Page 1

MODEL: XP15000EH

This manual provides information regarding the operation and maintenance of these products.

We have made every effort to ensure the accuracy of the information in this manual.

We reserve the right to change this product at any time without prior notice.

Page 2

INTRODUCTION

Congratulations on your selection of a this generator. We are certain you will be pleased with your purchase of one of

the finest generators on the market.

We want to help you get the best results from your new generator and to operate it safely. This manual contains all the

information on how to do that; please read it carefully.

As you read this manual, you will find information preceded by a symbol.

That information is intended to help you avoiddamage to your generator, other property, or

the environment.

W

e suggest you read the warranty policy to fully un derstand its coverage and your responsibilities of ownership.

AFEWWORDSABOUTSAFETY

Your safety and the safety of others are very important. And using this generator sa fely is an important responsibility.

To help you make informed decisions about safety, we have provided operating procedures and other information on

labels and in this manual. This information alerts you to potential hazards that could hurt you or others.

Of course, it is not practical or possible to warn you about all the hazards associated with operating or maintaining a

generator. You must use your own good judgement.

You will find imp ortant safety i nformation in a variety of forms, including:

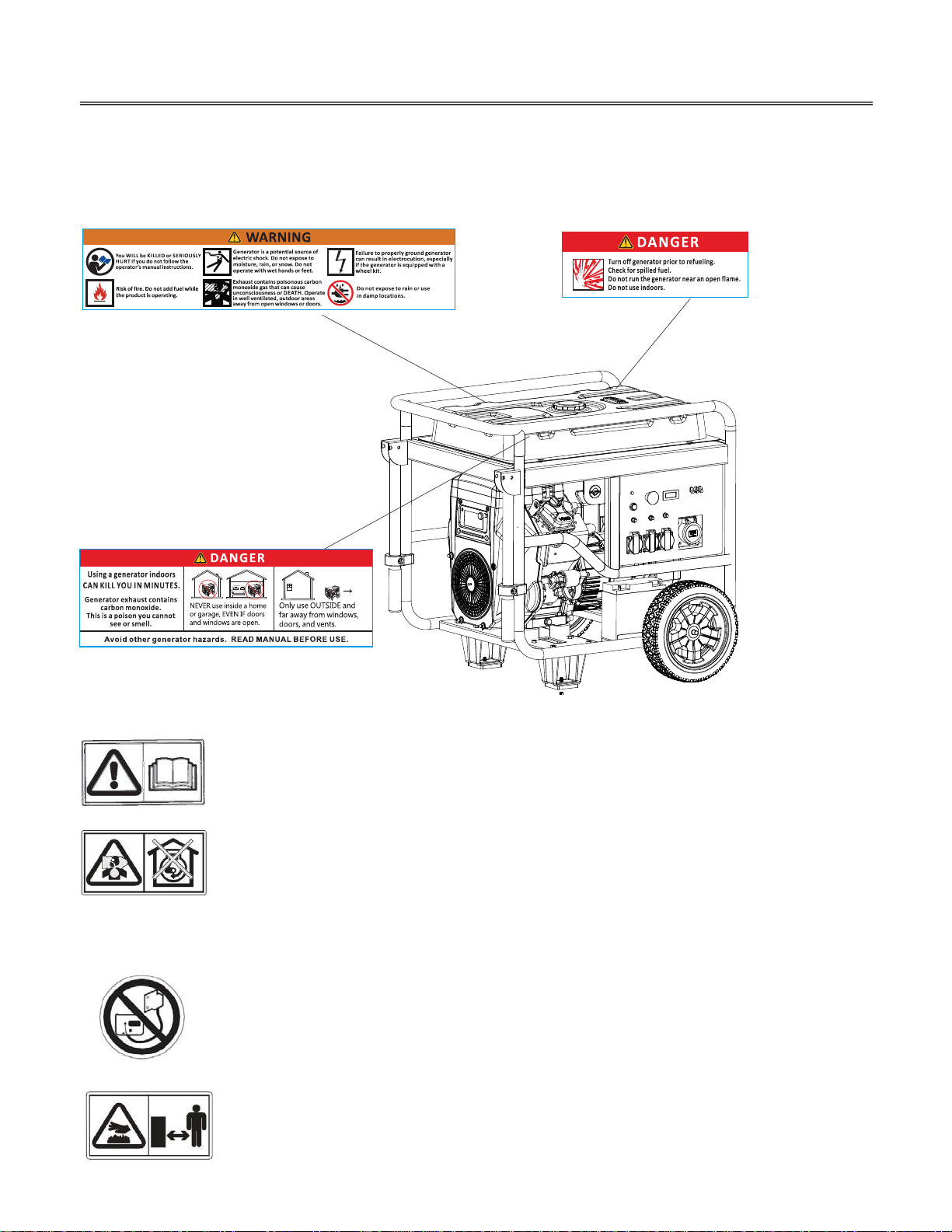

Safety Labels on the generator

.

Safety Headings such as IMP ORTANT SAFETY INFOR MATION.

Safety Section such as GENERATOR SAFETY.

Instructions howtousethisgeneratorcorrectlyandsafely.

This entire book is filled with important safety information please read it carefully.

When your generator need s scheduled main t enance, keep in mind your servicing dealer is specially trained in

servicing generators. Your authorized servicing deale r is dedicated to your satisfaction and will

be pleased to answer yo ur questions and concerns.

Safety Messages preceded by a safety alert symbol and one of three signal words, DANGER, WARNING, or

CAUTION.

1

Page 3

CONTENTS

GENERATOR SAFETY

IMPORTANT SAFETY INFORMATION ……………………………………………………………………………………………………………………….….4

Operator Respons ibility …………………………………………………………………………………………………………………………………….…..4

Carbon Monoxide Hazards ……………………………………………………………………………………………………………………… ……….….. 4

Electric Shock Hazards ………………………………………………………………………………………………………………………………… …….…. 4

Fire and Burn Hazards ………………………………… ………… ………………………… …………… ……………………………………… ………… .…..4

Refuel With Care ……… …………………………………… …………… ………………………… ……………………………… ………………… ……… .…..4

SAFETY LABEL LOCATIONS ………………………………………………………………… …………………………………… …………… …………. …………5

CONTROLS & FEATURES

COMPONENT & CONTROL L OCATIONS ………………………… …………………………………………………………………………………… .………6

CONTROLS ……………………………………………………………………… ………………… …………… ……………………… …………… …………… ……… 8

Fuel Valve Lever ……………………………………………………………………… ………………………… …………… ………………… …………….…… 8

Choke Knob ………………………………………………………………… ………… …………… ………………………… ……………………………….…… 8

Engine Switch ………………………………………………………… ……………… ………………………… ………………………… …………… …….…… 8

Circuit Breaker …………………………………………………………………………………………………… …………………… …………… ………….…… 8

FEATURES …………………………… ………………… …………………… …………………………… …………… ………………………… …………… …….…… 9

Oil Alert System …………………………………………………………………………………………… ………………… …………… ………………… .…… 9

Ground Terminal ……………………………………… ………………… …………… ………………………… ……………………………… …………….… 9

Fuel Gauge ……………………………………………………… …………… ………… ………………………… …………… ………………… ………………… 9

Volt Meter …………………………………………………… ………………………… ……………… ………………………… ………… ………………… …… 9

Hour Meter ………………………………………………………………………………………… ………………… …………… ………………… …….………10

AC Output Terminal/Cover ……………………….……………………………………………… …………… ………… ………………………….………10

………………………………………………………………………………………………… …………… ………………… ……………… . 4

………………………………………………………………………………………………………………………………….………… 6

BEFORE OPERATION

ARE YOU READY TO GET STARTED? ………………………………………………… ……………… …………………… ………… …………….……… .. 11

Knowledge …………… ……………………………………… …………… ………………………… ……………………………… ……….………..………… 11

IS YOUR GENERATOR READY TO GO? …………… …………………………………… …………… …………… …………………….………..…………

Check the Engine ……… ………………………… …………………………… …………………… …………… ………………… ……….………..…………11

Check the Battery ………………………………………………………………………………………… …………… …………… ……….………..……… 11

OPERATION

SAFE OPERATING PRECAUTION ………………………… …………………………………… …………… ………………………………… .………..…….12

STARTING THE ENGINE ……………… …………… ………………… …………… ………………………… …………… …………… ……….………..………12

STOPPING THE ENGINE …………………………………………………………………………………………………………… ………… .………..…………13

AC OPERATION ……………………………………………………………………………………………………… ……………………………….……… ..…… ..14

AC Receptacle ……………… ………………… ……………………… …………………………… ………………… ………………… ……….……… ..…… ..14

AC OUT PUT TERMINAL ……………………………………………………………………………………………………… …………… ….………..……… ..15

AC Applications ……………………………………… …………………………… …………………… ……………………………… ……….………..………16

STANDYBY POWER ………………………………………………………………… ……………… ……………………… …………… ……….………..………. 17

Connection to a Building’s Electrical System …………………………………………………… …………… …………………… .………..……. 17

System Ground ……………………………………… ………………… …………………………… …………… …………… …………………… .………..… 17

Special Requirements …………………………………………… ……………… ……………………… ………………… ………………….………..…….17

………………………………………………………………………………………………………………… ………………… ……… .………..…….. 12

SERVICING YOUR GENERATOR

THE IMPORTANCE OF MAINTENANCE ………………………………………………………… ………………………………… .………..…………... 18

MAINTENANCE SAFETY ……………………………………………………………………………… …………………………………… ……….……… ..……18

……………………………………………………………………………………………………………… ………………… …….……… ..…11

………………………………………………………………………………………… ……………… .………..…….….. 18

11

2

Page 4

CONTENTS

Safety Precautions …………………………………………………………………………………………… …………….………..……………………… .…18

MAINTENANCE SCHEDULE …………………………………………………………………………… …………… …………… .………..…………………… 19

REFUELING …………………………………………………………………………… ………………………… …………… …….……… ..………………………… 19

FUEL RECOMMENDATIONS ………………………………………………………………………………………… ………………… ……… .………..…….. 20

Gasolines Containing Alcohol ……………………………………………………………… ……………………………………….………..…………… 21

ENGINE OIL LEVEL CHECK ………………………… …………………… ……………………………………… …………… ……… .………..………………..21

ENGINE OIL CHANGE ……………… …………… …………………………………… …………………… ………………… …………… …………….……… ...22

OIL FILTER CHANGE …………………………………………………… …………… ……… ………………………… …… …………………… .………..……….

