Page 1

XP13000E GENERATOR

User Manual

REV: XP13000E-09142018

This manual provides information regarding the operation

and maintenance of these products. We have made every

effort to ensure the accuracy of the information in this

manual. We reserve the right to change this product at

any time without prior notice.

5800 Ontario Mills Pkwy

Ontario, CA 91764 USA

www.duromaxpower.com

Call our Customer Care Team Toll Free 8-5pm PST Mon-Fri

844-DUROMAX

Page 2

Page 3

CONTENTS

1.

2.

Introduction

Introduction .................................................................................................................... 6

General Safety Procedures ........................................................................................... 7

Quick Start Guide (Gasoline) ....................................................................................... 10

Generator Components ............................................................................................... 12

Package Contents ......................................................................................................... 14

Generator Setup

Shipping Braces ............................................................................................................ 16

Wheel Kit Installation .................................................................................................... 17

Adding Oil ...................................................................................................................... 18

Adding Gasoline ............................................................................................................ 19

Grounding the Generator ........................................................................................... 20

Grounding the Generator ........................................................................................... 20

3.

4.

Starting the Generator

Checking the Oil ........................................................................................................... 22

Check the Gas Level ..................................................................................................... 23

Starting the Generator ................................................................................................. 24

Using the Generator

AC Usage ......................................................................................................................... 28

Connecting a Load to the Generator ........................................................................... 30

Voltage Selector Switch ................................................................................................ 31

DC Usage ........................................................................................................................ 32

3

Page 4

CONTENTS

5.

6.

Maintenance and Care

Maintenance Schedule .................................................................................................. 34

Maintenance Log ........................................................................................................... 37

Checking the Oil ............................................................................................................ 38

Changing the Oil ............................................................................................................. 39

Cleaning the Air Filter .................................................................................................... 40

Spark Plug Maintenance ............................................................................................... 42

Emptying the Gas Tank ................................................................................................. 44

Cleaning the Fuel Filter Cup .......................................................................................... 46

Storage and Transportation ......................................................................................... 47

Specications .................................................................................................................. 48

Troubleshooting

Basic Troubleshooting .................................................................................................. 48

7.

8.

Changing / Inspecting the Carbon Brushes ............................................................... 51

Changing / Inspecting the AVR .................................................................................... 53

Warranty

.......................................................................................................................... 56

Contact Information

.................................................................................................. 60

4

Page 5

Page 6

INTRODUCTION

DuroMax has cemented its reputation as one of the markets leading power equipment companies

who are headquartered in the US. All of our products are manufactured to the strictest guidelines

and go through countless testing in all phases of production.

Evolving our strong engine line, DuroMax has complemented its oerings to include Pressure

Washers, Water Pumps, Engines and now oering V-Twin engines. Reliability is the highest

standard we hold ourselves to, whether its powering a heater during a winter storm that knocks

out power, dewatering a ooded property, or washing away a deck for the summer season

STOP

Please do not return

to store.

Duromax representatives are ready to help you

with any questions, concerns, or issues about your

new product. We can guide you through assembly,

start up, and how to operate your new generator.

We want you to be able to put your new generator

to use right away!

CALL US BEFORE YOU CONSIDER

RETURNING THE PRODUCT!

TOLL FREE

1-844-DUROMAX

Notice Regarding Emissions

Engines that are certied to comply with U.S. EPA emission regulations for SORE (Small o Road

Equipment), are certied to operate on regular unleaded gasoline, and may include the following

emission control systems: (EM) Engine Modications and (TWC) Three-Way Catalyst (if so equipped).

6

Page 7

GENERAL SAFETY PROCEDURES

SAFETY ALERT SYMBOL

The safety alert symbol is used with one of the safety words (DANGER,

CAUTION, or WARNING) to alert you of hazards. Please pay attention to

these hazard notices both in this manual and on the generator.

Please familiarize yourself with the following safety symbols and words:

● DANGER: Indicates a hazard that will result in serious injury or death if instructions are not

followed.

● WARNING: Indicates a strong possibility of causing serious injury or death if instructions are not

followed.

● CAUTION: Indicates a possibility of personal injury or equipment damage if instructions are not

followed.

DANGER: This generator produces poisonous carbon monoxide gas when running. This

gas is both odorless and colorless. Even if you do not see or smell gas, carbon monoxide

may still be present. Breathing this poison can lead to headaches, dizziness, drowsiness,

and eventually death.

● Use outdoors ONLY in non-conned areas.

● Keep several feet of clearance on all sides to allow proper ventilation of the generator.

WARNING: The exhaust from this product contains chemicals known to the State of

California to cause cancer, birth defects, or other reproductive harm.

WARNING: This generator produces heat when running. Temperatures near exhaust can

exceed 150°F (65°C).

● Do not touch hot surfaces. Pay attention to warning labels on the generator denoting

hot parts of the machine.

● Allow generator to cool several minutes after use before touching engine or areas

which heat during use.

7

Page 8

GENERAL SAFETY PROCEDURES

WARNING: This generator may emit highly ammable and explosive gasoline vapors,

which can cause severe burns or even death. A nearby open ame can lead to an

explosion even if not directly in contact with gas.

● Do not operate near an open ame.

● Do not smoke near generator.

● Always operate on a rm, level surface.

● Always turn generator o before refueling.

● Allow generator to cool for at least 2 minutes before removing fuel cap. Loosen cap

slowly to relieve pressure in tank.

● Do not overll gas tank. Gas may expand during operation. Do not ll to the top of

the tank.

● Always check for spilled gas before operating.

● Empty the gasoline tank before storing or transporting the generator.

● Before transporting, turn fuel valve to the o position and disconnect the spark plug.

WARNING: This generator produces a powerful voltage, which can result in electrocution.

● ALWAYS ground the generator before using it (see the “Grounding the Generator”

portion of the “PREPARlNG THE GENERATOR FOR USE section).

● Generator should only be plugged into electrical devices, either directly or with an

extension cord. NEVER connect to a building electrical system without a qualied

electrician. Such connections must comply with local electrical laws and codes. Failure

to comply can create a backow of power, which may result in serious injury or death

to utility workers.

● Use a ground fault circuit interrupter (GFCI) in highly conductive areas such as metal

decking or steel work. GFCls are available in-line with some extension cords.

● Do not use uncovered in rainy or wet conditions.

● Do not touch bare wires or receptacles (outlets).

● Do not allow children or non-qualied persons to operate.

8

Page 9

GENERAL SAFETY PROCEDURES

In addition to the above safety notices, please familiarize yourself with the safety and

hazard markings on the generator.

9

Page 10

QUICK START GUIDE

1.

2.

3.

Remove shipping braces

The shipping braces prevent engine movement during

shipment. Flip the generator over and remove the brightly

colored brace between the motor and the frame, and the

wood brace under the generator.

Add oil

The oil ll cap is located on the lower engine block to the

right of the recoil start housing. Remove the oil ll cap and

ll with 10w30 oil.

Add gasoline

The fuel cap is located on top of the fuel tank. Fill the tank

with fresh unleaded gasoline 87 octane or higher. The tank

is full when you see fuel in the bottom of the fuel lter cup.

DO NOT overll the tank.

4.

5.

Turn breaker o

The breaker is located on the right side of the front power

panel. Flip the breaker down to prevent accidental load

when starting the generator.

Turn gas valve on

The gas valve is located above the recoil start on the

bottom of the fuel tank. Rotate the valve clockwise to the

vertical position to turn on the gas supply.

10

Page 11

6.

Turn battery switch on

The battery switch is located on the top center of the main

power panel. Turn the switch ON to allow power to the

push button start.

7.

8.

9.

Turn idle control o

The idle control is located on the top center of the main

power panel. Turn the switch OFF to prevent the unit trying

to idle down before the engine is warmed up.

Start generator

The push button start left side of the main power panel.

Press the button for 1 second to start the generator.

Turn breaker on

The breaker is located on the right side of the front power

panel. Flip the breaker up to allow power to ow to the

receptacles.

10.

Connect your devices to the receptacles on the front panel.

Start with the largest loads rst.

