Page 1

II 2 GX

OPERATION MANUAL

EcoG

un

651

High-Pressure

Automatic Spraying Gun

This device is inTended for professional use. Before

commissioning The device please read This manual. in The

case of incorrecT use of The spray gun, serious injury To

The user or damage To The device may occur.

Page 2

Page 3

3

EcoGun 651

TABLE OF CONTENTS

SAFETY REGULATIONS 4

EQUIPMENT DESCRIPTION 5

TECHNICAL PARAMETERS 6

USE 7

COMMISSIONING 7

OPERATION 8

MAINTENANCE AND CLEANING 10

SAFETY OF OPERATION 12

TESTING OF PRODUCTS 12

PACKING OF PRODUCTS 12

DISPOSAL 12

WARRANTY TERMS 12

TROUBLESHOOTING 13

SPECIFICATION OF COMPONENTS - EST 651 14

DIAGRAM OF COMPONENTS OF THE GUN EST 651 15

DISPLAY OF COMPONENTS 16

DIMENSIONAL SKETCH 17

Page 4

4

EcoGun 651

SAFETY REGULATIONS

Earthing of the Equipment

Due to ow rate of the liquid at the high spraying pressure the

electro-static charge may be developed on the spraying gun under

certain circumstances. It may result in sparks of ames due to

discharging. To prevent this phenomena the spraying device must be

earthed. In addition the conductive connection (potential equalizing

cable) must be installed between the high-pressure device and the

gun during processing of the materials with the ignition point below

21°C (NITRO etc.).

Resistance to Pressure

All elements forming part of the high-pressure section of the

automatic spraying gun comply by their operating pressure with the

maximum pressure specied by the technical parameters.

Manipulation with High-Pressure Valve

The high-pressure gun operates with very high pressures.

Therefore never put your hand and/or ngers before the gun and

never focus the gun to the body. During assembly or disassembly of

the nozzle, resp. during cleaning or during any interruption of the

work proceed very carefully and secure the gun to prevent accidental

start (disconnection of the control air). This is to prevent accidental

start of the gun and possible subsequent injury.

Injury of Operator

The injury caused by the high-pressure liquid may be very serious.

In case of injury immediately seek the doctor and notify him/her on

type of material causing the injury.

Personal Protection at Work

During spraying and handling with the application materials, as

well as during cleaning of the equipment adhere to instructions of

manufacturers of the materials; use suitable personal protective

equipments (clothes, gloves, respirators, protection masks, resp.

breathing devices, protecting creams etc.) to protect the skin and

respiration tracts.

Although very small amount of fog is generated during the highpressure spraying, the spraying procedure cannot be considered for

the fog-free one. Even if the air contains very low number of the

particles, it is necessary to exhaust the solvent vapours, which are

especially dangerous.

Equipment Cleaning

During cleaning of the equipment with the ammable liquids it is

necessary to prevent the back-spraying into the closed vessel, as the

liquid stream can produce the explosive mixture of the gas and air.

Page 5

5

EcoGun 651

Workplace

Relevant standards apply to spraying and handling with the

ammable liquids. Regarding the ammability class of the coating

materials the areas and rooms, where the coating materials are

used, must be marked and modied in compliance with applicable

standards and regulations.

When the guns are used and operated in other countries, the

local standards and regulations apply.

EQUIPMENT DESCRIPTION

The automatic high-pressure spraying gun EcoGun 651 is designed

to application of the liquids by pressure supply. The gun consists

from two functional parts:

» Front part of the gun mechanical sections consists from stainless

coating substance (hereinafter referred to as NH) distribution

box with needle sealing to prevent leak of the pressure supplied

NH. The connecting angle-adjustable tting for the NH is tted

with the M14x1.5 thread. The second inlet of the NH is blinded

by the G1/8“ plug; when the plug is replaced with the NH

circulation line (not part of the supply), the NH circulation is

enabled (used for heavier NH etc.).

» The back part of the gun mechanical section consists from the

Duralumin body with pneumatic cylinder for opening (closing) of

the needle valve. The valve is opened by supply of the pressure

control air 5 bars before the piston by the 6 mm diameter hose.