ENGINE OIL RECOMMENDATION ………………………………………………………………………………………………………….………..………. 23

AIR CLEANER SERVICE ………………………………………………………… ………………………… …………… …………………… .……….…………...23

FOAM AIR FILTER CLEANING ……………… ………………… …………… ………………………………………… ………… ……………… .………..….. 24

SEDIMENT CAP CLEANING …..…………………………………………………… …………………………… …………… …………………… .………..…..24

SPARK PLUG SERVICE ………………………………………………………… ……………………………………… ………… ……………….………..……… 24

BATTERY SERVICE ………………………… ………………… ……… …… ………………………… …………… …… …… ……………….………..…………… 25

Battery Removal ………………………………………………………………………………………………………………… …….………..……………….25

Battery Charging …………………………………………………………………………………… ………………………… …… .………..………………….26

22

STORAGE

STORAGE RECAUTION …………………………………………………………………………………… …………………………………… .………..………..28

STORAGE PROCEDURE ……………… ………………………… …… …………………… ………………… ………………… …………………….………..….29

STORAGE PRECAUTIONS ……………………………………………………………… ……… ……… ………… …… ……………… …… ………….………...30

REMOVAL FROM STORAGE ………………………………………… …………… …………… ……………………… …………… ……………… .………..…30

TRANSPORTING

TAKING CARE O F UNE XP ECTED PROBL E M S ………………………………………………………………………………………………….……… ..…..32

ENGINE PROBLEMS ……………………………………………………………………………… ………………… ………………… ……….………..………….32

GENERATOR PROBLEMS ………………………………………………………………………………………………………………….………..……………..33

TECHNICAL INFORMATION

SERIAL NUMBER LOCATION …………………………………………………………… ………………………… …………… ……… .………..……………. 34

CARBURETOR MOD IFI CATION FOR HIGH ALTITUDE

OPERATION ……………………………………………………………………………………………………………………………………… .………..….……… 34

SPECIFICATIONS ……………………………………………………………………… ……………………………… …………… …………….……… ..………... 35

WIRING DIAGRAM ………………………………………………………………………………………… …………… ……………… .………..………………..36

……………………………………………………………………………………………………… …………… ………………… ………… .………..……….28

Cleaning …………………………………………………………………………………………………………………………… ……………….………..………28

Fuel ……………………………………………………………………………………… ………………… …………………… ………… ………….………..……..28

……………………………… …………………………………………… ……………… ……………… ……………… ………….………..…....31

Engine Will Not Start …………………………………………………… ………………………… ……………………………… …….………..……………32

Engine Lacks Power ……………………………………………………………………………………………………… ………………… .………..……….. 32

No Power at the AC Receptacles …………………………………………………………… ……………………………… .……… ..………………….

………………………………………………………………………………………………… ……………… .………..………. 34

33

OPTIONAL PARTS

Wheel Kit ………………………………………………………… …………………… ………… …………………………… .………..……………………….… 38

INDEX

………………………………………………………………………………………………………… ………………… ………………… .………..…….………

…………………………………………………………….………………………………………………………………… …….………..…….38

3

39

Page 5

GENERATOR SAFETY

IMPORTANT SAFETY INFORMATION

THIS generators are designed for use with electrical equipment that has suitable power requirements. Other uses can

result in injury to the op erator or damage to the generator and other property.

Most acciden ts can be prevented if you follow all instructions in this manual and on the generator. The most comm on

hazards are discussed below, along with the best way to protect yourself and others.

Operator Re sponsibility

Know how to stop the generator quickly in case of emergency.

Understand the use of all generator controls, output receptacles, and connections.

Be sure that anyone who operates the generator receives proper instruction. Do not let children operate the generator

without parental superv isi on.

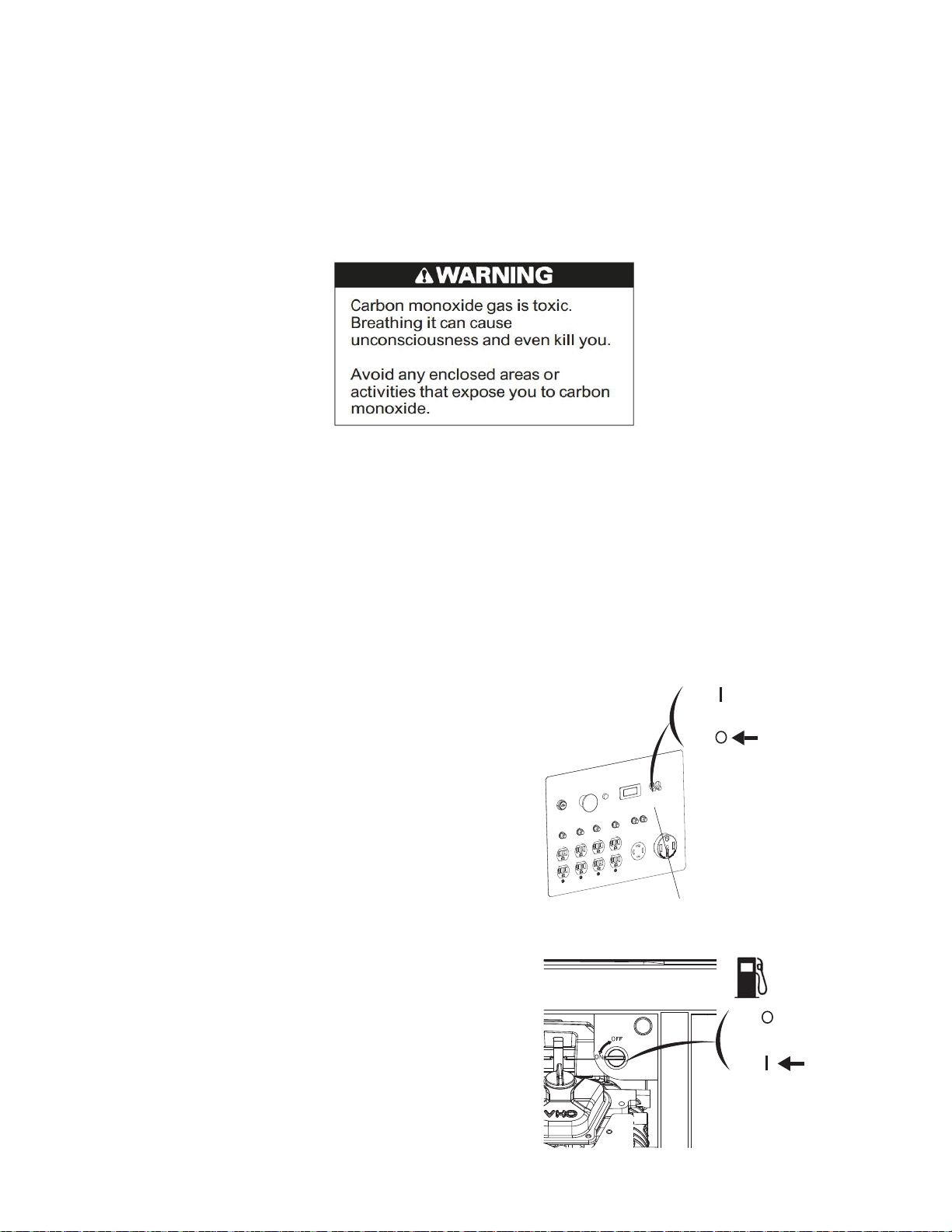

Carbon Monoxide Hazards

Exhaust contains poisonous carbon monoxide, a colorless, odorless gas. Breathing carbon monoxide can cause loss

of consciousness and may lead to death.

If you run the generator in an a rea that is confined , or even pa rtly enclosed area, the air you breathe could contain

dangerous amount of exhaust gas.

Never run your generator inside a garage, house, or near open windows or doors.

Electric Shock Hazards

The generator produces enough electric power to cause a serious shock or electrocution if misused.

Using a generator or electrical appliance in wet conditions, such as rain or snow, or near a pool or sprinkler system,

or when your hands are wet, could result in electrocution. Keep the generator dry.

