Page 1

www.durr.com

OPERATING MANUAL

EcoGun AA MAN 2 P

Version: 01

as of: 09/2014

Page 2

Pos: 1.2 /APT/Übergreifende Kapitel/00 _Intro/Copyright @ 21\mod_13625 56028335_20.docx @ 296788 @ @ 1

TRANSLATION OF THE ORIGINAL OPERATING

MANUAL

Manufacturer

Dürr Systems GmbH

Application Technology

Carl-Benz-Str. 34

D-74321 Bietigheim-Bissingen

Tel: +49 (0)7142 78-0

Page 3

Transmission as well as duplication of this document, utilization and

communication of its contents is not allowed, unless expressly granted.

Any violations will oblige to compensation. All rights reserved for the

case of the granting of a patent or utility pattern registration.

=== Ende der Liste für Textmarke Copy right ===

.

Page 4

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Version: 01 as of: 09/2014

4 / 46

TABLE OF CONTENTS

1 Introduction ............................................................................................ 6

1.1 Safety Notes and Symbols ....................................................................... 7

1.2 Intended Use............................................................................................ 8

1.3 Reasonably foreseeable misuse .............................................................. 8

1.4 Continuing Documentation ....................................................................... 9

2 Safety .................................................................................................... 10

2.1 Qualification of Specialists ..................................................................... 10

2.2 Safety of the Work Environment ............................................................ 10

2.3 Safe Handling of the Spray Guns ........................................................... 10

2.4 Grounding .............................................................................................. 11

2.5 Material and Air Hoses ........................................................................... 11

2.6 Cleaning ................................................................................................. 12

2.7 Handling of Liquids, Paints and Enamels ............................................... 12

3 Transportation and Storage ................................................................ 13

3.1 Transportation ........................................................................................ 13

3.2 Storage .................................................................................................. 13

4 Description of Function ....................................................................... 14

5 Commissioning .................................................................................... 15

6 Operation ................................ ................................ .............................. 16

6.1 Operational Checks ............................................................................... 16

6.2 Air connection ................................ ................................ ........................ 16

6.3 Material connection ................................................................................ 16

6.4 Operation of the high pressure spray gun .............................................. 17

6.5 Flat jet regulation ................................................................................... 17

6.6 Trigger forces ......................................................................................... 17

6.7 Round jet regulation ............................................................................... 18

6.8 Adjustment of atomization air cap .......................................................... 18

6.9 Spray Gun guidance .............................................................................. 20

6.10 Filter selection ........................................................................................ 21

6.11 Adjustment of pre-air .............................................................................. 21

Page 5

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Version: 01 as of: 09/2014

5 / 46

6.12 Fault Elimination .................................................................................... 22

7 Service/Maintenance ........................................................................... 24

7.1 Cleaning ................................................................................................. 25

7.1.1 Cleaning Agents .............................................................................................. 25

7.1.2 Notes on the Cleaning ..................................................................................... 26

7.1.3 Lubrication ....................................................................................................... 26

7.2 Cleaning of parts .................................................................................... 27

7.2.1 Cleaning of spray tip Ref. 001248-U8 ............................................................. 27

7.2.2 Cleaning of filter ............................................................................................... 28

7.3 Replacement of parts ............................................................................. 29

7.3.1 Replacement of needle .................................................................................... 29

7.3.2 Replacement of inverted cup seal ................................................................... 29

7.3.3 Replacement of valve ...................................................................................... 30

7.3.4 Replacement of spray tip 001248-U8 .............................................................. 30

7.3.5 Replacement of gasket .................................................................................... 30

8 Disposal ................................................................................................ 32

9 Technical Data ...................................................................................... 33

9.1 Connection Values ................................................................................. 33

9.2 Overpressure ................................................................ ......................... 33

9.3 Air Consumption .................................................................................... 33

9.4 Workplace-Specific Sound Pressure Level ............................................ 35

9.5 Material consumption ............................................................................. 36

9.6 Spare Parts List ..................................................................................... 36

9.6.1 General ............................................................................................................ 36

9.7 Spare Parts ............................................................................................ 42

10 Contacts & Hotlines ............................................................................. 43

Page 6

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

6 / 46

Pos: 2 /CCP/Übergreifende Kapitel/01 Ei nleitung @ 25\ mod_1367830694 136_20.docx @ 3 57561 @ 12 @ 1

1 Introduction

This operating manual provides information about the safe operation,

service and maintenance of the product.

This operating manual must always be kept available for personnel

use at the product location. If the product ends up with a third party,

this operating manual must accompany it.

All tasks described in this manual must only be performed by qualified

personnel.

Any work that is not described in this operating manual must only be

performed by the manufacturer.

Every user of this product must read and understand this manual prior

to operation.

Dürr Systems GmbH does not accept any liability for damages or

injury resulting from non-compliance with this manual.

For questions, please contact either our service or spare parts

departments, or a subsidiary of Dürr Systems GmbH (see chapter 11

"Contacts & Hotline").

All representations and specifications in this document are

subject to technical changes.

Page 7

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

7 / 46

1.1 Safety Notes and Symbols

This manual uses symbols and signal words to

draw attention to specific dangers.

D A N G E R

Danger to life and limb

The red "Danger" safety note indicates that there is high risk present

that could potentially result in death or a severe injury.

