Page 1

INDEX

Important Information

1. Notes ...................................................... 30

1.1 CE - Labelling ................................. 30

1.2 Guidelines .......................................30

1.3 General Notes ................................. 30

1.4 General Safety Notes ..................... 30

1.5 Electrical Safety Notes ...................31

1.6 Warnings and Symbols..................31

2. Product Information ............................ 32

2.1 Correct Usage ................................ 32

2.2 Use other than that for the

intended purpose ........................... 32

2.3 Product description ........................ 32

3. Delivery Contents ................................. 33

3.1 Special Accessories ....................... 33

3.2 Disposable material ........................ 33

4. Technical Data ...................................... 34

5. Function ................................................ 36

6. Functional Description ....................... 37

6.1 Compressor .................................... 37

6.2 Control unit with pressure switch ... 37

Installation

7. Storage and

transport requirements ....................... 38

8. Requirements for Set-up .................... 39

8.1 Environmental Requirements ......... 39

8.2 Compressed Air Connection .........40

8.3 Electrical connection ....................... 41

8.4 Pressure switch check and setting42

8.5 Motor circuit breaker adjustment ... 42

8.6 Commissioning ............................... 43

8.7 Draining off condensed water .......43

9. Repairs and Maintenance ................... 44

9.1 Draining off condensed water .......44

9.2 Safety valve .................................... 44

9.3 Filter change ................................... 44

10. Circuit Diagram ..................................... 45

Use

11. Operation............................................... 47

11.1 Turning on the compressor ............ 47

12. Maintenance .......................................... 48

12.1Pressure reducer (accessory) ...... 48

12.2Adjusting the pressure reducer ....48

12.3 Draining off condensed water ....... 48

12.4Safety valve ....................................49

12.5 Filter change ................................... 49

13. Maintenance intervals - Operator /

Technician ............................................. 50

14. Decommissioning ................................ 50

Trouble-shooting

15. Tips for Technicians ............................ 51

16. Tips for Operators ................................ 53

Disposal

17. Disposal of appliance .......................... 54

Parts list

Compressor 51../52.. ............................. 56-62

29

Page 2

IMPORTANT INFORMATION

1. NOTES

1.1 CE - Labelling

CE-Symbol of conformity. This symbol of

conformity guarantees that this appliance

conforms to the relevant safety guidelines of

the European Union.

1.2 Guidelines

This appliance conforms to the following

safety guidelines:

• Machine guidelines 98/37EG, with

amendments.

• Electro-magnetic Compatibility 89/336/

EWG, with amendments.

• Low-voltage guidelines 73/23/EWG, with

amendments.

• Pressure vessel guidelines 87/404/EWG.

1.3 General Notes

• These Installation and Operating

Instructions form an integral part of the unit.

They must be kept close to the unit and in

readiness whenever required. Precise

observance of these instructions is a precondition for use of the unit for the intended

purpose and for its correct operation.

Die Montage- und Gebrauchsanweisung

sollte gegebenenfalls an Nachfolger weiter

gegeben werden.

• Safety for the operator as well as troublefree operation of the unit are only ensured if

use is made of original equipment parts.

Moreover, use may only be made of those

accessories that are specified in the

technical documentation or that have been

expressly approved and released by Dürr

Dental for the intended purpose.

Dürr Dental cannot guarantee for the safety

or proper functioning of this unit in the case

where parts or accessories are used which

are not supplied by Dürr Dental.

• The guarantee does not cover damage to

caused to this unit where parts or

accessories are used which are not

supplied by Dürr Dental.

30

• The guarantee is valid for 1 year

commencing from the date of delivery. Any

work performed under guarantee will

neither extend nor renew the guarantee.

• Dürr Dental only regard themselves as

being responsible for the equipment with

regard to safety, reliability and proper

functioning if assembly, resettings,

changes or modifications, extensions and

repairs have been carried out by Dürr

Dental or an agency authorised by Dürr

Dental and if the equipment is used in

conformity with the Installation and

Operating Instructions.

• These Installation and Operating

Instructions conform to the relevant version

of the equipment and the underlying safety

standards valid at the time of going to

press. All switches, processes, trade

marks, software programs and appliances

named in this document are registered

names.

• Any reprinting of the technical

documentation, in whole or in part, is

subject to prior approval of Dürr Dental

being given in writing.

1.4 General Safety Notes

This compressor has been designed and

constructed by Dürr Dental so that correct

usage of the appliance is virtually free of any

possible injury or danger. In spite of this, we

feel it is our duty to mention the following

safety measures in order to prevent any

possible danger to all personnel.

• When using this compressor all local and

relevant regulations must be observed! In

the interests of trouble-free operation the

operator is responsible for observing

these regulations.

• Retain the packaging for possible return of

the product to the manufacturers. Ensure

that the packaging is kept out of the reach

of children. Only the original packaging

provides adequate protection during

transport of the unit.

Should return of the product to the

manufacturers be necessary during the

guarantee period, Dürr Dental accepts no

responsibility for damage occurring during

transport where the original packaging

was not used!

Page 3

• Before every use the operator must check

the functional safety and the condition of

the appliance.

• The operator must be knowledgeable in the

operation of the appliance.

• The product is not designed to be used in

medical treatment areas where there exists

the danger of explosion. Areas where

explosions could occur are those where

flammable anesthetic material, skin

cleansers, oxygen and skin disinfectants

are present. This appliance is not to be

used in areas where the atmosphere could

cause fire.