If the generator is stored outd oors, unprotected from the weather, check all of the electrica l components on the

control pan el before each use. Moisture

or ice can cause a malfunction or short circuit in electrical

components that could result in electrocution.

Do not connect to a building’s electrical system unless an isolation switch has been installed by a qualified electrician.

Do not use th e generator without pro tective switch-off device.

Fire and Burn Hazards

The exh aust system gets hot enough to ignite some materials.

Keep the generator at least 1 meter away from buildings and other equipment during o peration.

Do not enclose the generator in any structu re.

Keep f lammable materials away from the generator

The muffler becomes very hot during operation an d remains hot for a while after stopping the engine. Be careful

not to touch the muffler while it is h ot. Let the engine cool before storing the generator indoors.

Refuel With Care

Gasoline is extremely f lammable, an d gasoline vapor can expl o de. Allow the engin e to cool if the generator has been in

operation. Refuel only outdoors in a well ventilated area with the engine OFF. Do not overfill the fuel tank. Never smoke

near gasoline, and keep other flames and sparks away. Always store gasoline in an approved container. Make sure that

a

ny spilled fuel has been wiped up before starting the engine.

4

Page 6

GENERATOR SAFETY

SAFETY LAB EL LOCATIONS

These labels warn you of potential hazards that can cause seriou s injury. Read them carefully. If a label comes off

or becomes hard to read, contact your THIS servicing dealer for a placement.

THIS generator is designed to give safe and dependable service if operated according to

instructions.

Read and understand the Owner ’s Manual before operating the generator. Failure to do so could

result in personal injury or equipment damage.

Exhaust contains poisonous carbon monoxide, a colorless, odorless gas. Breathing carbon

monoxide can cause loss of consciousness and may lead to death.

If you run the generator in an area that is confined, or even partially enclosed area, the air you

breathe could contain a dangerou s amount of exhaust gas.

Never run your generator inside a garage, house or near open windows or doors.

Do not connect to a building’s electrical system unless an isolation switch has bee n installed by

a qualified electrician.

Connections for standby power to a building ’s Electrical system must be made by a

qualified Elec trician and must comply with all app licable laws and electrical codes. Im proper

connections can allow electrical current from the generator to bac k feed into the utility lines.

Such back feed may electrocute utility company workers or others who contact the lines during

a power outage, and w hen utility power is restored, the generator may explode, burn,

or cause fires in the building’s electrical system.

A hot exhaust system can cause serious burns. Avoid contact if the engine has been running.

5

Page 7

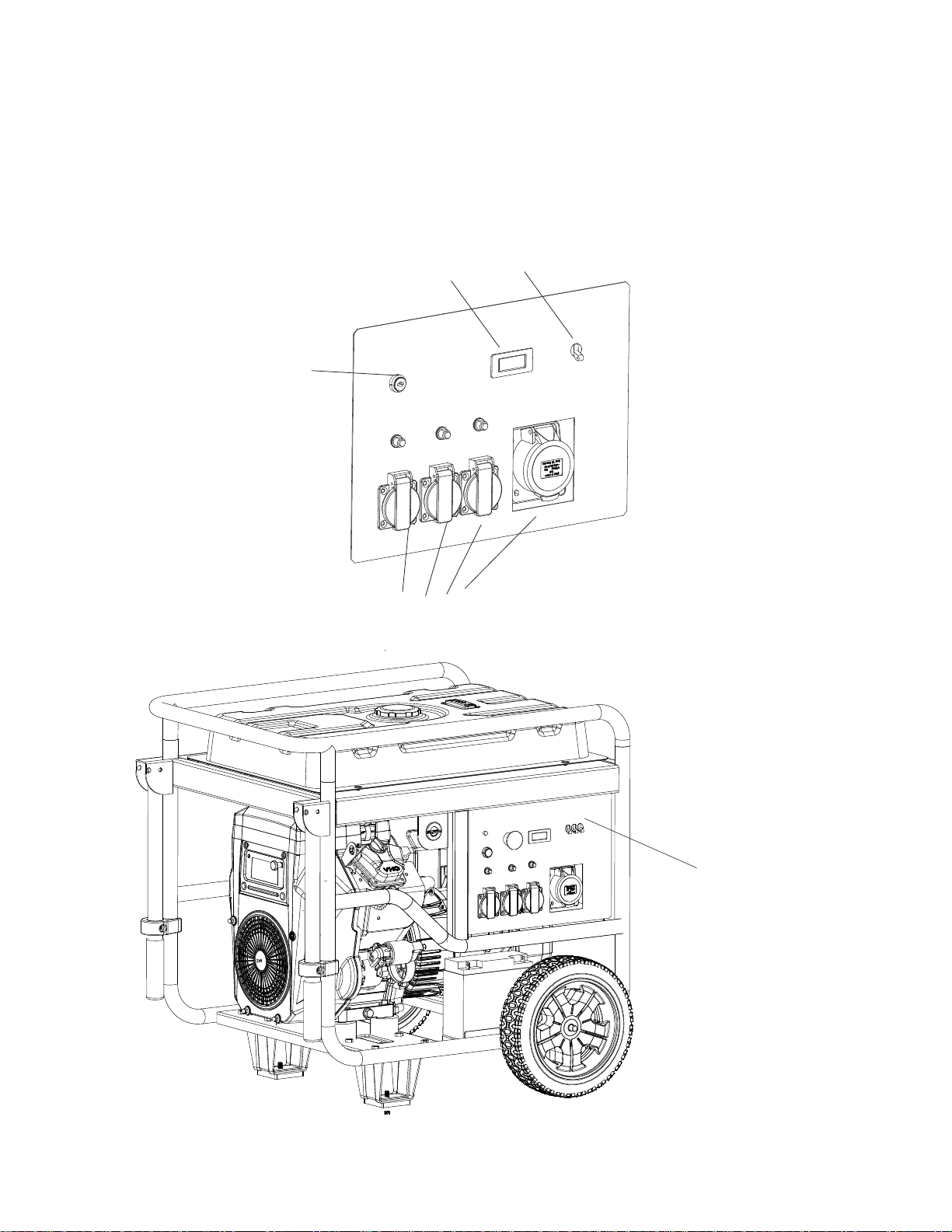

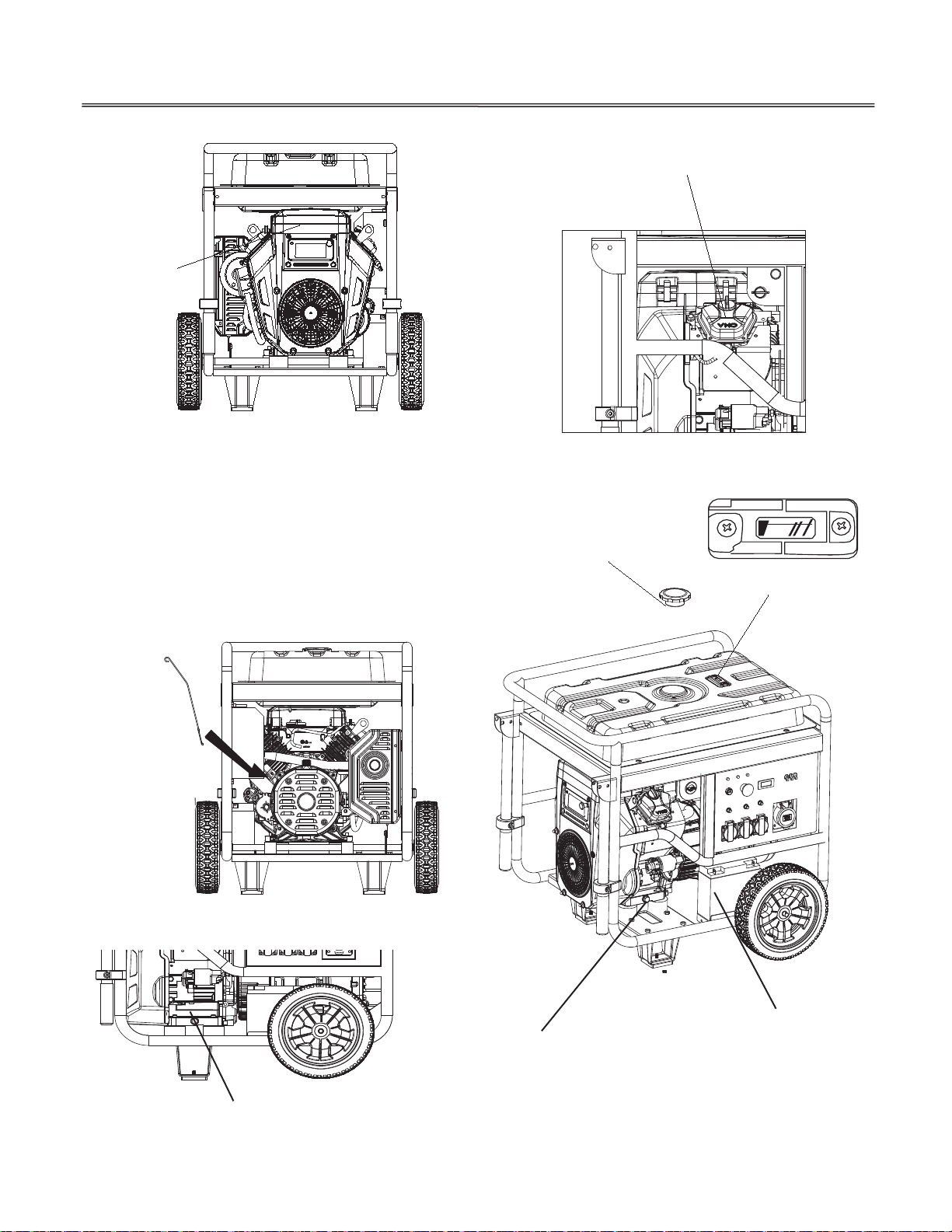

CONTROLS & FEATURES

COMPONENT & CONTROL LOCATIONS

Use the illustrations on these pages to locate and identif y the most frequently used controls.