W A R N I N G

Danger of severe injuries

The orange "Warning" safety note indicates that

there is risk present that could potentially result in

severe injury.

C A U T I O N

Danger of injuries

The yellow "Caution" safety note indicates that

there is risk present that could result in injury.

A T T E N T I O N

Danger of material damage and production

delay or downtime

The blue "Attention" safety note indicates that there

is risk present that could result in a material

damage and/or a fault.

Pos: 3 /CCP/SG_EcoGun/EcoGun A S MAN Gravity Feed/02_ 01 Best. Verwendung @ 37\mo d_140240099 9474_20.docx @ 4 72719 @ 2 @ 1

Page 8

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

8 / 46

1.2 Intended Use

Pneumatically operated paint spray gun with pump support in the

high pressure range (up to max. 250 bar) for processing liquid,

sprayable media with consideration of the manufacturer references.

The high pressure spray gun is led by hand and operated by the

operator to coat the work piece.

Installations where the spray gun is operated must meet the

applicable national and international safety regulations.

The spray gun is suitable for the operation in zone 1, protection class

II 2 G IIA T6.

The spray gun may only be operated in the range of application

intended by Dürr Systems GmbH.

The spray gun may only be operated with components that are suited

for the operation with the systems and have been authorized by

Dürr Systems GmbH.

The spray gun must not be equipped and operated with components

of other manufacturers if their use was not clarified explicitly with Dürr

Systems GmbH.

In case of questions on the range of application, our "Service"

department will be glad to inform you.

Pos: 4 /CCP/SG_EcoGun/Übergreife nd/0201 Nicht bes t. Verwendung @ 3 1\mod_1389870 550754_20.do cx @ 414229 @ 2 @ 1

1.3 Reasonably foreseeable misuse

The atomizer must only be used as described.

Any other use is not approved by Dürr Systems.

- Do not spray any material on people or animals.

- Never spray liquid nitrogen.

Pos: 5 /CCP/SG_EcoGun/Übergreifend/ 0102 Weiterführende Doku @ 31 \mod_1389961 783915_20.docx @ 414551 @ 2 @ 1

Page 9

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

9 / 46

1.4 Continuing Documentation

Also refer to the following documentation when operating the device.

- Operating manuals for other components

within the installation

- Material Safety Data Sheets (MSDS) for

the coating materials

Pos: 6 /CCP/SG_EcoGun/EcoGun A S MAN Gravity Feed/02 -02 Sicherheit @ 37\mod_140 2401038015_20.d ocx @ 472742 @ 12222222 @ 1

Page 10

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

10 / 46

2 Safety

2.1 Qualification of Specialists

The spray gun may only be commissioned, operated, serviced and

repaired by qualified and trained personnel.

If you need any support in the training of your

personnel, contact our training department (see

chapter "Contacts & Hotline)".

2.2 Safety of the Work Environment

Ensure that the work environment is always kept clean and well

illuminated.

Ensure that the floor of the work environment is antistatic according to

EN50053 part 1, §7-2, measurement acc. to DIN 51953 and that all

persons are wearing antistatic shoes within the work environment.

Ensure that the operators are wearing antistatic gloves when painting.

This allows a grounding through the spray gun handle.

Follow all local rules concerning the paint mist suction and ensure that

these are available at the workplace and are operated properly.

Ensure that material and air hoses are available and are used that are

laid out for the corresponding working pressure.

Ensure that personal protection outfit is available

to the personnel and this is used. Wearing

personal protection outfit such as breath and skin

protection and anti-slip safety shoes where

appropriate reduces the risk of injuries.

Ensure that there are no sources of ignition such as open fire, sparks,

glowing wires or hot surfaces in the environment and that people do

not smoke in the room.

2.3 Safe Handling of the Spray Guns

Check the firm seat of all screws and nuts before every

commissioning, in particular after maintenance and cleaning works.

Attention: The spray jet is pressurized and may cause dangerous

injuries.

Page 11

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

11 / 46

Please pay attention to the following safety note at all times:

- Absolutely avoid direct skin contact with paint or cleaning agents.

- Always wear safety clothing such as goggles, breath mask,

protection suit, safety shoes and gloves.

- Never direct the spray gun towards yourself, other persons or

animals and never reach into the spray jet.

- Disconnect the compressed air supply before all jobs at the device

and in case of stoppages and malfunctions.

- In case of stoppages, ensure that the spray gun is not triggered by

mistake.

- Before maintenance operations, relieve the spray gun pressure.

- In case of malfunctions, eliminate the error according to chapter

6.8 "Possible errors".

Danger of skin injuries:

In case of skin injuries by paint or cleaning agent, note down which

paint and/or cleaning agent you have used and you consult a doctor

immediately.

2.4 Grounding

Due to the high flow velocity of the paint and the air, electrostatic

charges may occur at the device. These may cause spark or flame

formation in case of discharge.

- Ensure that the device is grounded during every spraying process

and ground the workpieces to be coated.

- All persons inside the working area should be grounded, for

instance by wearing antistatic shoes. In addition, antistatic gloves

should be worn during painting for grounding through the spray

gun handle.

2.5 Material and Air Hoses

Ensure that the connected material and air hoses meet the

mechanical and chemical requirements. Pay attention to the data

sheets of the paint manufacturers. Make sure that the material of the

material hose is chemically steady against the sprayed materials.

