Page 1

Gasoline Engine

Owner’s Manual

DuroMax Customer Service

info@duromaxpower.com

or call 844-DUROMAX Monday - Friday 7am to 5:00pm. PST

Product Support (Product: information, application, service info & warranty questions)

support@duromaxpower.com

or call 844-DUROMAX Monday - Friday 7am to 5:00pm. PST

This manual provides information regarding the operation and maintenance of these products.

We have made every effort to ensure the accuracy of the information in this manual.

We reserve the right to change this product at any time without prior notice.

Please keep this manual available to all users during the entire life of the engine.

Page 2

CONTENTS

SAFETY PRECAUTIONS............................................................................................................................................2

PARTS DESCRIPTIONS .............................................................................................................................................

BATTERY CONNECTION (electric-start type)..........................................................................................................4

PRE-OPERATION INSPECTION................................................................................................................................4

ENGINE OIL...........................................................................................................................................................4

FUEL AND FUEL TANK........................................................................................................................................6

STARTING THE ENGINE ............................................................................................................................................7

RUNNING THE ENGINE..............................................................................................................................................8

LOW OIL SENSOR.................................................................................................................................................8

OPERATING AT HIGH ALTITUDE......................................................................................................................

SHUTTING DOWN.........................................................................................................................................................9

EXHAUST CONTROL SYSTEM.................................................................................................................................9

MAIN

TENANCE...........................................................................................................................................................10

MAINTENANCE SCHEDULE............................................................................................................................10

CHANGING THE ENGINE OIL..........................................................................................................................11

CLEANING THE AIR CLEANER........................................................................................................................12

CLEANING THE DEPOSIT CUP.......................................................................................................................13

SPARK PLUG ......................................................................................................................................................13

CARBURETOR IDLE ADJUSTMENT...............................................................................................................14

TRANSPORT, STORAGE AND REMOVAL FROM STORAGE...........................................................................15

TRANSPORT.......................................................................................................................................................15

STORAGE............................................................................................................................................................15

REMOVAL FROM STORAGE...........................................................................................................................16

SERVICE AFTER STORAGE............................................................................................................................16

SPECIFICATIONS.......................................................................................................................................................17

TROUBLESHOOTING ..............................................................................................................................................

I. START ENGINE DIFFICULTLY......................................................................................................................17

II. LOW GASOLINE ENGINE POWER OUTPUT...........................................................................................19

III. GASOLINE ENGINE WILL NOT RUN SMOOTHLY.................................................................................19

IV. STOPS SUDDENLY WHEN RUNNING......................................................................................................20

V. GASOLINE ENGINE IS EXCESSIVELY HOT............................................................................................20

VI. THERE IS ABNORMAL NOISE WHEN ENGINE RUNNING..................................................................21

WIRING DIAGRAM.....................................................................................................................................................22

EXPLODED VIEW AND PARTS LIST(7HP)............................................................................................................24

EXPLODED VIEW AND PARTS LIST(16HP)..........................................................................................................27

.3

9

.17

1

Page 3

SAFETY PRECAUTIONS

WARNING:

Before operating the engine, be sure to read and familiar with the manual carefully, otherwise

personal injury or equipment damage may produce.

Please pay special attention to the following:

1. Running the engine in a well-ventilated place, keep it at least one meter away from building

walls or other equipments, keep away from inflammables such as gasoline, matches and so on

to avoid possibility of fire.

2. Keep the engine out of reach of children and pets to avoid accidents.

3. Operator of engine has been specially trained.

4. Refuel in a well-ventilated area with the engine stopped, and in places refueling or storing

gasoline, no smoking and any flames or sparks.

5. Refuel the fuel tank not too full so as to avoid fuel’s spilling out. If there is spilled fuel around, be

sure to clean it thoroughly before starting.

6. Locate the engine on a level-working platform to avoid fuel’s spilling out.

7. Maker sure the fuel filler cap is tightened securely.

8. The exhaust muffler is very hot during running the engine even after the engine stops. Never

touch it, or you may get burns. Transport or store the engine with it cooling down entirely.

2

Page 4

PARTS DESCRIPTION

The main parts of engine are located as follows

3

Page 5

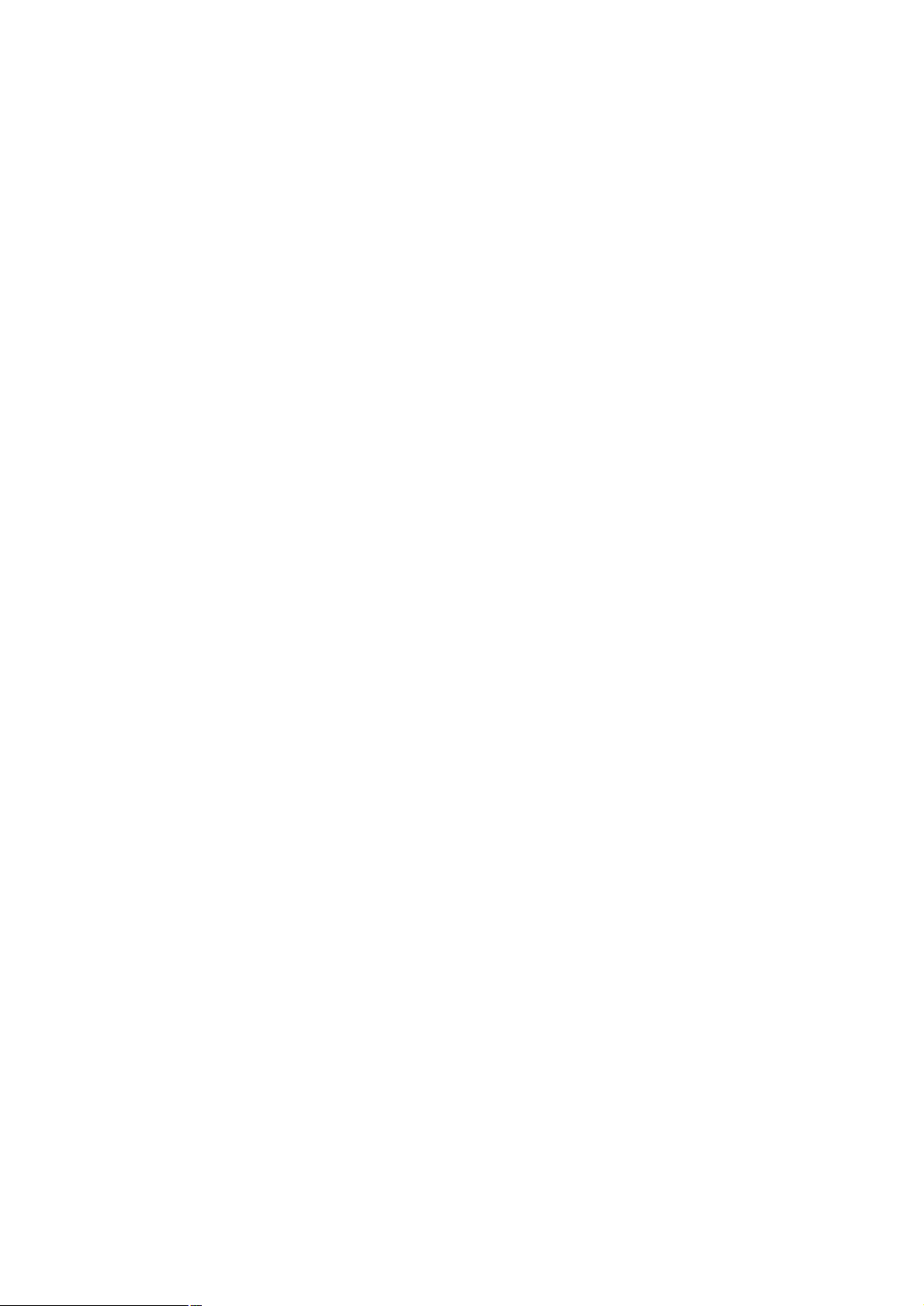

BATTERY CONNECTION (electric-start type)

In the case that the specifications of the battery are 12V and more than 18A.h connect its

positive lead to the electromagnetic coil while connect its negative lead to engine mount strew,

base screw or any place capable of grounding with the engine well.

