Page 1

customer_service@maxtool.com

or call 1-800-629-3325 (option 3) Monday - Friday 7am to 5pm. PST

Product Support (Product: information, application, and service info & warranty questions)

support@maxtool.com

or call 1-800-629-3325 (option 4) Monday - Friday 7am to 5pm. PST

This manual provides information regarding the operation and maintenance of these products.

We have made every effort to ensure the accuracy of the information in this manual.

We reserve the right to change this product at any time without prior notice.

Page 2

1

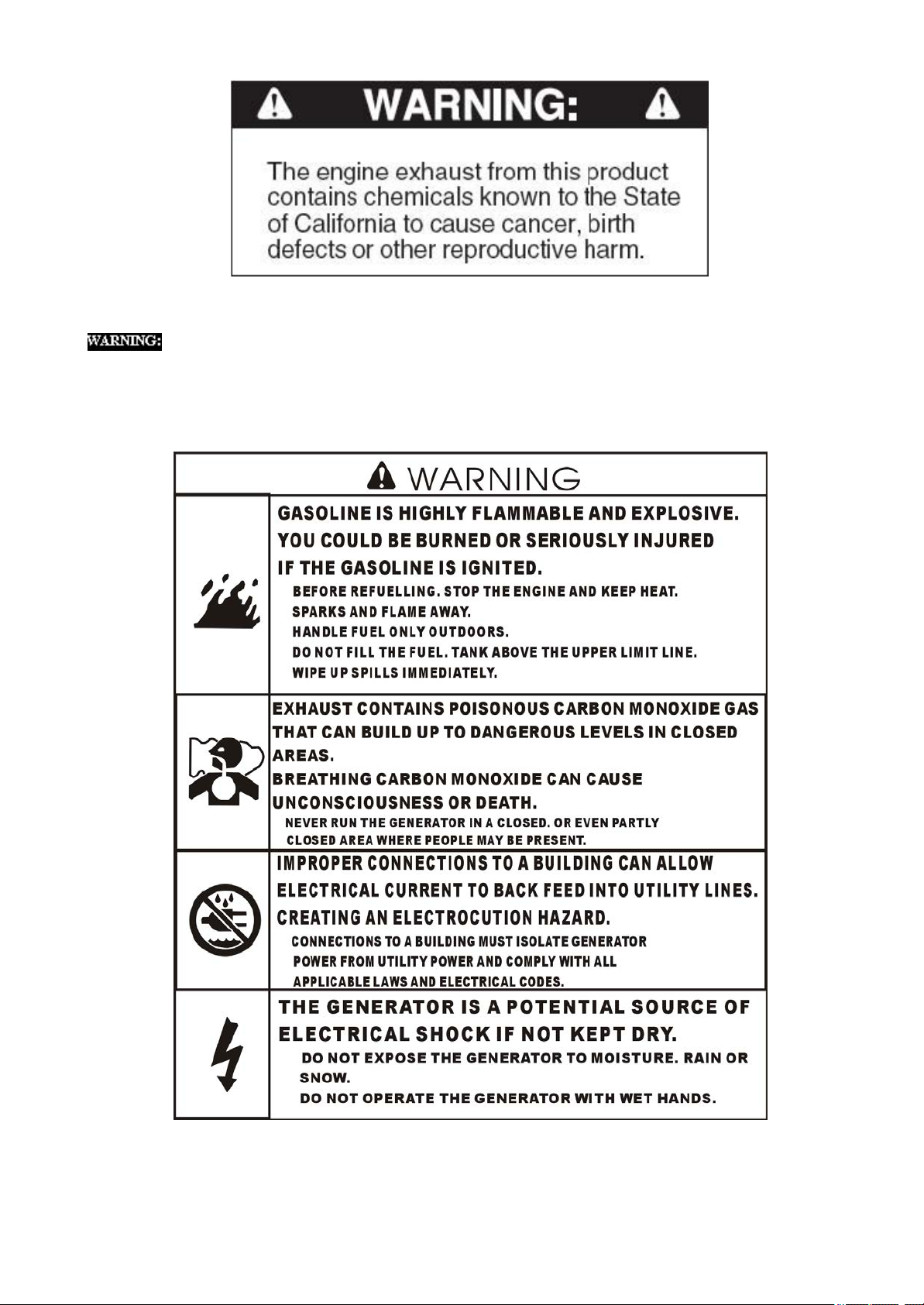

The generator is a potential source of electrical shock if misused. Do not expose the generator to