Make sure that on the used high-pressure hose the manufacturer, the

manufacturing date and permissible operating pressure are

recognizable.

Attention: The electrical resistance of the complete highpressure hose must be smaller than 1 MOhm.

Page 12

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

12 / 46

2.6 Cleaning

- Uncouple the device from the pneumatic inlet and relieve the

pressure.

- Ensure that the ambient temperature is at least 5°C below the flash

point of the used cleaning agents.

- Only use moistened cloths and paintbrushes to clean. Never use

any hard objects and never spray on cleaning agents with a gun.

Attention: In closed tanks, an explosive gas-air-mixture may

form. Therefore, never spray into a closed tank when cleaning

the device with solvent.

2.7 Handling of Liquids, Paints and Enamels

When preparing and processing paints and when cleaning the device,

observe all processing rules by the manufacturers of the used paints,

solvents and cleaning agents.

When painting and preparing and cleaning, wear the stipulated

protection outfit:

- goggles

- protective clothes

- protective gloves

- skin protection cream where appropriate

- respirator

Operate the device in a spray booth or at a spray wall with ventilation

turned on (suction) to ensure sufficient health and environmental

protection.

Wear corresponding protective clothing when processing hot materials

(max. 60°C).

Pos: 7 /CCP/Übergreifende Kapitel/03 Tra nsport und Lage rung @ 25\m od_13679205389 54_20.docx @ 35 8417 @ 12 @ 1

Page 13

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

13 / 46

3 Transportation and Storage

3.1 Transportation

If damage is present upon receipt of the component, contact Dürr

(refer to chapter 11 "Contacts & Hotline").

Pos: 8 /CCP/Übergreifende Kapitel/0302 Lagerung @ 33\ mod_139479 3517476_20.docx @ 429129 @ 2 @ 1

3.2 Storage

Environmental conditions in the storage area:

- Temperature: 10 °C – 40 °C

- Humidity: 35% – 90%

Pos: 9 /CCP/SG_EcoGun/EcoGun A S MAN Gravity Feed/04_F unkt @ 37\ mod_14024014 94265_20.docx @ 472949 @ 1 @ 1

Page 14

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

14 / 46

4 Description of Function

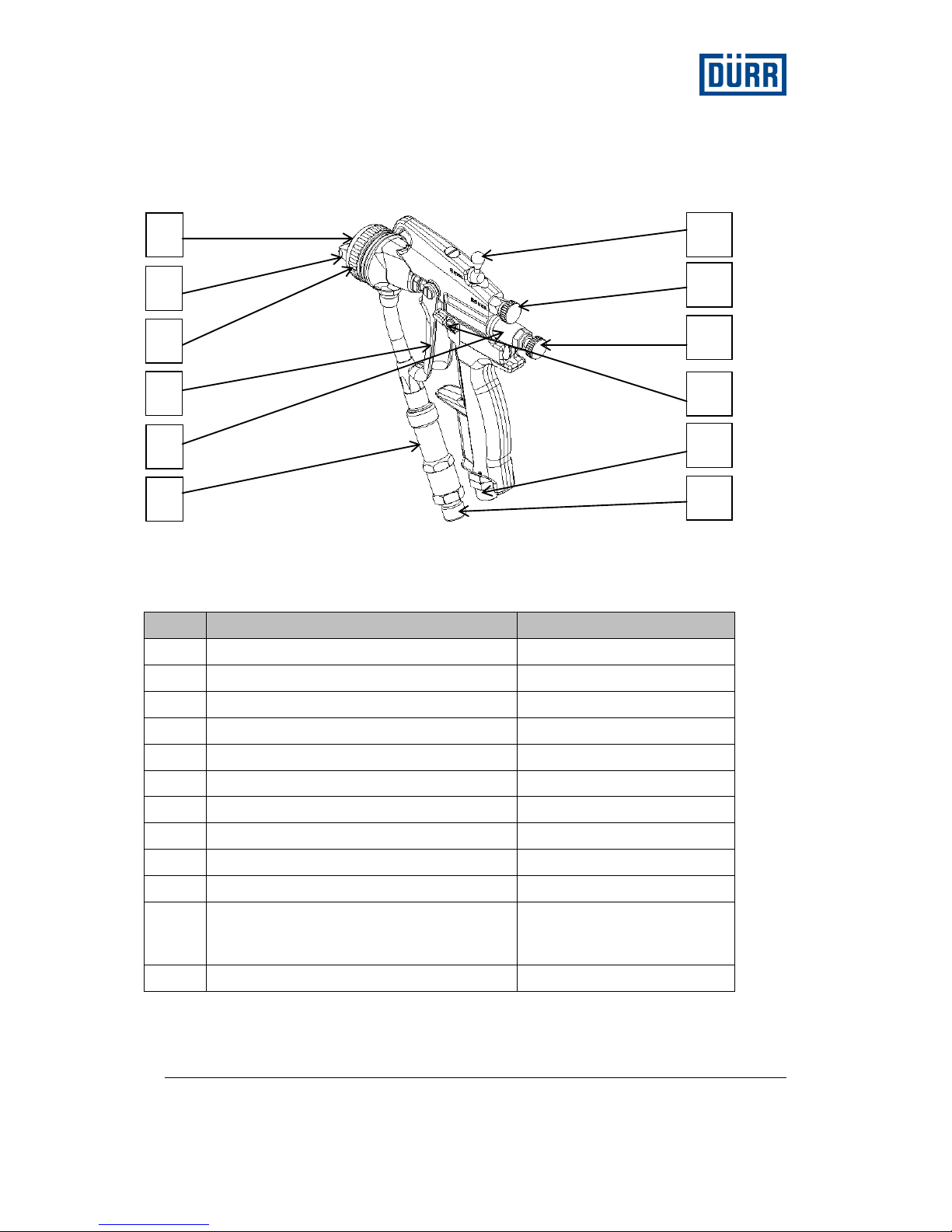

Fig. 1: Paint spray gun

Pos.