Make sure the battery leads are connected tightly and no corrosion is found. If any, eliminate it.

WARNING:

● The battery may give off explosive gas;

keep sparks, flames and cigarettes away.

Charge or use it in an area with good

ventilation.

● The battery contains sylphlike acid

(electrolyte). Contact with skin or eyes

may cause severe burns. Wear protective

clothing and a face shield.

If electrolyte gets in your skin, flush with

water; if gets in your eyes, flush with water for at least 15 minutes and call a physician at once.

● Electrolyte is poisonous. If swallowed, drink large quantities of water or milk, and follow with

milk of magnesia or vegetable oil and oil a physician.

● Keep out of reach of children.

CAUTION:

● Do not add tap water to the battery instead of distilled water, or the battery life will be

short-need.

● Do not add distilled water over electrolyte upper level mark, or electrolyte will spill out to corrupt

the engine parts. If so, be sure to wash them away with water.

● Make sure not to connect the battery leads in reverse or-deer, or short-circuit or breaker’s

cutting may result.

PRE-OPERATE INSPECTION

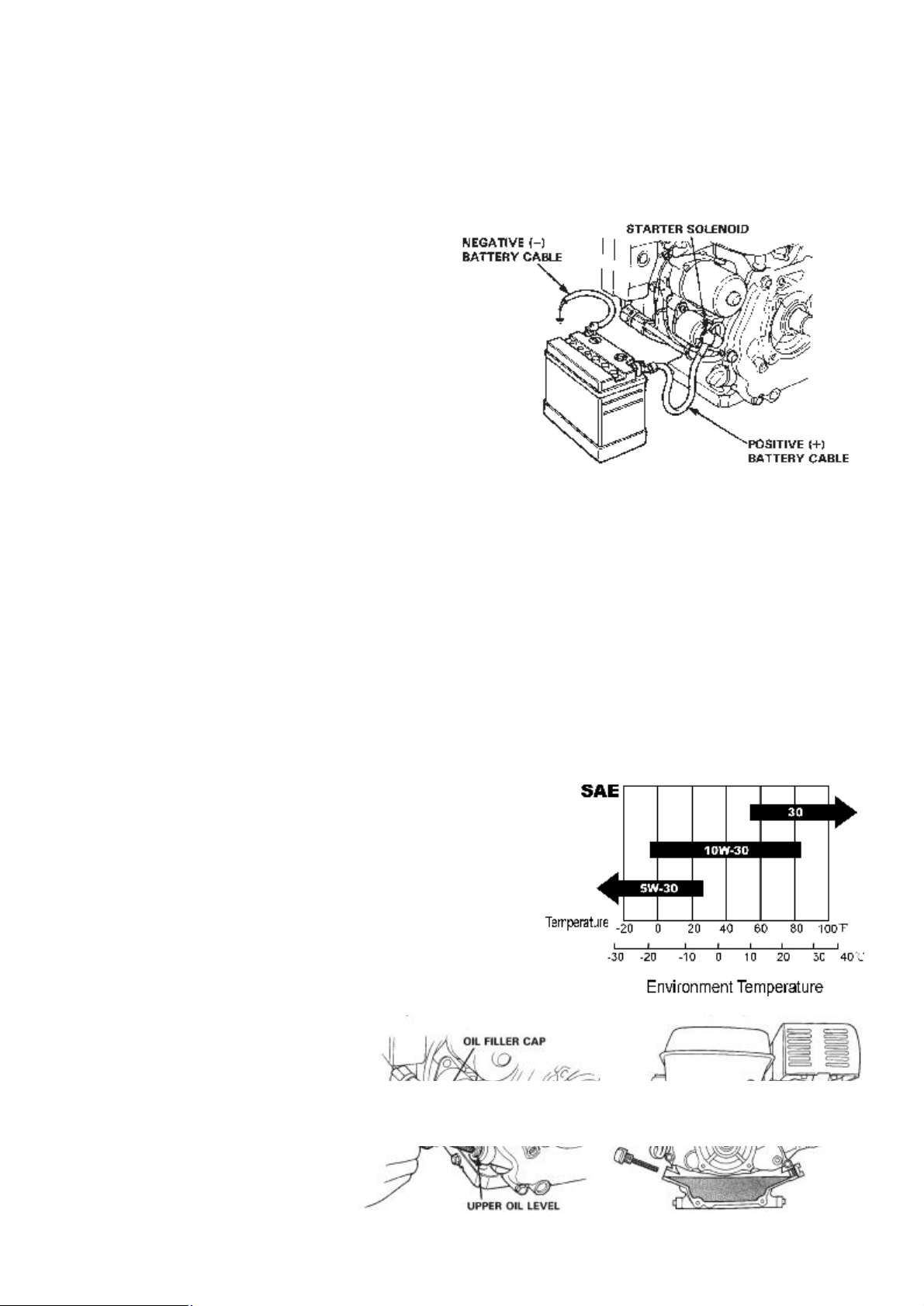

ENGINE OIL

CAUTION:

● Engine oil is key factor in deciding the engine’s

performance. Do not apply engine oil with additives

or 2-stroke gasoline oil, as they haven’t enough

lubrication, which may shorten the en-gene’s service

life.

● Check the engine with it

stopped on a level ground.

Engine oil recommended:

SAE10W-30

As viscosity varies with

regions and temperatures,

so the lubricant has to be

4

Page 6

selected in accordance with our recommendation.

Check

1. Ensure that the engine is stopped on a level ground.

2. Remove the dipstick and clean it.

3. Reinsert the dipstick into the oil filler without screwing it, and check oil level.

4. If the oil level is too low, add the recommended engine oil up to the oil filler neck.

5. Reinstall the dipstick.

CAUTION: Run with insufficient engine oil may damage the engine severely.

