.1.2 Clean baths and roller sets,

• Open the green catches (44) and stop clips

(45)

• Swivel the dryer packet (8) towards the rear.

• Swivel the display upwards

• Remove the rinse and (6) film insert roller sets

(3)

26

3

30

• Lift the developer and fixer roller sets (5), tilt to

the side and let the chemicals run off

5

31

9000-608-25/30 2011/04/13

Page 27

32

33

Ù

Ù

• Place the roller sets in the sink, spray using

"spray cleaner and allow ca. 10 min to take

effect.

22

• On the side press the lever and remove the

lifting bath (22)

• Rinse the lifting bath (22) thoroughly under

warm, running water (min. 40 °C).

• Rinse the roller sets thoroughly under warm,

running water .

• Screw the large plugs (18, 21) into the baths.

• First fill the fixer bath with water, fig. 33.

• Then fill the developer bath with water.

• Place developer and fixer roller sets in

position.

Do not operate the developer unit

without developer/fixer roller sets.

Without developer/fixer roller sets

water will splash upwards out of the

unit as there will be no circulation

of the water in the baths. Danger of

eye injury!

• Close the green catches and clips.

• Swivel the display back into position.

• Replace cover (60).

• Plug in at mains (61), press power switch on.

• Start up unit, place cleaning film in film

insertion slot (1) until the film feed flap is

actuated, leave the film ca. 4 min in this

position.

• Let the unit run ca. 8 min (the hoses and

rotatory pump will be automatically cleaned).

• After ca. 8 min switch off the unit and

disconnect at the mains (61).

• Remove cover (60).

• Swivel the display upwards

• Open the green catches and clips.

60

• Lift the developer and fixer roller sets, drain

and remove.

• Unscrew the large plugs for developer (21)

and fixer (18) from their baths and drain the

water.

EN

34

2011/04/13 9000-608-25/30

1

27

Page 28

EN

35

36

28

37

16.1.3 Make up chemicals

• Screw the plugs for fixer (18) and developer

18

(21) into their baths.

• Replace the developer and fixer hoses back in

their collector.

21

• Put in place the separating barrier (52) between

developer and fixer baths.

Chemicals are dangerous to health

or aggressive. Irritate skin and eyes.

Danger of severe eye injury.

Damage irreversible.

52

When filling chemicals always wear

protective gloves and protective

glasses.

If there is any contact with the eyes,

immediately rinse thoroughly with

water and consult a doctor as soon

as possible.

Clean your hands thoroughly under

running water after finishing.

Please also refer to our special safety

brochure which you can find on the internet

at: http://www.duerr-ndt.de

or order it direct from Dürr NDT.

Usage of chemicals from third party

suppliers

When using chemicals from third party

suppliers please refer to the

manufacturer's instructions when making

up the chemicals.

All developer units which have already been

operated using chemicals from third party

suppliers can be converted to DürrXR24NDT

chemicals at any time.

Please note that the baths should be cleaned

thoroughly before changing chemical source

(refer to the manufacturer's instructions)

Usage of DürrXR24NDT chemicals

Dürr NDT developer and fixer chemicals

are based largely on natural ingredients.

Components such as Hydroquinol or

aldehyde are avoided as far as possible.

This reduces the accumulation of dirt in the unit

and thereby also reduces cleaning.

Concentrations

1.5l concentrated liquid mixed with water provide

5 l usable solution

6l concentrated liquid mixed with water provide

20 l usable solution

1.5 liters concentrated chemical in the baths

of the developer unit

1. Filling fixer bath (F) (fig. 36)

Pour the 1.5 liter bottle (fixer concentrated liquid)

carefully (avoid splashes which can lead to mixing

of chemicals) into bath and then fill to top

marking (54) with cold water.

9000-608-25/30 2011/04/13

Page 29

38

39

2. Filling developer bath (D) (fig. 37)

Pour the 1.5 liter bottle (developer concentrated

liquid) carefully (avoid splashes) into bath and

D

D

F

F

55

then fill to top marking (54) with cold water.

6 liters chemical concentrate in 20liter

container

Two clean and empty 20 liter canisters (55) are

required: for fixer and developer.

• Empty6 liter bottle of fixer (F) into canister and

fill with cold water to the 20 liter level.

