Page 1

II 2 GX

OPERATION MANUAL

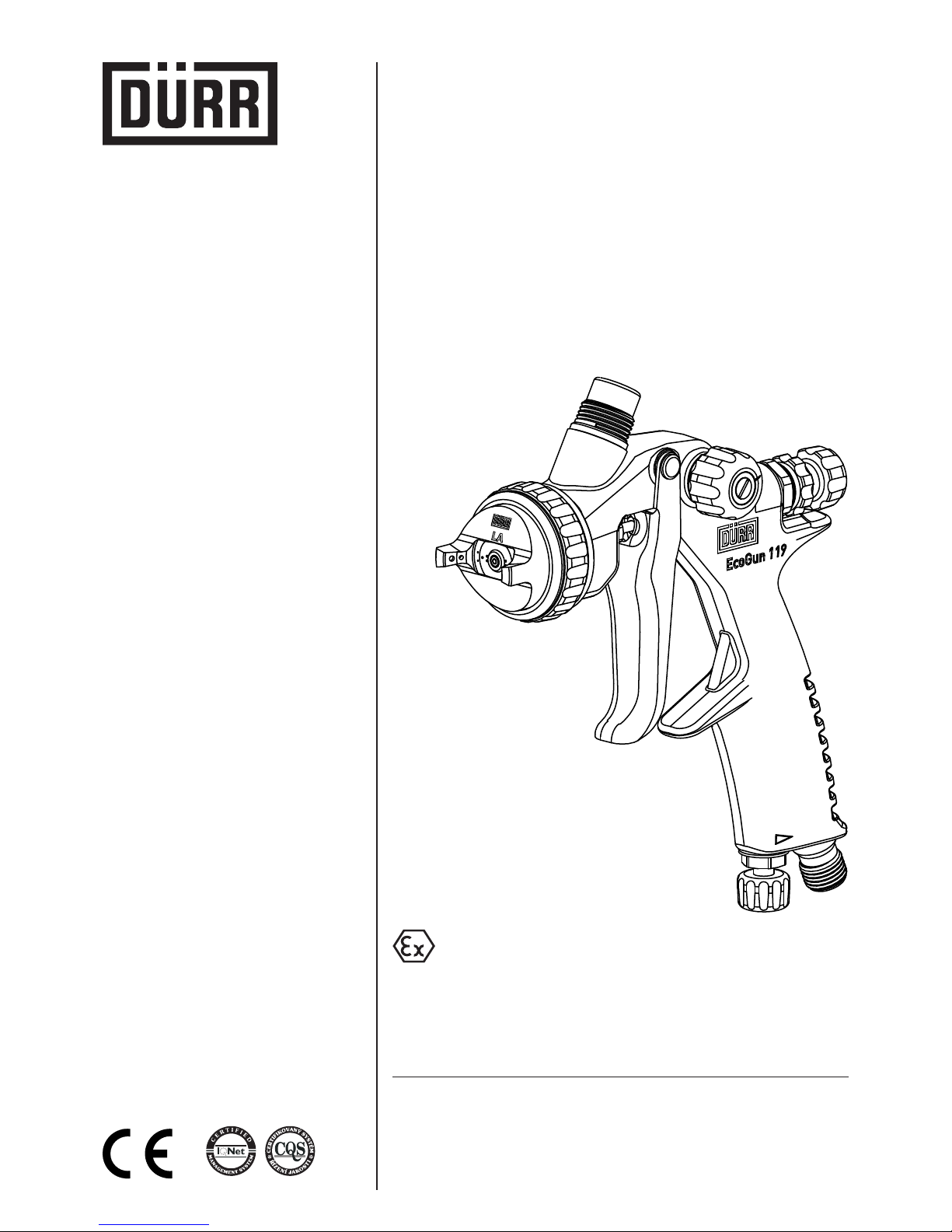

EcoG

un

119

air spray gun

These spray guns have been engineered for professional

use. read and undersTand This operaTion manual before

operaTing, doing any service or mainTenance procedure.

incorrecT use may resulT in serious personal injury or

damage To The spray gun.