1.5 Electrical Safety Notes

• The compressor may only be connected to

an earthed safety socket or CEE-socket,

depending on model of compressor.

• Before connecting the appliance to the

power supply check that the electrical

current and the frequency of the device as

described on the appliance are compatible

with that of the power supply.

• Check the appliance and the power supply

cables for possible damage before

switching on. Damaged cables, plugs and

sockets must be replaced before use.

• In danger situations or in cases of technical

defect immediately separate from the

power supply (unplug).

• In cases of repairs and/or maintenance the

compressor must be disconnected from

the mains supply, and the air supply hoses

as well as the pressurized container must

be depressurized.

1.6 Warnings and Symbols

In the Installation and Operating Instructions

use is made of the following terms or

symbols to denote information of special

importance:

Information and/or mandatory

regulations or prohibitions for the

prevention of personal injury or

substantial property damage.

Warning! High voltage.

Special information regarding the

economical use of the equipment and

other information.

CE-Labeling

Disconnect from mains supply.

Warning! Hot surface.

Warning!

Compressor starts automatically.

Check environment. The appliance

should not be used in wet or damp

conditions.

Recycling

Observe installation and operating

instructions!

31

Page 4

2. PRODUCT INFORMATION

2.1 Correct Usage

This compressor is only designed for

providing compressed air for dental units or

similar applications.

Mounting in medical treatment units:

During the development and production of

this surgery compressor all requirements

concerning medical products were taken into

consideration wherever possible. Thus this

appliance can be mounted in medical

treatment units.

Where this appliance is mounted in medical

treatment units, then the requirements of

guidelines 93/42 EWG must be observed on

installation and operation.

2.2 Use other than that for the

intended purpose

The compressed air provided by

this unit is not suitable for use in

breathing apparatus or similar

facilities without the addition of

special filters, such as those used

in surgical areas.

• The compressors are designed for use in

dry, ventilated rooms with an ambient

temperature of +10 to +40 °C.

• Do not set up the compressor in the rain.

The machine must not be used in wet or

damp conditions. Furthermore, operation in

the vicinity of gases or flammable fluids is

forbidden.

• Before installing the compressor in medical

facilities it must be checked that that the

available material is designed to satisfy the

requirements of the purpose for which is

intended. Please observe the technical

data.

• Any classification and conformity evaluation

should be carried out by the manufacturer

of the end product.

• Any other use or use beyond what is

specified is deemed to be not for the

intended purpose. The manufacturer

accepts no liability for damage resulting

therefrom. All risk is borne solely by the

user.

2.3 Product description

The Dürr Compressor 51../52.. provides an

oil-free, dry and filtered pressurized air, for

use in medical units.

32

Page 5

3. DELIVERY CONTENTS

Compressor with / out Dry Air System

(DAS):

Compressor accessories .......... 5410-002-50

nstallation and

operating instruction ............. 9000-610-01/01

Compressor with Dry Air System (DAS)

only:

Collection tank ............................ 3413-001-00

Operating instructions DAS ...... 9000-610-34

3.1 Special Accessories

The following parts are not standard and

must be ordered separately.