• Empty 6 liter bottle of developer concentrated

liquid (D) into canister and fill with

to the 20 liter level.

• Place a cover securely on each container and

mix the contents.

1. Filling fixer bath (F) (fig. 40)

• Using a suitable container with a spout

opening (56) carefully pour some of the fixer

mixture into the fixer bath of the unit as far as

the upper marking (54) (avoid splashes which

might cause mixing of chemicals).

2. Filling developer bath (D) (fig. 41)

• Using the container (56) carefully pour some

of the developer mixture into the developer

bath of the unit as far as the upper marking

(54) (avoid splashes which might cause mixing

of chemicals).

• The remaining chemical mixtures should be

stored in the 20 liter containers in a dark place

56

until needed.

• Rinse the empty containers as well as the

filling vessel thoroughly with water and keep

for further use.

cold water

EN

40

2011/04/13 9000-608-25/30

41

29

Page 30

EN

42

• Remove separating wall or barrier.

• Place lifting bath (22) in position.

• screw in the small plug of the lifting bath.

60

16.1.4 Insert roller sets

The developer unit must never be

operated without its roller sets!

Without the roller sets it is possible that

the developer and fixer fluids will be

59

6

5

58

3

22

44

8

45

placed under pressure and will splash

vertically upwards out of the developer

unit.

Chemicals attack eyes and skin and

there is the possibility of severe

injury to the eyes.

Without the developer and fixer roller

sets there can be no circulation of

chemicals in the baths.

Danger of chemicals get into the

eyes and danger of mixing of

chemicals.

• Insert dryer packet (8) and swivel towards the

rear.

• Place roller sets for rinse (6), developer/fixer

(5) and film insertion slot (3) in place

respectively

Check that the guides slot into each other. If

necessary, rotate the toothed wheel of the

drive (58) until the worm screw correctly

engages with the transport drive

• Swivel the dryer packet (8) forwards.

• Close the green catches (44) and

stop clips (45)

• Place floating covers (59) for developer and

fixer baths in position

• Swing display back, i.e. in position.

• Replace cover (60). Be careful to ensure that

the lower lip of the lid aligns completely with

the guide of the housing cover

• Plug in at the mains.

30

9000-608-25/30 2011/04/13

Page 31

EN

2011/04/13 9000-608-25/30

31

Page 32

Trouble-shooting

17. Tips for operators

If it is not possible to solve the problems listed here with the aid of these Troubleshooting Tips,

then please call your Service Technician who will be glad to help.

Problem

EN

1. Completely not

operational

2. Film too bright

3. Film too dark • Set exposure times (where possible)

4. Yellowish-green

smear to film

Probable cause

• mains cable not correctly

plugged

• Cover not in position

• Power switched not pressed

long enough

• Developer used up

• Film exposure time on imaging

system too short

• Developer bath temperature

too low

• Film exposure time on imaging

system too long

• Developer bath temperature

too high

• Film not fixed correctly • Check whether fixer is still all right for

• Film developed using

program FINE GRAIN (with

process time 5:30)

Solution

• Plug mains cable in at electrical safety

socket and connector into rear side of

unit

• Place cover on correctly

• Press power switch min. 2 s

• Change chemicals (see section 16.1)

• Check regeneration levels.

• Set exposure times (where possible)

• Ask Service Technician to check and

reset if necessary.

• Ask Service Technician to check and

reset if necessary.

use: allow D4 films to lie ca. 56 s in fixer.

If the film becomes transparent then the

fixer is usable. If the smearing persists,

change the chemicals (see sec. 16.1ff)

• Choose a program with a longer

process time. Observe film processing

times

5. Dark smear or

streaks to film

6. Greenishbrown smear to

film

7. Film is streaky

32

• Light exposure into the

darkroom, e.g. through keyhole

• Darkroom lighting incorrectly

installed or pointing in wrong

direction

• Chemicals used up • Mix up new batch of chemicals

• Mixing of chemicals • Mix up new batch of developer

• Check the darkroom for stray ambient

light, if necessary black out light sources

• Lamps should only shine indirectly

chemicals

9000-608-25/30 2011/04/13

Page 33

Problem

Probable cause

Solution

8. General

background

fog to film

• Film stored too long

• Film incorrectly stored

• Developer bath-temperature

too high due to excessive room

temperature

• Check shelf life of film

• Observe correct storage conditions,

shelf life and manufacturer's instructions

on film packaging.