ENGI N E

SWITCH

HOU

R

METER

C RECEPTACLES

A

CIRCU I T

BREAKE R

CONTROL PANEL

6

Page 8

CONTROLS & FEATURES

AIR CLEANE R

CY LI ND E R

HEAD

OIL LEVEL

DIPSTIC K

FUEL TAN K CA P

EMPTY FULL

FUEL

GA UG E

ELECTR I C

STARTER

BATTERY

OIL DRAIN TUBE

7

Page 9

CONTROLS & FEATURES

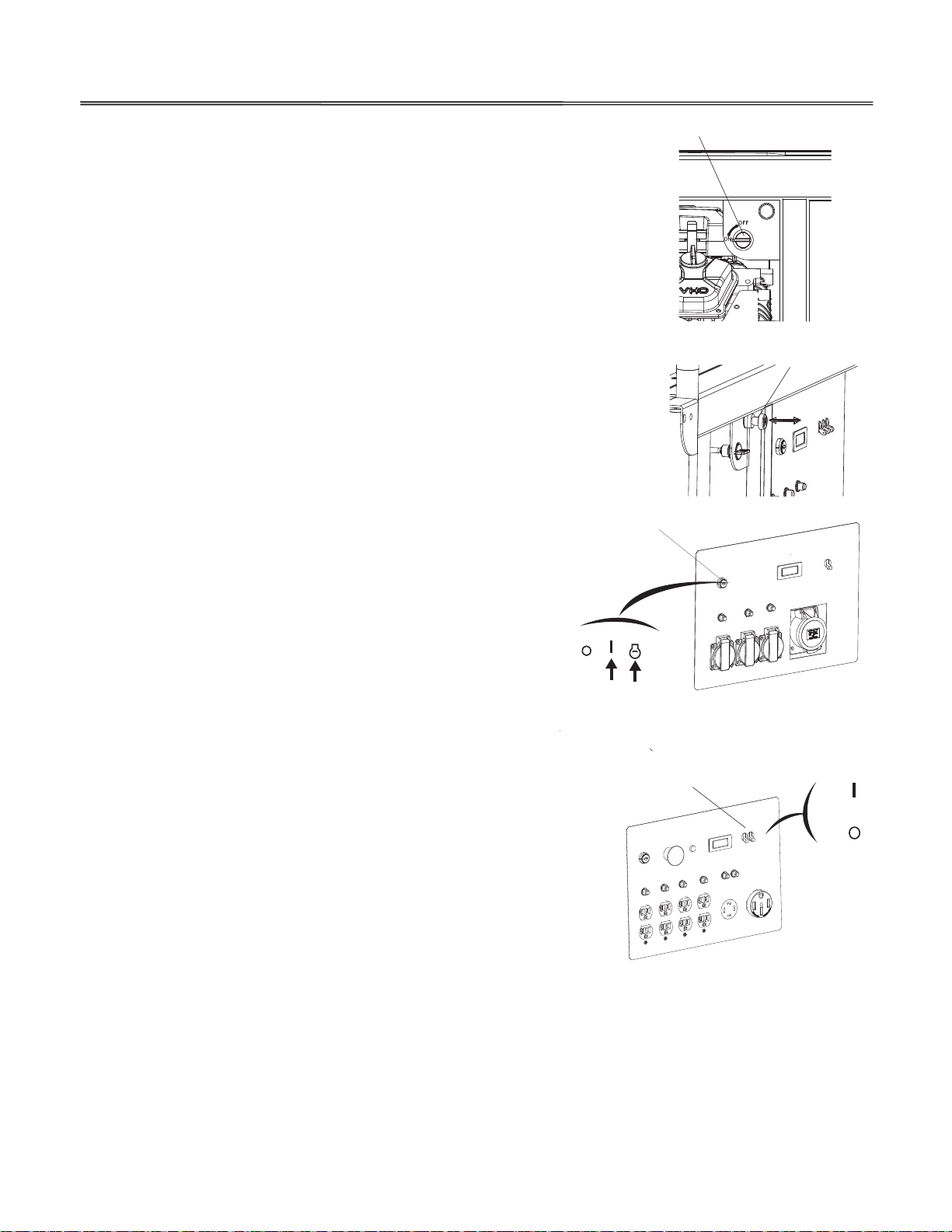

CONTROLS

Fuel Valve Lever

The fue l valve lever is located between the fuel tank and carburetor.

The fu el valve lever must be in the ON position for the engine to run.

After stopping the engine, turn the fuel valve lever to the OFF position.

Choke Knob

The choke knob opens

and closes th e choke valve in the ca rburetor.

The CLOSED position enriches the fuel mixture for starting a cold

engine.

The OP EN position provides the correct fuel mixture for operation

after starting, and for restarting a warm engine.

Engine Switch

Engine Switch

The engine switch controls the ignition system, and it operates the

electric starter.

FUEL VALVE LE VE

R

CHO K E KN O B

OPEN

CLOSED

OFF -- Stops the engine. The engine switch key can be removed/

inserted.

ON -- Running position.

START -- Operates the electric starter.

Circuit Breaker

The circu it breaker will automatically switch

OFF, if there is a short circuit or a significant

overload at the receptacles or output

terminals.

The circuit breaker may be used to switch

thegeneratorpowerONorOFF.

OFF

ON

STAR

CIRCUIT

BREAKE R

ON

OFF

8

Page 10

CONTROLS & FEATURES

FEATURES

Oil Alert System

The Oil Alert system is designed to prevent engine damage caused by an insufficient amou nt of oil in the

crankcase. Before the oil level in the crankcase can fall below a safe limit, the O il Alert system will automatically stop the

engine

(the engine switch will remain in the ON position).

If the engine stops and will not restart, check the engine oil level (see Page 21) before trouble shooting in other areas.

Ground Terminal

The ground terminal is connected to the frame of the generator, the metal noncurrent carryin g parts of the ge nerator,

and the ground terminals of each receptacle.

Before using the ground terminal, consult a qualified electrician, electrical inspector, or loc al agency having jurisdiction

for local codes or ordinances that apply to the intended use of the generator.

Attention ! It is compulsorily to make protective earthing before

operating the

Rules for Installing Electrical Facilities.

generator. Protective earthing must correspond to

Earthing devices and grounding conductors must be selected in accordance

with chapters 1.7 and 1.8 of Rules for Installing Electr ical Facilities.