Outlet of the pressure NH is closed by release of the air before

the piston to the atmosphere. The control air is separately

controlled by means of the three-way electro-magnetic valve.

In addition, the gun is tted with the holder with 10 mm hole for

xing to the handling device.

CAUTION

All workers assigned to operation and maintenance of the device must be

provably acquainted with the safety regulations and with the device operation

and maintenance manual!

Page 6

6

EcoGun 651

TECHNICAL PARAMETERS

Maximum gun power (acc. to the nozzle used) . 30 ÷ 250 l/h

Max. NH operating pressure .................................. 300 bar

Recommended control air pressure ............................5 bar

(Control) Air quality:

– Max. due point .....................................................+3°C

– Max. oil content ............................................. 25 mg/m

3

– Max. size of solid particles.................................... 40 μm

NH connecting thread size .................................. M 14x1,5

Control air connecting size (insertion coupling) ...................

.......................................... to connect the ø 6.0x4.0 hose

Max. gun control rate ........................... 3-times per second

Gun weight (without nozzle) ....................................563 g

Connecting threads in the gun body ......................... G 1/8“

Noise level .........................................................75 dB(A)

Ambient temperature ................................ +5°C až +40°C

Environment classication

Noise Level

The noise level depends on the nozzle system size and on the inlet

pressure value. The noise level of the gun reaches up to 75 dB(A).

Acc. to the act no. 272/2011 Coll., the maximum allowed noise level

is 85 dB(A).

II 2 GX

Page 7

7

EcoGun 651

USE

The automatic high-pressure spraying gun EcoGun 651 is intended

to surface treatment of the products by the high-pressure spraying

of commonly used NH, even the water-born materials. During the

work procedure, the sprayed material is atomized under the highpressure up to 300 bars. It can be used even for spraying of other

materials, which do not damage the spraying gun materials by their

composition. The gun is designed to remote control by the pressure

air controlled by the three-way electro-magnetic valve. It can be

used for all spraying devices of the VYZA type so-far produced in

Dürr Systems Czech Republic a.s., which do not exceed the HN max.

operating pressure. When other high-pressure devices are to be

used, the operation of the automatic gun must be consulted in the

manufacturing plant in advance. The gun is intended for equipment

of the automatic production lines and enables also interruption of

the spraying regarding the shape of the sprayed object and the

production line cycle. Combination of the high pressure of the NH and

the special high-pressure nozzle results in even layer of the applied

NH with minimum y-out of small particles to the environment. The

nozzle suitable for the particular application must be selected on

basis of previous tests and recommendation of the manufacturer.

COMMISSIONING

Before commissioning of the gun, the preservation grease must be

removed from the surface by suitable degreaser. Internal section

must be ushed out by the pressure solvent connected to the inlet

angle-adjustable tting for the NH and opening of the needle valve

with subsequent injection of the pressure control air 5 bar.

Upon cleaning the gun is tted with suitable high-pressure nozzle or

with the holder tted with the rotating nozzle. The nozzle is tted

directly to the cup nut with protecting cover, which forms part of

the gun; the rotating nozzle is xed to the holder, which is installed

directly to the gun upon screwing of the cup nut with protecting

cover.

The assembled gun is xed to the manipulator through the holder,

connected to the pressure control air 5 bar through the three-way

electromagnetic valve of ow ca 150 l/min. and the NH supply from

the high-pressure device; then tighten the cut nut on the NH angleadjustable tting. The hose must be electro-static conductive for

transport of the ammable liquids. In case of handling with the NH of

quicker sedimentation rate, which requires circulation, the circulation

high-pressure hose can be connected by unscrewing the plug in the

gun front section and tting of the NH circulation line (not part of the

supply). The general connection is done acc. to the wiring diagram.

Page 8

8

EcoGun 651

CAUTION

Relevant standards apply to spraying and handling with the ammable liquids.