Connect devices

11

Page 12

GENERATOR COMPONENTS

3. Fuel Valve

2. Air Cleaner

4. Fuel Tank

5. Power Panel

6. Handles

7. Battery

1. Recoil Start

8. Oil Fill and Dipstick

1. Recoil Start – Easy Pull Recoil Start to start the engine without the electric start.

2. Air Cleaner - a removable, cleanable, oiled, element that cleans the air going into the engine.

3. Fuel Valve - On/O valve that allows gasoline to the fuel switch.

4. Fuel Tank - All metal 7.8 Gallon gasoline fuel tank.

5. Power Panel - Contains the start switch, plugs, meters, and circuit breakers.

6. Handles - Longest handles of any DuroMax Model allow easy movement across any surface.ad.

7. Battery - 12V DC 7ah Battery that powers the Electric Start System

8. Oil Fill and Dipstick - Use to add or check the oil.

9. Engine Switch – Push Button start switch. Press for 1 second to start the generator. Hold for 3

seconds to stop the generator.

10. Charging Light - Will light when the generator is charging the onboard battery.

11. Low Oil Alert – Will light only if the generator shuts down due to low oil.

12

Page 13

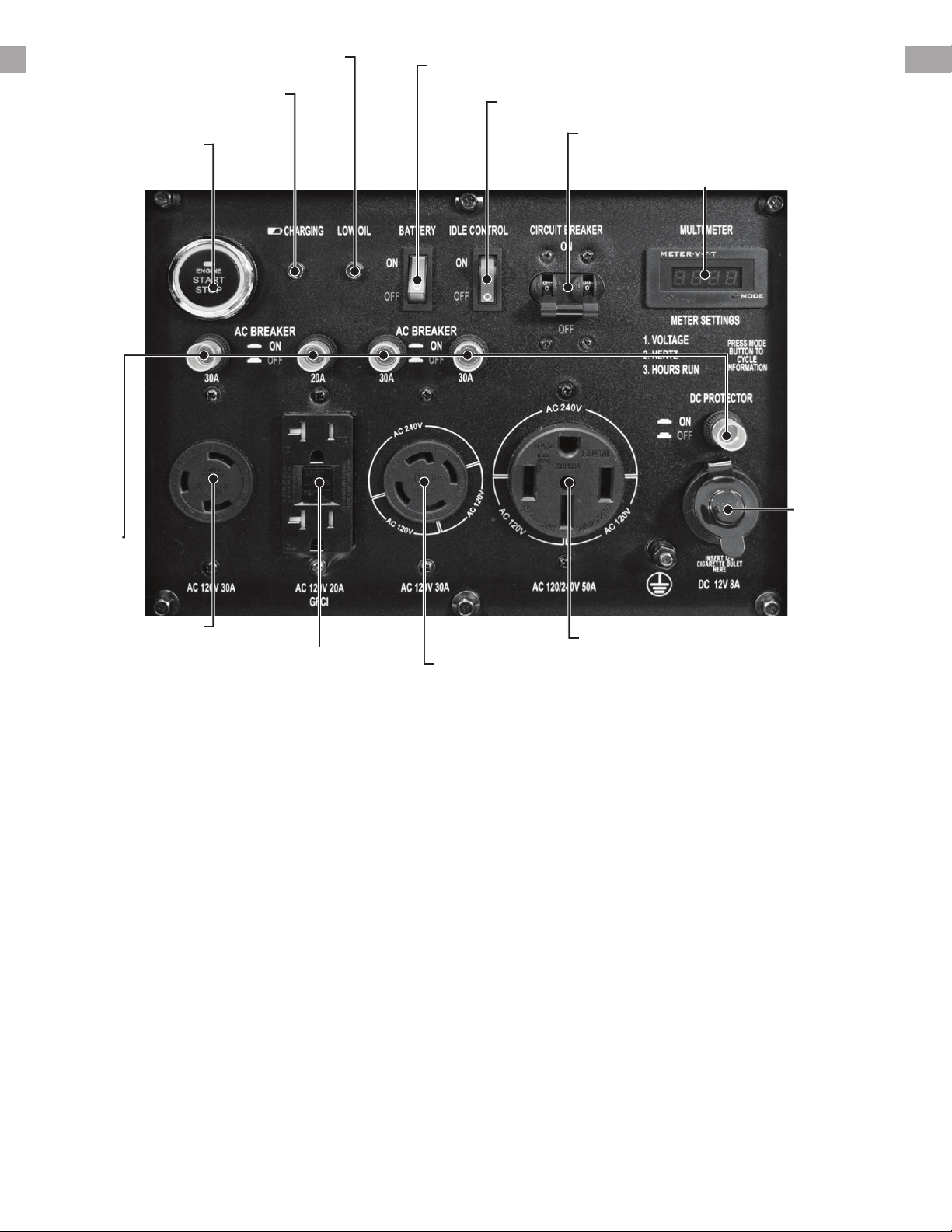

11. Low Oil Alert

12. Battery Switch

10. Charging Light

9. Engine Switch

13. Idle Control

14. Circuit Breaker

15. Multimeter

16. 12V Auto

21. Circuit

Protectors

20. 30A 120v

Receptacle

12. Battery Switch – Prevents battery discharge during storage.

13. Idle Control - Slows the engine to save fuel and lower noise when no load.

14. Circuit Breaker - Protects the panel from overload and short circuits.

15. Multimeter – Displays voltage, hertz, and time running.

16. 12v Auto - Provides a 12v automotive style plug for appliances and chargers.

17. 120/240v 4-Prong Receptacle - Use to connect electrical devices that run 120 or 240 Volt,

60Hz, single phase, AC current (NEMA 14-50)

18. 120/240v 4-Prong Twist Lock - Use to connect electrical devices that run 120 or 240 Volt, 60Hz,

single phase, AC current (NEMA 14-30)

19. GFCI 20A

Receptacle

18. 30A 240v Receptacle

17. 50A Receptacle

19. 120v 3-Prong GFCI Receptacle - Use to connect electrical devices that run 120 Volt, 60Hz,

single phase, AC current (NEMA 5-20)

20. 120v 3-Prong Twist Lock - Use to connect electrical devices that run 120 Volt, 60 Hz, single

phase, AC current (L5-30).

21. Circuit Protectors - Protects the receptacles from overload.

13

Page 14

PACKAGE CONTENTS

Your generator comes with the items listed below. Please check to see that all of the following

items are included with your generator.

Double Sided

Screw Driver

Phillips and slot blade

screwdriver used for generator

maintenance.

Oil Funnel w/ hose

Spanner Spark Plug Wrench

Assorted wrenches used in

generator maintenance and

assembly. Commonly 8mm,

10mm, 13mm, and 15mm.

Used in spark plug

maintenance, inspection, and

installation.

Plug Ends

Used to add oil to the

generator without messy spills.

● Note: Actual tools may dier in appearance or design from image shown.

14

Plug heads for the receptacles

found on the generator are

included to make or rewire

your own cords.

Page 15

GENERATOR SETUP

Proper setup of your generator will get you going as soon as possible while making sure you and

your equipment are safe and cared for.

Page 16

GENERATOR SETUP

Step 1 - Remove Shipping Braces

Unpack

1.

a. Remove the generator from the box.

b. Place the largest piece of packing foam on a at surface.

c. Flip the generator upside down on the pad.

CAUTION: NEVER Attempt this if you have put fuel or oil

Remove braces

2.

a. Completely remove each of the 4 bolts holding the

orange metal brace in place.

in the generator.

b. Remove the brace.

c. Cut the nylon tie strap holding the wood brace in

place.

d. Grab the end of the second brace and pull it out.

e. This piece is no longer needed and can be discarded.

Note: Shipping braces can be thrown away.

They will not be needed again.

