Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

X-RAY FILM PROCESSOR DÜRR XR 04

Page 2

2

Page 3

CONTENTS

Important information

1. Notes......................................................... 4

1.1 Test of conformity .............................. 4

1.2 General Notes.................................... 4

1.3 General Safety Notes ........................ 4

1.4 Notes concerning Medical Appliances

5

1.5 Electrical Safety Notes ...................... 5

1.6 Warnings and Symbols .....................5

2. Product information ................................ 6

2.1 Use in accordance

with regulations.................................. 6

2.2 Use not in accordance

with regulations.................................. 6

3. Model survey ........................................... 6

4. Delivery schedule .................................... 6

4.2 Special extras .................................... 6

5. Technical data.......................................... 6

7. Function description ...............................7

6. Function principle ................................... 7

Installation

8. Installation

Requirements .......................................... 8

8.1 Installation site ................................... 8

8.2 Installation possibilities of the

Processor........................................... 8

Gebrauch

9. Changing chemicals

and water .................................................. 9

9.1 Taking off daylight attachment........... 9

9.2 Cleaning film transport .................... 10

9.3 Removing heater .............................11

9.4 Disposing of used chemicals .......... 11

9.5 Mixing new chemicals ..................... 11

9.6 Assembling of the XR 04 ................. 12

10. Operation ...............................................12

11. Replacing film transport cogs ............. 13

12. Wiring diagram ...................................... 14

Disposal

13. Disposing of Appliance ......................... 14

3

Page 4

IMPORTANT INFORMATION

1. NOTES

1.1 Test of conformity

This product was tested for conformity to the

Guidelines 93/42/EWG of the European Union

and has been found to satisfy all criteria of

these guidelines.

1.2 General Notes

• These Installation and Operating Instructions

form an integral part of the unit. They must

be kept close to the unit at all times. Precise

observance of these instructions is a precondition for use of the unit for the intended

purpose and for its correct operation. New

personnel must be made aware of the

contents, and they should be passed on to

future operating staff.

• Safety for the operator as well as troublefree operation of the unit are only ensured if

use is made of original equipment parts.

Moreover, use may only be made of those

accessories that are specified in the

technical documentation or that have been

expressly approved and released by Dürr

Dental for the intended purpose.

• Dürr Dental cannot guarantee for the safety

or proper functioning of this unit in the case

where parts or accessories are used which

are not supplied by Dürr Dental.

• Dürr Dental are only responsible for the

equipment with regard to safety, reliability

and proper functioning where assembly,

resettings, changes or modifications,

extensions and repairs have been carried

out by Dürr Dental or an agency authorized

by Dürr Dental and if the equipment is used

in conformity with the Installation and

Operating Instructions.

• These Installation and Operating Instructions

conform to the relevant version of the

equipment and the underlying safety

standards valid at the time of going to press.

All switches, processes, trade marks,

software programs and appliances named in

this document are registered names.

• Any reprinting of the technical

documentation, in whole or in part, is subject

to prior approval of Dürr Dental being given

in writing.

1.3 General Safety Notes

This appliance has been designed and

constructed by Dürr Dental so that correct

usage of the appliance is virtually free of any

possible injury or danger. In spite of this, we

feel it is our duty to mention the following

safety measures in order to prevent any

possible danger.

• When using this appliance all local and

relevant regulations must be observed!

Converting or modifying the appliance in

any way is strictly prohibited. In such cases,

any and all guarantees immediately become

invalid. The operation of modified

appliances can be punishable by law. In the

interests of trouble-free operation the

operator is responsible for observing these

regulations.

• Retain the packaging for possible return of

the product to the manufacturers. Ensure

that the packaging is kept out of the reach of

children. Only the original packaging

provides adequate protection during

transport of the unit.

Should return of the product to the

manufacturers be necessary during the

guarantee period, Dürr Dental accepts no

responsibility for damage occurring during

transport where the original packaging was

not used!

• Before every use the operator must check

the functional safety and the condition of the

appliance.

• The operator must be knowledgeable in the

operation of the appliance.

• The product is not designed to be used in

medical treatment areas where there exists

the danger of explosion. Areas where

explosions could occur are those where

flammable anesthetic material, skin

cleansers, oxygen and skin disinfectants are

present. This appliance is not to be used in

areas where the atmosphere could cause

fire.

4

Page 5

1.4 Notes concerning Medical Appliances

• This product is a technical medical

appliance and, as such, may only be

operated by trained personnel, or persons

who, as a result of specialist knowledge, are

familiar with this type of appliance.

• Do not lie multi-socket units on the floor.