Regarding the ammability class of the coating materials the areas and rooms,

where the coating materials are used, must be marked and modied in compliance

with applicable standards and regulations. The gun earthing is implemented via

the high-pressure hose from the equipment, however with application materials

of the ignition point below 21°C (NITRO etc.) or with materials, which are heated

to values exceeding the ignition temperature due to operational reasons, an

additional earthing is recommended by the potential equalizing cable (use the

metal conductor, optimally the steel rope of ø 5 mm, resp. copper wire min.

4 mm

2

).

OPERATION

1. The fault-free operation of the gun depends on preparation

of NH. Devote maximum care to mixing, treating to optimum

viscosity and ltration of the NH. Use of the proper solvent is

crucial for dilution of the NH and cleaning of the gun.

2. Select the nozzle type acc. to the shape and dimension of

the object, the NH type and viscosity (suitable nozzle can be

recommended by OTS of the manufacturing plant).

3. The optimum NH operation pressure is selected on basis of the

test spraying by the selected nozzle (onto the white paper), see

the high-pressure device operation manual. Selection of proper

operating pressure is crucial to the operation life of the gun,

and particularly the high-pressure nozzles. Do not exceed the

indispensable pressure!

4. If the nozzle hole is clogged, wash it in clean solvent and remove

the contaminants causing the clogging by the air jet. Cleaning of

the rotating nozzles is much simpler: remove the contaminants

by rotation and ushing and put the nozzle back to operation by

turning back. During cleaning or any manipulation do not turn

the gun against yourself or any other person, lock the supply of

the NH and pressure control air.

5. On long-term interruption of the work or when other type of

the NH us used, clean the gun internal section by pumping the

solvent applicable to the sprayed NH into the high-pressure

section instead of the NH. After approx. 5 minutes, when the

solvent dissolves the residual NH, ush the gun by pulses and

observe the solvent colour. When the solvent without traces of

formerly used starts to outlet, the gun is clean and ready for

other use.

6. Even on short-term interruption of the work, immerse the gun

neck, as well as the used nozzles, to the vessel with solvent.

Page 9

9

EcoGun 651

7. Daily on completion of works clean the gun and ush it acc. to

procedure specied in paragraph 5.

NH Filtration

Standard spraying gun is not tted with the NH lter, for proper

function is thus necessary to ensure perfect ltering of the application

material before inlet to the gun (e.g. F50 lter with the same

replaceable lter cartridge). Size of the lter cartridge in relation to

the nozzle equivalent size is specied in this reference table.

NOZZLE

EQUIVALENT SIZE

IN 0.1MM

FILTER SIEVE SIZE

MESH

USE

from 16 200 (74 µm) pickle, glazing, clear

lacquer, articial-resin

lacquer

25 - 30 100 (149 µm) primer, effect lacquer,

llers, marking paint

from 40 60 (250 µm) dispersion, latex,

acrylic paint,

polyurethane paint

Daily clean the lter and cartridges as needed, particularly on change

to other NH. Do not let the contaminated lter cartridge dry-up after

removal from the lter, as the NH residuals cannot be removed. The

cartridge must be immersed into proper solvent immediately after

removal from the lter.

The NH lter, which is installed directly to the angle-adjustable NH

tting on the gun, is optionally available. This lter is tted with the

MASCHEN sieve 200, 100 or 50. It is also possible to select the NH

tting thread size between M14x1.5 or G1/4“.

Page 10

10

EcoGun 651

MAINTENANCE AND CLEANING

1. Pressure air free of water, oil and mechanical impurities must be

used for the gun control.

2. Do not let the NH dry-up in the gun and/or surface. Removal of

the dry-up HN is difcult and it can result in damage of smooth

surface of the part and thus more difcult next cleaning (NH is

easy collected on the damaged surface). Cleaning must be done

by washing with proper solvent, not by immersion into the gun,

as it can adversely affect function and operation life of the gun.

3. When the high-pressure nozzle hole is clogged, do not clean it

by any metal objects, such as wires, pins, use instead special

cleaning wires, or clean the device acc. to instructions specied

in section „Operation“, point 4.

4. When the NH with rough pigments is sprayed, it is necessary to

check the sealing of the closing needle at least once in the shift;

the leak results in discharge of the NH from the hole between

front and back section of the gun body. When the NH leaks

from the hole, the gun must be disassembled and the sealing

module, resp. worn needle must be replaced.