16

Page 17

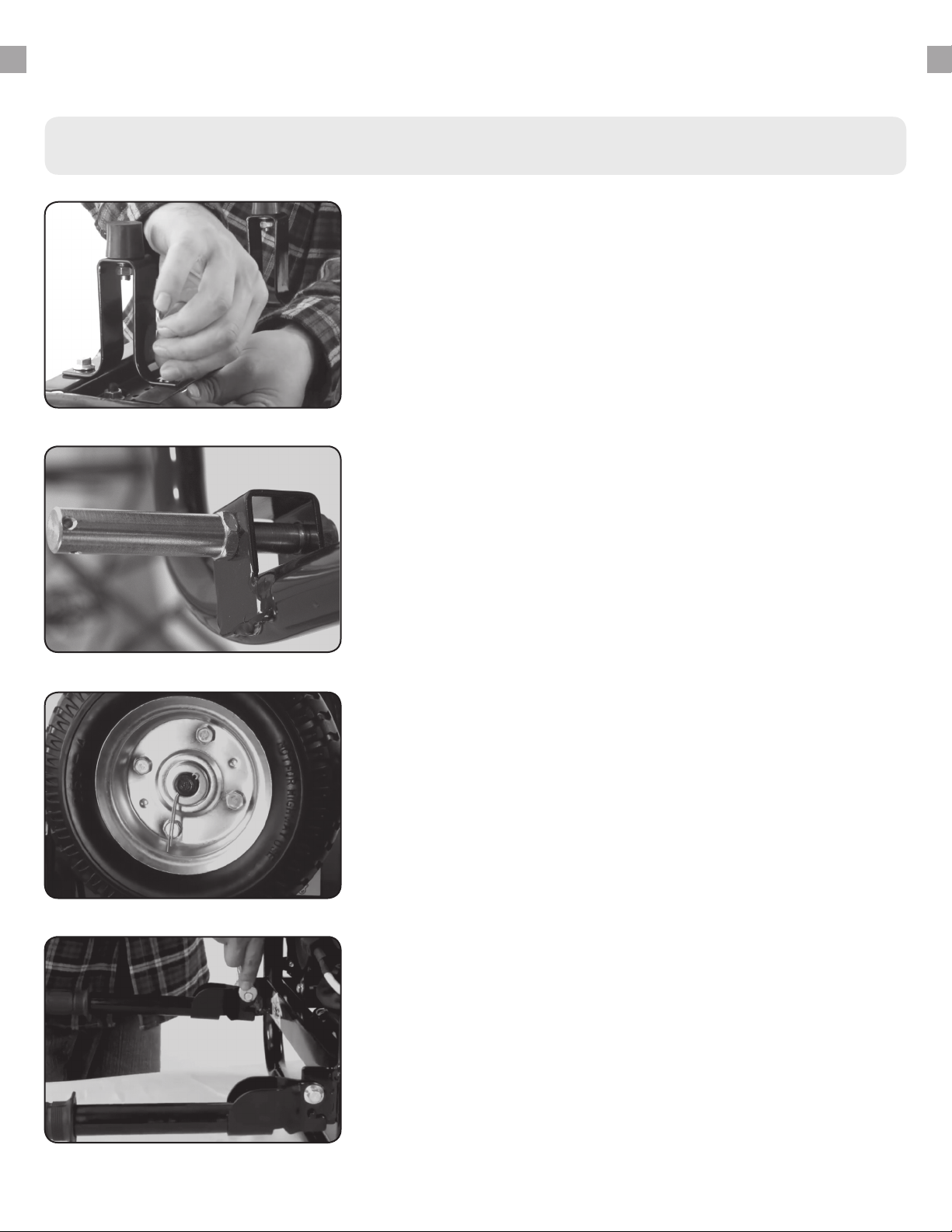

Step 2 - Wheel Kit Installation (Optional)

Install support legs

1.

Secure the support legs to the frame with provided bolts and

lock nuts.

Install wheels

2.

a. Insert wheel bolt through frame and secure with

provided nut.

b. Slide one wheel over each axle end and secure with

the provided retaining pins.

Install Handles

3.

Attach the handles to the brackets on the frame using the

provided bolts and nuts.

Do not over tighten the handles, it will prevent

free movement.

17

Page 18

SAE

GENERATOR SETUP (CONTINUED)

Step 3 - Adding Oil

The generator requires engine oil to operate properly. The generator, when new from the package

contains no oil in the crankcase

generator for the rst time. This amount is equal to the oil capacity of the engine crankcase:

Engine Oil Capacity 40.5 . oz (1.2L)

WARNING: Do not apply engine oils with additives or 2-stroke gasoline engine oils. They don’t

have enough lubrication, and may shorten the engine’s service life.

30

10W-30

*

. You must add the proper amount of oil before operating the

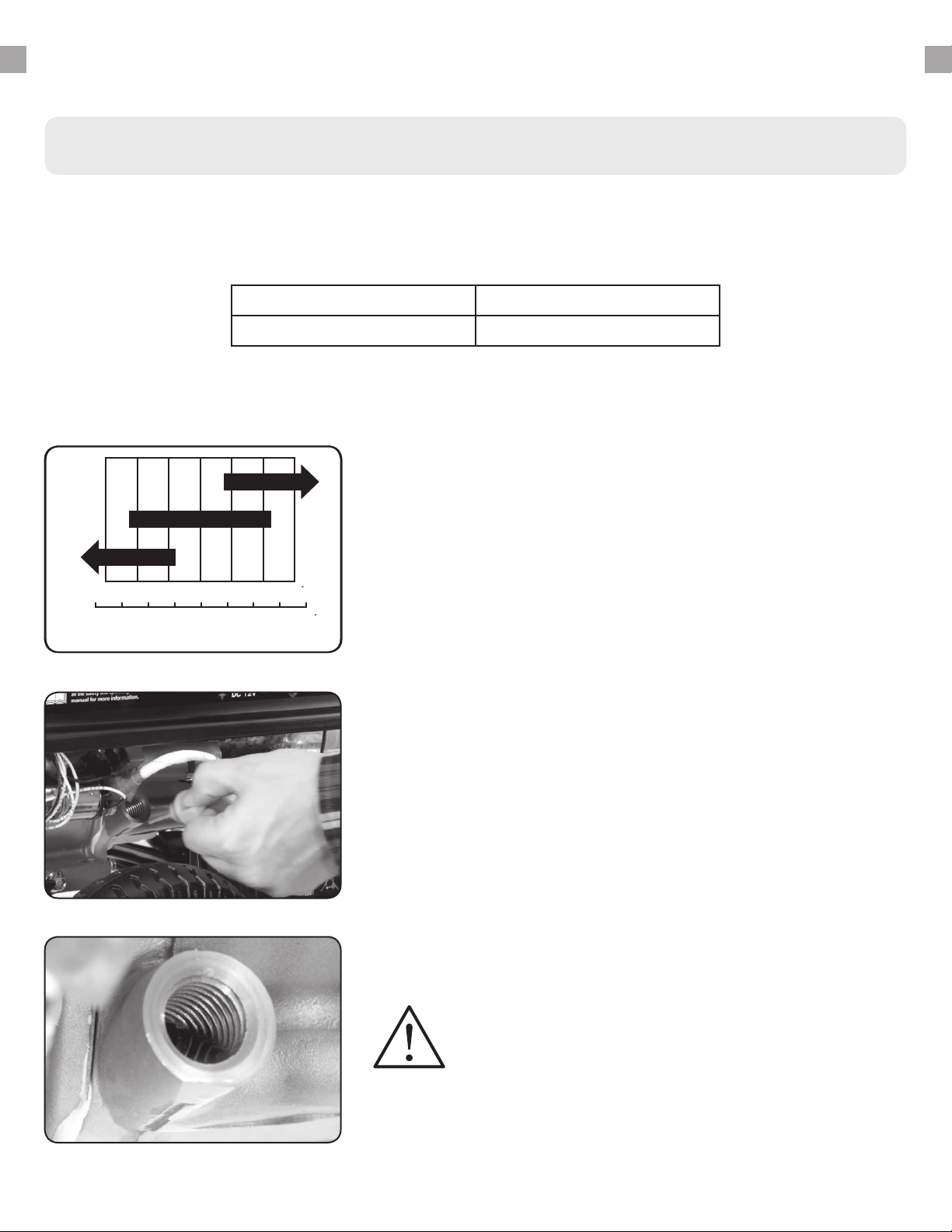

Model Number XP13000E

Engine oil recommended: SAE 10W-30. Viscosity varies with

regions and temperatures. Choose your oil viscosity using the

chart to the left.