• Reduce the room temperature

17.1 Fault message on display with audible signal

Display

BEFORE OPENING

DISCONNECT FROM

MAINS

SERVICE INTERVAL

REACHED!

FAULT WATER TOO

LOW!

FAULT WATER TOO

HIGH!

FAULT

ROLLER DRIVE

further message to

come...

Either at beginning of or

during developer

process

After switching on the

unit

After insertion of a film

with delay of ca. 35 s

Either at beginning of

or during developer

process

Either at beginning of

or during developer

process

Cause

Safety relay on PCB

(main board) defect

Service interval

reached.

Water inflow to

water bath

interrupted

- Waste water

drainage blocked,

badly laid or not

ventilated

- Electrical bridging

caused by

accumulation of lime

scale on level sensor.

RPM-Signal from

motor interrupted,

possibly cable or

connector defect

Stray ambient light can lead to

pre-exposure of film material.

If necessary a separating wall or

barrier of lead protection can be

put up.

EN

Solution

Arrange maintenance by our

service technician.

Work can continue.

Before opening unplug at the

mains and remove all power!

Arrange maintenance by our

service technician.

Work can continue.

Check whether the water tap

is open and/or inflow hose is

connected

Remove blockage or check

whether the waste water

drainage-hose has been laid

correctly (water pocket).

Work can only be continued

after removal of problem

Arrange maintenance by our

service technician.

Problem during film development:

film is only carried at shortest

process time (5:30min) ! Too little

fixing process!

2011/04/13 9000-608-25/30

33

Page 34

18. Tips for technicians

see also section 19 Tips on Troubleshooting

Problem

1. Completely not

operational

2. Supply of

fresh water

interrupted

EN

3. Developer

temperature

not suitable

4. Film too bright

5. Film too dark

Probable cause

• Mains fuse defect

• Appliance fusing defect

• Water intake valve blocked or

defect

• Water inflow blocked

• Level indicator sensor has lime

scale (electrical bridging)

• Process heater defect

• Air in system, rotary pump not

vented. (Unit filled with water or

chemicals at ca. 20 °C starts

without warm-up.)

• Developer bath temperature too

low

• Temperature of developer too

high or process heater defect

Solution

• Check fuse and replace where necessary

• Check fuse and replace where

necessary (see section 19.8)

• Check valve and replace where

necessary (see section 19.10)

• Clean fine filter or coarse filter in water

hose

• Clean level indicator sensor (see section

19.12)

• Process heater and PTC-sensing device

need replacing (see section 19.9)

• Vent rotary pump by starting and

stopping the unit several times over a

short period. Electrical supply switch ON

/ OFF

• Check process heater and/or PTC-sensor,

replace if necessary (wsection 19.9)

• Measure the temperature and enter

"CALIBRATION?" in service menu

• Check process heater and/or PTC-sensor,

replace if necessary (section 19.9)

• Measure the temperature and enter

"CALIBRATION?" in service menu

6. Yellowishgreen smear to

film

7. Greenishbrown smear

to film

8. Film not

completely dry

• No chemicals in developer/fixer

roller sets (level in bath too low)

• No agitation or circulation of

chemicals

• Film not rinsed • Level indicator sensor in water bath has

• Dryer performance incorrectly

set

• Ventilation fan defect

• Heating defect

• Check the profile of seals and roller sets,

if necessary replace.

• Check rotary pump for possible signs of

air in hose

closed off the water intake valve - check

waste water drainage, if necessary clean

and realign hoses (see 9.2)

• Further possibilities, see above:

Solutions for 2. "No fresh water inflow"

• Reset the dryer performance

• Replace the ventilation fan

• Change the temperature control fuse

Fault message on display with audible signal see 17.1

34

9000-608-25/30 2011/04/13

Page 35

43

19. Tips for Troubleshooting

19.1 Before beginning work

60

• Turn off the unit at the main power

switch.

• Disconnect the plug (61).

61

• Remove cover (60).

• The housing panels required for working need

to be removed.