moisture, rain or snow. Do not let the generator get wet, and do not operate it with wet hands.

These labels warn you of potential hazards that can cause serious injury. Read them carefully.

Page 3

2

SAFETY

INFORMATION

Read and understand this instruction manual before operating your generator. You can help prevent

accidents by being familiar with your generator’s controls, and by observing safe operating

procedures.

Operator Responsibility

Know how to stop the generator quickly in case of emergency.

Understand the use of all generator controls, output receptacles, and connections.

Do not let children operate the generator without parental supervision.

Carbon Monoxide Hazards

Exhaust contains poisonous carbon monoxide, a colorless and odorless gas. Breathing exhaust

can cause loss of consciousness and may lead to death.

If you run the generator in an area that is confined, or even partially enclosed, the air you breathe

could contain a dangerous amount of exhaust gas. To keep exhaust gas from accumulating,

provide adequate ventilation.

Electric Shock Hazards

The generator produces enough electric power to cause a serious shock or electrocution if misused.

Using a generator or electrical appliance in wet conditions, such as rain or snow, or near a pool or

sprinkler system, or when your hands are wet, could result in electrocution. Keep the generator dry.

If the generator is stored outdoors, unprotected from the weather, check all of the electrical

components on the control panel, before each use. Moisture or ice can cause a malfunction or short

circuit in electrical components, which could result in electrocution.

Do not connect to a building electrical system unless a qualified electrician has installed an isolation

switch.

Fire and Burn Hazards

The exhaust system gets hot enough to ignite some materials.

-Keep the generator at least 3 feet (1 meter) away from buildings and other equipment during

operation.

-Do not enclose the generator in any structure.

-Keep flammable materials away from the generator.

The muffler becomes very hot during operation and remains hot for a while after stopping the

engine.

Be careful not to touch the muffler while it is hot. Let the engine cool before storing the generator

indoors.

Gasoline is extremely flammable and is explosive under certain conditions. Do not smoke or allow

flames or sparks where the generator is refueled or where gasoline is stored. Refuel in a

well-ventilated area with the engine stopped.

Fuel vapors are extremely flammable and may ignite after the engine has started. Make sure that

any spilled fuel has been wiped up before starting the generator.

Page 4

3

CONTENTS

SAFETY INFORMATION……………………………………………………………..2

COMPONENT IDENTIFICATION…………..…………………………………….…4

WATTAGE REFERENCE CHART……..……………………………………… . ... ..7

SPECIFICATIONS…………………………………………….………………….……8

WIRING DIAGRAM………………………………………………………….……..…9

ASSEMBLY………………………………………………………..……………….……10

PRE-OPERATION CHECK……………………………………………………...…….10

STARTING THE ENGINE/STOPPING THE ENGINE………………..…….………12

OPERATING INSTRUCTIONS………………………………………….…….…….. .12

MAINTENANCE…………………………………………..…………………….………15

STORAGE…………………………………………………..……………………………18

TROUBLESHOOTING…………………………………..……………………………..19

WARRANTY SERVICE INFORMATION……………………………..………….….24

Page 5

4

Page 6

5

.