Page 2

Page 3

3

EcoGun 119

CONTENTS

SAFETY REGULATIONS 5

Vibrations and noise 5

Work with gun 5

Personal protection during work 6

EQUIPMENT USE AND DESCRIPTION 6

EcoGun 119 spraying gun 6

Air path - used material 6

Coating material path - used material 7

Advantages of new gun 7

TECHNICAL PARAMETERS 8

COMMISSIONING 9

Options for coating material supply 9

Direct connection of air quick-couplings to the gun 9

ADJUSTING OF GUN 9

Advance timing adjustment 9

OPERATION 9

Control of coating material amount 10

Control of spray shape 10

Control of air supply to gun 10

Replacement of needle gland 11

Replacement of air valve sealing 11

MAINTENANCE AND CLEANING 13

Cleaning and maintemamce principles 13

Important principles for high-quality function 14

GUN VARIANT 15

Gravity Cup 600 ml G 3/8“ 15

Other optional accesssory 15

OPERATION SAFETY 16

PRODUCT TESTING 16

PRODUCT PACKING 16

DISPOSAL 16

WARRANTY TERMS 17

The warranty is not provided 17

COMBINATIONS OF NOZZLE SETS 17

SPECIFICATION OF COMPONENTS 18

Page 4

4

EcoGun 119

Illustration 19

Accessory delivered with device 20

Air valve set - ident. number 906 552 20

Needle sealing set - ident. number 906 765 21

TROUBLESHOOTING 22

Page 5

5

EcoGun 119

SAFETY REGULATIONS

Appropriate standards apply to spraying and handling with

ammable liquids. Areas and rooms, where coating materials

are handled with, shall be identied and adapted regarding the

ammability of the coating materials in compliance with applicable

standards and regulations.

In case the spraying guns are used and operated in other countries,

then relevant national standards and regulations apply.

Electrostatic charge (electricity) can occur under certain

circumstances due to ow of air and liquids. During discharge it may

result in sparking and/or aming.

To prevent such situation it is necessary to use hoses with

guaranteed electrostatic drop-in particularly for coating materials

with ignition point below 21°C (nitro-, acetone coating materials

etc.) and some coating materials of 2nd ammability class preheated

to higher temperature - it is necessary to ensure certied hoses with

such identication.

Vibrations and noise

The vibration level transferred to hands does not exceed maximum

allowed value acc. to NV 272/2011 Coll.

The noise level depends on size of nozzle system and on input

pressure value, which ranges from 80 to 90 dB(A). Allowed permitted

nose level acc. to act no. 272/2011 Coll. is 85 dB(A) and thus it is

necessary to use hearing protection equipments.

Work With gun

SThe spraying gun operates with pressure to 4 bar, air pressure

- recommended 1,8-2,5 bar. Do not focus the gun to yourself, other

persons or animals. Solvents and thinners may cause chemical burn.

During nozzle assembly, disassembly, cleaning or each interruption

of work proceed very carefully and ensure locking of the gun to

prevent eventual starting. Thus you may prevent the injury. Before

all repair works the gun shall be disconnected from pressure air

supply.

CAUTION

Do not use the basic variants of the guns for solvents from chlorohydrocarbon

family, as e.g. 1.1.1. trichlorethan and metylchloride may cause chemical

reaction with aluminium and with galvanized, resp. zinc-coated parts and thus

create explosive mixture with eventual explosion effect.

CAUTION

All persons authorised to operation ad maintenance of the equipment must be

provably acquainted with the safety regulations and with the operation and

maintenance manual for the equipment.