5W-30

-20 20 40 60 800 100 F

-30-40 -10 0 10 20

-20

ENVIRONMENTAL TEMPERATURE

30

40 C

* A small amount of oil from factory testing may be present on

arrival.

Add oil

1.

a. Make sure the generator is on a level surface.

b. Unscrew the oil ller/dipstick cap from the engine .

c. Using a funnel, add the appropriate amount of oil

into the crankcase. You will know the crankcase is

full when the oil level has reached the lower lip of

the opening you have just poured the oil into.

d. Replace oil ller cap.

WARNING: DO NOT overll the crankcase. This

may damage the motor and shorting overall life

of your generator.

18

Page 19

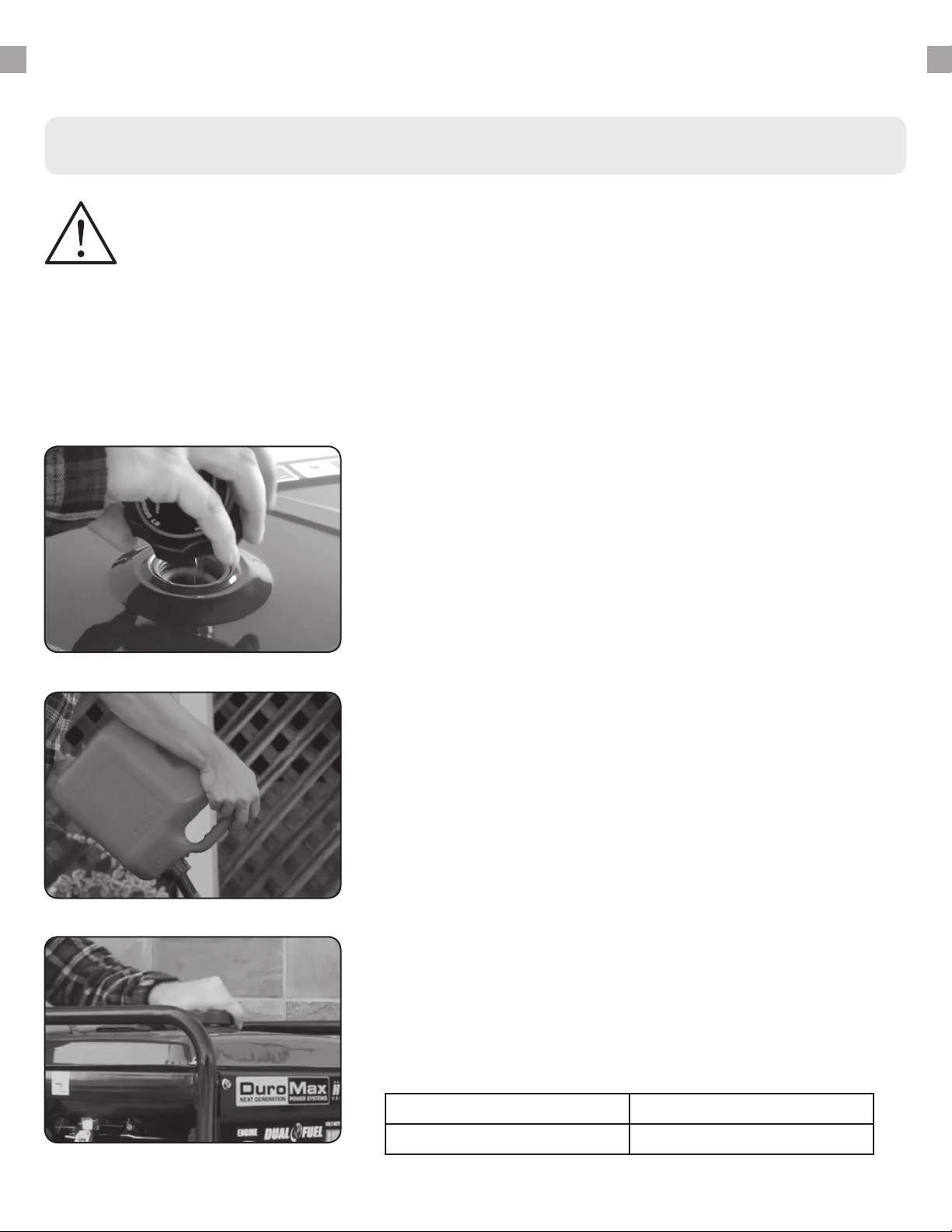

Step 4 - Adding Gasoline

WARNING: Gasoline and gas fumes are highly ammable.

● Do not ll tank near an open ame.

● Do not overll. Always check for fuel spills.

To ensure that the generator runs smoothly use only FRESH, UNLEADED GAS WITH AN OCTANE

RATING OF 87 OR HIGHER.

Add Gasoline

2.

a. Make sure the generator is on a level surface.

b. Unscrew gas cap and set aside (NOTE: the gas cap

may be tight and hard to unscrew).

c. Slowly add unleaded gasoline to the fuel tank. Be

careful not to overll. Please refer to the chart below

to nd the gas capacity of your generator model. The

fuel gauge on the top of the gas tank indicates how

much gasoline is in the generator gas tank.

d. Replace fuel cap and wipe up any spilled gasoline

with a dry cloth.

NOTE: Gas can expand. Do not ll the gas tank

to the very top. Leave a minimum of 1.5 in of open

IMPORTANT:

● Never use an oil/gasoline mixture. Never use old gas.

● Avoid getting dirt or water in the fuel tank.

● Gas can age in the tank and make it hard to start up

the generator in the future.

● Never store generator for extended periods of time

with fuel in the tank.

space.

Model Number XP13000E

Gas Tank Capacity 7.9 US Gallons (30L)

19

Page 20

GENERATOR SETUP (CONTINUED)

Step 5 - Grounding the Generator

Attach grounding wire

1.

a. Ground the generator by tightening the grounding

nut against a grounding wire.

b. Connect the other end to a copper or brass

grounding rod that’s driven into the earth.

A generally acceptable grounding wire is a No. 12 AWG

(American Wire Gauge) stranded copper wire.

Grounding codes can vary by location. Please contact a local

electrician to check the grounding regulations for your area.

WARNING: Failure to properly ground the generator can result in electrocution.

High Altitude Operation

At high altitude, the standard carburetor air/fuel mixture will be too rich. Performance will decrease, and

fuel consumption will increase. A very rich mixture will also foul the spark plug and cause hard starting.

Operation at an altitude that diers from that at which this engine was certied, for extended periods of

time, may increase emissions. High altitude performance can be improved by specic modications to the

carburetor. If you always operate your generator at altitudes above 5,000 feet (1,500 meters), have a dealer

perform this carburetor modication. This engine, when operated at high altitude with the carburetor

modications for high altitude use, will meet each emission standard throughout its useful life. Even with

carburetor modication, engine horsepower will decrease about 3.5% for each 1,000-foot (300-meter)

increase in altitude. The eect of altitude on horsepower will be greater than this if no carburetor

modication is made.

When the carburetor has been modied for high altitude operation, the air/fuel mixture will be too lean

for low altitude use. Operation at altitudes below 5,000 feet (1,500 meters) with a modied carburetor may

cause the engine to overheat and result in serious engine damage.

20

Page 21

STARTING THE GENERATOR

If this is not your rst time using the generator there are still steps you should take to prepare it for

operation each time you use it.

IMPORTANT: At this point you should be familiar with the procedures described in the rst

portion of this section entitled “GENERATOR SETUP” If you have not yet read this section, go

back and read it now.

21

Page 22

BEFORE YOU START YOUR GENERATOR

Step 1 - Check the oil

Check the oil

1.

The generator is equipped with an automatic shuto to

protect it from damage due to low oil. Nonetheless, you

should check the oil level of the engine before each use to

ensure that the engine crankcase has a sucient amount.

To check the oil level:

a. Make sure the generator is on a level surface.

b. Unscrew the oil ller/dipstick cap.

c. With a dry cloth, wipe the oil o of the stick on the

inside of the cap.

d. Insert the dipstick as if you were replacing the

cap and then remove again. There should now be

oil on the stick. If there is no oil on the stick, or oil

only at the very end of the stick, you should add

oil until the engine crankcase is lled (see “Adding

Oil” portion of the “Maintenance” section).

e. Be sure to replace the cap when nished checking

oil.