Pressure reducer ....................... 3410-008-00

Wooden cabinet ......................... 5110-500-00

Dry Air System,

upgrade set ................................ 1640-500-52

3.2 Disposable material

Filter set compressor .................. 0832-982-00

Filter set DAS ............................... 1610-121-00

Sterile filter DAS ........................... 1640-981-00

33

Page 6

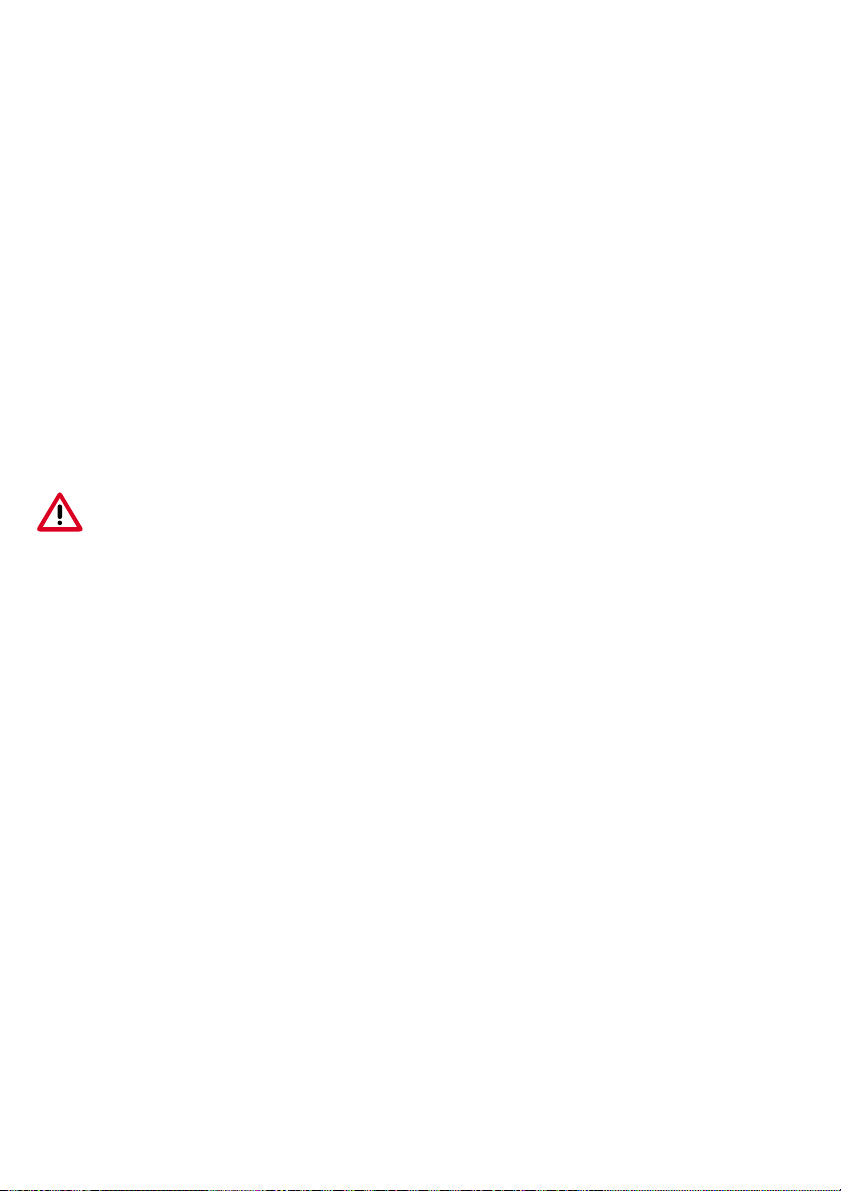

4. TECHNICAL DATA

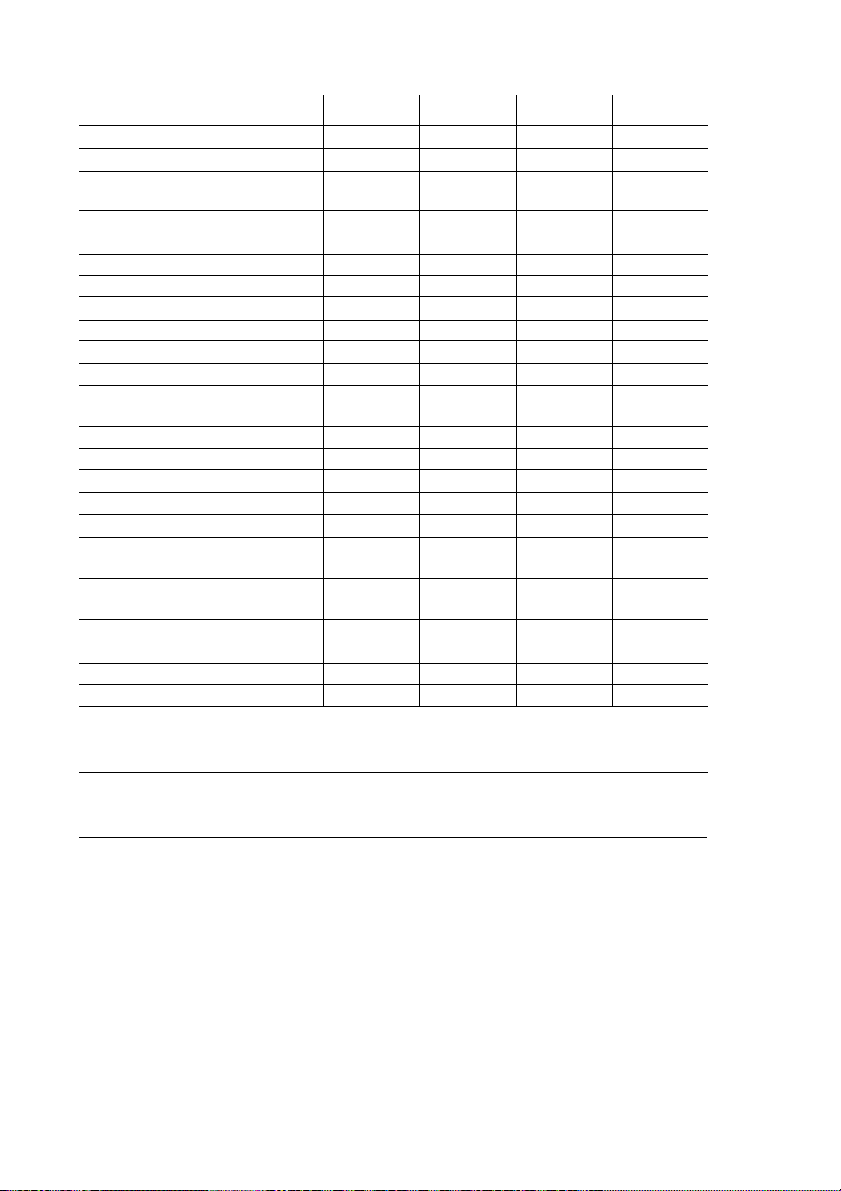

Model 5110-01 5111-01 5120-51 5121-51

Voltage V 230/1~ 230/1~ 400/3~ 400/3~

Frequency Hz 50 50 50 50

Current consumption

at 7 bar A 3,8 3,8 1,5 1,5

Motor circuit

breaking set at A 4,2 4,2 1,6 1,6

Power rating kW 0,68 0,68 0,71 0,71

R.P.M. min

Mains fuse rating A16161010

Fuse type IP 44 IP 44 IP 44 IP 44

Noise level dB(A) 66 66 66 66

No. cylinders 1111

Flow rate

at 5 bar l/min 55 53 55 53

* Charge time min3333

Open/Shutoff pressure bar 5,5 – 7,5 5,5 – 7,5 5,5 – 7,5 5,5 – 7,5

Safety valve setting bar8888

Vessel volume l25252525

Duty cycle %ED 100 50 100 50

DAS - yes - yes

Filtration, filter

(0832-982-00) compr. µm 10 10 10 10

Filtration, fine filter

(1610-121-00) dry air µm - 3,5 - 3,5

Filtration, sterile filter

(1640-981-00) dry air µm - 0,01 - 0,01

Weight kg 39 48 39 48

Dimensions

Transport and storage conditions

Temperature