GROUND

TERM IN A L

Usually, copper g rounding conductor needed of minimum 4mm

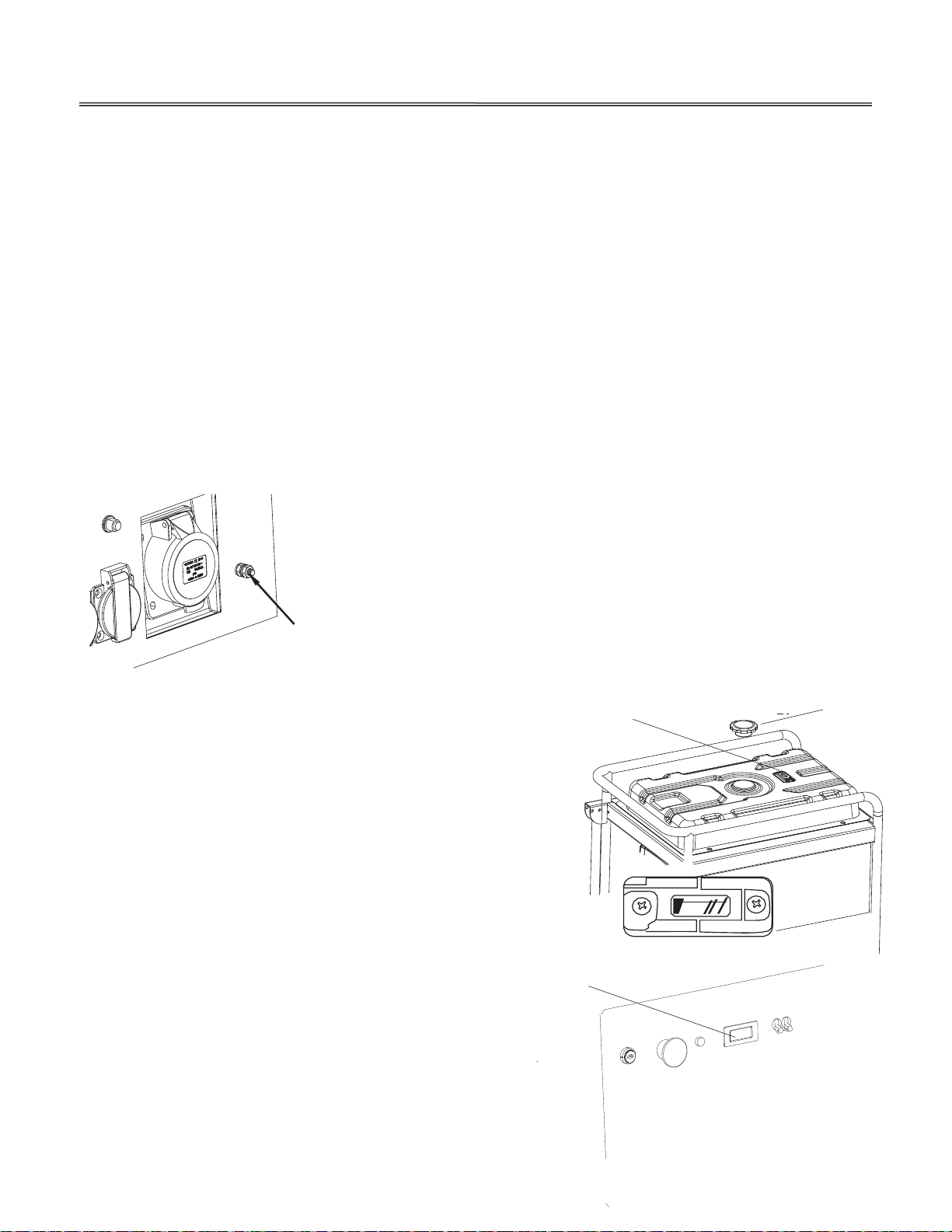

Fuel Gauge

The fuel gauge is a mechanical device that measures the fuel level in the

tank. The red indic ator in the window will reflect the level in relation

to full or empty. To provide increased operating time, start with a full

tank before begi nning operation. Chec k the fuel level with the generator

on a level surface. Always refuel with the engine OFF and cool.

Hour Meter

The hour meter indicates the hours the generator has been operated.

Use it to determine when s cheduled maintenance should be

Performed

.

FUEL GAUGE

Hour Meter

EMPTY FULL

²

section.

FUEL TAN K C A P

9

Page 11

BEFORE OPERATION

ARE YOU READY TO GE T STARTED?

Your safety is your responsibility. A little time spent in preparation will significa ntly reduce your risk of injury.

Knowledge

Read and understand this manual. Know what the controls do and how to operate them.

Familiarize yourself with the generator and its operation before you begin usin g it. Know how to quic kly shut off

the generator in case of an emergency.

If the generator is being used to power appliances, be sure that they do not exceed the generator’s load rating .

IS YOUR GENERATOR READY TO GO?

For your s a fety, and to maximize the service life of your equ ipment, it is very important to take a few moments before

you operate the generator to check its cond ition. Be sure to take care of a ny problem you find, or have your servicing

To prevent a possible fire, keep the generator at least 1 meter a way from building walls and other equipment during

operation. Do not plac e flammable objects close to the engine.

Before beginning your preoperation checks, be sure the generator is on a level surface and the engine switch is in the

OFF position.

Check the Engine

Check the oil level (see page

19). A low oil level will cause the Oil Alert system to shut down the engine.

Check the air cleaner (see page 21).A dirty air clean er element will restrict air flow to the carburetor, reducing engine

and generator performance.

Check the fuel level (see pa ge 18).Starting with a full tank will help to eliminate or reduce operating interrup tions for

refueling.

Check the Battery

Check the fuel electrolyte level (see page 24).

If the electrolyte level is

below the LOWER level, sulfation and battery plate dama ge will occur.

BATTE RY

10

Page 12

OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the generator for the first time, please review th e GENERATOR SAFETY section and the chapter titled

BEFORE OPER ATION.

For your safety, do not operate the generator in an enclosed area such as a garage. Your generator’s exhaust contains

poisonous carbon monoxide gas that can collect rapidly in an enclosed area and cause illness or death.

Before connecting an AC appliance or power cord to the generator:

Use grounded 3 prong extension cords

for single phase generator and 5 prong extension cords for three generator,

tools, an d appliances, or double insulated tools and appliances.

Inspect cords and plugs, and replace if dama ged.

Make sure that the appliance is in good working order. Faulty appliances or power cords can create a potential for

electric shock.

Make sure the elect rical rating of the tool or appliance does not exceed that of the gen erator. Never exceed the

maximum power rating of the generator. Power levels between rated and maximum may be used for no m ore than

30 minutes.

Operate the generator at least 1 meter away from buildin gs and other equ ipment.

Do not operate the generator in an enclosed structure.

ON

STARTING THE ENG INE

OFF

1. Make sure that the circu it breaker is in the OFF position.

The generator maybe hard to start if a load is connected.

CIRCU I T

BREA K E R

2. Turn the fuel valve lever to the ON position.

OFF

ON

FUEL VALVE LEV ER

11

Page 13

OPERATION

Pull the choke knob to the CLOSED position to start a cold engine.

3.

CLOSED

Leave the choke knob in the OPEN position to restart a warm engine.

Start the engine. Turn the engine switch to the START position, and hold

4.

it there until the engine starts. When the engine starts, release the

key,allowingtheswitchtoreturntotheONposition.

If

theenginefailstostartwithin5seconds,releasethekey,andwaitat

ON

least 10 seconds before operating the starter again.

OFF

STAR

NOTICE

Using the electric starter for more than 5 seconds at a time will Overheat the starter motor and can damage it.

5.

If the choke knob was pulled to the CLOSED position to start th e engine,

gradually move it to the OPEN position as the engine warms up.

CHOK E KNO B

3-1.

4-1.

ENGIN E SWI T CH

6

. Generator needs to operate for 3-5 minutes without load, then

it can out put power.

1 Make sure that the AC circuit breaker is in the OFF position. The generator may be hard to

start if a load is connected.

2 Turn the gasoline fuel valve to the "OFF" position.

3 Connect the propane gas hose to the regulator/decompression valve.

4 Connect the propane gas collar to the gas supply and then turn on the propane gas supply.

5 Press the button on top of the pressure release valve down two or three times.

OPEN

CHOK E KNOB

12

Page 14

6 The choke operates differently on propane gas.

a. If the engine is warm (the unit was run recently) start with the choke half open.

i. Wait 30 seconds and then push the choke lever all the way to the "OPEN" position.

b. If the engine is cold (the unit was not run recently) start with the choke "OPEN".

7 Turn the engine key switch to the START position and hold it there for 5 seconds, or until the

engine starts.

Operating the starter motor for more than 5 seconds can damage the motor. If the engine fails to start,

release the switch and wait 10 seconds before operating the starter again.

If the speed of the starter motor drops after a period of time, it is an indication that the battery should

be recharged.

When the engine starts, allow the engine switch to return to the ON position.

Stopping the Engine

In an emergency:

To stop the engine in an emergency, move the engine switch to the OFF position.

In normal use:

1 Turn the AC circuit breaker to the OFF position. Disconnect DC battery charging cables.

2 Turn the engine switch to the OFF position.

3 Turn the off the propane gas supply.

Connect to propane

assup

p

l

g

y.

Decompression

Valve / Regulator

STOPPING THE ENGI NE

To stop the engine in an emergency, simply turn the engine switch to the OFF position. Under normal conditions, use

the following procedure.

ON

1.

Move the circuit breaker to the OFF p osition.

OFF

CIRCU I T

BREA K E R

Page 15

TurntheengineswitchtotheOFFposition

2.

OFF

ON

ENGINE SWICH

.

STAR

OPERATION

2-1.

Turn th e fuel valve lever to the OFF position.

4.

ON

OFF

FUEL VALVE LEVER

4.

AC OPERATION

If an appliance beings to operate abnormally, becomes sluggish or stops suddenly, turn it off immediately. Disconnect the

appliance, and determine whether the problem is in the appliance or the rated load capacity of the generator has been

exceeded.

Substantial over loading may damage the generator.Marginal over loading may shorten the service life of the generator.

NOTICE

Receptacle

AC

1. Start the engine (see page 11).

2. Switch ON the circuit breaker.

CIRCUIT

BRE AK ER

ON

OFF

3. Plug in the appliance.

Most motorized appliances require more

than their rated wattage for startup.

13

Page 16

OPERATION

AC Applications

Before connecting an appliance or power cord to the generator:

Make sure that it is in good wo rking order. Faulty appliances or Power cords can c reate a poten tia l for electrical

shock.

If an app liance begins to operate abnormally, becomes slugg ish, or stops suddenly, turn it

off immediately. Disconnect the appliance, and determine w hether the problem is the appliance or the rated

load capacity of the generator has been exceeded.

Make sure that the electrical rating of the tool or appliance does not exceed that of the generator. Never exceed

the maximum power rating of the generator. Power levels between rated and maximum may be used for no more

than 30 minutes.

NOTICE

Substantial overloading will open the circuit breaker. Exceeding the time limit for max imum power ope ration or slightly

overloading the generator may not swit ch the circuit breaker OFF, but will shorten the service life of the gen erator.

Limit operation requiring maximum power to 30 minutes.

Maximum power is:

60Hz 13 kVA

For continuous operation (longer than 30 minutes), do no t exceed the rated

power. Rated power is:

60Hz 12 kVA

14

Page 17

OPERATION

The total power requi rements (VA) of all app liances conn ec ted m ust be considered. Appliance

and power tool manufacturers usually list rating information near the model number or serial number.