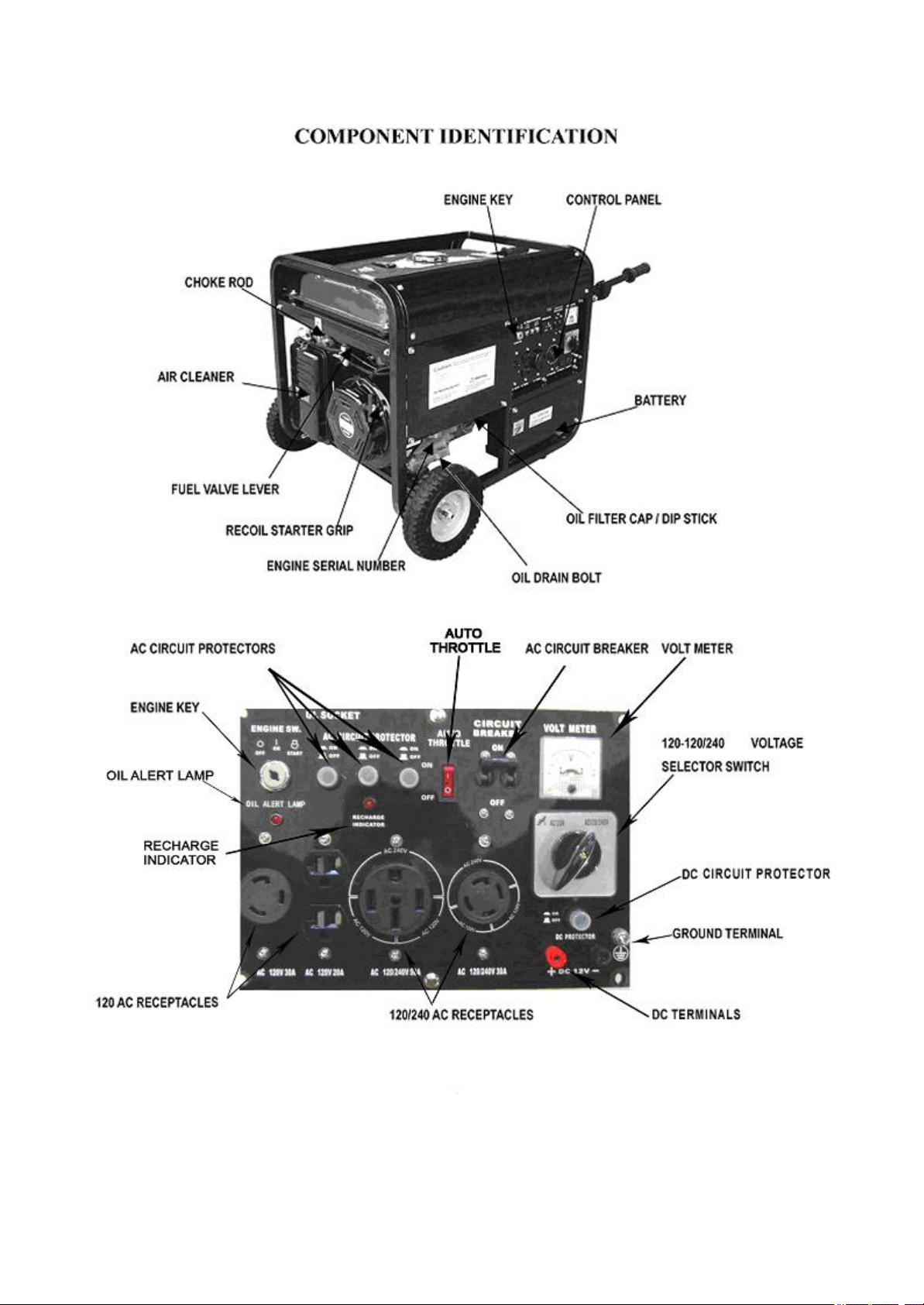

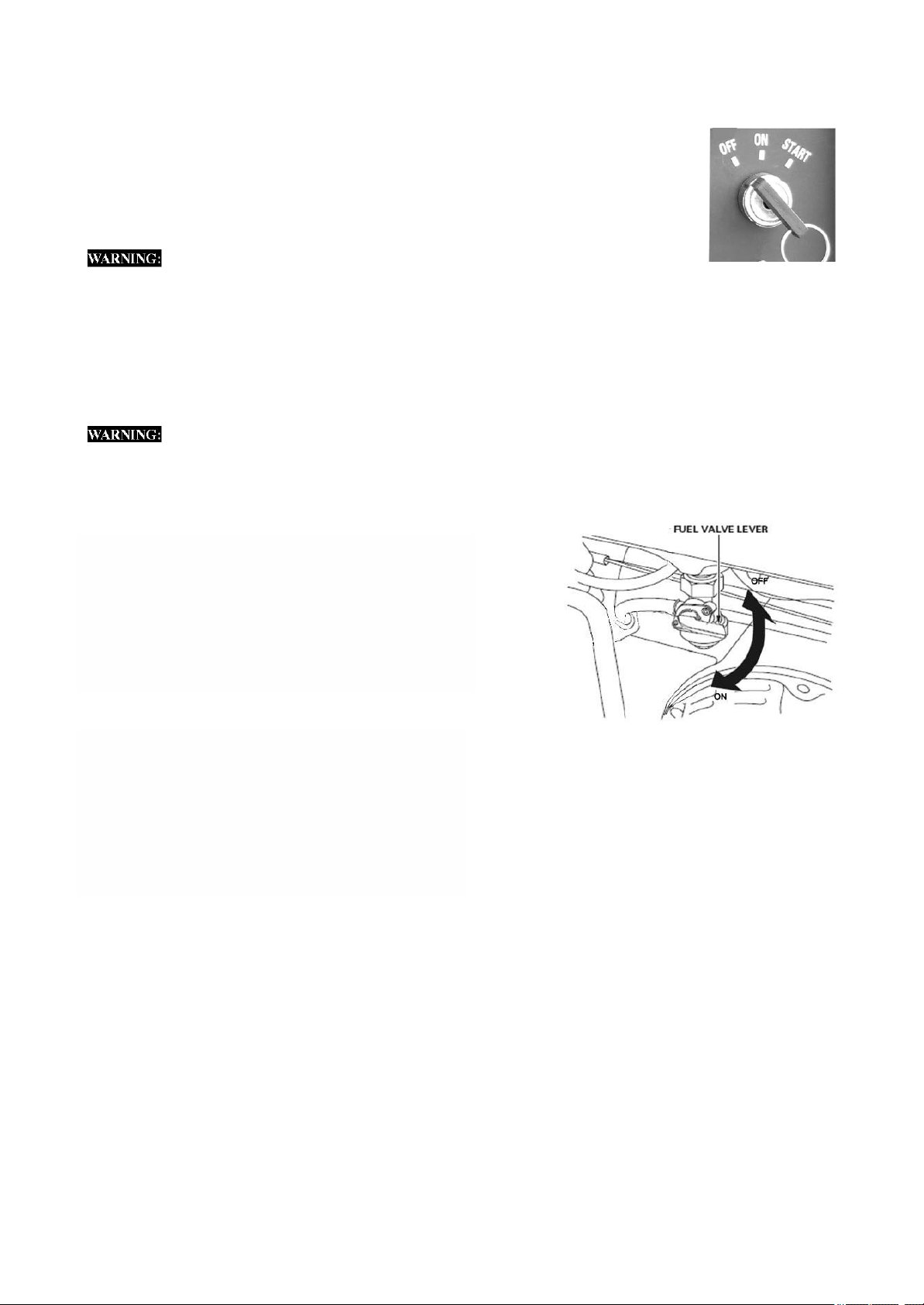

Engine Key

To start and stop the engine.

Key position:

OFF: To stop the engine. Key can be removed / inserted.

ON: To run the engine after starting, or to pull start the unit.

START: To start the engine by operating the starter motor.

Do not turn the key switch to START position when the engine is running to

prevent damage to the starting motor.