Designation

Ref. no.:

A

Spray tip

001248-U8

B

Air Cap

001248-U2

C

Lock nut

001248-4

D

Trigger

001248-U4

E

Locking piece

001240-7

F

Insert filter

001233-75

G

Air regulation

001248-U6

H

Round jet regulation

001240-U5

I

Regulation screw

001236-5

J

Security bolt

001237-3

K

Swivel air connection

G1/4“

001133-U11

L

Material connection

001248-U7

Page 15

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

15 / 46

5 Commissioning

• Attach air hose to connection (K)

• Attach material hose to connection (L)

• Before the first use, flush the material supply inclusive nozzle with solvent

respectively cleaning agent.

• Material flow and spray pattern depend on the size of the spray nozzle, the

viscosity of material and the material pressure.

Pos: 11 /CCP/SG_EcoGun/Übergreifend/10 02 Betrieb @ 2 9\mod_1384 944709997_20.docx @ 400370 @ 12 @ 1

Page 16

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

16 / 46

6 Operation

6.1 Operational Checks

Checks can be performed both during operation and especially during

operational breaks. These checks can prevent later damages and

production interruptions.

Check the following conditions:

- All hoses are undamaged.

- All connections are correct.

- The air cap is clean.

- The atomizer is clean.

Pos: 12 /CCP/SG_EcoGun/EcoGun AS MA N Gravity Feed/08 _Bedien @ 37 \mod_1402401 346281_20.do cx @ 472903 @ 22 2255233 @ 1

6.2 Air connection

Swivel air connection 1133-U11, connecting

thread G ¼ “

Air supply for flat jet air cap and round jet air.

- Clean and dry air increases the spraying

quality and extends the life span of your

high pressure spray gun.

6.3 Material connection

Attention High Pressure! – Consider all

safety regulations!

Swivel material connection 1248-U7,

Connecting thread NPSM ¼ “. Use only

permissible high-pressure hose.

Take care of the right position of the ballcone seal.

Page 17

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

17 / 46

6.4 Operation of the high pressure spray gun

Turn trigger lock Ref. 1237 – 3 by

90 degrees downwards (spray gun

is now released).

Pull trigger Ref. 1248 - U4 up to the

first pressure point (pre-air).

Pull trigger Ref. 1248 - U4

completely, high pressure spray jet

starts.

Secure high pressure spray gun all

times, after ending the spraying

procedure, by turning trigger lock

90° upwards.

Note:

In order to avoid a drop formation at the spray gun, keep the

pre-air valve 1-2 sec. open after spraying.

6.5 Flat jet regulation

The atomization air is regulated with the air regulation ref.1248 - U6

Right Turn - less air - low atomization

Left Turn - more air - high atomization

Pos: 13 /CCP/SG_EcoGun/EcoGun AS MA N Gravity Feed/08 _02_Betrieb_Pis tführung_Gravity @ 37\mod_ 1402401090916 _20.docx @ 47276 5 @ 3 @ 1

6.6 Trigger forces

Trigger pressure adaptation according to the

material pressure.

Pressure force is adjustable from approx.80 - 250 bar (1.138 -

3.557 PSI).

- 250 bar tighten screw

Ref.1236-5 completely.

- 80 bar -unscrew screw

1236-5 to tappet.

Page 18

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

18 / 46

For pressures in between 80 and 250 bar

choose a correspondingly intermediate

adjustment of the screw Ref.1236-5.

6.7 Round jet regulation

With the round jet regulation Ref.1240-U5

atomization air is added to the flat jet cap.

Clockwise rotation - less air -little

adjustment to round jet.

Counter clockwise rotation - more air -high adjustment to round

jet.

6.8 Adjustment of atomization air cap

Put pump pressure at 0 , release trigger

Ref.1248-U4 completely - pressure of hose

relieves.

b.) Secure spray gun by a 90 ° clockwise

rotation of the safety lever Ref.1237-3.

c.) Release lock nut Ref.1248-4 by hand.

d.) Put atomization cap Ref.1248-U2 into

required position.

e.) Tighten lock nut Ref.1248-4 by hand.

The position of the atomization air cap and the

spraying nozzle determines the direction of the

spray jet.

Turn the atomization cap according to the desired spray

direction -the spraying nozzle turns with it).

Page 19

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

19 / 46

Illustration 2: Air cap adjustment

Page 20

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

20 / 46

6.9 Spray Gun guidance

The paint spray gun must always be held at a

90° angle to the painting surface

Page 21

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

21 / 46

6.10 Filter selection

The mesh size of the filter should not be bigger

than the nozzle size!