• Other systems should not be plugged into

the same multi-socket unit.

1.5 Electrical Safety Notes

• The appliance may only be connected to an

earthed safety socket.

• Before connecting the appliance to the

power supply check that the electrical

current and the frequency of the device as

described on the appliance are compatible

with that of the power supply.

• Check the appliance and the power supply

cables for possible damage before

switching on. Damaged cables, plugs and

sockets must be replaced before use.

• Never touch open supply outlets and

patients simultaneously.

1.6 Warnings and Symbols

In the Installation and Operating Instructions

use is made of the following terms or symbols

to denote information of special importance:

Information and/or mandatory

regulations or prohibitions for the

prevention of personal injury or

substantial property damage

Warning of dangerous electrical

voltage.

Special information regarding the

economical use of the equipment and

other information

CE-Labeling without Notified Body

Number

Observe Installation and Operating

Instructions!

Date of manufacture

5

Page 6

2. PRODUCT INFORMATION

4. DELIVERY SCHEDULE

2.1 Use in accordance with regulations

The Dürr XR 04 X-ray developing machine is

to be used exclusively for the automatic

development of intra-oral X-ray films.

Use in accordance with the regulations

includes compliance with the instructions for

mounting and usage as well as compliance

with the provisions on setting up, installing and

operating the machine, and on warranty.

Use in accordance with the regulations also

includes compliance with all legal provisions

in force in the place where the machine is

being used, with regard to work safety and the

disposal of chemicals.

2.2 Use not in accordance with regulations

If the machine is used for a purpose other than

the one stated in the regulations, the

manufacturer shall not be legally liable for any

damage arising as a result of same. In such

cases, the user shall incur the risk.

3. MODEL SURVEY

X-ray film Processor XR 04

Model:Model:

Model: 1740-01 (230 V)

Model:Model:

1740-02 (110 V )