» The replacing is performed as follows: Unscrew the body with

carbide seat (15). Unscrew the stop nut (10) from the back

section and remove the spring (7). With the supplied key

unscrew the closing needle (14), secure the opening needle (6)

by the key in the back section. Remove the opening needle

with the piston backward. Disassemble the 4 screws (11) and

separate the front section from the back one. Press the sealing

module (12) out by means of the supplied key. Upon cleaning of

the sealing module area the disassembly is completed. Visually

check the needle for damage in the contact area with the sealing

elements of the sealing modules, resp. replace the needle for

the new one. Assembly of the new sealing modules requires

skills and care to prevent cutting of both sealing O-rings of

the modules. Apply the machine oil to the module and press it

carefully completely into the gun body. Apply the machine oil

onto the needle with piston, insert it carefully from the back

side to both sealing modules - do not apply force. Assemble the

other parts in reverse order specied in the previous section.

5. Disassembly of the individual gun parts, even if it is easy, shall

not be performed often and needlessly. The assembly works can

be done with common maintenance tools and supplied special

key. Replacing of spare parts of the gun must be assigned

exclusively to the qualied maintenance staff.

6. Keep the gun and other accessory in perfect cleanness, as it is

crucial for fault-free operation.

Page 11

11

EcoGun 651

Important Rules for Fault-free Operation

» Cleanness of whole automatic gun and high-pressure nozzle.

» Properly treated control air (free of contaminants, water and oil).

» Filtered application material of proper viscosity - adhere to

instructions of manufacturers of the materials.

» Do not exceed necessary pressure for the NH atomizing in vain,

otherwise the operation life of the gun parts may be decreased.

» If the device was used for application of two-component substances

and materials of similar properties, only solvents recommended

by manufacturers of these substances can be used. Cleaning must

be performed always before expiration of the material pot life.

» On completion of work, the device should be regularly cleaned.

Compilation of regular cleaning and maintenance schedule is

recommended to ensure reliable function and life of the device.

CAUTION

Never put your ngers and/or hand to the spraying beam. The liquid pressure

can cause very severe injury with permanent damage of the skin.

Do not disassemble any part of the piston, when the device is pressurized!

Page 12

12

EcoGun 651

SAFETY OF OPERATION

The product complies with the regulations and standards applicable

to the product of this type.

All workers assigned to operation and maintenance of the device

must be provably acquainted with the safety and health protecting

regulations for work in painting shops and with the high-pressure

valve operation and maintenance manual.

The operating company must ensure training of the operators

and t the workers with specied personal protecting equipments.

Training, resp. supply of additional details, can be requested from

the device supplier.

TESTING OF PRODUCTS

» Each gun is subject to factory functional and pressure testing

PACKING OF PRODUCTS

» According to individual parts for delivery.

DISPOSAL

» After termination of the service life of the parts or the sprayer,

after cleaning the sprayer can be put into sorted waste.

» Packaging materials for the product (Catalogue number 200101,

see Regulation of the Ministry of the Environment No. 381/2001

Coll.) are liquidated as mixed communal waste. Put the used paper

package into a separate waste collection.

WARRANTY TERMS

» See Service Manual

No warranty is provided

» In the case of mechanical damage or incorrect handling of the

product.

» In the case of damage, wearing or failure caused by incorrect or

inadequate maintenance, abrasion, corrosion or the use of unstable

parts or materials.

» In the case of unpermitted and unprofessional intervention into the

device.

RELATED STANDARDS

EN ISO 12100, EN ISO 13732-1, EN 894-1+A1, EN ISO 4414, EN 1037+A1,

EN 1070, EN 1127-1, EN 13463-1, EN 60079-0, EN 60721-3-7, EN ISO 11204,

Page 13

13

EcoGun 651

» The warranty is not applicable for parts of a consumer nature, for

example, sealing elements, springs, jet with needle, stop valve and

the jet for which wearing depends on the abrasive properties of the

applied substance, pressure and other circumstances.