Relative humidity

Operating conditions

Temperature

Relative humidity

(H x L x D) cm 68 x 40 x 39 68 x 39 x 40 68 x 39 x 4068 x 40 x 48

-25 °C to +55 °C

10% to 90% (no condensation)

+10 °C to 40 °C

up

to 70%

-1

1400 1400 1400 1400

* Time taken for the compressor to reach the

shut-off pressure of 7.5 bar from start-up

pressure of 0 bar

34

Page 7

Model 5210-01 5211-01 5220-51 5221-51

Voltage V 230/1~ 230/1~ 400/3~ 400/3~

Frequency Hz 50 50 50 50

Current consumption

at 7 bar A 3,8 3,8 3,5 3,5

Motor circuit

breaking set at A 4,2 4,2 3,6 3,6

Power rating kW 0,68 0,68 1,5 1,5

R.P.M. min

Mains fuse rating A16161010

Fuse type IP 44 IP 44 IP 44 IP 44

Noise level dB(A) 69 69 69 69

No. cylinders 2333

Flow rate

at 5 bar l/min 115 110 155 110

* Charge time min 1,5 1,5 1,5 1,5

Open/Shutoff pressure bar 5,5 – 7,5 5,5 – 7,5 5,5 – 7,5 5,5 – 7,5

Safety valve setting bar8888

Vessel volume l25252525

Duty cycle %ED 100 50 100 50

DAS -ja-ja

Filtration, filter

(0832-982-00) compr. µm 10 10 10 10

Filtration, fine filter

(1610-121-00) dry air µm - 3,5 - 3,5

Filtration, sterile filter

(1640-981-00) dry air µm - 0,01 - 0,01

Weight kg 48 56 48 56

Dimensions

(H x L x D) cm 68 x 40 x 45 68 x 40 x 48 68 x 40 x 4568 x 40 x 48

Transport and storage conditions

Temperature

Relative humidity

-25 °C to +55 °C

10% to 90% (no condensation)