Recoil Starter

To start the engine, turn the key to on, pull the starter grip lightly until resistance is felt, then pull briskly.

Do not allow the starter grip to snap back against the engine. Return it gently to prevent damage to the starter.

Fuel Valve Lever

The fuel valve is located between the fuel tank

and carburetor. When the valve lever is in the ON

position, fuel is allowed to flow from the fuel tank

to the carburetor. Be sure to return the fuel valve

lever to the OFF position after stopping the

engine.

Choke Rod

The choke is used to provide an enriched fuel

mixture when starting a cold engine. It can be

opened and closed by operating the choke rod

manually. Pull the rod out toward CLOSED to

enrich the mixture for cold starting

Voltage Selector Switch

The voltage selector switch switches the main power carrying windings of the generator to produce

‘‘120V ’’ or ‘‘120/240V’’. If a 240V appliance is connected to the 4-prong receptacles, the switch

must be in the ‘‘120/240V’’ position. If only a 120V appliance is being connected select the "120V"

position.

Switch Position

120/240V: The 120V and 120/240V receptacles can be used simultaneously.

120V: Do not use the 120/240V twist lock receptacle in this position. The most power will be available

at the 50A 120/240V receptacle.

Page 7

6

Change the Voltage Selector Switch after turning the AC circuit breaker to OFF. The generator may

be damaged if the Voltage Selector Switch is changed with the breaker in the ON position.

Ground Terminal

The generator ground terminal is connected to the frame of the generator, the metal

non-current-carrying parts of the generator, and the ground terminals of each receptacle.

DC Receptacle

The DC receptacle may ONLY be used for charging 12 volt automotive type batteries.

The battery must be connected to the generator DC receptacle with the proper polarity (battery

positive to generator positive (+) and battery negative to the generator negative (-).

Do not start the vehicle while the battery charging cable is connected and the generator is running.

The vehicle or the generator may be damaged.

DC Circuit Protector

The DC circuit protector automatically shuts off the DC battery charging circuit when the DC

charging circuit is overloaded, when there is a problem with the battery, or when the connections

between the battery and the generator are improper.

Oil Alert System

The Oil Alert system is designed to prevent engine damage caused by an insufficient amount of oil in

the crankcase. Before the oil level in the crankcase can fall below a safe limit, the Oil Alert system

will automatically stop the engine (the engine switch will remain in the ON position). The Oil Alert

system should not take the place of checking the oil level before each use.

If the engine stops and will not restart, check the engine oil level before troubleshooting in other areas.

AC Circuit Breaker

The AC circuit breaker will automatically switch OFF if there is a short circuit or a significant

overload of the generator at the receptacle. If the AC circuit breaker is switched OFF automatically,

check that the appliance is working properly and does not exceed the rated load capacity of the circuit

before switching the AC circuit breaker ON again. The AC circuit breaker may be used to switch the

generator power ON or OFF.

AC Circuit Protector

The AC circuit protectors will automatically switch OFF if there is a short circuit or a

significant overload of the generator at the 20A 120V, 30A 120V plug. If an AC circuit

protector switches OFF automatically, check that the appliance is working properly and

does not exceed the rated load capacity of the circuit before resetting the AC circuit

protector ON.

Page 8

7

Tool or Appliance

Rated* (Running) Watts

Additional Surge (Starting) Watts

Essentials

Light Bulb-75 watt

75

-

Deep Freezer

500

800

Sump Pump

800

1200

Refrigerator/Freezer-18 Cu. Ft.