Page 6

6

EcoGun 119

Personal Protection during Work

During spraying and handling with the application materials

and during cleaning of the equipment follow instructions and

recommendation of manufacturers of particular materials. Use

suitable work protection aids to protect skin, respiratory tract and

eyes (clothes, gloves, respirators protecting masks, resp. breathing

apparatuses, goggles, protection creams etc.).

EQUIPMENT USE AND DESCRIPTION

EcoGun 119 air spraying gun is a gun allowing connection of

top vessel (gravity supply of coating material).

Atomising system with decreased pressure of atomising air at the

gun jet mouth, similar to RP system.

The gun features very good grip and balance in hand, as well

as easy less wearisome handling. Assembly threads of connecting

elements are glued with suitable sealing compound (LOCTITE 542).

The spraying gun can handle all types of coating materials,

which are intended to application by spraying, and whose chemical

composition does not disturb the spraying gun components.

Recommended distance of nozzle mouth to the sprayed surface

(spraying distance) depends on side of nozzle assembly and type of

coating material, it ranges from 150 to 190 mm.

Semi-automatic needle seal ensures maximum period

of maintenance-free and reliable operation of the seal.

Mechanical re-tightening of the needle seal enables increased

interval between service repairs. The system joints advantages

of automatic and mechanical design of the needle seal retightening.

ecogun 119 sPraying gun

This type of the gun can handle following types of the coating

materials:

Solvent-based – synthetic, nitro, acetone, polyurethane, epoxy

and acrylic, primers, llers and nish varnishes

Water-based – acrylic, silicate, silicone and polyurethane

substances

and other application materials of similar properties.

Work environment IE 72 acc. to EN 60721-3-7.

air Path - used material

Gun body Al alloy with Ni surface layer

Sealing elements POM, PE, PTFE

Parts Stainless steel, brass

Page 7

7

EcoGun 119

coating material Path - used material

Gun body Al alloy with Ni surface layer

Sealing elements PTFE, POM

Parts Stainless steel AISI 304, brass with Ni surface

layer

adVantages of neW gun

» Progressive design and ergonomic shape of the gun body guarantee

very good grip

» Extremely light gun of weight only 487 g

» High transfer efciency exceeding legislative requirements related

to the environment

» New atomising system with decreased atomising output pressure

at the jet mouth, high atomisation neness and beam distribution

quality

» New series of modernized nozzle assemblies

» New ergonomic control elements of completely totally new design

» Normally supplied nozzle assemblies featuring perfect tightness

» Special gun body surface treatment guarantees perfect cleanability

» sGun body sealing system made from very resistant materials

guarantees resistance against cleaning in washing machines

» New PTFE sealing elements

» Semi-automatic gland increasing operation life

» High resistance against solvents

» High inspection level of each product

Page 8

8

EcoGun 119

TECHNICAL PARAMETERS

Maximum allowed input air overpressure ....................4 bar

Operating air pressure - recommended* ............ 1,8-2,5 bar

Air consumption* (LA, LW) .......................250-300 Nl.min

-1

Air consumption* (LH) .............................300-400 Nl.min

-1

Power range of sprayed coating material* ..... 40-680 g.min

-1

Spraying distance * .......................................150-190 mm

Air quality:

– Max. dew point .....................................................+3°C

– Max. oil content ............................................... 1 mg/m

3

– Max. size of solid particles......................................5 μm

– Max. temperature ...............................................+40°C

Gun weight ............................................................487 g

Connecting sizes

– Air supply ..........................................................G 1/4“

– Supply of coating material ...................................G 3/8“

Environment classication

* It depends on size of nozzle assembly and type of application

material

II 2 GX

Page 9

9

EcoGun 119

COMMISSIONING

Before commissioning the gun must be cleaned from preservative

substances by suitable degreasing agent – ush the gun with solvent

suitable for the coating material to be applied.

The gun is factory adjusted and prime-sprayed (quality

test).