19.2 Remove front panel

• Swivel the display upwards

• Open the green catches (44) above roller

sets (3)

• Remove the roller set to the film insertion

slot (3).

• Unscrew the two grey rapid release catches

44

(68) from the front panel (56).

• Unscrew the 3 Philips screws (cross-headed)

(57) and remove the front panel (56).

45

19.3 Remove rear panel

• Open the green catches (44) and clips (45)

8

holding dryer packet (8).

• Swivel the dryer packet (8) towards the rear

and detach.

• Unscrew the 3 Philips screws (cross-headed)

(57) and remove the rear panel (67).

EN

1144

45

2011/04/13 9000-608-25/30

3

19.4 Remove side panels

• Remove front (56) and rear panels (67), lift the

side panels (55) upwards.

57

19.5 After completing work

• Replace all housing panels to their original

55

positions.

57

67

55

68

56

Never operate the unit if the panels

are not correctly positioned or

not screwed into place! The unit

is connected to power supply Danger of electric shock.

• Replace cover (60), plug in at the mains

35

Page 36

DRYER 30%

[ENTER]=OK

DRYER 30%

[ENTER]=OK

DRYER 30%

[ENTER]=OK

to select service function

EN

Switch off unit at main power switch

+ simultaneously press (min. 4 s)

(press min. 2 s)

unit in service mode

• Start service function

19.6 Service operation plan

•

use button

• Select the service function

• Change settings

or to alter parameters

Use 1s, to confirm new values

Use

Switch off unit using power switch

*1 The language selected, frequency or values

appear first on start up

*2 Factory settings

(press min. 2 s)

• End service function

36

9000-608-25/30 2011/04/13

Page 37

EN

2011/04/13 9000-608-25/30

37

Page 38

EN

46

19.7 Replacing display unit

91

• Disconnect the connector of the display cable

(92) from the PCB (main board) (86) and guide

through the opening (91).

92

86

93

• Lift off the display (90) upwards.

• Insert new display in reverse sequence.

90

47

48

38

19.8 Check the fusing of the unit

• Open the flap to the rear of the unit (64) by

pushing not too hard with the tip of a

64

screwdriver.

65

• Press the spring and remove the fuse

holder (65).