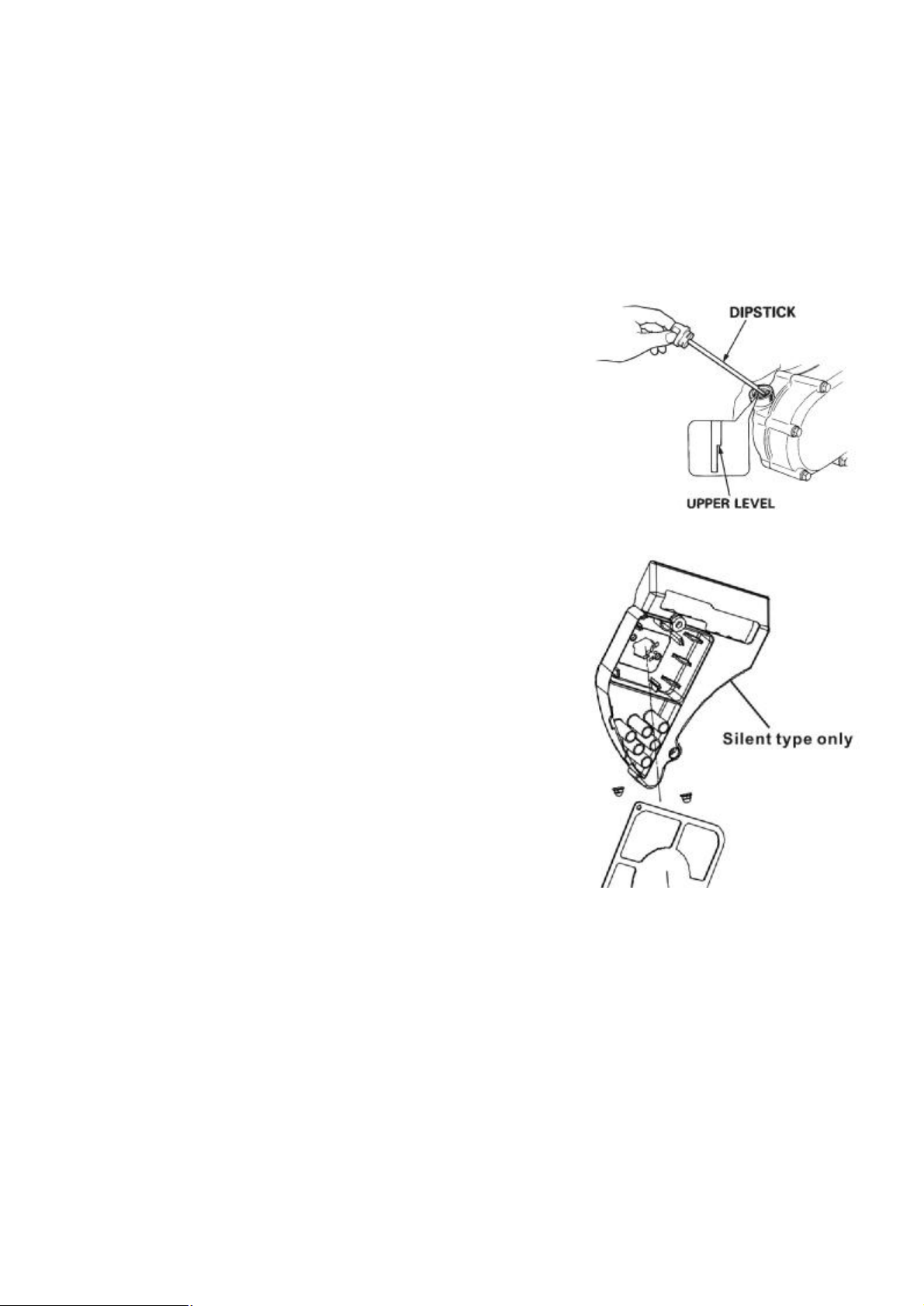

OIL IN THE REDUCTION GEAR BOX (only for the model

equipped with it) 1/2 Reduction gear with an auto-centrifugal

clutch

Brand of the box oil is the same as that of engine oil.

Oil capacity: 0.5liters for 190N, 0.3liters for 170N. Check the oil

lever in the following order.

1. Remove the dipstick and clean it.

2. Reinsert the dipstick without screwing it in, and then check

oil level

.

3. If the oil level is too low, add the

recommended engine oil until it arrives the

upper level mark.

4. Reinstall the dipstick.

AIR CLEANER

I. Double-core type

Dismantle the air cleaner housing and check its

filter element, make sure it clean and intact,

otherwise clean or replace it.

II. Dust-collecting type

1. Dismantle the dust-collecting hood and check

the filter element of the air cleaner; make

sure it is clean and intact, otherwise clean or

replace.

2. Check whether there is any dust or dirt inside

the dust-collecting hood, if any, clears away.

III. Single-core type

5

Page 7

Dismantle the air cleaner housing and check its filter element, make sure it is clean and intact,

otherwise clean or replace.

IV. Oil-bath type

1. Dismantle the air cleaner housing and check its core, make sure it is clean and intact,

otherwise clean or replace.

2. Check oil level and oil quality. If the oil level is too low, add the recommended engine oil up to

oil level mark.

CAUTION:

Never run the engine without an air cleaner, or severe wear of the engine may result.

FUEL AND FUEL TANK

Fuel

To ensure that the engine runs smoothly use only FRESH, UNLEADED GAS WITH AN

OCTANE RATING OF 87 OR HIGHER. Using unleaded gasoline will decrease the possibility of

producing car boll deposit and will prolong the engine’s service life. Never apply used or polluted

gasoline or a mixture of gasoline with engine oil. Make sure the fuel is free of dirt and water.

Gasoline Containing Alcohol

If you decide to use a gasoline containing alcohol (fuel blend), be sure its octane rating is at least

as high as that recommended by the company. There are two types of“gasohol”. One contains

ethanol, and the other contains methanol. Neither gasoline containing more than 10% ethanol nor

5% methanol is allowed to be used. If methanol content in the fuel blend exceeds 5%, it may bring

bad effect on the engine performance, besides, it may damage metals, rubber and plastic parts.

CAUTION: Handle fuel with care because it change plastic and painted surface.

It is normal when you hear occasionally light spark knock or pinking with the engine running under

heavy load.

If “spark knock” or “pinking” occurs at a steady speed under normal load, change brand of

gasoline; if Such phenomena still happen, consult your dealer for help, otherwise the

engine may be damaged.

Fuel Tank

Fuel tank capacity: 3.6liters for 170N , 6.5liters for 190N.

6

Page 8

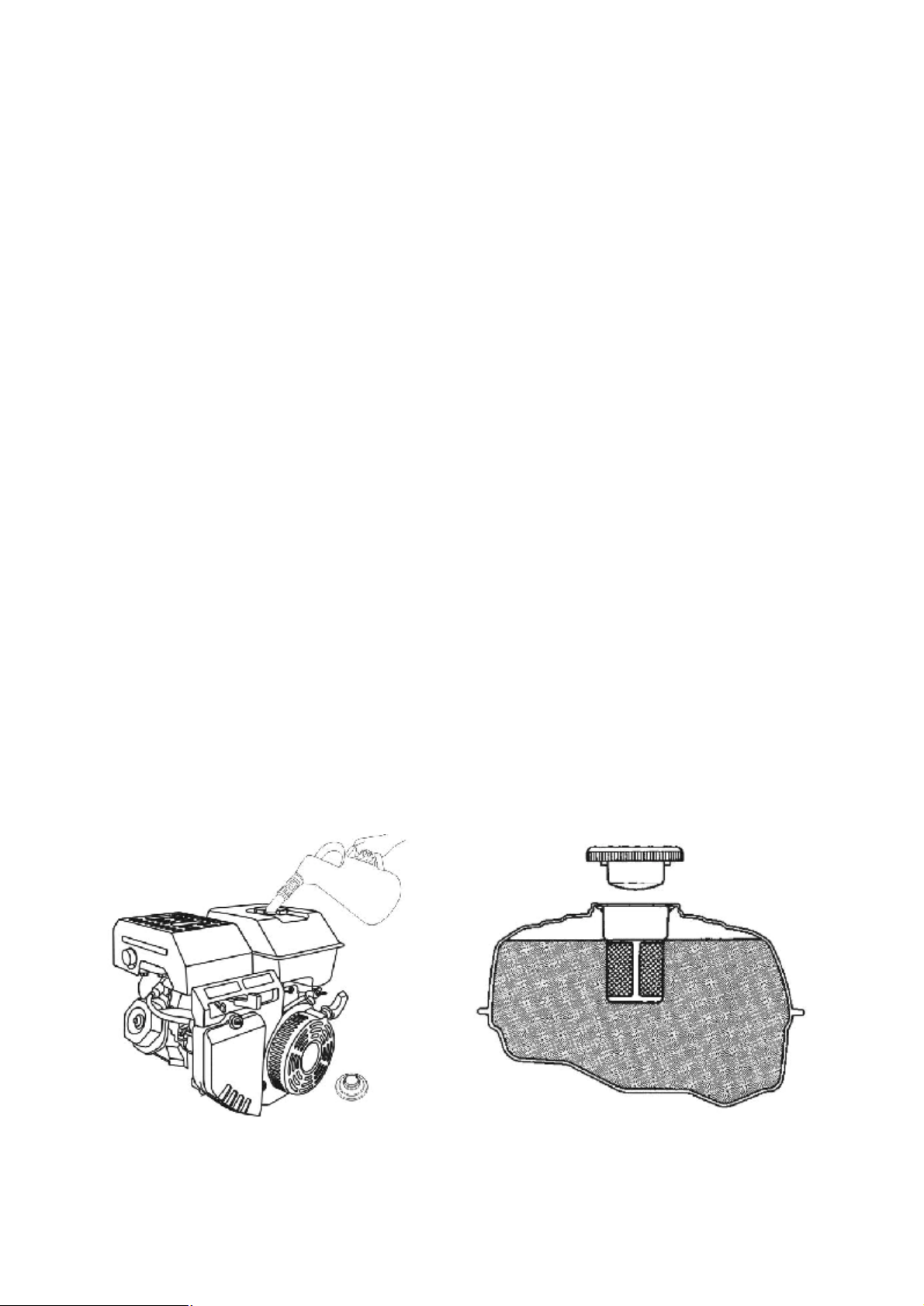

Check

1. Remove the fuel filler cap and check fuel level.

2. If the fuel level is too low, refuel the tank. Remember adding

fuel not over the fuel filler shoulder.