NOTE: The oil capacity for your generator can be found in

the “Specications” section of this manual.

22

Page 23

Step 2 - Check the gas level

Check Fuel Level

1.

Before starting the generator, check to see that there is

sucient gasoline in the fuel tank. The fuel gauge on top of

the tank will give a rough estimate of the gasoline level. The

gauge will appear white then ll red as the tank is lled.

Note: Fuel gauge may not register with less than 1/3 fuel

tank full.

WARNING: Gasoline and gasoline fumes are highly ammable.

● Do not ll tank near an open ame.

● Always allow engine to cool for several minutes before refueling.

1

● DO NOT overll fuel tank. Fuel expands when shaken or heated. ALWAY leave 1

space or more at the top of the tank.

● ALWAYS use fresh fuel or stabilized fuel. Old gasoline (older than 30 days) can cause

permanent damage to the fuel system.

● Always check for fuel spills.

/2“

23

Page 24

STARTING THE GENERATOR

Starting the Generator

Turn breaker OFF

1.

The breaker is located on the right side of the front power

panel. Flip the breaker down to prevent accidental load

when starting the generator.

Turn gas valve on

2.

The gas valve is located above the recoil start on the bottom

of the fuel tank. Rotate the valve clockwise to the vertical

position to turn on the gas supply.

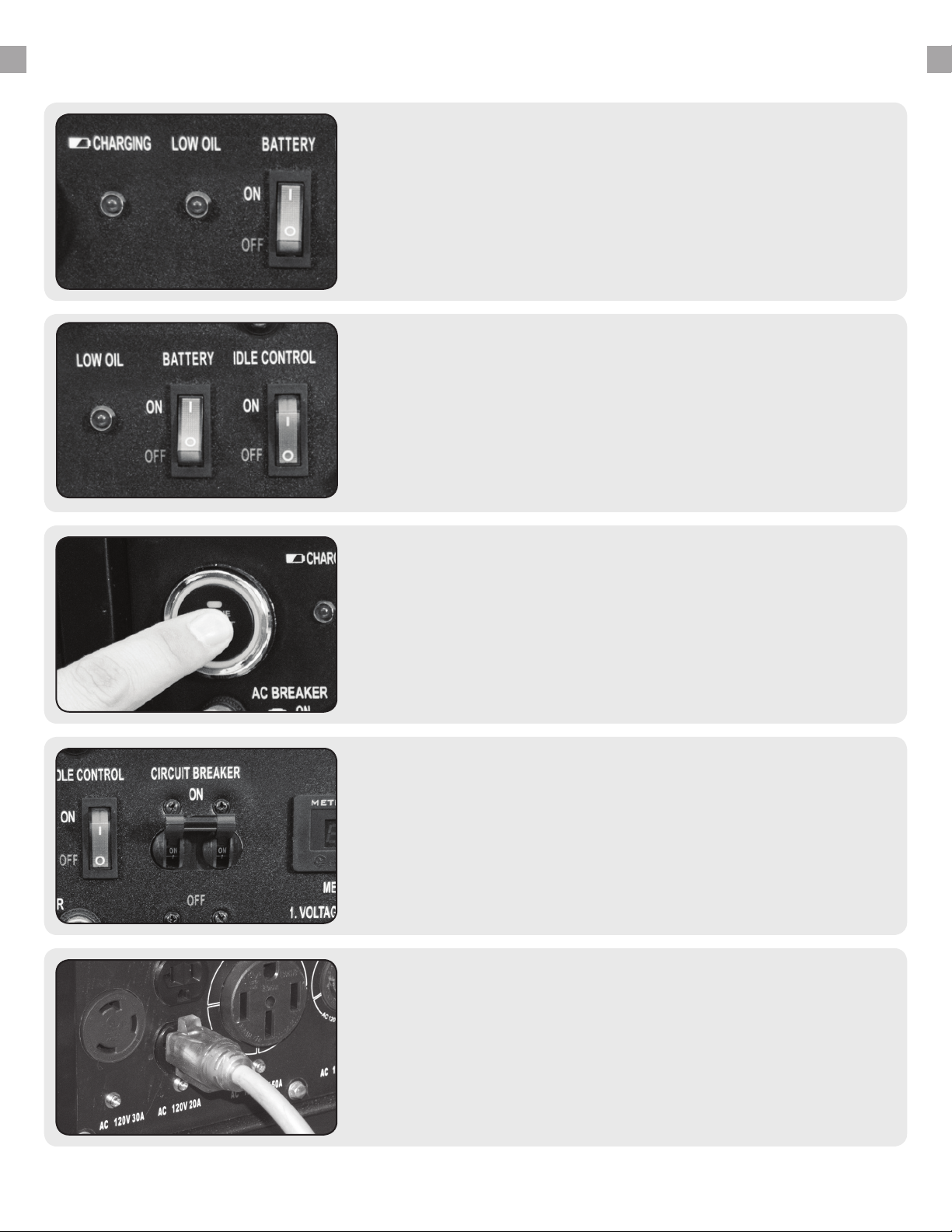

Turn battery switch ON

3.

The battery switch is located on the top center of the main

power panel. Turn the switch ON to allow power to the push

button start.

Turn idle control OFF

4.

When the engine starts, allow the engine switch to return to

the ON position.

24

Page 25

Start the Generator

5.

The push button start left side of the main power panel.

Press the button for 1 second and release to start the

generator.

Turn breaker ON / Connect

6.

The breaker is located on the right side of the front power

panel. Flip the breaker up to allow power to ow to the

receptacles. Connect your devices to the receptacles on the

front panel. Start with the largest loads rst.

CAUTION: Disconnect all electrical loads from the generator before attempting to

start!

WARNING: Operating the starter motor for more than 5 seconds can damage the

motor. If the engine fails to start, release the switch and wait 10 seconds before

operating the starter again.

25

Page 26

26

Page 27

USING THE GENERATOR

If this is not your rst time using the generator there are still steps you should take to prepare it for

operation each time you use it.

IMPORTANT: At this point you should be familiar with the procedures described in the rst

portion of this section entitled “GENERATOR SETUP” If you have not yet read this section, go

back and read it now.

Page 28

USING THE GENERATOR

AC Usage

● You may connect electrical devices running on AC current according to their wattage

requirements.

● The chart below shows the rated and surge wattage of your generator according to its model

number.

● The rated wattage corresponds to the maximum wattage the generator can output on a

continuous basis.

● The surge wattage corresponds to the maximum amount of power the generator can output for

a short period of time. Many electrical devices such as refrigerators require short bursts of extra

power, in addition the rated wattage listed by the device, to stop and start their motors. The

surge wattage ability of the generator covers this extra power requirement.

Fuel Source Rated (Running Wattage) Surge (Peak) Wattage

Gasoline 10500 13000

The total running wattage requirement of the electrical devices connected to the generator should

not exceed the rated wattage of the generator itself. To calculate the total wattage requirement of

the electrical devices you wish to connect, nd the rated (or running) wattage of each device. This

number should be listed somewhere on the device or in its instruction manual.

If you cannot nd this wattage, you may calculate it by multiplying the Voltage requirement by the

Amperage drawn: Watts = Volts x Amps. If these specications are not available you may estimate

the Watts required by your device by using the chart on the next page.

Once you have found the rated wattage requirement of each electrical device, add these numbers

to nd the total rated wattage you wish to draw from the generator. If this number exceeds

the rated wattage of the generator, DO NOT connect all these devices. Select a combination of

electrical devices, which has a total rated wattage lower than or equal to the rated wattage of the

generator.

28

Page 29

Tool or Appliance Rated (Running) Watts Additional Surge Watts

Electric water heater (40 gal) 4000 0

Hot plate 2500 0

Radial arm saw 2000 2000

Electric Stove 1500 0

Circular Saw 1500 1500

Air compressor (1 HP) 1500 3000

Window air conditioner 1200 1800

Miter saw 1200 1800

Microwave 1000 2000

Well water pump 1000 1500

Reciprocating saw 960 1040

Sump pump 800 1200

Refrigerator freezer 800 1200

Furnace blower 800 1300

Computer 800 0

Electric drill 600 900

Television 500 0

Deep freezer 500 800

Garage door opener 480 600

Stereo 400 0

Box fan 300 600

Clock radio 300 0

Security system 180 0

DVD Player 100 0

Common light bulb 75 0

CAUTION - The generator can only run at its surge wattage capacity for a very short time.