• Check fuse and replace where necessary. For

order number see section 4.1 Special

accessories

62

9000-608-25/30 2011/04/13

Page 39

49

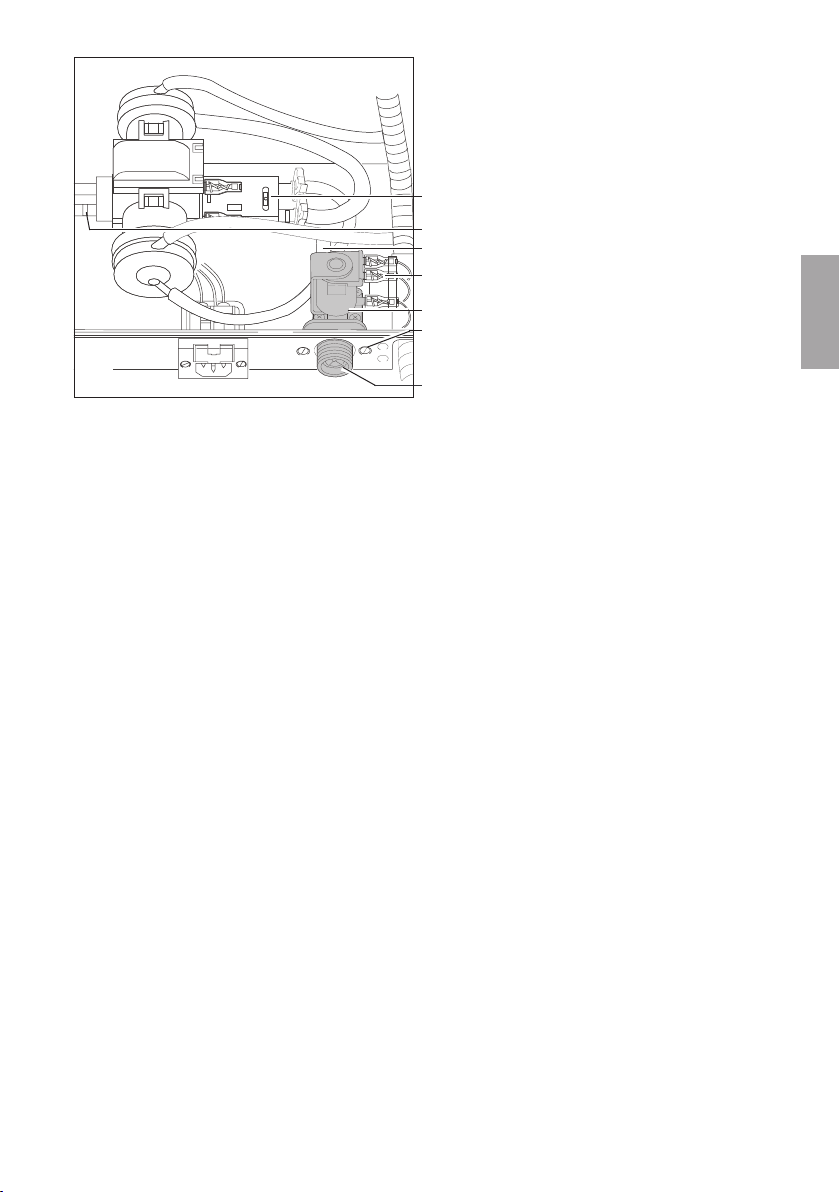

19.9 Replacing process heater with PTC-sensor

• Remove all panels.

• Drain off chemicals (see section 16.1.1)

• Disconnect connector (93, fig. 43) at PCB

(main board) (86).

16

• Unscrew the screw on mounting of the

17

rotatory pump and lift this upwards.

79

• Remove both the two connectors from the

rotatory pump and also the connector on the

80

process heater (16).

15

• Remove the process heater from its mounting

81

and disconnect the hoses.

• Install the new process heater according to

instructions.

34

• Replace all connections to rotatory pump and

process heater.

• Reconnect connector (93, fig. 43) at PCB

(main board) (86).

• Replace all housing panels to their original

positions.

19.10 Check water intake valve

• When water intake valve is not switched on:

• Start service operation (see section 19.6),

menu "INDIVIDUAL TEST" and then select

option "Water intake valve".

• If the valve does not activate despite unit

being switched on (voltage) then replace the

complete valve set (15), see section 19.11 "

Replace water intake valve".

EN

2011/04/13 9000-608-25/30

19.11 Replace water intake valve

First check water intake valve,see section

19.10, if defect then replace it.

• Close the water tap.

• Remove the water hose carefully from water

inflow (34) of the appliance.

• Disconnect the connection cable (80) from the

valve unit

• Carefully disconnect the internal water hose

(79) to the rear of the valve

• Undo the screw (81) to the side of the water

inflow and replace the complete valve

39

Page 40

EN

50

19.12 Level indicator sensor

“water”

• Close the water tap.

• Remove the lid.

• Open the green catches and clips.

• Swivel the dryer packet towards the rear.

• Remove the roller set "Water".

• Clean the level indicator sensors (82)+(83), in

order to avoid any formation of a bridge

caused by lime scale.

• To test the function the unit must be operated

without the roller set "water".

82

• Simulate a film insertion and the display

83

should cause message "Water too low" to

appear.

• Build a bridge between the two level indicator

sensor (82)+(83), and the message

"Water too high" should appear - the sensors

are now freed. Cleaning is complete. If there is

any deviation, refer to section

Troubleshooting, 17.1

19.13 Changing light barrier

sensors

The light barrier spare parts set is required

order number 1734-993-00.

Instructions are included with the spare parts

set, please refer to these.

40

9000-608-25/30 2011/04/13

Page 41

EN

2011/04/13 9000-608-25/30

41

Page 42

EN

42

9000-608-25/30 2011/04/13

Page 43

EN

2011/04/13 9000-608-25/30

43

Page 44

Dürr NDT GmbH & Co. KG

Höpfigheimer Straße 22 · 74321 Bietigheim-Bissingen, Germany

Tel: +49 7142 993811-0 · Fax: +49 7142 993811-299

info@duerr-ndt.de · www.duerr-ndt.de

Loading...

Loading...