WARNING:

● Gasoline is extremely flammable and is explosive

under certain conditions. Refueling in a well-ventilation

area with the engine stopped. Do not smoke and smoke

and allow flames or sparks in the area where gasoline

is stored or where the fuel tank is refueled.

● Do not overfill the tank (there should be no fuel in the

filler neck). After refueling, make sure the fuel filler cap

is set back securely.

● Be careful not to spill fuel when refueling. Spilled fuel

or fuel vapor may ignite. If any fuel is spilled, make

sure the area is dry before starting the engine.

● Avoid repeated or prolonged contact with skin or

breathing of fuel vapor. Keep out of reach of children.

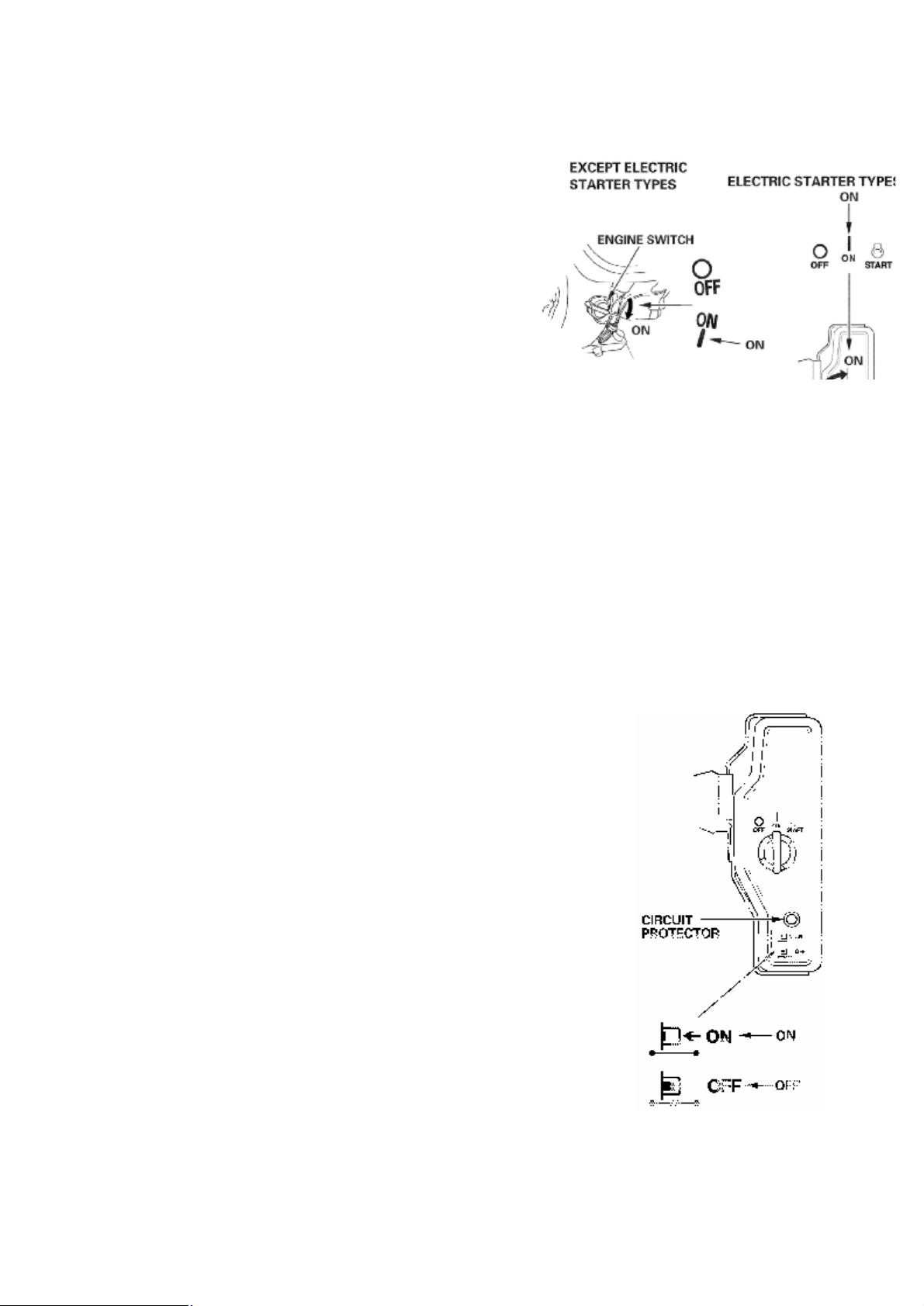

STARTING THE ENGINE

1. Push the fuel cock to“ON”.

2. Push the choke lever to “CLOSE”.

NOTE: if the engine is hot, closing the choke is unnecessary.

3. Move left the throttle lever a little.

4. Start the engine as follows:

a) Hand-operated kick-starter Push the engine switch to“ON”. Pull slightly the starting rope handle

7

Page 9

up until feeling anti-action, and then make a rapid pull.

CAUTION:

Releasing the handle suddenly may make it hitting the

engine. Release the handle slowly conforming to its

recoiling force.

b) Electric starter

Push the engine switch to “START”and remain there

until the engine starts. Once the engine starts, reset the

engine switch to “ON”.

CAUTION:

Use the engine switch not more than 5 minutes each time to avoid

damage of the engine. Try once more 10 minutes later after last

attempt failures.

RUNNING THE ENGINE

1. Preheat the engine and push back the choke lever to “OPEN”.

2. Set the throttle lever in proper position to ensure the engine runs

at required velocity.

ENGINE OIL ALARM

The engine oil alarm is designed to function when the engine oil in the crankcase is insufficient.

Lack of engine oil may damage the engine. Oil may damage the engine. Once oil level in the

8

Page 10

crankcase is too low, the engine oil alarm will stall the engine automatically to make it free of

damage while the engine switch is still at “ON”.

CAUTION:

If cannot restart the engine, check the engine oil level first before go to other check items.

BREAKER (Electric-start type)

The breaker will cut off automatically to protect the charging circuit of the battery in the case that

short circuit or incorrect connection of the battery poles occurs.

The green indicator in the breaker will jump out with the circuit cutting off. After finding troubles and

troubleshooting, depress the breaker button to tune the breaker on.

OPERATING ON HIGHLANDS

On highlands, the standard mixture ratio is relatively too big so the engine performance may be

impaired while the fuel consumption may increase, besides, too big mixture ratio will pollute the

spark plug to result in starting the engine difficultly. This problem can be solved by amending the

carburetor technological status. If always using on highlands with a height above sea level of 1800

meters, ask your dealer for doing the job.

CAUTION:

Amended engine applicable to highlands may be damaged seriously in area below altitude of 1800

meters for overheating, because its mixture ratio is too small for operation in low altitude area. In

the case, ask your dealer to recover the engine to its normal technical status.

STOP

In emergency, push the engine switch to “OFF” to stall the

engine; to stop it in normal, do as follows:

1. Push right the throttle lever to the bottom.

2. Push the engine switch to “OFF”.

3. Set the fuel cock to “OFF”.

CAUTION:

Sudden stopping at high speed under heavy load is

forbidden, otherwise damage will result.