Connect only electrical devices requiring a rated (running) wattage equal to or less than

the rated wattage of the generator. Never connect devices requiring a rated wattage

equal to the surge wattage of the generator.

NOTE: The above wattage gures are estimates only.

Try to check the wattage listed on your electrical devices before consulting this chart.

29

Page 30

USING THE GENERATOR (CONTINUED)

Connecting a load to the generator

NOTE: Be sure to attach devices to the correct receptacle (outlet).

● 120v devices can be directly connected to the 120v ONLY receptacles.

● 120v devices can be connected to the 120/240v receptacle using an appropriate adapter.

● 240v devices can ONLY be connected the 240v receptacle.

CAUTION: Do not connect 50Hz or 3-phase loads to the generator.

Plug in devices

1.

Plug in devices to the appropriate receptacle. When using

the generator in 120/240v mode, balance the load as closely

as possible. Placing more load on one side of the circuit will

reduce the breaker trip period.

Turn breaker on

2.

Flip the circuit breaker up to the on position to allow power to

the receptacles.

Turn on connected devices

3.

Start or turn on appliances starting with the biggest loads

rst.

30

Page 31

Choosing the right power cord

Long or thin cords can drain the power provided to an electrical device by the generator. When

using such cords, allow for a slightly higher rated wattage requirement for the electrical device. See

table below for recommended cords based on the power requirement of the electrical device.

DEVICE REQUIREMENTS WIRE GAUGE BY LENGTH (ft.)

AMPS WATTS (120/240V) 10 25 50 100 150

5 600/1200 18 16 14 12 10

10 1200/2400 16 14 12 10 8

15 1800/3600 14 12 10 8 6

20 2400/4800 12 10 8 6 4

25 3000/6000 10 8 6 4 4

30 3600/7200 8 6 4 4 NR

40 4800/9600 6 4 4 NR NR

50 6000/1200 4 4 2 NR NR

*NR = NOT RECOMMENDED

31

Page 32

USING THE GENERATOR (CONTINUED)

DC Usage

CAUTION: The DC receptacle is for 12 Volt automotive-type appliances only. Do not

connect any other device to this receptacle.

Start the generator

1.

The push button start left side of the main power panel.

Press the button for 1 second and release to start the

generator.

Connect the 12v appliance

2.

Use the standard 12v automotive plug to connect to chargers,

tools, appliances, and more.

32

Page 33

Idle Control Usage

WARNING: Power is unusable when idle control is engaged.

Idle Control

1.

The idle control feature lowers the RPM of the generator

when there is no load to save gas and decrease engine

noise.

When a load is applied the engine will resume normal

speed to provide usable power.

Turn on the idle control when using intermittent loads like

power tools and air compressors.

● DO NOT use the idle control function when using the generator for backup house

power.

● Idle control function will cause massive uctuations in voltage and hertz.

● Low amperage loads may not trigger the idle up function.

33

Page 34

USING THE GENERATOR (CONTINUED)

Using the Digital Multimeter

When the generator is started the display when read the current voltage.

Press the MODE button to cycle through the multimeter functions.

Voltage

1.

Displays the current voltage in Volts. American power is 220v - 240v

(+/- 10%).

Frequency

2.

Displays the current frequency in Hertz. American power is 60 Hz (+/- 10%)

Hours Running

3.

Displays the current running time in Hours. Hold down the MODE button

to reset.

Hours Total

4.

Displays the total running time in Hours.

34

Page 35

MAINTENANCE AND CARE

Proper maintenance and storage of your generator is essential to ensure trouble free use of your

generator when you need it.

By following the maintenance and care requirements, you can keep your generator running

smooth and ecient for years to come.

35

Page 36

MAINTENANCE AND CARE

Proper routine maintenance of your generator is essential for safe, economical, and trouble-free

operation. It will also help reduce air pollution.

WARNING: Improper maintenance, or failure to correct a problem before operation, can

cause a malfunction in which you can be seriously injured or killed. Always follow the

inspection and maintenance recommendations and schedules in this instruction manual.

● Make sure the engine is o before you begin any maintenance or repairs.

● Let the engine and exhaust system cool before touching.

● To reduce the possibility of re or explosion, be careful when working around

gasoline. Use only a nonammable solvent, not gasoline, to clean parts. Keep

cigarettes, sparks, and ames away from all fuel related parts.

Maintenance Schedule

Remember that this schedule is based on the assumption that your machine will be used for its

designed purpose. Sustained high-load, high temperature operation, or use in unusually wet or

dusty conditions, will require more frequent service.

REGULAR SERVICE PERIOD

SERVICE

BEFORE

EACH USE

EVERY MO. OR

20 HRS

EVERY 3 MO. OR

50 HRS

EVERY 6 MO. OR

100 HRS

EVERY 12 MO.

OR 300 HRS

ENGINE OIL CHECK

CHANGE

AIR CLEANER CHECK

CHANGE

SEDIMENT CUP CLEAN

SPARK PLUG CLEAN-

ADJUST

REPLACE

SPARK ARRESTOR CLEAN

IDLE SPEED CHECK /

ADJUST

VALVE CLEARANCE CHECK-

ADJUST

COMBUSTION

CHAMBER

CLEAN

500 HOURS

FUEL TANK / FILTER CLEAN

FUEL TUBE CHECK EVERY 24 MO. (REPLACE IF NECESSARY)

TO BE PERFORMED AT EVERY MONTH INDICATED OR HOUR INTERVAL WHICH EVER COMES FIRST

36

Page 37

MAINTENANCE LOG

Date Generator Hours Maintenance Performed

37

Page 38

MAINTENANCE AND CARE (CONTINUED)

Checking the oil

Check the oil

1.

The generator is equipped with an automatic shuto to

protect it from damage due to low oil. Nonetheless, you

should check the oil level of the engine before each use to

ensure that the engine crankcase has a sucient amount.

To check the oil level:

a. Make sure the generator is on a level surface.

b. Unscrew the oil ller/dipstick cap.

c. With a dry cloth, wipe the oil o of the stick on the

inside of the cap.

d. Insert the dipstick as if you were replacing the

cap and then remove again. There should now be

oil on the stick. If there is no oil on the stick, or oil

only at the very end of the stick, you should add

oil until the engine crankcase is lled (see “Adding

Oil” portion of the “Maintenance” section).

e. Be sure to replace the cap when nished checking

oil.

NOTE: The oil capacity for your generator can be found in

the “Specications” section of this manual.

38

Page 39

Changing the oil

Worn out or dirty oil does not cool the generator properly and can lead to catastrophic engine

damage.

In addition to regular oil changes, it is necessary to drain the oil from the crankcase if it has

become contaminated with water or dirt.

Remove drain plug

2.

Using a 10 mm hex wrench, unscrew the oil drain plug, which

is located on the crankcase underneath the oil ller/dipstick

cap.

Allow all the oil to drain from the generator.

Drain oil

2.

Drain oil into an approved oil disposal container. Contact

your local auto parts store for information on oil disposal.

Replace drain plug

3.

Replace the oil drain plug and tighten with a 10 mm hex

wrench.

39

Page 40

MAINTENANCE AND CARE (CONTINUED)

Cleaning the air lter

Routine maintenance of the air cleaner helps maintain proper airow to the carburetor. Check

that the air cleaner is free of excessive dirt after every use.

Note: Improper maintenance may cause less air to enter the engine or dirty air to enter the

engine causing overheating and engine wear.

Open lter cover

1.

Unhinge the clasps at the top and bottom of the air cleaner

cover.

Remove lter element

2.

Remove the sponge-like elements from the casing.

Wipe out lter casing

3.

Wipe the dirt from inside the empty air cleaner casing.

40

Page 41

Wash lter element

4.

Wash the sponge-like elements in household dish detergent

and warm water.

Dry lter element

5.

Allow the elements to dry completely.

Add engine oil to elements

6.

Soak the dry elements in a small amount of engine oil. Ring

out any excess oil.