Operating conditions

Temperature

Relative humidity

+10 °C to 40 °C

up

to 70%

-1

1400 1400 1400 1400

* Time taken for the compressor to reach the

shut-off pressure of 7.5 bar from start-up

pressure of 0 bar

35

Page 8

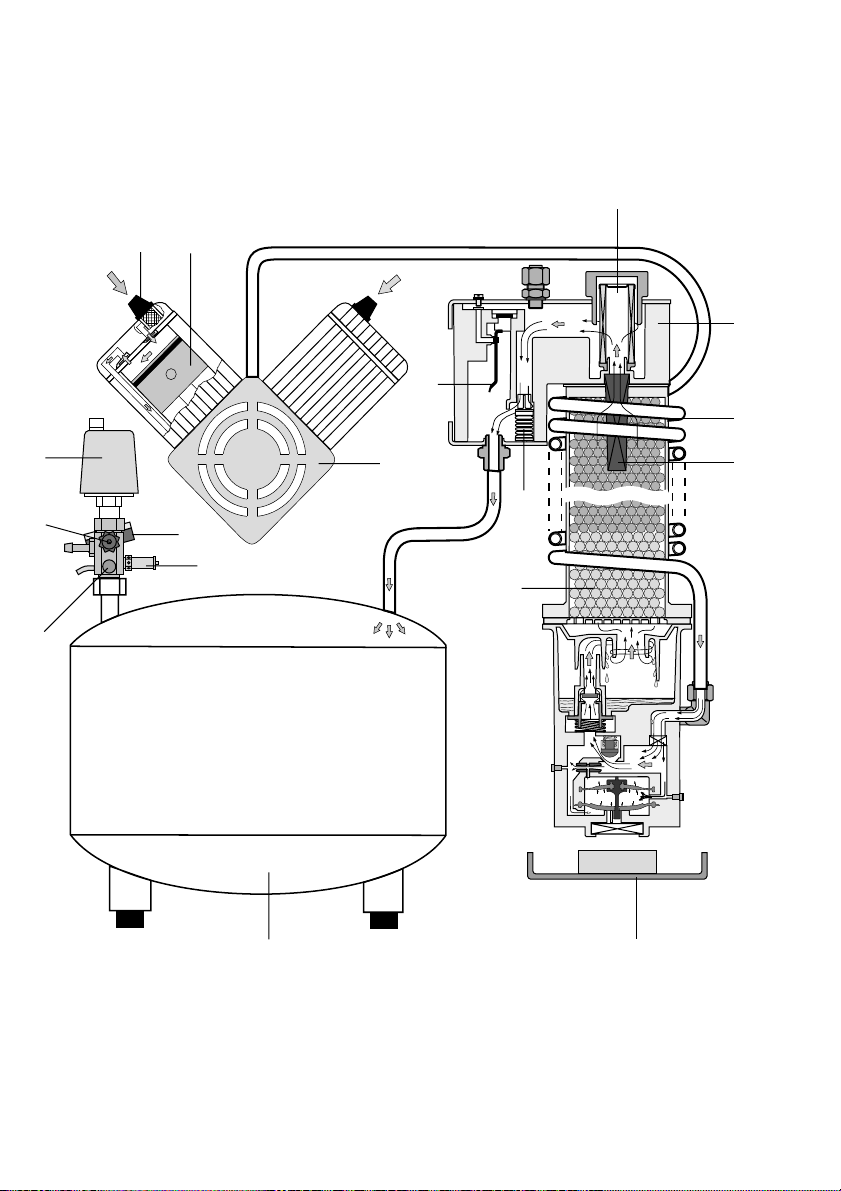

5. FUNCTION

17 18

1

2

8

3

16

14

13

15

12

10

11

4

7

6

5

36

Page 9

6. FUNCTIONAL DESCRIPTION

6.1 Compressor

Atmospheric air is drawn into the cylinder

chamber via a suction filter (17). The piston

(18) in the cylinder then compresses this air.

The inlet/outlet valve cuts off one flow route

thereby forcing the air directly into the tank

(10) via the non-return valve.

Where a DAS is present (2), the

compressed air is led through the spiral

cooling pipe (3) to the dry air system (2). In

this way the air, warmed on compressing, is

now cooled whereby most of the water

present in the air is extracted as

condensated water. Each time the

compressor motor is sitched ioff this

condensated water is collected in the

collection tank (5). The partially dry air is then

fed through the drying agent (6), the

Sintermetallfilter (4) and the fine filter (1) as

dry and hygienic air into the compressor

chamber (10). The non-return valve (7)

ensures the compressed air cannot escape.

The compressor motor (11) continues to

provide compressed air until the pressure

switch (16) registers that the pressure

correct level has been achieved. (The actual

pressure can be read off the pressure

gauge (15).)

If the maximum relative humidity in the tank

(10) is exceeded, then the Polyamidband

Hygrostat (8) expands, whereby a valve is

opened and dry air from the tank flows in the

reverse direction towards the DAS (2).

During this phase the unit is regenerating.

This means that the humidity present in the

DAS is carried via the dry air to the collection

tank (5). This regeneration procedure

repeats irself until such time as the pre-set

relative humidity at the Hygrostat (8) is

reached.

6.2 Control unit with pressure switch

If a user appliance (turbine etc.) draws off

compressed air, the tank pressure drops. If

in the tank the pre-set minmum pressure as

set at the pressure switch (16) is reached,

then the compressor motor is activated.

When the pre-set maximum pressure is

reached, the compressor motor is switched

off.

The control unit is fitted with a pressure

gauge (15) which displays the tank

pressure. A safety valve (12) prevents the

maximumm pressure from being exceeded,

eg in case of a defect.

The control unit is also fitted with a

condensed water drain tap (13) and a shutoff valve (14).

37

Page 10

INSTALLATION

7. STORAGE AND TRANSPORT

REQUIREMENTS

The compressor is packed in a carton for

transport. This prevents any damage to the

appliance during transport. Always use the

original packing for the machine wherever

possible.

Transport the machine in an upright

position.

During storage and transport,

protect the appliance at all times from

damp, dirt and extremes of

temperature. Take special care to

avoid any electrical parts from

becoming wet.

The surgery compressor is ready for

immediate installation. If the appliance is in its

original packing it can be stored in a warm,

dry and dust-free room.

(see technical data)

Retain the original packing if at all

possible. If this is not possible

dispose of the packing in an

environmentally correct way. The

transport carton can be disposed of

as paper waste.

38

The compressor must be

transported in pressure-free state.

Before transport empty the

compressor and bleed the hoses.

Vor Before transport or storage any

condensated water in the pressure vessel

must be drained off. (See section 8.7

Draining condensed water off).

Page 11

8. REQUIREMENTS FOR SET-UP

Set-up and commissioning

should only be carried out by an

authorized technician.

Observe local rules and

regulations

8.1 Environmental Requirements

• The appliance should only be installed and

operated in a well-ventilated, dry and dustfree room.

• The compressor must be installed in a

position that allows the identification plate to

be easily visible at all times and where

accessible for repairs and maintenance.

• The appliance must be placed on a

smooth, flat and stable floor.

(Note compressor weight, see technical

data).

The air intake side and the

ventilation grille on motor side

must both be free and there must

be adequate distance from the

nearest walls (c. 20 centimeter).

The power cable and the air hoses

must not be bent or twisted.

As the compressor starts

operation automatically as soon

as pressure falls below a set

amount, a warning sign in

accordance with ISO 7000-0017

must be displayed warning of

automatic operation.

39

Page 12

The room temperature must not be allowed

to fall below 10 °C otherwise a trouble-free

operation of the control unit within the

machine cannot be guaranteed.

If room temperatures exceed 40 °C, additional ventilation must be provided by installing

a fan (see Fig. 1).

The compressor unit gives off about

70 % of its electrical energy as heat

energy causing the ambient

temperature to rise if ventilation is

inadequate.