Pressure air is to be supplied through following hose:

» up to 10 meters -nominal inner diameter 8 mm

» over 10 meters - nominal inner diameter 9,5 mm

oPtions for coating material suPPly

EcoGun 119 model spraying gun features following supply

options:

– Upper supply for gravity cup 600 ml with thread G 3/8“

direct connection of air quick-couPlings to the gun

The gun design enables connection of air quick-couplings to the

gun. The air input tting may house the quick-coupling mandrel,

e.g. type 26 SFIW 13 from RECTUS.

The manufacturer recommends to use brand quick-couplings

with low pressure loss and long operating life.

The quick-couplings may be used to the air inlet only

during application of water-based coating materials, which

do not require electro-static drop-in.

ADJUSTING OF GUN

The gun does not require any adjustment, when basic maintenance

requirements are followed. Each gun is factory adjusted and primespayed. Upon disassembly and reassembly due to replacement of

the nozzle assembly or worn components it is necessary to inspect

adjustment of following elements.

adVance timing adjustment

» Start of air before opening of coating material outlet

Reproduction of Dürr Systems Czech Republic component quality

ensures that the advance timing is permanently set during common

replacement of the nozzle set and d not require any adjustment.

» Needle gland is tightened semi-automatically with possible

manual tightening.

OPERATION

Important prerequisite of the high-quality proper function is

proper maintenance. The gun is designed in such manner that the

requirements may be easily adhered to.

Page 10

10

EcoGun 119

The nozzle assemblies are made from stainless steel AISI 304 and

they are delivered as spare parts as complete nozzle with needle. To

achieve high-quality spraying it is necessary to take care of cleanness

of the nozzle assembly, prevention of nozzle neck damage, cleanness

and integrity of very precise holes in the air jet. Upon replacing or

cleaning of the nozzle it shall be properly tightened to make it tight.

Recommended torque on the nozzle is 10 Nm.

The gun is factory adjusted and prime-sprayed (quality test).

control of coating material amount

This regulation restricts the lift of the

needle which throttles the ow of material

in the nozzle. By loosening the locking

nut (35) and subsequently turning the

stop screw (20), the lift of the needle and

the volume the material is changed. After

reaching the disered lift of the locking nut

(35), tighten it again. We recommend

using this method only temporarily. A

more suitable manner is to select a smaller

nozzle set or reducing the pressure of

the sprayed air (if it will not reduce the

quality of the spraying). Fully tightening

of the stop bolt will prevent the lift of the needle and any undesired

spraying during handling.

control of sPray shaPe

Air runs out of the wing holes in the air

jet and the air widens the beam shape.

Its amount is controlled by turning of the

control wheel. Left-side turning increases

supplied air amount and enlarges the

beam.

control of air suPPly to gun

This control (7) is located on the gun

butt and enables throttling the air supply

amount to gun and thus the operator can

decrease the air amount for spraying, resp.

completely stop the supply, without any

handling on the air control in distribution

lines.

Page 11

11

EcoGun 119

REPLACEMENT OF THE NOZZLE SET

After dismantling the stop bolt (20) and the securing nut (35),

remove the spring of the needle (18) with the bearing of the needle

(19) and the needle (2). For easier handling, press the lever which

will suppress the needle from the rear part of the gun. Remove

the nozzle from the front part of the gun by unscrewing (1).

Dismantle the nozzle from the gun by the attached wrench (41).

Before assembly of a new nozzle set, it is recommended to clean

the assembly areas. Attach the new nozzle and fully tighten. The

recommended tightening moment on the nozzle is 10 Nm. Behind

the gun, insert the needle with spring and bearing, and replace the

locking nut, bolt stop and nozzle.

rePlacement of needle gland

Upon any leakage it is necessary to re-tighten the gland (9) by

the gland screw (12) by clockwise rotation of the screw to condition,

where the gland is again tight. In case the gland screw cannot rotate

and the gland still leaks, the gland shall be replaced for a new one.

Unscrew the gland screw (12) and remove the old gland assembly.