6.11 Adjustment of pre-air

a.) Unscrew breech ring cap Ref.1240-7

and take out needle.

b.) Release needle carrier Ref.1248-13 with

screw wrench SW 6, to counter hold needle

end Ref.1248-14.

c.) Adjust needle:

More pre-air - screw out

needle

Less pre-air - screw in

needle

d.) Fixate needle, by tightening needle

carrier Ref.1248-13 - to counter hold the

needle end Ref. 1248-14.

Page 22

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

22 / 46

6.12 Fault Elimination

F

a

ul

t

Possible cause

Elimination

1.

D

e

cr

e

a

s

e

in

p

ai

nt

fl

o

w

w

h

e

n

s

pr

a

yi

n

g:

* Filter of gun

clogged.

* Viscosity too high.

* Too low material

pressure.

Clean the filter

Water down the paint.

Increase air inlet

pressure of the

pump.

2.

Ir

re

g

ul

ar

je

t:

* Airless nozzle

clogged.

* Filter of gun

clogged.

* Nozzle to wide or

worn out.

* Viscosity to high.

* No, or not enough

atomizer air.

* Air slits dirty.

* Atomizer air pressure to high or too

Replace nozzle

Clean the filter

Insert new

nozzle .

Open regulation

no. 1248 – U6

Clean with a

brush.

Do not u use a

wire brush!

Adjust pressure

Page 23

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

23 / 46

low.

regulation valve.

3.

S

pr

a

y

g

u

n

st

ill

s

pr

a

y

s

w

h

e

n

cl

o

si

n

g:

* Seal washer or

needle ball worn

out.

* Needle spring has

lost stress.

* Needle seal too

strong thus needle

can

not be moved

through the spring.

* Needle and needle

sealing dirty.

Change parts

Replace spring

Change sealings

4.

S

pr

a

y

g

u

n

le

a

k

s

p

ai

nt

o

* Needle seal worn.

* Packing gland is

not installed

tight enough.

Replace sealings

Tighten packing

gland.

Page 24

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

24 / 46

n

n

e

e

dl

e

s

e

al

:

5.

S

pr

a

y

g

u

n

is

bl

o

w

in

g:

* Valve spring

fatigue.

* Valve sealing

worn.

* Valve defective.

Replace spring

no.1136 -20

Change valve

sealing

Change valve.

6.

S

pr

a

y

g

u

n

h

a

s

n

o

or

to

lit

tl

e

pr

eai

r

* Pre-air stroke

screw not properly

adjusted

Adjust pre-air

A regular cleaning and maintenance increases the service life of the

spray gun. We offer expert service for the general overhaul on our

premises.

Pos: 16 /CCP/Übergreifende Kapitel/08 Wa rtung Instandhal tung @ 29\mo d_138417969 1971_20.docx @ 3 98014 @ 1 @ 1

7 Service/Maintenance

Page 25

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

25 / 46

Repairs or the product components are not approved by the

manufacturer. Damaged parts must be replaced.

For questions about the service and maintenance

tasks, or to obtain training, contact our training

department (see chapter 11 "Contacts &

Hotline)".

Pos: 17 /CCP/SG_EcoGun/EcoGun A S MAN Gravity Feed/ 09_01_Wart_Re inig @ 37\mod_1 4024011918 90_20.docx @ 472 811 @ 2333 @ 1

7.1 Cleaning

7.1.1 Cleaning Agents

W A R N I N G

Explosion and fire hazard due to easily

inflammable materials.

This may result in casualties or severe injuries.

Do not smoke in the working area. Do not ignite any fire and no open

flame in the working area.

W A R N I N G

Danger of injury

When working with cleaning materials, harmful

vapors may develop.

Observe the manufacturer's notes by all means.

Only use cleaning agents approved by the paint manufacturer for the

used paints or the purging agent that is used in the painting

installation.

A T T E N T I O N

Danger of material damage and production

interference

Damage of the parts to be cleaned.

Do not use any ultrasonic bath to clean.

With waterbased paints, you may use alcohols like isopropanol or nbutanol as cleaning agent. You may remove rough-dried residues of

waterbased paint with an organic solvent approved by the paint

manufacturer.

If parts cannot be cleaned directly with purging agent, a soft brush or

a bristle brush, you may immerse the parts in a cleaning bath.

Page 26

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

26 / 46

A T T E N T I O N

Danger of material damage and production

interference

Receptacles of sheet metal, high-grade steel or other metals may lead

to damages at the surface of the air cap (electrolysis).

Only use electrically non-conductive receptacles for a cleaning bath.

7.1.2 Notes on the Cleaning

W A R N I N G

Danger due to pressurized lines

Severe injuries may result.

Depressurize all lines before the cleaning.

Purge the spray gun immediately after the use with the cleaning agent

appertaining to the paint. Purge until the cleaning agent emerges

clean from the spray gun.

- Only use cloths and soft brushes.

- Do not use any compressed air. Compressed air can press soilings

into the openings of the spray gun and influence the function.

- Do not bring purging agent on the spray gun with pressure.

- Do not use any abrasive materials (emery, wire wool and so forth).

- At the end of the cleaning, wipe the spray gun dry with a soft cloth.

7.1.3 Lubrication

O ring, needle guiding, needle packing and lever bearing must be

lubricated regularly with silicon-free oil or silicon-free grease.