EXHAUST CONTROL SYSTEM

With the engine running, carbon monoxide, oxide of nitrogen and hydrocarbon will produce, and in

certain conditions, oxide of nitrogen and hydrocarbon will react chemically each other to make

9

Page 11

smoke while carbon monoxide is toxic, so exhaust control of them is very important. The company

decreases the exhaust emissions by introducing poor-fuel carburetors and other devices into the

engine to solve the problem.

To keep the exhaust of your engine with in the standard exhaust emission, pay attention to the

following:

1. Maintenance

Maintain the engine

periodically in accordance

with the maintenance

schedule in the manual. The

maintenance schedule is

made out on the base of

normal use in normal

conditions, if using under

heavy load, dusty or wet

circumstances or in high

temperature, service of the

engine should be done more

often.

2. Replacement of Parts

We recommend that you

should choose such parts which are manufactured by the company or equivalent to these in quality

as replacement ones. Replacement without so high quality as the original may impair the exhaust

the exhaust control system in effectiveness.

3. Modifying

Modifying the exhaust control system may make actual exhaust emissions exceeding statutory

limit values. Illegal modification as such:

a) Dismantle or modify any part of air intake or exhaust system.

b) Modify or take off speed-adjusting connection device or speed adjustment device to result in the

engine’s running beyond the set parameters.

4. Problems Affecting Exhaust Emissions

a) Difficult starting or difficult stopping.

b) Unstable idling.

c) Give off black smoke or consume too much fuel.

d) Poor ignition sparks or sparks returned.

Once you find any of above problems, contact your dealer for help.

MAINTENANCE

MAINTENANCE SCHEDULE

Each

Frequency

Item

Oil level check √ Engine oil

Replace √ √

Oil level check √ Reduction gear

oil

PDF created with pdfFactory Pro trial version www.pdffactory.com

Replace √ √

time

First

month or

20 hrs

10

Each

season or

50 hrs

Every 6

month or

100 hrs

Each

year or

300 hrs

Page 12

Air cleaner

Check √

Clean

√① √②*

Replace √**

Deposit cup Clean √

Clean, adjust √ Spark plug

Replace √

Spark eliminator Clean √

Idling Check-adjust

Valve clearance Check-adjust

Fuel tank & fuel

filter

Clean

√②

√②

√②

Fuel supply line Check Every two years (do a replacement if necessary)

CAUTION:

Use only parts from the company or equivalents in quality; otherwise engine damage may result.

NOTE:

*: only for inside-ventilating double-core carburetors.

**: only for paper core air cleaners. Every two years or 600 hours’ later for dust collecting air

cleaners.

① More often than that in the schedule if in dusty circumstances.

② Should be done by your dealer unless you are specially trained and is well equipped with tools.

WARNING:

Stall the engine before service. If service is required with the engine running, be sure to keep good

ventilation in the area. The exhaust emissions from the engine contain toxic carbon monoxide,

inbreathing of it may result injury and even death.

REPLACEMENT OF ENGINE OIL

A still hot engine is helpful to drain out the engine oil in the crankcase rapidly and entirely.

11

Page 13

1. Turn off the oil filler cap and drain plug to drain engine oil

thoroughly. Reinstall the drain plug and screw in securely.

2. Fill the specified engine oil up to the upper level mark.

3. Reinstall the oil filler cap.

Engine oil capacity in the reduction gear box is 0.3 0.5 liters,

engine oil capacity in the crankcase is 0.6(1.1) liters.

NOTE:

Do not dump oil containers or discarded engine oil into rubbish

boxes or onto the ground. For the sake of environmental

protection, we suggest you take in discarded engine oil with a

closed container and bring to local recycling station.

SERVICE OF AIR CLEANER

A dirty air cleaner may block enough air’s flowing into the

carburetor. To keep the carburetor in good working conditions,

please service the air cleaner periodically. If operating the engine

in extremely dusty area, the job should be done more often.

WARNING:

Never clean the air cleaner core in gasoline or low flash-point

detergents, or explosion may happen.

CAUTION:

Never run the engine without an air cleaner, or air with dirt and dust may enter the engine so speed

the engine’s wear.

Dual element type

Unscrew the wing nut, dismantle the air cleaner housing.

Check if the two cores are damaged, if so, replace with new

one.

a) Foam filter element: clean with home detergents and

warm water (or non-flammable or high flash-point cleansing

solvents) and dry up, then soak in clean engine oil until

saturated. Squeeze out excess oil, otherwise, the engine

will discharge smoke in starting stage.

b) Paper filter element: knock the core against a solid plane

to get rid of accumulated dust or blow out dust from inside to

outside with high-pressure air flow (not more than 30psi).

Never clean with a brush, as brushing may force the dust

into the core fiber. If the core is extremely filthy, replace with

a new one.

Dust-collecting type

1. Unscrew the wing nut, dismantle the air cleaner housing,

check if the two cores are damaged, if so, replace with new

one.

a) Foam filter element: clean with home detergents and

warm water (or non-flammable or high flash-point cleansing solvents) and dry up, then soak in

12

Page 14

clean engine oil until saturated. Squeeze out excess oil, otherwise, the engine will discharge

smoke in starting stage.

b) Paper filter element: knock the core against a solid plane to got rid of accumulated dust or blow

out dust from inside to outside with high-pressure air flow (not more than 30psi). Never clean with a

brush, as brushing may force the dust into the core fiber. If the core is extremely filthy, replace with

a new one.

2. Clean the dust-collecting hood: screw off the three special semi-round screws and remove the

hood, wash parts with water and then dry up. Reinstall the hood.

CAUTION:

● When reinstalling the dust collecting core air cleaner, make sure to embed the fin on the pre-air

cleaner hood in the dent in the dust-collecting hood.

● Install the air guide in correct order.

Single-core type

1. Remove the wing nut and air cleaner housing, and take out the filter element.

2. Clean with home detergents (or high flash-point cleansing solvents) and warm water, and dry

up.

3. Soak in clean engine oil until saturated; squeeze excess oil, or the engine will exhaust smoke in

starting stage.

4. Reinstall the filter element and air cleaner housing.

Oil bath type

1. Remove the nut and air cleaner housing, and take out the filter element.

2. Clean with home detergents (or high flash-point cleansing solvents) and warm water, and dry

up.

3. Soak in clean engine oil until saturated. Squeeze excess oil, or the engine will discharge smoke

in starting stage.

4. Empty the air cleaner housing of oil. Clear away the dust inside with non-flammable or high

flash-point cleansing solvents, and dry it up.

5. Fill the air cleaner housing with the specified engine oil up to the standard oil level mark.

6. Reinstall the air cleaner.

WASHING OF DEPOSIT CUP

Set the fuel cock at “OFF”, disconnect the

deposit cup and O-ring. Wash in non-flammable

or high flash-point cleansing solvents, and then

try them up, at last, reinstall it. Set the fuel cock

to “ON” and check for leaks.

WARNING:

Gasoline is extremely flammable and explosive

in certain condition. Keep cigarette, sparks and

open flames away.

● After reinstalling the deposit cup, make sure the area around the engine is dry enough.

SPARK PLUG

Spark plug type: BPR6ES (NGK) or NHSP LD F6RTC

13

Page 15

Proper spark plug clearance ensures the engine’s normal running under no deposit around the

spark plug. Warning Be careful not to touch the muffler during or just after running the

engine.

1. Remove the spark plug cap.

2. Clear away dirt around the spark plug base.

3. Dismantle the spark plug with a spark plug

wrench.

4. Clean with a steel brush. If the insulator is

damaged, replace the spark plug instead.

5. Measure the spark plug clearance with a

feeler. The clearance should be 0.7~0.8mm.

If adjustment is necessary, bend the side

electrode carefully.

6. Check if the spark plug gasket is in good

conditions, or replace with a new one. Screw

on the spark plug to the bottom first by hand

and then screw in by a spark plug wrench. If

a new spark plug is used, twist 1/2 more

turns after impacting the gasket, if reinstall

the original one, just twist 1/8-1/4 more

turns.

CAUTION:

● The spark plug must be tightened securely, or it may become very hot to damage the

engine.