STANDBY POWER

Connect ions to a Building ’s Elect rical System

Your generator can supply power to a building ’s electrical system. If th e generator will be used as

an

alternative

to utility company power, an isolation switch must be installed to disconnect the utility lines from

the building when the generator is connected. Installation must b e perform ed by a qualified electrician and must

comply with all applicable laws and electrical codes.

In some areas, generators are required by law to be registered with local utility compa nies. Check local regulations for

proper registration and use procedures.

System Ground

THIS generators have a system ground that c onnects the gen erator frame comp onents to the ground term inals in the

AC output receptacles. The system ground is not connected to the AC neutral wire. If the generator is

tested with a receptacle tester, it will not show the same ground circuit c ondition as for a home receptacle.

In some areas, generators are required to be registered with loca l utility companies.

If the generator is used a t a construction site, there may be additional regula tions that must be observed.

15

Special Requirements

Page 18

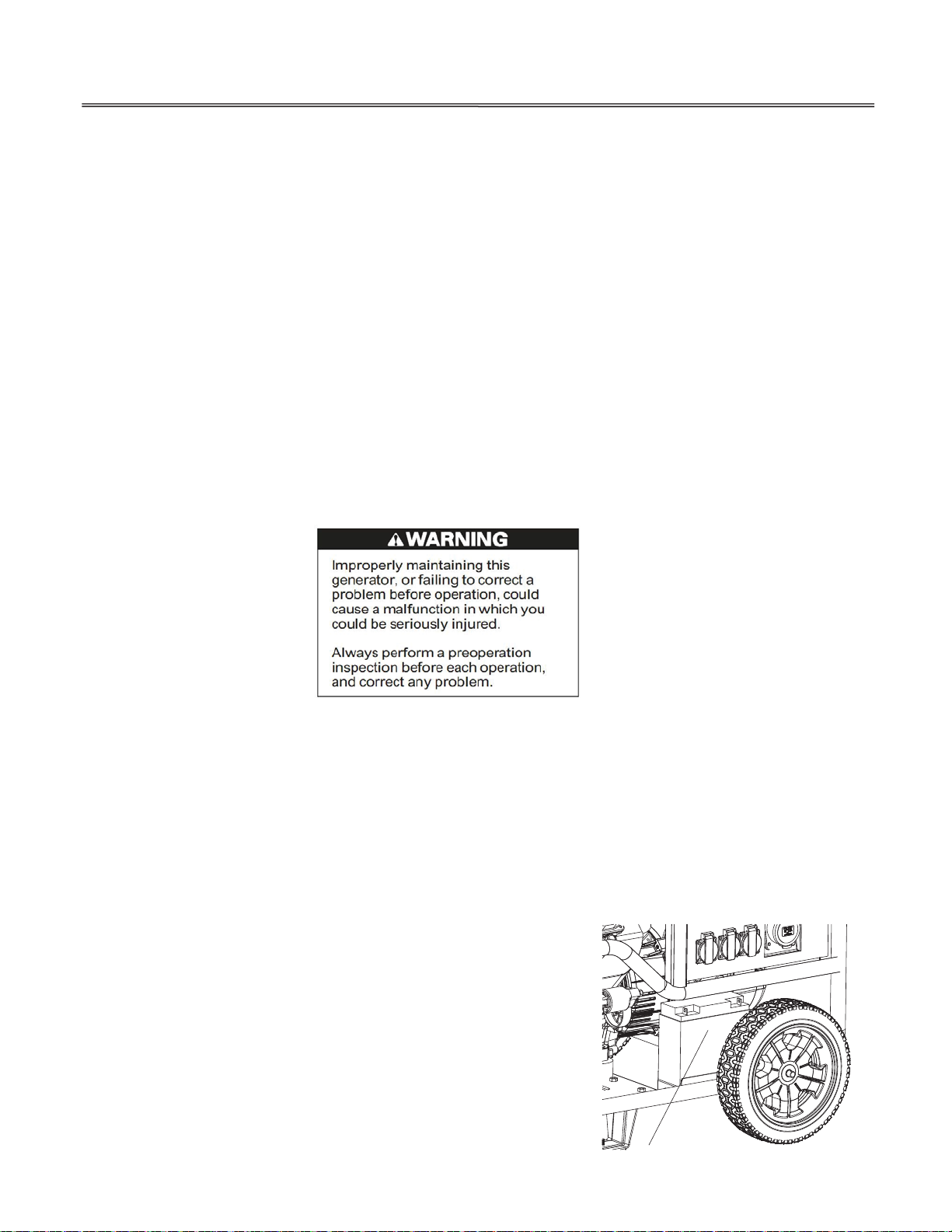

SERVICING YOUR GENERATOR

THE IMPORTANCE OF MAINTENANCE

Good maintenance is essential for safe, economical, and trouble free operation. It will also help reduce air pollution.

To help you properly care for yo ur generator, the following pages include a maintenanc e schedule, routine insp ection

procedures, and simple maintenanc e procedures using basic hand tools. Other service tasks that are mo re difficu lt or

require

special tools are best handled by professionals and are normally performed by a THIS

technician or other qualified mechanic.

The maintenance schedule applies to normal

operating condition s. If you operate your generator under

unusual conditions, such as sustained high load or high temperature operation, or use it in dusty

conditions, consult your servicing dealer for recommendations applicable to your individua l needs and use.

Remember that your servicing dealer knows your generator best and is fully equipped to maintain and repair it.

MAINTENA NCE SAFETY

Some of the most important safety precautions follow. However, we cannot warn you of every conceivable hazard that

can arise in performing maintenance. Only you can decide whether or not you should perform a given task.

Safety Precautions

Make sure the engine is off before you begin any maintenance or repairs. This will eliminate several potential hazards:

Carbon monoxide poisoning from engine exhaust.

Be sure there is adequate ventilation whenever you operate the engine.

Burns from hot parts.

Let the engine and exhaust system cool before touching.

Injury from moving part s.

Do not run the engine unless instructed to do so.

16

Page 19

SERVICING YOUR GENERATOR

Read the instructions before you begin, and make s ure you have the tools and skills required.

To reduce the possibility of fire or explosion, be careful when working around gasoline. Use only a nonf lammable

solvent, not gasoline, to clean parts. Keep cigarettes, spa rk s, and flames away from all fuel related parts.

E

.

m

r

ol

en

MAINTEN A NCE SCHEDUL

*

NOTE: (*) Replace thepaper element only.

(1) Servi c e more frequen tly when used industry areas

(2) These items should be serv ic ed by your servicing dealer, un less you have the proper too l s and are

echanically p roficient. Refer to our shop manual for service procedures.

(3) For commercial use, log hou

Failure to f

REFUELING

With th e

low this maintenance schedule could result in nonwarrantable failures.

gine stopped, check the fuel gauge. Refill the fueltank if the fuel level is low.

s of o peration to determine propermaintenance intervals.

17

Page 20

SERVICING YOUR GENERATOR

FUEL GAUGE

EMPTY FULL

Refuel in a well ventilated a rea before starting the engine. If the engine has b een running, allow

FUEL TAN K

it to cool. Refuel

carefully to avoid spilling fuel. Do not fill the fuel tank above the upper limit mark (red) on the fuel strainer.

Never refuel the engine inside a building where gasoline fumes may reach flames or sparks. Keep gasoline away from

appliance pilot lights, barbecues, electric appliances, power tools, etc.

Spilled fuel is not only a fire hazard, it causes environmental damage. Wipe up spills immediately.

NOTICE

Fuel can damage paint and pla stic. Be careful not to spill fuel when filling you r fuel tank. Damage caused by spilled fuel

is not covered under warranty.

NOTE:

Gasoline spoils very quickly depending on factors suc h as light, exposure, temperature and time.

In worst cases, gasoline can be contaminated wit hin 30days.

Using contaminated gasoline can seriously damage the engine (carburetor clogged, valve stuck).

Such damage due to spoiled fuel is disallowed f rom coverage by the warranty.

To avoid this please strictly follow these recommendations:

On ly use specified gasoline .

Use fresh and clean gasoline.

To slow deterioration, keep gasoline in a certified fuel container.

If long storage (more than 30 days) is foreseen, drain fuel tank and carburetor (see page27).

FUEL RECOMMENDATIONS

Use automotive unleaded gasoline with a Research Octane Number of 91 or higher (a Pump Octane Number of 86 or

higher).

Never use stale or contam inated gasoline or an oil/gasoline mixture.

Avoid getting dirt or water in the fuel tank.

18

Page 21

SERVICING YOUR GENERATOR

Gasolines Containing Alcohol

If you decide to use a gasoline containing a lc ohol (gasohol), be sure it’s octane rating is at least as high as that

recommended by THIS. There are t wo types of ‘ ‘gasohol’’: one containing ethanol, and the other containing methanol.

o not use gasohol that contains more than 10% ethanol. Do not use gasoline containing methanol (methyl or wood

D

alcohol) that does not also contain cosolvents and corrosion inhibitors for methanol. Never use gasoline containing more

than 5% methanol, even if it has c osolvents and corrosion inhi bitors.

NOTE:

Fuel system damage or engine performance problems resulting from the use of fu els that contain alcohol is not

covered under the warranty.

THIS cannot endorse the use of fuels containing methanol sinc e evidence of their suitability is as yet incomplete.