800

1600

Water Well Pump-1/3 HP

1000

2000

Heating/Cooling

Window Air Conditioner-12000 BTU

1200

1800

Window Fan

300

600

Furnace Fan Blower-1/2 HP

800

1300

Kitchen

Microwave Oven-1000 watt

1000

2000

Coffee Maker

1500

-

Electric Stove- Single Element

1500

-

Hot Plate

2500

-

Family Room

DVD/CD Player

100

-

VCR

100

-

Stereo Receiver

450

-

Color Television- 27”

500

-

Personal Computer w/17” Monitor

800

-

Other

Security System

180

-

AM/FM Clock Radio

300

-

Garage Door Opener- 1/2 HP

480

520

Electric Water Heater- 40 Gallon

4000

-

DIY / Job Site

Quartz Halogen Work Light

1000

-

Airless Sprayer- 1/3 HP

600

1200

Reciprocating Saw

960

960

Electric Drill- 1/2 HP

1000

1000

Circular Saw- 7 1/4”

1500

1500

Miter Saw- 10”

1800

1800

Table Planer- 6”

1800

1800

Table Saw / Radial Arm Saw- 10”

2000

2000

Air Compressor- 1- 1/2 HP

2500

2500

WATTAGE REFERENCE CHART

Electric equipment, especially engines produce strong current when being started. The table below offers references

when you connect those installations to generator.

*Wattages listed are approximate only. Check tool or appliance for actual wattage.

Page 9

8

SPECIFICATIONS

Generator

Model

XP12000E

Frequency

60 HZ

Max. AC Output

12000 Watt

Rated AC Output

9500 Watt

Run Time

8 hour

Engine

Standard

Features

Model

XP18HPE

Type

Air Cooled, OHV, 4-Stroke

Displacement

457 cc

Output

9.5kw / 3600 rpm

Fuel

Unleaded Gasoline

Fuel Tank Capacity

8.3 Gallon

Decibel

<72 dBA

Oil Alert

Standard

Battery

12V 18A/hr.

Fuel Gauge

Standard

Air Cleaner

Standard

Silencer

Standard

Voltmeter

Standard

Receptacle

2×NEMA 5-20R

1×NEMA 5-30R

1×NEMA L14-30R

1×NEMA 14-50R

Plug(Not included with

your generator)

2×NEMA 5-20P

1×NEMA 5-30P

1×NEMA L14-30P

1×NEMA 14-50P

Voltage Selector

Standard

DC Circuit Breaker

Standard

DC Receptacle

Standard

AC Circuit Breaker

Standard

AC Circuit Protector

Standard

AC Receptacle

2 Pole 120V AC

3 Pole 120V/240V AC

Dimensions

Length

34"

Width

27"

Height

32"

Gross Weight

240 lbs.

Page 10

10

ASSEMBLY

Wheel Kit Installation

1 Install the axle assembly on the generator.

2 Install the two wheels on the axle shaft using the flange nuts.

3 Install the two stands on the under frame using the flange nuts.

Starter Cables Connection

1 Route the starter cable under the tank.

2 Connect the starter cable to the battery positive (+) terminal first, then to the negative (-)

terminal. When disconnecting, disconnect at the battery negative (-) terminal first.

Battery posts, terminals and related accessories contain lead and lead compounds. Wash hands after

handling.

PRE-OPERATION CHECK

Engine Oil

Engine oil is a major factor affecting engine performance and

service life. Non-detergent and 2-stroke engine oils will damage

the engine and are not recommended.

Check the oil level BEFORE EACH USE with the

Use 4-stroke motor oil that meets or exceeds the

generator on a level surface and the engine stopped.

requirements for API service classification SJ.

Always check the API SERVICE label on the oil container to be sure it includes the letter SJ.

Page 11

11

SAE 10W-30 is recommended for general, all-temperature use. Other viscosities shown in the

chart may be used when the average temperature in your area is within the indicated range.

1 Remove the oil filler cap and wipe the dipstick clean.

2 Check the oil level by inserting the dipstick into the filler neck without screwing it in.

3 If the level is low, fill to the top of the oil filler neck with the recommended oil.

Fuel

Check the fuel gauge, and refill the tank if the fuel level is low.

Refuel carefully to avoid spilling fuel. Do not fill above the shoulder of the fuel strainer.

Gasoline is highly flammable and explosive, and you can be burned or seriously injured when

refueling.