Pos: 18 /CCP/SG_EcoGun/EcoGun AS MA N Gravity Feed/09 _02_Instand @ 37\mod_14 02401244620_20. docx @ 472834 @ 2 3333 @ 1

Page 27

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

27 / 46

7.2 Cleaning of parts

W A R N I N G

Danger due to pressurized lines

Severe injuries may result.

Depressurize hoses before starting any jobs at the spray gun.

Remove paint residue.

Immediately after usage or longer interruptions

the spray gun has to be scavenged with the

relevant thinner for the paint in question

(cleaner).

In this case it is necessary to scavenge the

spray gun with thinner with the assistance of the

feeding pump until the cleaner leaves the gun

clear. Never immerse the paint spray gun in the

cleaning agent.

7.2.1 Cleaning of spray tip Ref. 001248-U8

Adjust the pump pressure at 0 bar, release trigger

Ref. 1248-U4 completely - pressure of hose relieves.

Secure spray gun by a 90 ° clockwise rotation of the

safety lever Ref. 1237-3

Remove the lock nut Ref.1248-4 by hand

Take off nozzle Ref.1248-U2 and blow it through, from

the front side

Insert nozzle set 1248-U2 and adjust it

Tighten lock nut 1248-4 by hand

Page 28

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

28 / 46

7.2.2 Cleaning of filter

We recommend to clean the filter (depending on

the used paint) from time to time in order to

avoid that the paint residues get hard which

could make the dismantling impossible.

Put pump into a pressure less condition.

Depending on the paint tube - see spare parts

drawing -

Release paint hose part Ref.1248-U7 with a

screw wrench SW17

Attention !!

Make sure to support the upper paint hose

part of the paint tube by clamping it with an

additional screw wrench SW 11.

Unscrew the filter downwards out of the paint

tube.

Clean the filter with a brush (no wire brush).

Mounting of parts vice versa, please be

thoroughly and take care of the right

position of o-ring 104-0022 in the upper part

of the paint tube.

Filter should jut out from paint tube approx. 4

mm.

Page 29

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

29 / 46

7.3 Replacement of parts

In any case detach the gun

from the pump!!!

7.3.1 Replacement of needle

Unscrew breech ring cap 1240-7

Take out needle with pressing disc and spring at

its end backwards.

Insert new needle with pressing disc and spring.

7.3.2 Replacement of inverted cup seal

o Dismantle needle according to point 7.3.1

o Dismantle trigger 1248-U4, by loosening trigger screw 1248-33;

remove trigger axle 1248-17

o Screw out tightening nut 1240-9

o Pull out complete connection piece 1248-3 to

the front

Attention!! Between connection piece

1248-3 and gun body there are for sealing

purposes one

o-ring 104 – 0018 and two sealings 1240 –

63.

o Unscrew packing gland 1248-12,substitute

distancing

gland 1248-11 and inverted cup seals 1248-10

with o-rings 104-0020.

o Mount the parts vice versa - please take care

that packing gland 1248-12 is not tightened to

strong.

Page 30

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

30 / 46

7.3.3 Replacement of valve

Dismantle lever according to point 7.3.2.

Turn out valve packing gland 1134-4 to the front.

Pull out valve packing gland seal 1133-42 to the

front.

Insert new valve packing gland seal 1133-42.

Mount the parts vice versa.

7.3.4 Replacement of spray tip 001248-U8

Adjust the pump pressure at 0 bar, release

trigger 1248-U4 completely - pressure of hose

relieves.

Secure spray gun by a 90 ° clockwise rotation of

the safety lever 1237-3

Remove the lock nut 1248-4 by hand.

Take off nozzle set 1248-U2 to the front side.

Push out nozzle carrier from nozzle set

backwards.

Deposit nozzle carrier complete in cleaning fluid

respectively install another nozzle carrier complete

according to these steps vice versa. (Cleaning

needle for nozzle order- number 00345-44)

o Replace if necessary, seal 1240-58.

Assembly in reverse order

Pos: 19 /CCP/Übergreifende Kapitel/09 E ntsorgung @ 2 9\mod_13841795 59462_20.docx @ 397616 @ 1 @ 1

7.3.5 Replacement of gasket

Adjust the pump pressure at 0 bar, release

trigger 1248-U4 completely - pressure of hose

relieves.

Secure spray gun by a 90 ° clockwise rotation of

the safety lever 1237-3.

Remove the lock nut 1248-4 by hand.

Take off nozzle set 1248-U2 to the front side.

Page 31

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

31 / 46

Release packing gland 1248-12.

Unscrew breech ring cap 1240-7 and take off

needle piece complete with springs and

pressing discs pull out backwards.

Unscrew sealing retaining screw by using

socket wrench SW 10 and replace in connection

with sealing ring 1240-25. At the same time

check the ball on needle piece 1248-U3.

Mounting of the parts according to these steps

vice versa.

Page 32

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

32 / 46

8 Disposal

W A R N I N G

Hazard of personnel and environmental

poisoning from media and operating materials

Refer to the safety data sheets for the media and

operating materials.

- Collect used medium and operating materials for disposal

according to the local regulations. Adhere to the work and

environmental protection regulations valid on site.

- Prevent waste from getting into the environment.

Pos: 20 /CCP/SG_EcoGun/EcoGun AS MA N Gravity Feed/12 _Entsorg @ 37\ mod_14024 01316410_20.docx @ 472880 @ @ 1

The spray gun is not subject to any special disposal regulations.