TROUBLESHOOTING

FAULT CAUSE REMEDY

Insufcient spraying

power

» Low pressure of

sprayed material

» Increase the pressure on the

pump

» Clogged lter cartridge

in the pump high-

pressure lter

» Clean, resp. replace the lter

cartridge

» Partially clogged

cartridge

» Clean, resp. replace the

cartridge

» Very small nozzle » Use larger nozzle

Bad spraying pattern

» Large nozzle » Select smaller nozzle

» Low pressure of

sprayed material

» Increase the material pressure

at the pump

» Low viscosity of

sprayed material

» Dilute the applied material

acc. to manufacturer's

instructions

Leak of the pressure NH

from sealing module

» Damaged sealing

module or needle

» Replace the sealing module

and needle for the new ones

Leak of pressure air

from sealing module

- spraying head

improperly opens

or closes at higher

pressure

» Damaged sealing

module or needle

» Replace the sealing module

and needle for the new ones

Page 14

14

EcoGun 651

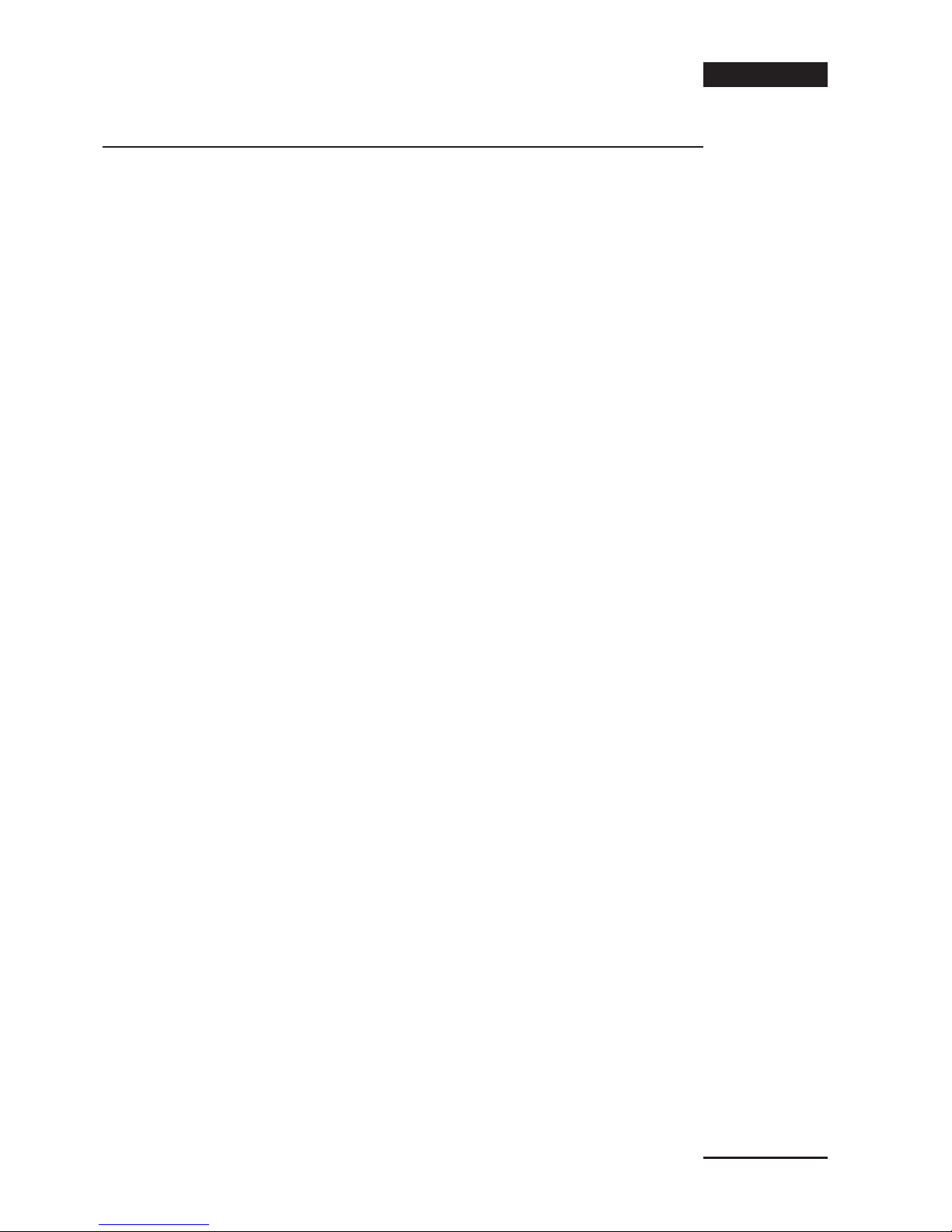

SPECIFICATION OF COMPONENTS - ECOGUN 651

POSITION NAME IDENTIFICATION NO. QUANTITY

1 NH body 651

Not supplied as spare

part

—

2 Air body 651 —

3 Rotating nozzle

Acc. to nozzle table

—

4 Nozzle —

5 Sealing 7

832 577

1

6 O-ring 11x1.8 105 028 1

7 Piston 651 807 404 1

8 Opening needle 651 907 406 1

9 Spring 813 656 1

10 Stop element MIX 805 083 1

11 Stop body 807 504 1

12 Stop nut 807 405 1