Before installation o new gland clean the gland area. Insert new

gland (9), spring guide (10) and gland spring (11) from the needle

sealing set. Tighten the gland screw to ensure proper tightness of

the gland.

rePlacement of air ValVe sealing

» Disassembly: Disassemble the end stop screw (20) and

locking nut (38) with spring (18), bearing (19) and needle (2).

Use wrench (41) to disassemble the control bushing (17) with

spring (16) from the gun. Press lever to insert the pin (15)

to the gun, and then remove it. Insert to the gun assembly

key (42), insert the mandrel assembly (38) from the air valve

set, insert needle to the mandrel and press lever to press out

the seal roller (13) from the gun. Seal will remain on the key

assembly (42), which then pull out from the gun.

9

10

11

12

Page 12

12

EcoGun 119

Use the assembly mandrel to press out the sealing U1 from

removed control bushing. Insert the mandrel (38) to the control

bushing and screw-in the end stop screw (20) to press the

sealing (13) out of the control bushing.

» Assembly: Insert the new sealing U1 (13) from the air valve

set to the assembly wrench (42) and tap it to the gun body.

Similarly insert the sealing U1 into disassembled control

bushing.

» Insert new pin (15) from the set to body, screw-in the spring

with control bushing to the body, insert needle and screw-in

the end stop screw with spring and spring bearing.

We recommend to leave repairs to the authorised service cent-

re, see service manual.

42

1334

2

423438

13

38

20

Page 13

13

EcoGun 119

MAINTENANCE AND CLEANING

cleaning and maintemamce PrinciPles

» Prevent drying of the COATING material in the gun or on the

surface. Its removal (when dried) is difcult and may result in

damage of smooth surface.

» Clean the holes in the nozzle assembly very carefully, as this is the

most important part affecting the spraying quality.

» During CLEANING of the gun front part keep the gun with nozzle

directing downward. Thus the entry of solvent with residues of the

coating material to gun air channels is prevented, as well as

subsequent damage to the gun function. After each cleaning

connect the gun to the pressure air supply and blow out the ai

channels by actuation of lever..

» As NEEDED after cleaning grease the level bushing (27), operational

part of the control screw (21) and threads of control screws with

suitable grease (MOLYKOTE Cu 7439).

» The gun is washed in appropriate solvent corresponding to type

of sprayed coating material. The gun can be washed in the gun

washing machine. However never immerse the gun to solvent and

prevent long-term stay of gun in the solvent vapour area.

» Regularly clean the sieves in vessels or in entry tting of the gun

coating MATERIAL.

CAUTION

Do not use any metal items for cleaning!!!

ředidlo

Connect

pressured air

1

Blow through

2

Page 14

14

EcoGun 119

imPortant PrinciPles for high-quality function

» Proper choice of the assembly nozzle acc. to type of the coating

material and size of the object (if you have any special requirements

please contact the sales-technical depts. of the manufacturer).

» Properly treated air for spraying (free of dirt, water and oil –

perfectly ltered).

» Filtered coating material of correct viscosity and free of dirt (follow

and adhere to the instructions of the manufacturers of particular

coating materials).

» Properly prepared (cleaned and maintained) spraying gun.

» Adhere to the recommended air pressure for atomising.

Page 15

15

EcoGun 119

GUN VARIANT

graVity cuP 600 ml g 3/8“

Plastic cup of volume 600 ml. Normally assembled cup shall ensure

reliable sealing with tting on the gun. The tting (31) houses the

factory inserted lter (32), which shall be removed during cleaning

and ushing of the gun to enable proper washing of the lter and

inlet tting. Before further using of the cup do not forget to insert the

clean lter back into the tting.

other oPtional accesssory

» Pressure control with separator

» Air contaminant separator

» Hose quick-couplings

» Hoses

» Compressor

» Personal protection equipments

Page 16

16

EcoGun 119

OPERATION SAFETY

The product complies with regulations ad standards related to the

products of such nature.