The motor fan provides efficient cooling to

the motor. For this to happen the air intake

1

and output must be unhindered. In extreme

cases a separate ventilation system must be

installed, see Fig. 1.

Do not place any objects on or

against the compressor; by a

room temperature of c. 40 °C the

cylinder and cylinder heads can

warm up to over 110 °C.

Fire risk!

40

8.2 Tryckluftsanslutning

The compressor is fitted as standard with a

control unit consisting of:

Pressure switch (16), pressure gauge (15),

safety valve (12), shut-off valve (14) and

condensed water drainage tap (13).

16

15

12

14

13

20

2

In order to ensure a constant

pressure flow, a pressure reducer

(as accessory) is recommended.

The pressure connection is carried out at the

connector nozzle (20) or the pressure

reducer (as accessory).

• The flexible pressure hose LW10 should be

pushed onto the connector nozzle and

secured from slipping using a hose clip.

The use of a flexible hose between

the fixed air connection and the

compressor helps to prevent the

transmission of vibration and noise.

Page 13

8.3 Electrical connection

Electrical connections should only

be carried out by a qualified

electrician.

(with the exception of those models

delivered supplied with either a

standard EEC plug or a shockproof

domestic plug according to model)

The compressor is supplied with a standard

EEC plug in the 400 V configuration and with

a shockproof domestic plug on the 230 V

model. All local and national regulations

concerning electrical connections must be

observed.

Mains voltage and frequency must coincide

with those shown on the identification plate.

No cables should be laid on the

unit. The hot surface of the unit

will melt and destroy the cable

insulation.

If the unit is connected directly to the mains

power supply then a power off switch must

be located in the vicinity of the unit that has a

minimum 3 mm contact gap (e.g. fuse box).

If the unit is connected to the mains power

supply via a plug and socket then, for safety

reasons, the socket must be easily

accessible so that the unit can be

disconnected in dangerous situations.

The relevant circuit must be fitted with a fuse

of maximal 16 A.

Observe the correct turning

direction for the alternating

current compressor unit (400 V):

The direction is clearly indicated by

an arrow on the ventilator cover. If the

direction of rotation is incorrect, there

is danger of the compressor unit

overheating.

If the turning direction is incorrect,

disconnect the unit at the mains and swap

the polarity of the two pressure switch power

supply cables.

When connecting the appliance to

a different outlet, check direction

of rotation!

41

Page 14

8.4 Pressure switch check and setting

The pressure switch (16) is factory-set.

At 5.5 bar the motor is switched ON.

21

At 7.5 bar the motor is switched OFF.

If required, the working pressure of

the compressor can be altered at the

pressure switch.

To do this, first the shutoff pressure and then

the connecting pressure must be set using

22

the pressure difference (

Before removing the protective

23

cap on the pressure switch, the

appliance must be disconnected

from the mains.

∆∆

∆P).

∆∆

3

Adjust cut-off pressure P

adjusting screw (22). (In direction of arrow

(+) it increases and in direction of arrow (-)

decreases). The pressure difference itself is

not altered in this operation. Note maximum

pressure (8 bar) as set at safety valve. The

shut-off pressure must be at least 0.5 bar

below that of the safety valve, otherwise the

safety valve will open and the compressor

motor runs continuously as it never achieves

the shut off pressure.

Adjust pressure difference

connecting pressure and shutoff pressure at

the adjustment screw (23), by turning it

towards plus (+) or minus (-).

using the

∆∆

∆P

between

∆∆

42

The tank must be under pressure when this

adjustment is carried out.

8.5 Motor circuit breaker adjustment

The motor circuit breaker (21) has been

factory-set. This value should be checked

during installation.

The motor circuit breaker is situated under

the pressure switch cover (16).

(See section 4. Technical Data).

• Measure max. current (value shortly before

shut off pressure is reached).

• Increase motor circuit breaker by adjusting

screw (21) approx. 0.3 A.

Page 15

8.6 Commissioning

• Check all compressed air connections.

• The unit must be connected to the power

16

supply correctly.

• Check that air filters are fitted correctly.

• Turn compressor at switch (16) to on.

(Position ‘I’)

• Check for abnormal noises from unit on

first use.

• For 400 V - compressors check rotation of

motor.

• Check on and shut-off pressures of the

compressor. (Approx.5.5 and 7.5 bar).

4

• Check safety valve for correct function,

(see 9.2 Safety valve).

8.7 Draining off condensed water

During transport condensated water may

accumulate in the tank due to temperature

differnces. Each time a compressor is set

up, first drain off the condensated water –

even from those compressors fitted with

DAS.

Proceed as follows:

• With the compressor switched on, and

maximum tank pressure, open the

condensated water drain tap (13) as far as

possible.

13

• Wait for the condensated water to be

blown completely out of the tank.

5

• Close the drain tap once more.

43

Page 16

9. REPAIRS AND MAINTENANCE

Repairs and maintenance should

only be carried out by a qualified

and authorized technician.

Only use parts and accessories

approved by the manufacturer.

Before all repairs and maintenance

the compressor must be switched

off and disconnected from power

supply (disconnect at mains).

The compressor surfaces are hot.

Let the compressor cool before all

repairs and maintenance.

9.1 Draining off condensed water

See 8.7.