● Only use recommended spark plug or the equivalent. Incorrect heat range of the spark

plug may damage the engine.

CARBURETOR IDLING

ADJUSTMENT

1. Start and preheat the engine until arriving

at the normal working temperature.

2. Obtain standard idling by adjusting the

throttle fixing screw under the engine’s

idling. Standard idling: 1700±150rpm.

14

Page 16

TRANSPORT, STORAGE AND REMOVAL FROM STORAGE

TRANSPORT

Transport with the fuel cock turned off. Transport or store the engine when it is cool so as to avoid

getting burns or fire.

CAUTION:

Do not incline the engine so as to avoid fuel’s spill. Spilled fuel or fuel vapor may ignite to cause

fire.

STORAGE

If the engine is not kept in use for a long time, be sure to store it properly. Make sure the storage

area is dry and free of dust.

1. Drain the fuel ...

a. With the fuel valve in the OFF position, remove and empty the sedi-ment cup.

b. Turn the fuel valve to the ON position and drain the gasoline from the fuel tank into a suitable

container.

c. Replace the sediment cup and tighten securely.

d. Drain the carburetor by loosening the drain screw. Drain the gasoline into a suitable container.

WARNING: Gasoline is extremely flammable and is explosive under certain conditions. Do not

smoke or allow flames or sparks in the area.

2. Replace engine oil.

3. Disconnect the spark plug. Fill about a spoon of fresh engine oil from the spark plug mount hole

into the cylinder. Crank the engine up to distribute engine oil evenly. Reinstall the spark plug.

4. Pull the starting rope slowly until feeling a slight anti-action, and then keep pulling it so as to

align the arrow of the starting sleeve with the hole of the starter. At this time, both the inlet and

outlet valves are closed so help prevent the engine inside from rusting.

5. Electric starter: disconnect the battery and store in dry and cool area. Charge once every

month.

6. Cover the engine so keep dust away.

15

Page 17

REMOVAL FROM STORAGE

Before reusing, service the engine in accordance with the instruction of the table

STORAGE TIME SERVICE ITEM

Within one month Non

One ~ tow months

Two month ~ one

year

Above one year

⑴ Screw off the drain plug and drain out fuel in the carburetor.

⑵ Turn off the engine switch first, disconnect the deposit cup and empty it.

Note: for the sake of environmental protection, we recommend to fill the discarded fuel into a

closed container and bring to local recycling station. Never pour freely.

Drain out original fuel of the fuel tank and

refuel

Drain out original fuel of the fuel tank and

refuel;

Drain out fuel in the carburetor①;

Empty the deposit cup②

Drain out original fuel of the fuel tank and

refuel;

Empty the fuel cup in the carburetor①:

Empty the deposit cup②

WARNING:

Fuel is extremely flammable and explosive under certain conditions. Keep cigarette, open flames

and sparks away from operating site.

16

Page 18

SPECIFCAIONS

MAIN SPECIFICATIONS

Model

XP7HP XP7HPE XP16HP XP16HPE

Items

Engine type 4-strok, OHV,25°,single-cylinder, force air-cooled

bore×stroke(㎜)

Rated

power(kW/rpm)

Max.

torque(N·m/rpm)

Displacement(ml) 208 420 420

Starting type

Ignition type Induction ignition

Lubricating type splashing

Fuel consumption

(g/kW-h)

Dry weight 33lbs. 35.3lbs. 73 lbs. 77 lbs. 73 lbs. 77 lbs.

Dimension(L×W×H

)(in.)

recoil

70×54 90×66 90×66

4.2/3600 8.5/3600 8.5/3600

13.2/2500 28.5/2500 28.5/2500

Electric

start

≤395 ≤375

14.25×12.3×13.2 17.7×16×17.4

recoil

Electric

start

recoil

Electric

start

TORQUE OF IMPORTANT BOLTS

S/N Item Specifications

1 Cylinder head bolt M8×1.25 24±2

2 Crankcase cover bolt M8×1.25 24±2

3 Tie-rod bolt M7×1 12±2

4 Flywheel bolt 70~80

5 8~10

TROUBLESHOOTING

I. START ENGINE DIFFICULTLY

1. By using kick-starter

TROUBLE CAUSE REMEDY

1. Normal cylinder

compression.

2. Normal spark plug

spark.

3. Something wrong

with the fuel system.

4. Fuel supply is not

smooth or no fuel

There is no enough fuel

in fuel tank of fuel cock is

closed.

Air vent in the fuel filler

cap is clogged.

Fuel cock is clogged. Clean first and then dredge.

Improper or clogged main

oil flow hole.

Torque Value(N﹒m)

Fill fuel, open fuel cock.

Dredge air vent.

Readjust or clean, blow to get through.

17

Page 19

supply.

1. Normal cylinder

compression.

2. Normal spark plug

spark.

3. Something wrong

with the fuel

system.

4. Smooth fuel flow.

1. Normal cylinder

compression.

2. Normal fuel

supply.

3. Normal

high-pressure coil

spark.

4. Spark plug is in

bad conditions.

1. Normal cylinder

compression.

2. Normal fuel

supply.

3. No high-pressure

coil spark.

4. Normal spark

plug.

1. Poor cylinder

compression.

2. Normal fuel

supply system.

3. Normal ignition

system.

Needle valve is not

closed properly or start

Dismantle needle valve and repair, clean,

blow to get through.

hole is clogged.

Float is damaged or

Repair float

sticking.

Fuel is too filthy or

Replace

deteriorated

There is water in fuel Replace

Too much fuel in engine Drain extra fuel, dry up spark plug

electrodes

Wrong fuel brand Select proper fuel brand corresponding

with the requirements

Too much carbon deposit

Clear away

and dirt around

electrodes.

Electrodes are burn

Replace spark plug

damaged seriously or

insulators damaged

Improper electrodes gap Adjust to proper value

High-pressure coil is

Replace

damaged

Ignition coil is damaged Replace

Magneto loses

Replace

magnetism

Piston ring is worn to or

Replace

even over its wear limit

Piston ring is broken Replace

Piston ring is sticking Clear up carbon fouling

Spark plug is not installed

Tighter with a gasket in

tighten or without a

gasket

Air leakage between

cylinder block and

cylinder head

Check cylinder gasket, and the flatness of

the surface by which cylinder block

contacting with cylinder head, tighten

cylinder head bolts in stipulated order to

stipulated torque.

Air leakage in valves

Check valve, clearance and tightness,

repair if necessary

WARNING:

● When testing the spark plug, never hold the high-voltage wire of the spark plug with wet hand.

18

Page 20

● Make sure there is no spilled fuel outside the engine and that the spark plug isn’t dipped with

fuel.

● To prevent fire, keep sparks far away from the spark plug mount hole.

2. By using starting motor

ITEM CAUSE REMEDY

Check battery connection Incorrect connection Correct

Check battery No charge or under charge,

corrosion

Starting motor functions

Be the same as kick-starter Conduct it in the same way

normally

Check the breaker, charge

up the battery or replace it

of kick-starter

Having fulfilled all the check items above, the engine still fails to work, contact your dealer for help.