Before buying fuel from an unfamiliar station, try to find out If the fuel contains alcohol, if it does, confirm the type

and p er centage of alcohol us e d.

If you n otice any undesirable operating symptoms while using a gasoline that contains alcohol, or one that you think

contains alcohol, switch to a gasoline that you know does not contain alcohol.

ENGINE OIL LEVEL CHECK

Check the engi ne oil level with the generator on a level surface and the engine stopped.

1. Remove the oil level dipstick and wipe it clean.

2. Fully insert

t

he dipstick, then remove it to check the oil level.

3. If the level is near or below the lower limit mark on the dipstick, open the

maintenance cover to access the oil filler cap. Remove the oil filler cap, and

fill with the recommended oil to the upper limit mark.

4. Reinstall the oil level dipstick and f iller cap.

OIL FILLER CAP

OIL LEVE L

DIPS TI CK

The Oil Alert system will automatically stop th e engine before the oil level falls below safe limits. However, to avoid the

inconvenience of an unexpected shutdown, check th e oil level regularly.

19

Page 22

SERVICING YOUR GENERATOR

ENGINE OIL CHANGE

Drain the oil while the engin e is warm to assure rapid and complete draining.

1. Placethegeneratoronwoodenblockstomakespaceforplacingasuitablecontainer.

2. Open the maintenance ov er to access the oil filler cap.

3. Remove the oil filler cap, oil drain bolt and sea ling washer, and drain the oil in to the container.

4. Install a new sealing washer and the oil drain bolt, and tighten the bolt securely.

5. Refill to the upper limit mark on the dipstick with the recommended oil. Tighten the oil filler cap securely .

Engine oil capacity:

oil filter replacement:

With

Approximately 1.6L

Wash your hands with soap and water after handling used oil.

OIL FILLER CAP

OIL DRAIN BOLT

Please dispose of used motor oil in a manner tha t is compatible with the environmen t. We suggest

you take it in a sealed container to your local service station or recycling center for reclamation. Do not throw it in the

trash, p our it on

the ground, or pour it down a drain.

OIL FILTER CHANGE

1. Drain the engi ne oil, and tighten the drain bolt securely.

2. Remove the oil filter, and drain the oil in to a suitable container.

D iscard the used oil filter.

3. Clean the filter moun ting base, and coat the O-ring of the new oil filter with clean engine oil.

4. Screw on the new oil filter by hand, until the O-ring contacts the filter mounting base, and then use an

oil filter socket tool to tighten the filter an add itional 7/8 turn.

TORQUE: 12N·m (1.2kgf·m)

5. Refill the crankcase with the specified amount of the recommended Oil (see pages 36 and 38). Reinstall the oil filler

cap.

6. Start the engine and check for oil filter leaks.

7. Stop the engine, and check the oil level as described on

page 21. If n ecessary, add oil to the upper limit mark on

the dipstick.

OIL FILLER

20

O-RING

Page 23

SERVICING YOUR GENERATOR

ENGINE OIL RECOMMENDATIONS

Oil is a major factor affecting engine performance and service life.

Use 4-st roke automotive detergent oil that meets or exceeds the requirements for API service category SE or later (or

equivalent).

SAE 10W-30 is recommended for general use. Other viscosities shown in the chart

may be used when the average temperature in your area is within the recommend ed

range.

The SAE oil viscosity an d service category are on the API label on the oil container.

CLEANER SERVICE

AIR

Release four latch tabs from the air cleaner cover, and remove the cover.

1.

2. Foam air f ilter:

Remove the foam air filter from the air cleaner housing.

a.

b. Check the foam air filter to be sure it is clean and in good condition.

Replace the foam air f ilter if it is damaged.

c. Reinstall the foam air filter in the air cleaner housing.

3. Paper air filter:

If the paper air filter is dirty, replace it with a new one. Do not clean the pa per air filter.

4. Reinstall the air cleaner cover.

5. Close the maintenance cover.

FOAMAIRFILTER

AIR CL EAN E R COVER

PAP E R AIR FI LTE R

AIR CLEAN E R COVE R

21

Page 24

SERVICING YOUR GENERATOR

NOTICE

Operating the engine without an air filter, o r with a damaged air filter, will allow dirt to enter the engine, causing rapid

engine wear.

FOAM A IR FILTER CLEANING

A dirty foam air filter will restrict air flow to the carburetor, reducing engine performance. If you operate th e generator

in very dusty areas, clean the foam air filter more frequently than specified in the Main tenance Schedule.

1. Clean the fo am air filter in warm soapy water, rinse, and allow to dry thoroughly, or clean in non-flammable solvent

and allow to dry.

2. Dip the foam air filter in clean engine oil, then squeeze out all excess oil. The engine will smoke when started if too

much oil is left in the foam air filter.

SEDIMENT CU P CLEANING

1. Turn the fuel valve lever to the OFF position, then remove the Sediment cup and the O-ring. Discard the O-ring.

2.

Wipe dirt from the air cleaner housing and cover using a moist rag. Be careful to prevent dirt from entering the air

duct t hat leads to the carburetor.

22

Page 25

SERVICING YOUR GENERATOR

2. Clean the sediment cup in nonflammable solvent, and dry them thoroughly.

3. Install the new O-ring and sediment cup, and tighten the sediment cup securely.

4. Make sure there is no fu el leakage.

SPARK PLUG SERVICE

Recommended spark plugs: F7TC

NOTICE

An incorrect spark plug can cause engine damag e.

If the engine is hot, allow it to cool before servicing the spark plug.

1. Disconnect the spark plug caps, and remove any dirt f rom around the spark p lu g area.

2.

Remove the spark plugs with a 180mm spark plug wrench

(commercially a

vailable).

3. Inspect the spark plugs. Replace them if the electrodes are worn or if the insulator

is cracked, chipped, or fouled.

4. Measure the spark plug electrode gap with a wire type feeler gauge. Correct the gap, if necessary, by carefully

bending the side electrode.

The gap sh ould be: 0.7 -- 0.8m m

5. Make sure that the spark plug sealing washers are in good condition, and th read the spark plug in by hand tprevent

cross threading.

6. After the spark plugs seat, tighten with a 21mmsparkplugwrenchto compress the washer.

If reinstalling a used spark plug, tighten 1/81/4 turn af ter the spark plug seats.

If installing a new spark plug, tighten 1/2 turn after the spark plug seats.

23

0.7 - 0.8mm

Page 26

SERVICING YOUR GENERATOR

NOTICE

A loose spark plug can overheat and damage the engine. Over tighten ing the spark plug can damage the threads in the

cylinder head.

7. Attach the spark plug caps.

BATTERY SERVICE

Your generator’s engine charging system charges the battery while the en gine is running. However, if the gen erator is

only u sed periodically, the battery must be cha rged monthly to maintain the battery service life.

Emergency Procedures

Eyes -- Flush with water from a cup or other container for at least fifteen minutes. (Water under pressure can dama ge

the eye.)

Immediately call a physician.

Skin -- Remove contaminated clothing. Flush the skin with large quantitie s of w ater. Call a physician immediately.

Swallowing -- Drink water or milk. Call a physician immediately.

Battery Removal

WARNING: Battery posts, terminals, and related accessories contain

lead and lead compound s. Wash hands after handling.

1. Remove the negative (-) cable from the

battery negative (-) terminal first, and

then remove the positive () cable from

the battery positive (+) terminal.

2. Remove the flange nuts, and remove the battery set plate.

3. Remove the battery from the battery tray.

24

+

_

Page 27

SERVICING YOUR GENERATOR

This symbol on the battery means that this product must not be treated as household waste.

NOTE:

An improperly dis posed of battery can be harmful to the environment

and hum an hea lth.

Always confirm local regulations for battery disposal.

Battery Charging

The battery is rated at 30 .0Ah (ampere hours). Charging current should equal 10% of the battery’s ampere hour rating.

1. Connect the ba ttery charger following the manufac tu rer ’s instruction s.

2. Charge the battery.

3. Clean the outside of the battery and the battery compartment with a solution of baking soda and water.

Battery Installation

1. Install the battery into the generator.

2. Connect the battery positive (+) cable to the battery positive (+ ) terminal first, and tighten the bolt securely.

3. Slide the battery boot over the positive (+) cable and terminal .

4. Connect the battery negative (-) cable to the battery negative (-) terminal, and tighten th e bolt securely.

25

Page 28

STORA GE

STORAGE PREPARATION

Proper storage preparation is essential for keeping yo u r generator trouble free and looking good. The following steps

will help to keep rust and corrosion from impairing your generator ’s function and appearance, and will make the engine

easiertostartwhenyouusethegeneratoragain.

Cleaning

Wipe the generator with a moist cloth. After the generator has dried, touc h up any damaged paint, and coat other areas

that may rust with a light film of oil.

Fuel

Gasoline will

oxidize and deteriorate in storage. Old gasoline will cause hard starting, and it leaves gum deposits

that clog th e fuel system. If the gasoline in your generator deteriorates during storage, you may need to have the

carburetor and other fuel system components serviced or replaced.

NOTE:

Gasoline spoils very quickly depending on factors suc h as light exposure, temperatu re and time.

In worst cases, gasoline can be contaminated wit hin 30days.

Using contaminated gasoline can seriously damage the engine (carburetor clogged, valve stuck).