Pos: 21 /CCP/SG_EcoGun/EcoGun AS MA N Gravity Feed/15 _TechDat @ 37\mod_1402401 611292_20.do cx @ 472995 @ 12 222

Page 33

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

33 / 46

9 Technical Data

9.1 Connection Values

Maximal admissible air pressure

8 bars

Recommended operating pressure

1.5 - 3.0 bars

Maximally permissible material temperature

when working without gloves

40 °C

Maximally permissible material temperature

when working with gloves

60 °C

Maximal admissible material pressure

250 bars

9.2 Overpressure

For short positive pressures of 10 - 12 bar (143 – 170 psi ) at

the air supply and higher pump pressures (above 250 bar –

3.556 psi material pressure) there is no danger of the

destruction of the high pressure spray gun.

Positive pressure in the material area are compensated by

automatic release of the paint needle.

Note: Leaving spraying material

9.3 Air Consumption

Air consumption of the high pressure paint spray

gun air regulation Ref. 1248 - U6 is adjusted

fully on max. see table designation „B “,.

These values below can be reduced by

operating the total air adjustment 1248-U6 by

approx. 80% (i.e. values are than only approx.

20 %)

Circular jet

Flatstream

1,0 bar = 5,0 cbm/h = 84.0 l/min

1,0 bar = 4.3

cbm/h = 72.0

l/min.

2,0 bar = 8.1 cbm/h = 136.0 l/ min.

2,0 bar = 6.9

Page 34

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

34 / 46

cbm/h = 115.0

l/min.

3,0 bar =11,1 cbm/h = 185.0 l/ min.

3,0 bar = 9.2

cbm/h = 154.0

l/min.

Page 35

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

35 / 46

9.4 Workplace-Specific Sound Pressure Level

Technical equipment

Noise emission of spray gun with air regulation 1248-U6 adjusted fully

on max.

Circular jet

Flatstream

1,0 bar = 67

dB/A

1,0 bar = 69 dB/A

1,5 bar = 71 dB/A

1,5

bar = 74

dB/A

2,5 bar = 78 dB/A

2,5

bar = 79

dB/A

Pos: 22 /CCP/SG_EcoGun/EcoGun AS MA N Gravity Feed/E rsatzteilliste @ 37 \mod_14016 95674581_20.docx @ 470677 @ 1222255 @ 1

Page 36

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

36 / 46

9.5 Material consumption

Material consumption values - depending on nozzle size and

pump pressure.

Material throughput values with following conditions:

Operating pressure: 100 bar

Nozzle size: 0.23 mm

Material viscosity.: 45 sec DIN 4 mm / 20°

Material throughput: approximately 0.26 l / min.

9.6 Spare Parts List

9.6.1 General

Designation

Refer

ence

No.

O-Ring 3,5 x 1,0

VITON

0001

040018

O-Ring 7,0 x 1,0

VITON

0001

040019

O-Ring 4,0 x 1,2

VITON

0001

040020

O-Ring 12 x 1,5

VITON

0001

040022

Sealing

0011

3342

Swivel air

connection

G1/4“

0011

33U11

Locking screw

M10x1

0011

3610

Page 37

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

37 / 46

Compression

spring

0011

3620

Valve pin

0011

3621

Valve pin

complete

0011

36U14

Valve

0012

3017

Sealing

0012

33-9

Washer

0012

3326

Screw

0012

3328

Insert filter red

50 µm - 295 msh

0012

3374

Insert filter

yellow 100 µm 150 msh

0012

3375

Insert filter white

180 µm - 80

msh

0012

3376

Insert filter

0012

3345

Sealing

0012

3349

Compression

washer, large

0012

3513

Compression

washer, small

0012

3514

Regulation

screw

0012

36-5

Prong ring ZA

4,0

0012

36-7

Page 38

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

38 / 46

Security bolt

0012

37-3

Locking piece

0012

40-7

Tightening nut

0012

40-9

Sealing ring

0012

4025

Sealing

0012

4058

Sealing

0012

4063

Regulation

screw complete

0012

40U5

Connection

piece

0012

48-3

Lock nut

0012

48-4

Seal washer

0012

48-9

Inverted cup

seal

0012

4810

Distance gland

0012

4811

Packing gland

0012

4812

Needle carrier

0012

4813

Needle end

0012

4814

Locking screw

0012

4816

Lever axle

0012

48-

Page 39

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

39 / 46

17

Counter nut

0012

4818

Paint tube upper part

0012

4819

Paint tube

connection

0012

4826

Holding bow

0012

4828

Compression

spring

0012

4829

Valve packing

gland

0012

4832

Flat head screw

0012

4833

Hexagon nut

0012

4834

Reduction nipple

0012

4836

Bushing

0012

4839

Paint tube

0012

4840

Paint tube lower part

0012

4841

Compression

spring

0012

4843

Atomizer air cap

0012

48U2

Page 40

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

40 / 46

Needle part

0012

48U3

Trigger

0012

48U4

Sealing retaining

screw

0012

48U5

Air regulation

0012

48U6

Material

connection

NPSM ¼

0012

48U7

Düsenträger

„VZ“ (please

state size)

0012

48U8

Material

connection,

swivel M16 x 1,5

0012

48U9

Material

connection

swivel G ¼“

0012

48U10

Paint tube

NPSM ¼“

0012

48.1U2

Repair set

0003

45172

Gasket set

0003

45173

Pos: 23 /CCP/SG_EcoGun/EcoGun AS MAN Gravity Feed/explosion2

@ 37\mod_1401889427422_20.docx @ 471889 @ @ 1

Page 41

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

41 / 46

Pos: 24 /CCP/Übergreifende Kapitel/100 3 Ersatzteile mit Ex @ 31\mod_ 1392286500573_ 20.docx @ 42018 2 @ 2 @ 1

Page 42

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

42 / 46

9.7 Spare Parts

A T T E N T I O N

Spare parts that have not been released by Dürr

Systems GmbH may not be able to resist the

loads.