1740-03 (230 V) with heater

1740-04 (110 V) with heater

4.1 Optional extras

1 X-ray film

Processor XR 04 ............................. 1740-01

1740-02

1740-03

1740-04

1 Securing set ........................... 1740-004-00

1 Chemical set...................... 1307-080-00/40

1 Guarantee card ...................... 9000-464-86

1 Instruction manual ............. 9000-600-05/01

1 Wall mounting ......................... 1740-011-00

4.2 Special extras

1 Heater, PC-board 110V ......... 1740-994+00

1 Heater, PC-board 230V ......... 1740-993+00

1 Table trestle ............................ 1740-012-00

5. TECHNICAL DATA

Model 1740 - 01 02 03 04

Voltage (V) 230 110 230 110

Current

Consumption

(mA) 35 - 400 -

Heater w/o w/o with with

Frequency (Hz) ................................... 50 - 60

Film run through time (adjustable min) 2 - 6

Total output (W) .......................................... 85

Heat output (W)........................................... 40

Protection rating Il, Protection type IP 21

Heating up time

(approx. min) (8 min / °C) ................... 20 - 30

Weight (kg) without chemicals ................ 7,5

6

Page 7

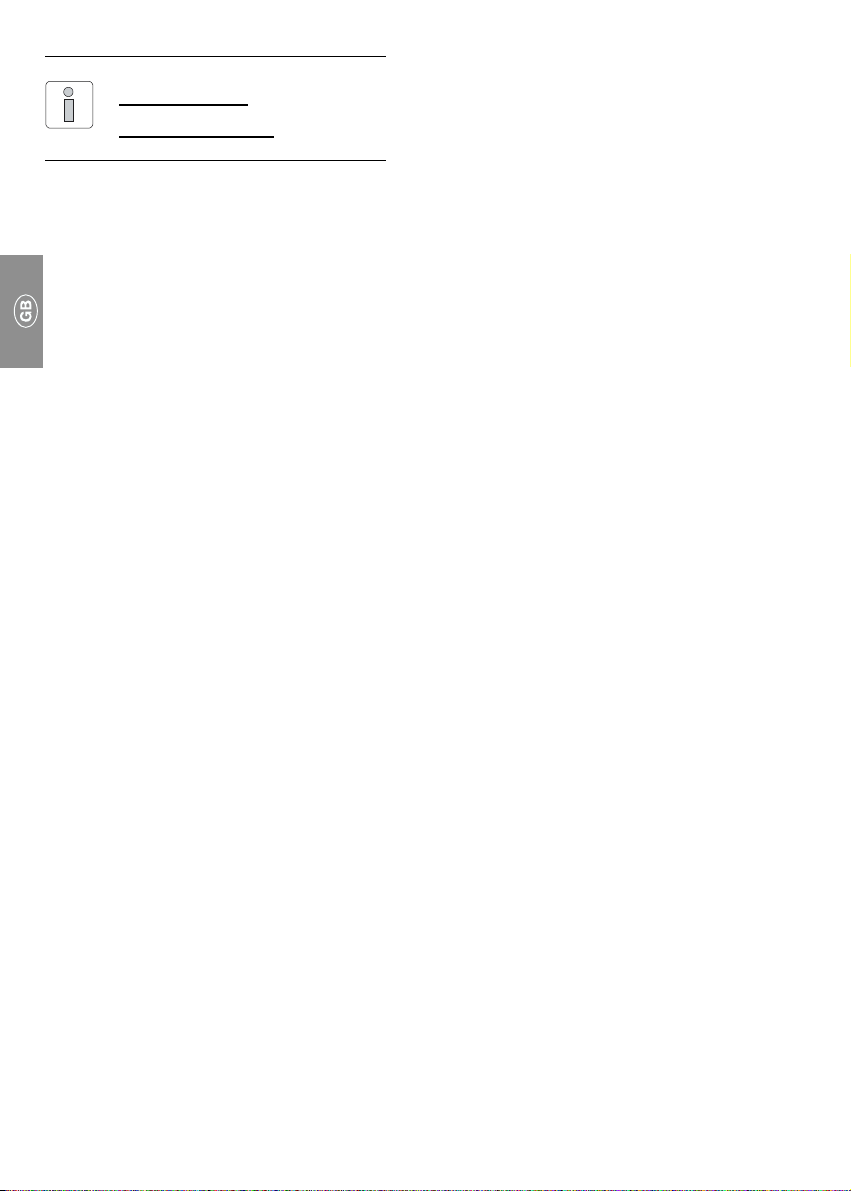

6. FUNCTION PRINCIPLE

3

45

2

1

7. FUNCTION DESCRIPTION

Switch on main switch (2).

Heater for Developer/Fixer baths is started

(8 min/°C to 25°C bath temperature).

Switch on regulator (1) for the film

transport and set the processing time

(2-6 min.).

The films are carried via the film transporter

through the Developer-/Fixer baths. The

processed film remains in the perforated

collector and should be taken out after

approx. 5 mins.

6

E Developer bath

F Fixer bath

W Water bath

1 Processing time regulator

2 Unit switch ON/OFF

3 Film transporter

4 Heater

5 Transporter drive

6 Perforated collector

7

Page 8

INSTALLATION

8. INSTALLATION REQUIREMENTS

10

8.1 Installation site

• The Processor XR 04 must be assembled in a

dry, well ventilated room.

Never expose the Processor to direct

sunlight!

With too strong sunlight pre-exposure of

films and overheating of chemicals can

1

11

2

12

occur.

8.2 Installation possibilities of the

Processor

To obtain perfect development results, the

installation area must be stable, flat and level.

• Assemble at or bring up to working height.

• Near a sink.

• Near a mains socket.

At a distance of approx.1.5 m from the

installation site of the XR 04, there should be a

mains socket for the power cable of the XR 04.

The mains socket should be sited so that the

power plug of the machine is easily visible

and accessible without danger.

(DIN 15990, para. 3.3.2 and 3.4)

For safety technical reasons the

power connection should only be

made shortly before putting the

machine into operation.

Wall mounting see. pict. 1.

• Mark the position for drilling the holes for the

XR 04 (10) on the wall.

• Drill the holes, insert wall plugs and fit screws.

• Hang XR 04 on the screws, adjust as

necessary, then tighten screws.

Table mounting see pict. 2.

Fit the upper part of the XR 04 onto the edge

of the table and fasten it (11).

Table installation see pict. 3.

For this assembly it is necessary to have a

separate table trestle (12), (not included in the

delivery schedule)

Order no.1740-012-00.

3

8

Page 9

13

14

GEBRAUCH

9. CHANGING CHEMICALS AND WATER

Before working on opened

equipment, pull out the mains plug.

• Change chemicals after approx. 200 films or

after 3 weeks at the latest.

• Change water twice a week.

The information for changing the

4

3

chemicals refer only when using

"DÜRR Chemicals"."DÜRR Chemicals".

"DÜRR Chemicals".

"DÜRR Chemicals"."DÜRR Chemicals".

In Germany, as well as some other

countries, used x-ray chemicals are

classified as special waste and must

be collected separately and disposed

of.

9.1 Taking off daylight attachment

Before taking off the daylight

attachment: Pull out mains plug.