●

Stop engine and keep heat, sparks, and flame away.

●

Refuel only outdoors.

●

Wipe up spills immediately.

Use unleaded gasoline with an octane rating of 86 or higher.

This engine is certified to operate ONLY on unleaded gasoline.

Unleaded gasoline produces fewer engine and spark plug deposits and extends exhaust system life.

Never use stale or contaminated gasoline or an oil/gasoline mixture. Avoid getting dirt or water in the

fuel tank.

Page 12

12

Starting the Generator:

CAUTION:

Disconnect all electrical loads from the generator before attempting to start!

1. Make sure that the AC circuit breaker is in the OFF position. The generator may be hard to start if

a load is connected.

2. Turn the fuel valve lever to the ON position.

3. The choke will need to be closed, slide the choke lever out to the CLOSED position.

4. Turn the engine switch to the START position and hold it there for 5 seconds or until the engine

starts.

WARNING:

Operating the starter motor for more than 5 seconds can damage the motor. If the engine fails to start,

release the switch and wait 10 seconds before operating the starter again.

If the speed of the starter motor drops after a period of time, it is an indication that the battery should be

recharged.

5. When the engine starts, allow the engine switch to return to the ON position.

6. Push the choke to the OPEN position as the engine warms up.

Stopping the Engine

In an emergency:

To stop the engine in an emergency, move the engine switch to the OFF position.

In normal use:

1. Turn the AC circuit breaker to the OFF position. Disconnect any DC Load attached to the DC

Output on the front panel.

2. Turn the engine switch to the OFF position.

3. Turn the fuel valve lever to the OFF position.

Page 13

13

OPERATING INSTRUCTIONS

Connections to a Building Electrical System

Connections for standby power to a building electrical system must be made by a qualified electrician.

The connection must isolate the generator power from utility power, and must comply with all applicable

laws and electrical codes. A transfer switch, which isolates generator power from utility power, is

prerequisite.

Improper connections to a building electrical system can allow electrical current from the generator to

back feed into the utility lines. Such back feed may electrocute utility company workers or others who

contact the lines during a power outage, and the generator may explode, burn, or cause fires when utility

power is restored. Consult the utility company or a qualified electrician.

Ground System

The portable generators have a system ground that connects generator frame components to the

ground terminals in the AC output receptacles. The system ground is not connected to the AC neutral

wire.

AC Applications

Before connecting an appliance or power cord to the generator:

Make sure that it is in good working order. Faulty appliances or power cords can create a

potential for electrical shock.

If an appliance begins to operate abnormally, becomes sluggish or stops suddenly, turn it off

immediately. Disconnect the appliance, and determine whether the problem is the appliance, or if the

rated load capacity of the generator has been exceeded.

Make sure that the electrical rating of the tool or appliance does not exceed that of the generator.

Never exceed the maximum power rating of the generator. Power levels between rated

and maximum may be used for no more than 30 minutes.

Substantial overloading will open the circuit breaker. Exceeding the time limit for maximum power

operation or slightly overloading the generator may not switch the circuit breaker or circuit protector

OFF, but will shorten the service life of the generator.

Page 14

14

AC Operation

Main Power Circuit

Receptacles Powered by

Each Main Circuit

Power Distribution

Main Circuit 1

2 and 5

2+5=39.6 A Rated

Main Circuit 2

1 and 4

1+4=39.6 A Rated

1 Start the engine .

2 Turn the voltage selector switch to either position.

With the voltage selector switch in the ‘‘120/240V’’ position, you can use the 120V and 120/240V

receptacles simultaneously. If you require more 120V only power, then select the "120V only" position,

this will disable the 120/240V twist lock plug.

3 Switch the AC circuit breaker ON.

4 Plug in the appliance.

Most motorized appliances require more than their rated power for startup.

Do not exceed the current limit specified for any one receptacle. If an overloaded circuit causes the

AC circuit breaker or AC circuit protector to switch OFF, reduce the electrical load on the circuit, wait

a few minutes and then reset the AC circuit breaker or AC circuit protector.