13 Screw M 4x20 114 142 4

14 O-ring 11x1.8 105 150 1

15 Sealing module 656 907 367 1

16 Sealing 807 380 2

17 Plug G 1/8“ 807 497 1

18 Fitting G 1/8“; M 14x1.5 807 379 1

19 Angle-adjustable tting 129 026 1

20 Angular coupling 131 017 1

21 Holder 807 494 1

22 NH circulation line 907 508 1

23 Closing needle S 906 896 1

24 Closing needle B 906 985 1

25 Body 1,5 S 907 511 1

26 Body 2,5 B 907 714 1

27 Sealing 135 008 1

28 Nozzle holder Exit 301 001 1

29 Fixing nut with protecting orice 134 003 1

ACCESSORIES SUPPLIED wITH DEVICE

Universal key 806 697 1

Assembly key 906 699 1

Allen wrench 3 152 011 1

Allen wrench 5 152 021 1

Test-tube brush 139 100 1

Page 15

15

EcoGun 651

ILLUSTRATIONS OF THE GUN ECOGUN 651

15

16

17

20

13

13

1

2

5

6

7

8

25

23

26

24

9

10

11

12

29

4

27

3

16

18

19

28

14

21

22

Page 16

16

EcoGun 651

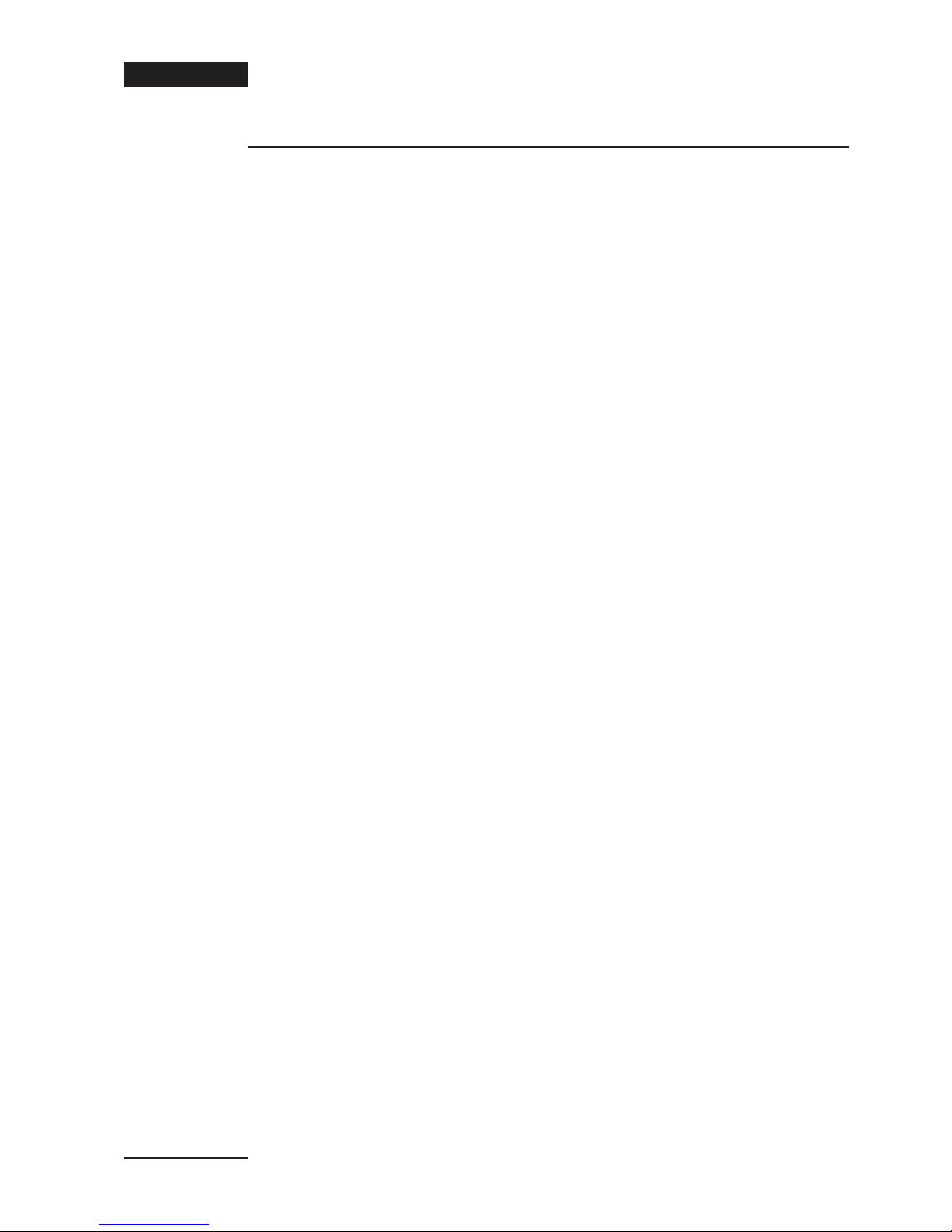

DISPLAY OF COMPONENTS

96

162

2,5

81

40

82,5

29

10

40

161

80

2,5

Page 17

17

EcoGun 651

DIMENSIONAL SKETCH

1. High-Pressure Gun EcoGun 651

2. Electro-Magnetic Valve for Control Air 3/2

3. Air Pressure Regulator

Page 18

18

EcoGun 651

Page 19

19

EcoGun 651

Page 20

2014 Dürr Systems Czech Republic a.s., Ledeč nad Sázavou

Dürr Systems Czech Republic a.s.,| Podolí 1237 | 584 01 Ledeč nad Sázavou |

Czech Republic

Tel.: +420 569 726 094 | Fax: +420 569 726 096 | E-mail: info.cz@durr.com

www.durr.com

www.durr-cz.cz

N02.035 GB

rev: 03

2014/10

WARRANTY CARD

TiTle and Type of producT producTion numBer

ouTpuT check producTion daTe dispaTch

sTamp and signaTure daTe of sale

Warranty Servicing Activity

Responsibility for potential defects is driven by Czech Civil Code No. 89/2012.

The warranty period for the products of the Dürr Systems Czech Republic a.s.

company is 36 months from the date of agreed sale supply, if not agreed otherwise in

the business contract. The warranty period is extended in case of an acknowledged

complaint by the time of arguable shutdown of the equipment, generally by the

time between the reporting of the defect and its due removal.

In case of application of an acknowledgeable defect, whose removal would

signicantly exceed the agreed deadline, the interested party can ask for free

lending of spare equipment for the necessary time.

The warranty does not apply to:

» Parts and materials of regular operating consumption stated in the documentation

supplied with the product and parts, whose life span is adequate to application

conditions;

» Defects arisen by inexpert use and maintenance of the product in conict with the

recommendations stated in the operating and maintenance manual;

» Defects arisen for reason of own modications of the equipment and use of

materials and parts that were not approved by the manufacturer for the operation

of the equipment.

EcoGun 651

Loading...

Loading...