9.2 Safety valve

The safety valve is set to 8 ba

manufacturer and then tested and stamped.

It may not be readjusted!

The safety valve must be checked for

correct functioning every six months.

To do this, open the knurled screw (12) at

12

max. tank pressure until air escapes from

the safety valve. Briefly allow air to blow

freely through the safety valve. Retighten the

knurled screw.

rr

r by the

rr

44

6

9.3 Filter change

The filter replacement interval will largely

depend on the extent of dust in the air.

Under normal conditions the filter needs

changing once a year.

See Installation Instructions

9000-416-016

Filter order numbers:

Compressor

Filter set ....................................... 0832-982-00

Dry Air System

Fine filter ...................................... 1610-121-00

Sterile filter ..................................... 1640-981-0

Page 17

10. CIRCUIT DIAGRAM

10.1 Version in 230 V 1~

Geräteliste

Q1 Pressure switch

X1 Power supply 230 V 50 Hz

M1 Compressor motor

Y1 Solenoid valve

(only for compressors without DAS)

M2 Ventilator

(only with anti-noise cover)

45

Page 18

10.2 Version in 400 V 3~

Parts list

Q1 Pressure switch

X1 Power supply 3/N/PE AC 400V 50Hz

M1 Compressor motor

Y1 Solenoid valve

(only for compressors without DAS)

M2 Ventilator

(only with anti-noise cover)

46

Page 19

USE

11. OPERATION

Operation of the compressor is relatively

easy and for the most part automatic.

In case of any danger disconnect

power supply (disconnect from

mains).

The compressor surfaces get hot.

Touching the surfaces could lead

to burns.

Automatic start-up. If the pressure

in the tank falls below a certain

level the motor starts and

continues to provide compressed

air until the maximum pressure is

16

7

reached.

11.1 Turning on the compressor

The compressor is switched on by turning

the handwheel on the control unit (16) to

position ‘I’. The motor starts and the

compressor fills to the maximum. On

reaching the shut-off level the motor stops.

The maximum permitted operating pressure

must not be exceeded. The maximum

permitted operating pressure is indicated on

the pressure gauge with a red line.

If the maximum permitted operating

pressure is exceeded, the compressor

motor must be disconnected from the power

supply (unplug at mains socket). Inform the

technician responsible.

47

Page 20

12. MAINTENANCE

In order to check that the compressor is

functioning absolutely correctly, the following

30

maintenance steps should be carried out

regularly.

12.1 Pressure reducer (accessory)

The fitting of a pressure reducer is strongly

recommended. (vor den Verbraucher)

The pressure reducer regulates the

pressure flow to achieve the desired

operating pressure. The pressure reducer is

mounted on the pressure switch.

31

8

12.2 Adjusting the pressure reducer

To adjust the pressure rate, operate the

nozzle, turbine, etc., lift up the adjusting ring

(30) and turn in the direction of the arrow +

(increase flow rate) or in the direction of the

arrow - (decrease flow rate), until the desired

flow rate is displayed. When finished replace

the adjusting ring, until it clicks gently in

place and the pressure reducer is protected

from unintentional adjustment. The desired

flow rate is now set. It can be read on the

pressure gauge (31).

For correct flow rates, see the

manufacturer’s operating instructions (e.g.

turbine etc.).

48

12.3 Draining off condensed water

Condensated water is removed automatically

in compressors fitted with a dry air system.

For compressors without DAS the

condensated water must be drained off at

least once a month!

In countries with high air humidity water

must be drained off daily!

Proceed as follows:

• With the compressor switched on, and

maximum tank pressure, open the

condensated water drain tap (13) as far as

possible.

13

• Wait for the condensated water to be

blown completely out of the tank.

9

• Close the drain tap once more.

Page 21

10

12.4 Safety valve

The safety valve is adjusted to 8 bar by the

manufacturer and then tested and stamped.

It may not be readjusted!

The safety valve must be checked for

correct functioning every six months.

To do this, open the knurled screw (12) at

max. tank pressure until air escapes from

the safety valve. Briefly allow air to blow

freely through the safety valve. Retighten the

12

knurled screw (12).

12.5 Filter change

17

The filter replacement interval will largely

depend on the extent of dust in the air.

Under normal conditions the filter needs

changing once a year.

11

1

35

See Installation Instructions

9000-461-016.

• Changing the suction filter (17).

Pull out the filter unit by the cap. Change

the complete filter unit.

• Changing the fine filter (1) of the DAS.

Unscrew cover (35). Pull out the fine filter

(1) and place new filter in position. Replace

cover.

Filter order numbers:

Compressor

Filter set ....................................... 0832-982-00

Dry Air System

Fine filter ...................................... 1610-121-00

Sterile filter ................................... 1640-981-00

49

Page 22

13. MAINTENANCE INTERVALS - OPERATOR / TECHNICIAN

Maintenance procedure Section Interval

Adjust pressure reducer 12.2 yearly

Drain condensated water *) 12.3 monthly

Check safety valve 12.4 every six month

Filter change 12.5 yearly

*) Only for non-DAS appliances.

In countries with high air humidity water must be drained off daily!

daily

14. DECOMMISSIONING

If the compressor is not going to be used for

a long period of time, it is recommended

draining the condensated water from the

tank. Allow the compressor to run for c. 10

minutes with the condensated water drain

tap (13) open. Then switch off at the main

switch, close the drainage tap and

disconnect from the mains.