Replace elements in casing

7.

Replace the sponge-like elements in the air cleaner casing and

replace the cover.

41

Page 42

MAINTENANCE AND CARE (CONTINUED)

Spark Plug Maintenance

The spark plug is important for proper engine operation. A good spark plug should be intact,

free of deposits, and properly gapped.

Improper maintenance may cause reduced fuel economy, misres, trouble starting, or damage

to the spark plug threads.

Remove spark plug cap

1.

Pull on the spark plug cap to remove it.

Remove spark plug

2.

Unscrew the spark plug from the generator using the spark

plug wrench included with this product.

Inspect spark plug

3.

Visually inspect the spark plug. If it is cracked or chipped,

discard and replace with a new spark plug. We recommend

using a F6RTC spark plug such as NGK BPR5ES.

42

Page 43

Measure plug gap

4.

Measure the plug gap with a gauge. The gap should be 0.7-0.8

mm (0.028-0.031 in).

Clean and re-gap

5.

If you are re-using the spark plug, use a wire brush to clean

any dirt from around the spark plug base and then re-gap the

spark plug.

Replace spark plug

6.

Screw the spark plug back into its place on the generator

using the spark plug wrench.

Replace spark plug cap

7.

Replace the spark plug cap.

43

Page 44

MAINTENANCE AND CARE (CONTINUED)

Emptying the Gas Tank

Before storing your generator for extended periods of time, you should drain your generator of

gasoline.

CAUTION: Do not store fuel from one season to another. Gasoline sold at the pump

today contains additives such as ethanol that even when stored properly may

damage the fuel system components.

Shut fuel valve o

1.

Turn the fuel valve to the “OFF” position.

Remove fuel lter cup

2.

Remove the fuel lter cup (see “Removing the Fuel Filter Cup”

earlier in this section.

Empty fuel lter cup

3.

Empty the fuel lter cup of any fuel.

44

Page 45

Drain gas from generator

4.

With a receptacle underneath the generator to catch the gas,

turn the fuel valve to the “ON” position. Drain all the gas from

the generator.

Shut fuel valve o

5.

Turn the fuel valve to the “OFF” position.

Replace fuel lter cup

6.

Reinstall the fuel lter cup.

Store emptied gas

7.

Store the emptied gasoline in a suitable place and add fuel

stabilizer to keep fuel fresh and usable.

45

Page 46

MAINTENANCE AND CARE (CONTINUED)

Cleaning the fuel lter cup

Shut fuel valve o

1.

Turn the fuel valve to the “OFF” position.

Remove fuel lter cup

2.

Unscrew the fuel lter cup from the fuel valve using a wrench.

Turn the valve towards you to unscrew

Clean lter cup

3.

Clean the cup of all sediment using a rag or brush.

Replace fuel lter cup

4.

Reinstall the fuel lter cup.

46

Page 47

Storage and Transportation

CAUTION: Never place any type of storage cover on the generator while it is still

hot.

When transporting your generator:

● Empty the gas tank (see “Emptying the Gas Tank” in the “Maintenance” section).

● Disconnect the spark plug.

● Do not obstruct any ventilation openings & keep the generator in a cool dry area.

Storage Period Storage Preparation

1. Turn o the main breaker.

If you plan on starting

the same day.

2. Allow the unit to run 3 - 5 minutes.

3. Turn o the key.

4. Store.

If you plan on starting

the unit again within

30 days.

If you do not plan to

start the unit for

longer than 30 days.

1. Turn o the main breaker.

2. Allow the unit to run 3 - 5 minutes.

3. Turn o the fuel valve.

4. Allow the unit to stall out.

5. Turn o the key.

6. Add fuel stabilizer to the gas remaining in the tank.

7. Store.

1. Turn o the main breaker.

2. Allow the unit to run 3 - 5 minutes.

3. Turn o the fuel valve.

4. Allow the unit to stall out.

5. Turn o the key.

6. Drain the fuel tank (See “Emptying the Gas Tank” in the “Maintenance” section)

7. Drain the carburetor

a. Remove the drain bolt from the carburetor.

b. Drain the small amount of remaining fuel from the carburetor bowl.

8. Oil the cylinder

a. Remove the spark plug.

b. Put 2 tbsp. of 10w30 motor oil directly into the spark plug hole

c. Pull the recoil start one time.

d. Replace the plug.

9. Remove the battery and place on tender indoors.

47

Page 48

SPECIFICATIONS

AC Rated Wattage 10500W

AC Surge Wattage 13000W

AC Rated Voltage 120/240V

AC Rated Frequency 60 Hz

AC Phase Single

DC Voltage 12V

DC Amperage 8.3A

Dimensions LENGTH 28in.

WIDTH 23in.

HEIGHT 23in.

Engine Type 4-Stroke OHV Forced-Air

Ignition System Non-Contact Transistor

Displacement 500cc

Starting Type Electric

Fuel Tank Capacity 7.9 US Gal. (30L)

Oil Capacity 40.5 . oz. (1.1L)

Run Time @ 50% (Gasoline) 8 hr.

Run Time @ 50% (Propane) 5 hr. (5 Gallon)

Noise Level <74db

48

Page 49

TROUBLESHOOTING

This section of the manual is to help you troubleshoot problems with your generator.

49

Page 50

TROUBLESHOOTING

Mode Description

Engine Switch is “O” Set engine switch to “run”

Fuel Valve is “Closed” Turn fuel valve to “open”

Choke is open. Close the choke

Engine is out of fuel Add fuel

Engine will not start

Engine runs, but there

is no electrical output.

Generator runs, but

does not support all

electrical devices connected.

Fuel is old or contaminated Change fuel

Spark Plug is dirty Clean spark plug

Spark Plug is broken Replace spark plug

Generator is not level

Oil is low Add / change oil

Circuit Breaker is “O” Turn “on” circuit breaker

Wiring connection is bad Replace extension cord(s)

Device connected to generator

is malfunctioning

Generator is overloaded

Device connected to generator

is bad

Air cleaner is dirty Clean / replace the air lter

Move generator to a level

surface

Disconnect malfunctioning

device

Disconnect 1 or more items to

reduce the load

Disconnect malfunctioning

device

50

Page 51

Changing / Inspecting the Carbon Brushes

The carbon brushes in conjunction with the AVR regulates power from the generator. The

carbon brushes are wearable parts and should be inspected every 250 running hours.

Remove generator cover

1.

Remove the 2 bolts of the generator cover then pull the cover

o the generator.

Remove bolt from brush

2.

Remove the bolt holding the carbon brush.

Disconnect AVR wires

3.

Remove the two wires from the AVR on the carbon brush

51

Page 52

TROUBLESHOOTING (CONTINUED)

Changing / Inspecting the Carbon Brushes (Cont.)

Install new brush

4.

Install new carbon brush with bolt.

Connect AVR wires

5.

Insert and connect the 2 wires from the AVR, be sure to connect

+ and – correctly.

Replace generator cover

6.

Replace the back cover of the generator and secure with the

2 bolts.

52

Page 53

Changing / Inspecting the AVR

The carbon brushes in conjunction with the AVR regulates power from the generator. If the

generator is overheated or overloaded, the AVR may be damaged and require replacement.

Remove generator cover

1.

Remove the 2 bolts of the generator cover then pull the cover

o the generator.

Remove AVR bolts

2.

Remove the 2 bolts holding the AVR.

Disconnect AVR wire clip

3.

Disconnect the wire clip.

53

Page 54

TROUBLESHOOTING (CONTINUED)

Changing / Inspecting the AVR (Continued)

Disconnect wires from brush

4.

Remove the 2 wires from the AVR on the carbon brush.

Install new AVR

5.

Install the new AVR with the 2 bolts.

Reconnect wires to brush

6.

Reconnect the wire clip.

Reconnect the AVR wire clip

7.

Insert and connect the 2 wires from the AVR, be sure to

connect + and – correctly.

54

Page 55

Replace generator cover

8.

Replace the back cover of the generator and secure with the

2 bolts.