All employees authorised with operation and maintenance

of the equipment shall be provably acquainted with safety

and health regulations for work in paint shops and with the

spraying gun operating and maintenance manual.

The operators shall perform training of the personnel and provide

them with specied personal protecting equipments. Training, resp.

more detailed information can provide the equipment supplier upon

request.

PRODUCT TESTING

» Each piece of equipments is subject to factory functional and

pressure testing.

PRODUCT PACKING

» Depends on individual parts of the delivery.

DISPOSAL

» On expiration of the components, resp. gun operation life it may

be disposed to the sorted waste material upon cleaning.

» The packing materials of the product (cat. no. 200101, see Decree

of the Environment Protection Ministry no. 381/2001 Coll.) shall be

disposed as mixed municipal waste. Used paper packing dispose

to the separate waste material.

RELATED STANDARDS

EN ISO 12100, EN ISO 13732+A2,

EN 894, EN ISO 4414, EN 1037, EN 1070, EN 1127-1, EN 13463-1,

EN 60079-0,

EN 60721-3-7/A1, EN ISO 11204,

Page 17

17

EcoGun 119

WARRANTY TERMS

» see service manual

the Warranty is not ProVided

» For mechanical damage of rough handling with the product.

» For damage, wearing or fault caused by improper or non-adequate

maintenance, abrasion, corrosion or use of non-original spare

parts, components and materials.

» For non-allowed or non-professional intervention on the device.

» The warranty does not apply to easily worn components, such as

sealing elements, springs and nozzle with needle, at which the

wearing depends on abrasive properties of the applied materials,

pressure and other circumstances.

COMBINATIONS OF NOZZLE SETS

air caP nozzle assembly

tyPe identification no. tyPe identification no.