50

13

12

Page 23

TROUBLE-SHOOTING

15. TIPS FOR TECHNICIANS

The following list of possible problem causes is designed for use by qualified

technicians. Repairs must only be carried out by qualified personnel.

Problem Solution

does not switch

on.

Probable cause

• No power.1. Compressor

• Pressure switch not on.

• Current higher than nominal

rating.

• Current continuously equal to

nominal rating.

• Ventilating valve defect, unit

runs with back pressure (nonDAS compressors only)

• Check mains fuse, if necessary

reset circuit breaker; if fuse is

blown, replace it. Check mains

current.

• Connect pressure switch and

wait 30 seconds. If the pressure

switch remains connected

briefly and then switches the

motor off, check the power

consumption: for all three

phases if three-phase and for

one phase if AC.

• Undervoltage: measure voltage,

call an electrician if necessary.

Capacitor defective (230 V 1~):

Check capacitor, replace if

necessary.

• Unit blocked mechanically,

piston seized (motor circuit

breaker triggered): pull out

mains plug, remove cover from

crank housing of overheated

compressor and turn fan wheel.

In the event of this not being

possible, replace piston and

cylinder, or entire unit.

• Motor circuit breaker set too low

(3~ only): measure current.

Adjust motor circuit breaker

accordingly (0.3 A higher than

current measured).

Motor circuit breaker defective:

Check motor circuit breaker and

replace if necessary.

• Check to ensure that ventilating

valve opens after unit is

switched on. Remove blockage

or replace.

51

Page 24

Probable causeProblem Solution

2. Compressor fails

to switch off.

3. Compressor

switches on

intermittently

without any air

being drawn off

by user.

4. Excessive

compressor

noise (e.g.

knocking

sound).

• Defective plate valve (inlet and/

or outlet valve) between

cylinder head and cylinder.

• Air escapes at ventilating valve

(non-DAS compressors only).

• Air blows through the DAS into

the collection tank.

• Leakage in compressed air

system

• Compressor capacity too low;

excessive air drawn off per

workstation, approx. 50 l/min.

• Worn piston compression seal.

• Air escaping down through dry

air system.

• Air escaping at non-return

valve.

• Leakage in connections.

• Damaged bearings

• Dismantle cylinder head and

install new plate valve.

• Check ventilating valve. (The

valve is open when power is off)

• Check dry air system control

head.

• Open shut-off valve and subject

tubes to pressure. Use spray to

find leak if necessary. Seal leak.

• Determine air requirements,

replace with larger compressor

if necessary.

• Replace piston and cylinder, or

entire unit.

• Dry air system is in

regeneration phase, air humidity

in tank is being reduced.

• Check non-return valve for air

leaks. Clean or replace nonreturn valve.

• Locate leak and seal.

• Check motor shaft bearings and

crankshaft bearings, replace if

necessary.

5 Supply

performance

loss, compressor

takes longer to

charge tank (For

charging

periods, see

Technical Data).

6. Water drips from

handset.

52

• Suction filter badly soiled.

• Defective plate valve (inlet and/

or outlet valve).

• Worn piston compression seal.

• Condensated water im tank.

• Suction filter should be replaced

at least once a year. Never

clean the filter with petrol or oil!

• Dismantle cylinder head and

install new plate valve.

• Replace piston and cylinder, or

entire unit.

• The condensed water must be

drained off at least once a

month. Or daily in tropical

zones or locations with high air

humidity.

Observe ambient temperature

of the compressor, (refer to the

requirements in the set-up

instructions.

Page 25

16. TIPS FOR OPERATORS

Probable causeProblem Solution

1. Compressor

does not switch

on.

2. Compressor fails

to switch off.

3. Compressor

switches on

intermittently

without any air

being drawn off

by user.

4. Excessive

compressor

noise (e.g.

knocking

sound).

• No power.

• Pressure switch not on.

• Compressor capacity too low;

excessive air drawn off per

workstation, approx. 50 l/min.

• Air escaping down through dry

air system.

• Air escaping at non-return

valve.

• Leakage in connections.

• Damaged bearings.

• Check mains fuse, if necessary

reset circuit breaker; if fuse is

blown, replace it. Check mains

current.

• Connect pressure switch and

wait 30 seconds.

• Contact your technician.

• Determine air requirements,

replace with larger compressor

if necessary.

• Contact your technician.

• Dry air system is in

regeneration phase, air humidity

in tank is being reduced.

• Check non-return valve for air

leaks.

• Locate leak and seal.

• Contact your technician.

• Contact your technician.

performance

loss, compressor

takes longer to

charge tank (For

charging

periods, see

Technical Data).

6. Water drips from

handset.

• Suction filter badly soiled.5 Supply

• Condensated water im tank.

• Suction filter should be replaced

at least once a year. Never

clean the filter with petrol or oil!

• The condensed water must be

drained off at least once a

month. Or daily in tropical

zones or locations with high air

humidity. Observe ambient

temperature of the compressor,

(refer to the requirements in the

set-up instructions).

53

Page 26

DISPOSAL

17. DISPOSAL OF APPLIANCE

• Unplug the unit

• Drain the compressor tank of air by

opening the condensated water tap.

(See 8.7 Draining off condensated water)

• Dispose of the compressor according to

local regulations concerning waste material.

54

Page 27

55

Loading...

Loading...