II. LOW GASOLINE ENGINE POWER OUTPUT

TROUBLE CAUSE REMEDY

When turning

throttle greater,

speed in crease

responds slow or

speed is

decreased even

engine stops

running

Ignition

system

Fuel supply

system

Incorrect ignition time

Air in fuel line or fuel line

clogged

Main oil flow hole is not

adjusted properly

In carburetor, needle valve hole

and main oil flow hole clogged

Fuel cock is clogged up

Too much carbon deposit in

combusting chamber

Too much carbon fouling in

muffler and exhaust pipe

Air cleaner is clogged up Clean air cleaner filter

Readjust ignition advance

angle

Exhaust air or dredge fuel

line

Readjust

Clean and blow to get

through

Clean, replace damaged

part

Clear away

Clear away

elemi

Intake pipe is leaking Repair or replace

Piston or cylinder or piston ring

Replace the worn

is worn

Poor

compression

Air leakage from the surface by

which cylinder block contacting

Replace cylinder gasket

with cylinder head

Too big or too small valve

Readjust it

clearance

Valve tightness is poor repair

III. GASOLINE ENGINE CANNOT RUN SMOOTHLY

TROUBLE CAUSE REMEDY

Engine is pinging

Piston, cylinder or piston ring is worn

excessively

Piston pin and piston pin hole are

worn excessively

Replace the worn

Replace piston or piston pin

Tie rod small head is worn excessively Replace tie rod

19

Page 21

Roller bearing for crankshaft main

shaft is worn

Engine is too hot Shoot trouble

Too much carbon deposit in

Abnormal combustion

combustion chamber

Improper gasoline brand or low

gasoline quality

There is water in float chamber Clean

Engine cannot start

because of spark

lacking

Improper spark plug electrodes

clearance

Incorrect ignition time Readjust

Something wrong with induced coil,

and so on

IV. STOP SUDDENLY WHEN RUNNING

TROUBLE CAUSE REMEDY

Fuel supply

system

Stop suddenly

when running

Ignition system

The other

Replace roller bearing

Clear away

Replace with qualified

gasoline

Adjust

Check and replace

damaged parts

Fuel is used up Refill fuel

Carburetor is clogged Check fuel line and dredge

Float is leaking Repair

Needle valve sticks

Dismantle float chamber

and criminate it

Spark plug is struck

through, or

short-circuited by carbon

Replace spark plug

deposit

Side electrode of spark

Replace spark plug

plug is dropped out

High-pressure wire is

Weld on

dropped out

Ignition coil is struck

Replace ignition coil

through to be

short-circuited

Parking wire is located

on engine body

Cylinder is pulled

damage, valve is

Find out meeting and

insulate

Repair or replace damaged

parts

dropped out

V. GASOLINE ENGINE IS EXCEESIVELY HOT

TROUBLE CAUSE REMEDY

Gasoline engine is

excessively hot

Improper ignition time Adjust ignition advance angle

properly

Insufficient fuel supply Refill engine oil

Exhaust pipe is blocked up Dredge exhaust pipe

Flow guard is leaking Repair damaged part

20

Page 22

Dirt or something like this fill up

noise during

among air cooling fins

Cooling fan is loosen, losing

Clear away dirt or something like

this

Reinstall well

function

The rod deformation makes

Replace tie rod

piston and cylinder bushing side

wear

Cylinder or piston or piston ring

Replace the worn

is worn, resulting in air flow

between cylinder and crankcase

Improper adjustment of engine

speed produces excessive

Readjust engine speed to proper

value by speed regulator

rotational speed

Crankshaft main bearing is burnt

Replace main bearing

out

NOTE: the gasoline should run under certain temperature. Generally, permitting temperature at the

flow guard outlet is between 80-110℃, while the temperature of the crankcase is about 60℃ under

the magneto. If temperatures surpass the limits, it is an indication that the gasoline engine is

excessively hot.

VI. THERE EXISTS ABNORMAL NOISE WHEN ENGINE RUNNING

TROUBLE CAUSE REMEDY

Abnormal noise

Piston, piston ring or cylinder is

worn

Tie rod or piston pin and piston pin

hole is worn

Replace the worn

Replace the worn

Crankshaft main bearing is worn Replace

Piston ring is broken Replace

There is an abnormal

combustion

Too much carbon deposit in

combusting chamber

Too small electrode clearance of

spark plug

Engine is flooded with fuel

Clear away carbon deposit

Adjust electrode clearance

properly

Check relative parts such as

carburetor

Improper fuel brand Replace fuel

Engine is excessively hot Find a cause and eliminate it

Improper valve clearance

The other

Fly wheel is not connected with

crankshaft tightly

Readjust calve clearance

properly

Connect tightly

21

Page 23

WIRING DIAGRAM

22

Page 24

Note: The diagram for other types may be different with the exception of electric-start type.

23

Page 25

EXPLODED VIEW AND PARTS LIST(7HP)