Push frame support (14) inwards with both

thumbs. Swing daylight attachment (13)

upwards and remove, see pict. 4.

5

9

Page 10

6

7

7a

9.2 Cleaning film transport

16

• Lift the film transport (3, Fig. 5) upwards to

remove and rinse with warm water at

approx. 40°C.

• If the film transport is very dirty it can be

separated into two pieces and cleaned.

Hereby :

• Pull the 4 snap fasteners of the film transport

(16) out until they click into place.

• Using even pressure pull the top half from

the bottom half (Fig. 6).

• Rinse both halves and, if necessary, clean

with a brush.

17

18

19

20

21

Please note that when cleaning the

open film transport the toothed belt

can get out of position. Therefore,

before reassembling the film transport

check the position of the cogs (19)

and the toothed belt (20) as follows:

• The transport arm (17) should be

clockwise (21) clockwise (21)

clockwise (21) until it aligns with marking

clockwise (21) clockwise (21)

(A).

• The film carrier (18) should now be aligned

with marking (B). If not, then correct the

position of the toothed belt (20):

• Fig. 7a: Hold the film transport, so that the

large, white cogs cannot turn.

Fig. 7b: Lift the toothed belt (20) from the

cogs (19), align the film carrier (18) with

marking (B).

Replace the toothed belt in the correct

position and press onto the teeth of the cog

wheel.

Here by take care that the toothed belt

sits correctly on the cog with no

overlap, otherwise there is the danger

that the belt comes loose from the

cogs during operation.

• Place the two halves of the film transport

against each other and replace the snap

fasteners.

turnedturned

turned

turnedturned

10

18

19

20

7b

Page 11

9.3 Removing heater

Only necessary with table-top model,

otherwise the Developer-/Fixer

containers cannot be removed.

Lift up Heater (4) and hang on frame.

9.4 Disposing of used chemicals

W

F

E

8

• Remove by rotating the 3 containers

Developer (E)/Fixer (F)/Water (W) and very

carefully take off downwards.

• Empty out chemical and water containers.

• Dispose of chemicals.

• Rince containers with warm water and clean

thoroughly.

9.5 Mixing new chemicals

Fill containers only up to the

markings.

Danger of "spillage" during

insertion of containers.

• Pour developer up to black marking in

container (E) and then fill up with fresh water

to the upper marking. Insert container and

rotate to fasten.

• Pour fixer up to the red marking in container

(F) and then fill up with fresh water to the

upper marking.

Insert container and rotate to fasten.

• Fill container (W) with white markings up to

the upper mark with fresh water.

9

Insert container and rotate to fasten.

11

Page 12

10

9.6 Assembling of the XR 04

• Replace heater (4) and film transporter (3),

4

see pict. 5.

13

• Replace daylight attachment (13).

• Put the perforated collector (6) in the water

container (6), see pict. 11 and right fold-in

6

page.

FWE

12

11

12

Pos. 1

Pos. 2

10. OPERATION

• Machine switch (2) ON.

Developer-/Fixer bath are being warmed up.

• Processor regulating timer (1) ON.

Set processing time, see pict. 12.

without heater:

Regulator on pos. 1

3 1/2 mins

with heater:

Regulator on pos. 2

2 1/2 mins.

• Place the wrapped exposed film in the

daylight attachment.

• Insert hands into rubber cuffs and unwrap

film.

• Enter film into the transporter system.

• Remove processed film from the water bath.

Washing: A min. of 5 mins in the perforated

collector (6) (max. 1 hour)

• Processor regulating timer (1) OFF.

Page 13

11. REPLACING FILM TRANSPORT COGS

• Remove the locking ring of the defective cog

and pull the cog from the roller.

• Align the transport arm (A) with marking (B),

press new cog into position and secure with

the locking ring.

• Place the toothed belt cog (X) onto the film

carrier roller (C) so that this appears as a D .

The transport arms (A) must be aligned with

the markings (B) and the film carrier (C)

shows a D shape.

• Place the toothed belt in position and

synchronise, see Point 9.2.

X

C

B

A

B

A

13

Page 14

12. WIRING DIAGRAM

30 31 32

X3

NTC

X2

43

2

1

X2

N

X1

L

X1

36 35 34 33

X3

X4

30 Mains

31 Heater

32 Processing time regulator

33 Drive motor

34 PC board

35 Unit switch

36 Fuse 100 mA T

14

DISPOSAL

13. DISPOSING OF APPLIANCE

The built-in electronic plate and components

must be disposed of in the same way as

electronic scrap metal.

The remaining structural components can be

disposed in accordance with the relevant local

regulations.

Loading...

Loading...