Such damage due to spoiled fuel is disallowed f rom coverage by the warranty.

To avoid this please strictly follow these recommendations:

Only use specified gasoline .

Use fresh and clean gasoline.

To slow deterioration, keep gasoline in a certified fuel container.

If long storage (more than 30days) is foreseen, drain fuel tank and carburetor (see page 27).

You can extend fuel storage life by adding a gasoline stabilizer that is formulated for that purpose, or you can avoid fuel

deterioration problems by draining the fuel tank and carburetor.

Adding a Gasoline Stabilizer to Extend Fuel Storage Life

When addin g a gasoline stabilizer, fill the fuel tank with fresh gasoline. If only partially filled, air in the tank will promo te

fuel deterioration during storage. If you keep a container of gasoline for refueling, b e sure that it contains only

fresh gasoline.

1. Add gasoline stabilizer following the manufacturer’s instructions.

2. After adding a gasoline stabilizer, run the engine outdoors for 10 minutes to be sure that treated gasoline has replaced

the untreated gasoline in th e carburetor.

3.

Stop the engine, and turnthefuelvalvelever to the OFF position.

26

Page 29

STORA GE

STORAGE PROCEDURE

1. Drain the fuel tank and carburetor.

a.

Unscrew the fuel tank cap, remove the fuel filter, and empty the

fuel tank into an approved gasoline container. We recommend

using a commercially available gasoline hand pum p to empty

the tank. Do not use an electric pump. Reinstall the fuel filter

and th e fuel tank cap.

b. Pull out the ca rburetor drain tube end under th e fan cover of the engine , and plac e it in a suitable co ntainer.

c.

Loosen the carburetor drain screw.

d.

Drain the gasoline from the ca rburetor into the container.

e. Tighten the carburetor drain screw securely.

2. Change the engine oil (refer to page 20).

3. Remove the spark plugs (see page 23).

4. Pour a table spoon (5-10cc) of clean engine oil into each cylinder.

5. Turn the engine for a few seconds by turning the engine switch to the START position to distribute the oil in

the cylinders.

6.

Reinstall the spark plugs.

7. Remove the battery and store it in a cool, dry place. Recharge it once a month.

8. Cover the generator to keep out dust.

27

Page 30

STORAGE

STORAGE PRECAUTIONS

If your generator will be stored with ga solin e in the fuel tank and carburetor, it is important to reduce the hazard of

gasoline vapor ignition.

Select a well ventilated storage area away from any appliance that operates with a flame, such as a furnace, water heater, or

clothes dryer. Also avoid any area with a spark producing electric motor, or where power tools are operated.

If possible, avoid storage areas with high humidity, because that promotes rust an d corrosion.

Unless all fuel has been drained from the fuel tank, leave the fuel valve lever in the OFF position to redu ce the possibility of

leakage.

Place th e generator on a level surface. Tilting can cause fu el or oil leakage.

With the engine and exhaust system cool, cover the generator to keep out dust. A hot engine and exhaust system can

ignite or melt some materials.

Do not use sheet plastic as a dust cover. A nonporous cover will trap moisture around the generator, promoting rust and

corrosion.

REMOVAL FROM STORAGE

Check your generator as described in the BEFORE OPERATION chapter of this manual.

If the fuel was drained during to rage preparation, fill the tank with fresh gasoline. If you keep a container of gasoline

for refuelin g, b e sure that it contains only fresh gasoline. Gasoline oxidizes an d deteriorates overtime,

causing hard starting.

28

Page 31

TRANSPORTING

If the generator has bee n running, allow the engine to coo l for at least 15 minutes before loadin g the generator on the

transport vehicle. A hot engine an d exhaust system can burn you and ca n ignite some materials.

Keep the generator level when transporting to reduce the possibility of fuel leakage. Move the fuel valve lever to the

OFF position.

When using ropes or tied owns traps to secure the generator for transportation, be s ure to only use the f rame bars as

attachment points. Do not fasten ropes or straps to any portions of the generator body.

29

Page 32

TAKING CARE OF UNEXPECTED PROBLEMS

hoke OPEN.

ove to CLOSED

toffuel.

efuel (p.18).

ad fu el; generator stored without

reatingordraininggasoline,orrefueled

bad gasoline.

rain fuel tank and carburetor

p.27).Refuel with fresh

asoline(p.18).

park plug wet with fuel (flooded engine

ry an d reinstall spark plug.

30

Engine Will Not Start Possible Cause Correction

1. Check control positions

2. Check fuel

3. Check engine oil level.

4. Remove and inspect spark

plug.

5. Take generator to an

authorized THIS

servicing dealer, or refer

to shop manual.

Fuel valve lever OFF. Turn lever ON.

C

Engine switch OF F. Turn engine switch to ON.

Ou

B

t

with

Low oil level caused Oil Alert to stop

engine.

Spark plug faulty, fouled, or improperly

gapped.

S

Fuel filter restricted, carburetor

malfunction, ignition malfu n c tio n, valves

stuck etc.

M

R

D

(

g

Add oil (p.20). Turn engine switch to

OFF and restart the engine.

Gap, or replace spark pl ug (p.23).

). D

Replace or repair faulty components

as necessary.

Engine Lacks Power Possible cause Correction

1. Check air filter. Air filter restricted.

Bad fuel; generator stored without

2. Check fuel.

3. Take generator to an

authorized THIS

servicing dealer, or refer

to shop manual.

treating or draining gasoline, or refueled

with bad gasoline.

Fuel filter restricted, carburetor

malfunction, ignition malfu n c tio n, valves

stuck etc.

Clean or replace air filter (p.22)

Drain fuel tank and carburetor (p.27).

Refuel with fresh gasoline

(p.18)

Replace or repair faulty components

as necessary.

Page 33

TAKING CARE OF UNEXPECTED PROBLEMS

31

NoPoweratthe

AC Receptacles

1. Check circuit b rea ker.

2. Check the power tool or

applianc e at a known

good AC power source.

3. Take generator to an

authorized THIS

servicing dealer, or refer

to shop manual.

Possible cause Correction

Circuit breaker left in the O FF position

after starting.

Faulty power tool or appliance.

Faulty generator.

Switch circuit breaker ON.

Replace or repair power tool or

appliance. Stop and restart the engine.

Replace or repair faulty components as

necessary.

Page 34

TECHNICAL INFORMA TION

SERIAL N U MBER LOCATION

ENGIN E SERIA L NU MB E R

DRAI N O I L LINE

Recordtheengineandframeserialnumbersanddatepurchasedinthespacesbelow.Youwillneedthisserialnumber

when ordering parts, and when making technical or warranty inquiries.

Engine serial number:_______________________ ____________ __

Frame serial number:_____________________________________

Date purchased:_________________________ _________________

CARBURETOR MODIFICATION FOR HIGH ALTITUDE OPERATION

At high a ltitude, h e standard carburetor air-fuel mixture will be too rich. Performanc e will decrease, and fuel consumption

will increa se. A very rich mixture will also foul the spark plu gs and cause hard starting.

Operation at an altitud e that differs f rom that at which this engine was certified, for extended periods of time, may increase

emissions.

High altitude performance can be improved by specific modifications to the carburetor. If you always operate your

generator at altitudes above 1,500 meters,

modification.

Even with carburetor modification, engine horsepower will decrease about 3.5% for each 300 meter increase in altitude.

h

ave your authorized THIS servicin g dealer perform this c arburetor

NOTICE

When the carburetor has been mod ified for high altitude operatio n, the air/fuel mixture will be too lean for low altitude use.

Operation at altitudes below 1,500 meters with a mod if ie d carbure tor may cause the engine to ove rheat and result

in serious engine damage. For use at

Low altitud es, have your servicing dealer return the carburetor to original factory specifications.

32

Page 35

TECHNICAL INFORMATION

SPECIFICATIONS

Dimensions

Model

Length

Width

Height

Dry mass(w eight)*

*with battery

XP15000E

870

mm

588

mm

mm

26

7

215kg

Engine

Model

Engine Type 4-stroke,overheadvalve,2cylind er

Displacement 7

Bore & Stroke

Cooling System Forced air

Ignition System Transistorized magneto ignition

Oil Capacity With oil filter replacement approximatly 1.5L

Fuel Tank Capacity 40L

Spark Plug F7TC(NHSPLD)

Battery 12V/

DHT720E

13cc

*71mm

0

8

21

AH

Generator

Model

Single-phase

Rated voltage 240V

60Hz

0A

AC output

Rated frequency

Rated Ampere 5

Rated output 12.5kW

Maximum output 15kW

Power factor

Tune up Specifications

ITEM SPECIFICATION MAINTENANCE

Spark plug gap 0.7-0.8mm Refer to page: 25

Valve clea rance(cold) IN:0.0

Other specifications No other adjustments needed.

Specifications may vary according to the types, and are subject to change without notice.

8-0.12mm EX:0.13-0.17mm See your authorized dealer

.8

0

33

Page 36

WIRING DIAGRAM

SINGLE PHASE DIAGRAM XP1500E

TECHNICAL INFORMATION

34

Page 37

Page 38

Product Support Product Information, Application, Service Info & Warranty Questions

Please email us at support@duromaxgenerators.com

or call (800) 629-3325 Monday – Friday 6:00 am – 6:00 pm (PST)

Loading...

Loading...