Material damage and production interference may

be the consequence.

Only use original spare parts.

Dürr Systems GmbH will refuse any and all liability

and guarantee for damages arising from the use of

foreign spare parts.

A T T E N T I O N

Spare parts in explosive areas

In explosive areas, only use spare parts that have been approved for

the respective ex zones.

Original spare parts by Dürr Systems GmbH meet the requirements of

the ATEX directives.

Should you have any questions, please contact our team who will be

glad to advise and support you (refer to Chapter 11 "Contacts &

Hotline").

Pos: 25 /CCP/SG_EcoGun/Übergreifend/10 - Service Eco Gun @ 38\mod _1404907528452 _20.docx @ 4808 99 @ 15555 @ 1

Page 43

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

43 / 46

10 Contacts & Hotlines

Europe

Germany

Dürr Systems Karlstein GmbH

Address

Seligenstädter Straße 53

63791 Karlstein am Main

Germany

Telephone

+49 (0)6188 787-0

Service

Service:

Tel: +49 6188 787 46

Fax: +49 6188 787 87

Petra.bohlander@durr.com

Spare parts

Tel: +49 6188 787 46

Fax: +49 6188 787 87

Petra.bohlander@durr.com

Parts repair

Tel: +49 6188 787 46

Fax: +49 6188 787 87

Petra.bohlander@durr.com

Ecopaint

training

Tel: +49 6188 787 48

Fax: +49 6188 787 87

Markus.pavelic@durr.com

France

Dürr Systems S.AS.

Address

Immeuble Gaia - 9 Parc Ariane

Boulevard des Chenes

78280 Guyancourt

France

Telephone

+33 1 81 88 01 40

Great Britain

Dürr Ltd

Address

Broxell Close

GB-Warwick

Warwickshire CV 34 5QF

Great Britain

Telephone

+44 1926 47 40 01

Italy

Verind S.p.A.

Address

Via Papa Giovanni XXIII 25/29

20090 Rodano, Milano

Italy

Page 44

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

44 / 46

Sweden

Dürr Systems Sweden

Address

Hängpilsg. 5

SE-42 677 Västra Frölunda

Sweden

Telephone

+46 31 29 28 20

Spain

Dürr Systems Spain S.A.

Address

C/Agricultura 39.Nave 30.Pol. Ind.

E-08840 Viladecans (Barcelona)

Spain

Russia

OOO Dürr Systems RUS

Address

Oruzheyny Lane 15A

125047 Moscow

Russia

Telephone

+7 495 741 00 51

Telefax

+7 495 741 00 52

E-Mail

durr@durr.msk.ru

America

Brazil

Dürr Brasil Ltda.

Address

CEP 04691-903

São Paulo - SP

Rua Arnaldo Magniccaro, 500

Brazil

Telephone

+55 11 56 33 35 54

Mexico

Dürr de México S.A. de C.V.

Address

Avenida La Noria, No. 168

Parque Industrial Querétaro

76220, Querétaro, Qro

México

Telephone

+52 442 192-57 12/-57 00

Page 45

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

45 / 46

USA

Dürr Systems, Inc.

Address

2469 Executive Hills Blvd.

Auburn Hills, MI 48326-2981

USA

Telephone

+1 248 74 58 50 02 12

Asia

China

Dürr Paintshop Systems Engineering

(Shanghai) Corp. Ltd.

Address

22-23F, Xingyuan Technology Building

418 Guiping Road, Shanghai, China 200233

China

Telephone

+86 21 62 19 37 19

India

Dürr India Pvt. Ltd.

Address

Srinivas Towers, II Floor, No. 5,

Cenotaph Road Teynampet,

Chennai - 600 018

India

Telephone

+91 124 40 75 56 4

Japan

Dürr Japan K.K.

Address

3-8-8 Nisso No. 16 Bldg.,

Shin-Yokohama, Kohoku-Ku,

Yokohama

222-0033 Japan

Telephone

+81 45 475 3671

Korea

Dürr Korea Inc.

Address

20/F, D-Cube City 662

Gyeongin-ro, Guro-gu

Seoul 152-888

Korea

Telephone

+82 25 69 22 44

Page 46

Operating Manual

© Dürr Systems GmbH

EcoGun AA MAN 2 P

Chyba! Pomocí karty Domů použijte u textu, který se má zde

zobrazit, styl Überschrift 1.

Version: 01 as of: 09/2014

46 / 46

Africa

South Africa

Dürr South Africa (Pty) Ltd.

Address

24 Worraker Street, Newton Park

Port Elizabeth 6045

South Africa

Telephone

+27 41 39 35 40 0

Document no.:

Version

as of

Released

Table of Contents

Loading...

Loading...