55

Page 56

WARRANTY

3-year Warranty

All DuroMax Power Equipment warrant the original purchasers to a 3-year Parts Warranty

(Residential Use ONLY: Unusually heavy or commercial use is covered for a period of 1-year) in

the event of failure due to defects in electrical or mechanical components. Freight on any items

submitted for replacement or repair under the Warranty are the responsibility of the equipment

owner. This warranty is non-transferable and only valid to the original purchaser.

Warranty Exclusions

The DuroMax Power Equipment warranty does not cover repairs or returns when the fault is:

Normal Wear and Tear, Installation Use or Maintenance Services, Cosmetic defects, Accessories,

Failures due to acts of God or Natural Disasters, or problems related to/from aftermarket or nonOEM parts.

Warranty Limitations

DuroMax Power Equipment does not claim or hold any obligation to loss of time, freight charges,

use of product, or any incidental damages from the use of this product. THIS WARRANTY IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED.

U.S. EPA AND CALIFORNIA EMISSIONS CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The U.S. Environmental Protection Agency (EPA), California Air Resources Board, and DuroMax

Power Equipment are pleased to explain the emissions control system’s warranty on your 2018

small o-road engine. In California, new equipment that use small o-road engines must be

designed, built, and equipped to meet the State’s stringent anti-smog standards. DuroMax Power

Equipment must warrant the emissions control system on your small o-road engine for the

period listed below provided there has been no abuse, neglect, or improper maintenance of your

equipment.

Your emissions control system may include parts such as: carburetors or the fuel injection system,

ignition system, catalytic converters, fuel tanks, valves, lters, clamps, connectors, and other

associated components. Also, included may be hoses, belts, connectors, sensors, and other

emission-related assemblies.

Where a warrantable condition exists, DuroMax Power Equipment will repair your small o-road

engine at no cost to you including diagnosis, parts, and labor.

MANUFACTURER’S WARRANTY COVERAGE:

This emissions control system is warranted for two years. If any emissions-related part on your

equipment is defective, the part will be repaired or replaced by DuroMax Power Equipment.

56

Page 57

OWNER’S WARRANTY RESPONSIBILITIES:

● As the small o-road engine owner, you are responsible for performance of the required

maintenance listed in your owner’s manual. DuroMax Power Equipment recommends that you

retain all receipts covering maintenance on your small o-road engine, but DuroMax Power

Equipment cannot deny warranty solely for the lack of receipts or your failure to ensure the

performance of all scheduled maintenance.

● As the small o-road engine owner, you should however be aware that the DuroMax Power

Equipment may deny you warranty coverage if your small o-road engine or a part has failed

due to abuse, neglect, or improper maintenance or unapproved modications.

● You are responsible for presenting your small o-road engine to a DuroMax Power Equipment

distribution center or service center as soon as the problem exists. The warranty repairs should

be completed in a reasonable amount of time, not to exceed 30 days.

● If you have any questions regarding your warranty coverage, contact us at 844-DUROMAX or

email support@duromaxpower.com.

DEFECTS WARRANTY REQUIREMENTS:

The warranty period begins on the date the engine or equipment is delivered to an ultimate

purchaser and extends for a period of Two Years.

GENERAL EMISSIONS WARRANTY COVERAGE:

DuroMax Power Equipment warrants to the ultimate purchaser and each subsequent owner that

the engine or equipment is:

1. Designed, built, and equipped to conform with all applicable regulations adopted by the Air

Resources Board; and

2. Free from defects in materials and workmanship that causes the failure of a warranted part for

a period of two years.

The warranty on emissions-related parts will be interpreted as follows:

1. Any warranted part that is not scheduled for replacement as required maintenance in the

Owner’s Manual must be warranted for the warranty period stated above. If any such part fails

during the period of warranty coverage, it must be repaired or replaced by the manufacturer

according to Subsection (4) below. Any such part repaired or replaced under the warranty must

be warranted for the remaining warranty period.

57

Page 58

WARRANTY (CONTINUED)

1. Any warranted part that is scheduled only for regular inspection in the Owner’s Manual must be

warranted for the warranty period stated above. A statement in such written instructions to the

eect of “repair or replace as necessary” will not reduce the period of warranty coverage. Any

such part repaired or replaced under warranty must be warranted for the remaining warranty

period.

2. Any warranted part that is scheduled for replacement as required maintenance in the Owner’s

Manual must be warranted for the period prior to the rst scheduled replacement point for

that part. If the part fails prior to the rst scheduled replacement, the part must be repaired or

replaced by the engine manufacturer according to Subsection (4) below. Any such part repaired

or replaced under warranty must be warranted for the remainder of the period prior to the rst

scheduled replacement point for the part.

3. Repair or replacement of any warranted part under the warranty must be performed at no

charge to the owner at a warranty station.

4. Notwithstanding the provisions of Subsection (4) above, warranty services or repairs must be

provided at all manufacturer distribution centers that are franchised to service the subject

engines.

5. The owner must not be charged for diagnostic labor that leads to the determination that

a warranted part is in fact defective, provided that such diagnostic work is performed at a

warranty station.

6. The manufacturer is liable for damages to other engine components proximately caused by a

failure under warranty of any warranted part.

7. Throughout the emissions warranty period stated above, the manufacturer must maintain a

supply of warranted parts sucient to meet the expected demand for such parts.

8. Any replacement part may be used in the performance of any warranty maintenance or repairs

and must be provided without charge to the owner.

a. Such use will not reduce the warranty obligations of the manufacturer.

9. Add-on or modied parts that are not exempted by the Air Resources Board may not be used.

The use of any nonexempt add-on or modied parts will be grounds for disallowing a warranty

claim. The manufacturer will not be liable to warrant failures of warranted parts caused using a

nonexempt add-on or modied part.

10. The manufacturer issuing the warranty shall provide any documents that describe that

manufacturer’s warranty procedures or policies within ve working days of request by the Air

Resources Board.

58

Page 59

Exhaust Emission Warranty Parts List.

1. Fuel Metering System

i. Carburetor and internal parts (and/or

pressure regulator or fuel injection

system).

ii. Air/fuel ratio feedback and control

system.

iii. Cold start enrichment system.

2. Air Induction System

i. Controlled hot air intake system.

ii. Intake manifold.

3. Ignition System

i. Spark Plugs.

ii. Magneto or electronic ignition system.

iii. Spark advance/retard system.

4. Air Injection System

i. Air pump or pulse valve.

ii. Valves aecting distribution of ow.

iii. Distribution manifold.

5. Catalyst or Thermal Reactor System (i)

Catalytic converter.

i. Thermal reactor.

ii. Exhaust manifold.

6. Particulate Controls

7. Traps, lters, precipitators, and any other

device used to capture particulate

emissions.

8. Electronic controls.

9. Vacuum, temperature, and time sensitive

valves and switches.

*Note: The parts list for equipment less than or equal to 80 cc only includes the fuel tank.

**Note: As they relate to the evaporative emission control system.

DuroMax Power Equipment will furnish with each new engine written instructions for the

maintenance and use of the engine by the owner.

10. Hoses, belts, connectors, and assemblies.

11. Evaporative Emission Warranty Part List

i. Fuel Tank*

ii. Fuel Cap

iii. Fuel Line

iv. Fuel Line Fittings

v. Clamps**

vi. Pressure Relief Valves**

vii. Control Valves**

viii. Control Solenoids**

ix. Electronic Controls**

x. Vacuum Control Diaphragms**

xi. Control Cables**

xii. Control Linkages**

xiii. Purge Valves

xiv. Vapor Hoses

xv. Liquid/Vapor Separator

xvi. Carbon Canister

xvii. Canister Mounting Brackets

xviii. Carburetor Purge Port Connector

59

Page 60

CUSTOMER SERVICE

Duromax Power Equipment is comitted to ensuring that our products perform when they need

to. Our generators are your lifeline in the event of an emergency. Should you have any problems,

please contact our customer service department:

DUROMAX POWER EQUIPMENT

5800 Ontario Mills Parkway

Ontario, CA 91764

Customer Service: 844-DUROMAX

Customer Service Hours: 8-5pm PST

Website: www.duromaxpower.com

Email: customer_service@duromaxpower.com

60

Page 61

Page 62

5800 Ontario Mills Parkway

Ontario, CA 91764

United States

844-DUROMAX

Loading...

Loading...