24

Page 26

Item Part Q

ty

Description Item Part Qty Description

1

GBT5789-86 13 Flange bolt M6×12

2

DJ168F-11300-B 1 Cover assembly

3

DJ168F-11011-A 1 cover assembly

4

DJ168F-13204-A 1 Lock Nut

5

DJ168F-13203-A 1 Adjusting Nut

6

DJ168F-13201-A 1 Arm, valve rocker

7

DJ168F-13006-A 1 Rotator, valve

8 DJ168F-13202-A 2 Fastening Bolt 52 DJ168F-11002-D 1 Pin, dowel, 7×12

9 DJ168F-13005-A 1

10 DJ168F-13004-A 1

11 DJ168F-13300-A 1 Plate, push rod guide 55 DJ168F-11001-C 1 Crankcase cover

12 DJ168F-13003-A 2 Spring, valve 56 DJ168F-11600-A 1 Dipstick cover

13 DJ168F-13010-A 1 Returnrer, Exhaust Valve 57 DJ168F-11014-A 2 Oil seal, 25.14×35×7

45 DJ170F-11100-C 1 Crank case assy.

46 GB276-89-6205 2

47 DJ168F-15100-A 1 Speed Regulating Gear

48 DJ168F-15100-A 1 centrifugal assy.

49 DJ168F-13100-B 1 Camshaft assy.

50 DJ168F-12100-QT 1 Crankshaft Assembly

51 DJ170F-12200-B 1 Tie-rod Assembly

53 DJ170F-11003-B 1 Crankcase Gasket

54 DJ168F-11007-A 1 Oil Filler Assembly

14 GBT5787-B8-60 4 Flange bolt M8×60 58 GBT5787-B8-35 6 bolt M8×35

15 DJ168F-18500-B 1 Spark Plug F7TC 59 DJ168F-18100-C 1 Ignition Coil

16 DJ170F-11200-B 1 Head comp, cylinder 60 GBT5787-B6-25 2 bolt M6×25

17 DJ168F-14006-C 1 Outlet Gasket 61

18 DJ170N-14400-A 1 Muffer Assembly 62 DJ170N-15200-A 1 speed adjuster

19 DJ168F-14002-A 2 Bolt head, M8×35 63 DJ170N-15201-A 1 Speed Regulating Bar

20 GBT6177-N-8 2 Flange nut M8 64 DJ168F-16200-C 1 Flywheel

21 DJ168F-14001-A 2 Bolt Stud, 6×90 65 DJ168F-16002-A 1 Flywheel Fan

22 DJ168F-14003-B 1 Inlet Gasket 66 DJ168F-16000-A 1 Starting Cup

23 DJ168F-14004-A 1 Connecting

Block,Carbretor

24 DJ168F-14005-A 1 Carbretor Gasket 68 DJ168F-11400-A 1 Wind Shiel Assembly

25 DJ170N-14100-A 1 Carburetor Assembly 69 DJ170N-16121-A 1 Recoil Sarer

26 DJ168F-14027-A 1 Air Cleaner Gasket 70 DJ170N-16122-A 1

DJ168F-11012-A

67 GBT6177-N-14 1 Flange nut M14

1 Air-leading Cover

recoil starter

27 DJ170N-11013-A 1 Tube, Breather 71 GBT5787-B6-8 3 Bolt Flange M6×8

28 DJ170N-11420-A 1 AirCleaner Assembly 72 DJ168F-15001-A 1 Shaft, governor assy.

29 GBT6177-N-8 2 Flange nut M8 73 DJ168F-15003-A 1 Pin Lock

30

DJ170F-12301-A

4

Piston Ring A

74 DJ168F-15004-A 1 Speed Regulating Arm

25

Page 27

31

DJ170F-12302-A

1

Piston Ring B

75 DJ168F-15005-A 1 Lock Bolt

32

DJ170F-12304-A

33 DJ170F-12303-A 1 Wave Ring 77 DJ170F-15007-B 1 Back Spring B

34 DJ170F-12304-A 1 Side Ring 78 DJ168F-15006-A 1 Pulling Rod

35 DJ170F-12300-A 1 Scraper Ring Set, Piston 79 DJ170F-15008-A 1 Fine Regulating Spring C

36 DJ168F-12003-A 2 Clip, piston pin 80

37 DJ170F-12002-A 1 Pin, piston 81

38 DJ170F-12001-B 1 Piston 82 DJ168F-18300-A 1 Amplifier

39 DJ168F-13002-A 1 Intake Valve 83 DJ168F-18200-A 1 Oil Sensor Assembly

40 DJ168F-13001-A 1 Exhaust Valve 84 GBT5787-B6-16 2 bolt M6×16

41 DJ170F-13008-A 2 Rod, push 85 DJ168F-11004-A 2 Drain Plug Washer

42 DJ170F-13009-A 2 Tappet Litter Valve 86 DJ168F-11005-A 2 Washer, drain lug

43 DJ170F-11010-C 1 Casket, cylinder head 87

44 DJ168F-11009-A 2 Set Pin, 10×14 88

1 Side Ring 76 GBT6177-N-6 3 Flange nut M6

DJ1P65F-14008-A 2 Tube clip

DJ170N-14007-A 1 Outlet pipeφ6×φ10×295

DJ170N-14302-A 1 Fuel cock

DJ170N-14300-A 1 Fuel tank

89 GBT5787-B6-16 3 bolt M6×16 90 GBT93-LW-8 2 spring washer

26

Page 28

EXPLODED VIEW AND PARTS LIST (16HP)

27

Page 29

Ite

Part Q

m

Description Item Part Q

t

y

1 GBT5787-B6-8 3 Bolt Flange M6×8 44

2

DJ190N-16122-A 1 recoil starter

3 GBT5787-B6-12 9 Bolt Flange M6×12 46

4

DJ190N-16121-A 1 Starter comp, recoil

5

GBT6177-N-14 1 Flange nut M14

6

DJ188F-16001-A 1 Pulley, starter

7

DJ188F-16002-A 1 Fan, cooling

8

DJ188F-16200-C 1 Flywheel comp

9

DJ188F-11014-A 2 Oil seal, 35×52×8

10

DJ190F-11100-C 1 Crank case assy.

11

DJ188F-11004-A 2 Bolt, drain lug

12

DJ188F-11005-A 2 Washer, drain lug

Description

t

y

DJ188F-13006-A 1 Rotator, valve

45

DJ188F-13300-A 1 Plate, push rod guide

DJ188F-13202-A 2 Bolt, pivot

47

DJ188F-13201-A 2 Arm, valve rocker

48

DJ168F-13203-A 2 Nut, Arm, valve rocker

49

DJ168F-13204-A 2 Nut, pivot adjusting

50

DJ188F-11011-A 1 Exhaust piper

51

DJ188F-11300-B 1 Cover comp, head

52

DJ188F-11015-A 1 Bolt, head cover

53

DJ188F-14006-A 1 Casket (B) EX. Pipe

54

DJ188F-14002-A 2 Bolt head, M8×48

55

GBT6170-N-8 3 Nut M8

13

DJ188F-11009-A 2 Pin, dowel, 12×20

14

GB276-89-6207 1 Radial ball bearing (6207)

15

DJ190F-12100-QS 1 Crankshaft comp

16

DJ190F-13100-C 1 Camshaft assy.

17

DJ190F-11003-B 1 Packing, case cover

18

DJ188F-12004-A 1 Balancing Shaft

19

DJ188F-18300-A 1 Amplifier

20

DJ188F-18200-A 1 Oil Sensor

21

DJ188F-11001-D 1 Crankcase cover

22 GBT5787-B8-35 7 Bolt Flange M8×35 65

23

DJ190F-12200-B 1 Connecting rod assy.

24

DJ190F-12002-A 1 Pin, piston

25

DJ188F-12003-A 2 Clip, piston pin

26

DJ190F-12001-B 1 Piston

27 DJ190F-12304-A 1 Side Ring 70

28 DJ190F-12303-A 1 Wave Ring 71

29 DJ190F-12304-A 1 Side Ring 72

30

DJ190F-12302-A

31

DJ190F-12301-A

32

DJ190F-11010-C 1 Casket, cylinder head

33

DJ190F-13009-A 2 Lifter, valve

34

DJ190F-13008-A 2 Rod, push

35

DJ188F-13001-A 1 Valve, IN.

36

DJ188F-13011-A

37

DJ188F-11200-B 1 Head comp, cylinder

38

GBT5787-B10-80 4 Flange bolt M10×80

39

DJ168F-18500-B 1 Plug, spark

40

DJ188F-13010-A 1 Returner intake valve,lower

41

DJ188F-13003-A 2 Spring, valve

1

Piston Ring B

1

Piston Ring A

1 oil seal,Valve 79

56

57

58

59 DJ190N-14400-A 1 Muffer Assembly

60 DJ190N-14401-A 1 muffler protector

61 GBT5787-B6-8 4 Bolt Flange M6×8

62

63

64

66

67 DJ188F-14027-A 1 Gasket,Air Cleaner

68

69

73

74

75

76

77

78

80

81

82 DJ170N-15201-A 1 handle

83

84 DJ190N-14301-A 1 fule filler Cap

DJ190N-14009-A 1 Pipe comp EX.

GBT6175-N-8 2 Nut M8

DJ190N-14009-C 1 Pipe comp EX.

DJ177F-14001-A 1 Bolt head, 8×105

DJ190N-14003-B 1 Packing, carburetor

DJ190N-14004-A 1 Insulator, carburetor

DJ188F-14005-B 1 Packing, insulator

DJ190N-14100-A 1 Carburetor assy.

DJ190N-11013-A 1 Tube, breather

DJ190N-14203-A 1 Case comp, air cleaner

GBT6177-N-6 3 Flange nut M6

DJ190N-14202-A 1 Retainer Filter Element

DJ190N-14201-A 1 Element, air cleaner

DJ190N-14204-A 1 Cover comp, air cleaner

DJ190N-14207-A 1 Clip, air cleaner ware

DJ188F-11012-A 1 Shroud comp

DJ188F-18100-C 1 Coil assy. ignition

GBT5787-B6-25 2 Flange bolt M6×25

DJ188F-15100-A 1 Governor kit

DJ188F-15007-C 1 Spring, governor

DJ188F-15008-A 1 Spring, throttle return

DJ188F-15006-A 1 Rod, governor

DJ188F-15004-A 1 Arm, governor

28

Page 30

42

DJ188F-13005-A 1 Retainer, EX. Valve spring

43

DJ188F-13004-A 1 Retainer, IN. Valve spring

85 DJ190N-14300-A 1 fule filler

86 DJ1P65F-11038-A 1 Tube Cock

87 DJ190N-1400-A 1 Outlet pipeφ6×φ10×320 88 DJ170N-18400-A 1 Choke Switch

89

GBT5787-B8-20 2 Flange bolt M8×20

90

GBT5787-B8-35 2 Flange bolt M8×35

91 GBT93-LW-8 4 spring washer 92 GBT-W-8 4 flat washer

93 DJ188F-13002-A 1

95 DJ188F-11017-A 1

EX. Valve

Clip, wire

94

DJ190N-14001-B 1 Bolt head, 8×120

96

GB276-89-6202 2 Radial ball bearing (6202)

97 DJ188F-11039-C O-Ring 98 DJ190N-15200-A 1 speed adjuster

99

DF2500H-34118-A 1 Clip, wire 100 DJ188F-11006-A

101

DJ188F-11007-A Dipstick 102 DJ168F-11002-D

103

DJ168F-11002-F 1 Pin Φ9x14 104 DJ188F-15009-A

105

DJ188F-15003-A 1 Pin Lock 106 DJ188F-15002-A

107

DJ188F-15001-A 1 Moving Staff 108 DJ168F-15005-A

1 Dipstick cover

1 Pin Φ7x14

1

Oil Seal Moving Staff

1 Plain Washer

1 Lock Bolt

29

Loading...

Loading...