LA 908 385

12L 908 395

13L 908 396

14L 908 397

16L 908 398

LH 908 386

12L 908 395

13L 908 396

14L 908 397

16L 908 398

LW 908 387

12L 908 395

13L 908 396

14L 908 397

16L 908 398

LA - top coatings

LH - HVLP

LW - water born paints

Nozzle set consists of nozzle with distribution plug and needle

Page 18

18

EcoGun 119

SPECIFICATION OF COMPONENTS

Position name identification no. quantity

1 Air Cap Specied in table

„Combinations of

Nozzle Sets“

1

2 Nozzle Set 1

3 Body EcoGun 119 Not supplied —

4 O-ring 33.3 x 1.6 105 081 1

5 O-ring 105 173

6 Air Fitting 808 378 1

7 Air Supply Control 908 374 1

8 O-ring 105 031 1

9 Gland 70° 806 674 1

10 Spring Quide 806 675 1

11 Gland Spring 804 290 1

12 Gland Screw 806 466 1

13 Sealing U1 135 016 1

14 Piston Seat 135 017 1

15 Spindle

907 722

1

16 Spindle Spring

124 082

1

17 Bushing L 808 095 1

18 Pressing Spring 124 089 1

19 Bearing L 808 097 1

20 End Stop Screw

808 096

1

21 Control Screw 808 380 1

22 Sealing 806 948 1

23 Control Bushing 808 379 1

24 Control Wheel 806 464 1

25 Ring Set

906 439

1

26 Screw 114 247 1

27 Trigger pin 808 377 1

28 Ring 3,2 117 017 1

29 Trigger 806 510 1

30 O-ring

105 153

1

31 HP Fitting

806 556

1

32 Filter Set 906 499 1

33 Gravity Cup 600 ml 908 382 1

34 Sealing of the roller 135 002 1

35 Locking nut 807 709 1

Page 19

19

EcoGun 119

illustration

Eco

Gun 119

26

25

24

23

22

21

2

18

19

20

17

13

16

15

14

34

33

30

32

31

3

4

2

1

9

10

11

27

7

29

6

12

28

8

5

35

Page 20

20

EcoGun 119

accessory deliVered With deVice

Position name identification no. quantity

40 Allen Key Size 7 152 019 1

41 Universal Wrench 806 697 1

42 Assembly Wrench 806 698 1

43 Cleaning Brush 139 100 1

44 Gun Hook 904 599 1

45 Sealing 807 708 1

46 Insert 128 670 1

47 Assembly Rod 907 520 1

25 Ring Set 906 439 1

air ValVe set - ident. number 906 552

Position name identification no. quantity

13 Sealing U1 135 016 1

15 Spindle 906 561 1

34 Sealing of the roller 135 002

38 Assembly Mandrel 806 403 1

34 15 13

38

25

46

42 40

43 41

44

45

47

Page 21

21

EcoGun 119

needle sealing set - ident. number 906 765

Position name identification no. quantity

9 Gland 70° 806 674 1

10 Spring Quide 806 675 1

11 Gland Spring 804 290 1

12 Gland Screw 806 466 1

9

10

11

12

Page 22

22

EcoGun 119

TROUBLESHOOTING

fault cause remedy

The gun does not

spray or spray

intermittently

air released from nozzle

» Empty cup for coating material » Add coating material -

supply

» Loose nozzle in gun body » Properly tighten the nozzle

» Damaged gland in gun body » Replace the gland

» Nozzle hole clogged » Clean

» Coating material amount

control closed

» Set control

» Loosen cup » Properly tighten

no air from jet

» Closed air supply

» Closed air supply control

» Open supply

» Open air control on gun

Resulting spray

curved or clubbed

» Dirt in annular section of jet

and nozzle

» Remove dirt, do not damage

jet

» Damaged jet hole or nozzle

neck

» Replace for a new one

» Dirt in wing or auxiliary holes » Clean, do not damage the

holes

» Improperly tightened jet » Properly tighten the jet

Resulting spray

features little colour

in the middle

» To much air to wings » Set proper amount by

control of spray width

» High air pressure for spraying » Decrease the air pressure

» Low viscosity of coating

material

» Adjust viscosity acc. to

manufacturer instructions

Low atness of

resulting spray

» Low amount of air to wings » Set higher amount by

control of spray width

» Low air pressure for spraying » Increase pressure

» High viscosity » Properly adjust and measure

with viscosimeter

Page 23

23

EcoGun 119

Page 24

www.durr.com

www.durr-cz.cz

© 2014 Dürr Systems Czech Republic a.s. ., Ledeč nad Sázavou

Dürr Systems Czech Republic a.s.

Podolí 1237 | 584 01 Ledeč nad Sázavou | Czech Republic

Tel.: +420 569 726 094 | Fax: +420 569 726 096 | E-mail: info.cz@durr.com

N01.057 GB

rev: 01

2014/9

WARRANTY CARD

TiTle and Type of producT producTion number

ouTpuT check producTion daTe dispaTch

sTamp and signaTure daTe of sale

Warranty Servicing Activity

Responsibility for potential defects is driven by Czech Civil Code No. 89/2012.

The warranty period for the products of the Dürr Systems Czech Republic

company is 36 months from the date of agreed sale supply, if not agreed

otherwise in the business contract. The warranty period is extended in case of

an acknowledged complaint by the time of arguable shutdown of the equipment,

generally by the time between the reporting of the defect and its due removal.

In case of application of an acknowledgeable defect, whose removal would

signicantly exceed the agreed deadline, the interested party can ask for free

lending of spare equipment for the necessary time.

The warranty does not apply to:

» Parts and materials of regular operating consumption stated in the documentation

supplied with the product and parts, whose life span is adequate to application

conditions;

» Defects arisen by inexpert use and maintenance of the product in conict with

the recommendations stated in the operating and maintenance manual;

» Defects arisen for reason of own modications of the equipment and use

of materials and parts that were not approved by the manufacturer for the

operation of the equipment.

EcoGun 119

Loading...

Loading...