AC Receptacle Selection

The generator has two separate main power producing circuits. These two circuits supply equal power

to different receptacles shown when the voltage selector switch is in the 120/240V position.

When two or more receptacles are used; prevent overloading by dividing the load between the two

power circuits.

The chart below shows the rated load in amperes that can be connected to each receptacle to balance

the generator.

The total rated ampere draw is 65A in 120V ONLY.

The table shows the specifications when the 120/240V locking plug receptacle is used for 120V.

Page 15

15

DC Operation

The DC terminals may ONLY be used for charging 12 volt automotive type batteries.

Connecting the battery cables:

1 Before connecting the battery charging cables to a battery that is installed in a vehicle,

disconnect the vehicle ground battery cable from the battery negative (-) terminal.

Batteries give off explosive gases; keep sparks, flames and cigarettes away. Provide adequate

ventilation when charging or using batteries.

Battery posts, terminals and related accessories contain lead and lead compounds. Wash hands

after handling.

2 Connect the positive (+) battery cable to the battery positive (+) terminal.

3 Connect the negative (-) battery cable to the battery negative (-) terminal.

4 Connect the plug of the battery cable to the generator DC receptacle.

5 Start the generator.

Do not start the vehicle while the battery charging cable is connected and the generator is running.

The vehicle or the generator may be damaged. An overloaded DC circuit, excessive current draw by

the battery, or a wiring problem will trip the DC circuit protector. If this happens, wait a few minutes

before pushing in the circuit protector to resume operation.

Disconnecting the battery cables:

1 Stop the engine.

2 Disconnect the plug of the battery cable to the generator DC receptacle

3 Disconnect the other end of the negative (-) battery cable from the battery negative (-)

terminal.

4 Disconnect the other end of the positive (+) battery cable from the battery positive (+)

terminal.

Page 16

16

5 Reconnect the vehicle ground battery cable to the battery negative (-) terminal.

High Altitude Operation

At high altitude, the standard carburetor air/fuel mixture will be too rich. Performance will decrease,

and fuel consumption will increase. A very rich mixture will also foul the spark plug and cause hard

starting. Operation at an altitude that differs from that at which this engine was certified, for extended

periods of time, may increase emissions. High altitude performance can be improved by specific

modifications to the carburetor. If you always operate your generator at altitudes above 5,000 feet

(1,500 meters), have a dealer perform this carburetor modification. This engine, when operated at

high altitude with the carburetor modifications for high altitude use, will meet each emission standard

throughout its useful life. Even with carburetor modification, engine horsepower will decrease about

3.5% for each 1,000-foot (300-meter) increase in altitude. The effect of altitude on horsepower will be

greater than this if no carburetor modification is made.

When the carburetor has been modified for high altitude operation, the air/fuel mixture will be too

lean for low altitude use. Operation at altitudes below 5,000 feet (1,500 meters) with a modified

carburetor may cause the engine to overheat and result in serious engine damage.

The Importance of Maintenance.

Good maintenance is essential for safe, economical, and trouble-free operation. It will also help

reduce air pollution.

Improper maintenance, or failure to correct a problem before operation, can cause a malfunction in

which you can be seriously injured or killed.

Always follow the inspection and maintenance recommendations and schedules in this instruction

manual.

Maintenance Safety

Make sure the engine is off before you begin any maintenance or repairs.

Let the engine and exhaust system cool before touching.

To reduce the possibility of fire or explosion, be careful when working around gasoline. Use only

a nonflammable solvent, not gasoline, to clean parts. Keep cigarettes, sparks, and flames away

from all fuel-related parts.

Maintenance Schedule

Remember that this schedule is based on the assumption that your machine will be used for its

designed purpose. Sustained high-load or high-temperature operation, or use in unusually wet or dusty

conditions, will require more frequent service.

MAINTENANCE

Page 17

17

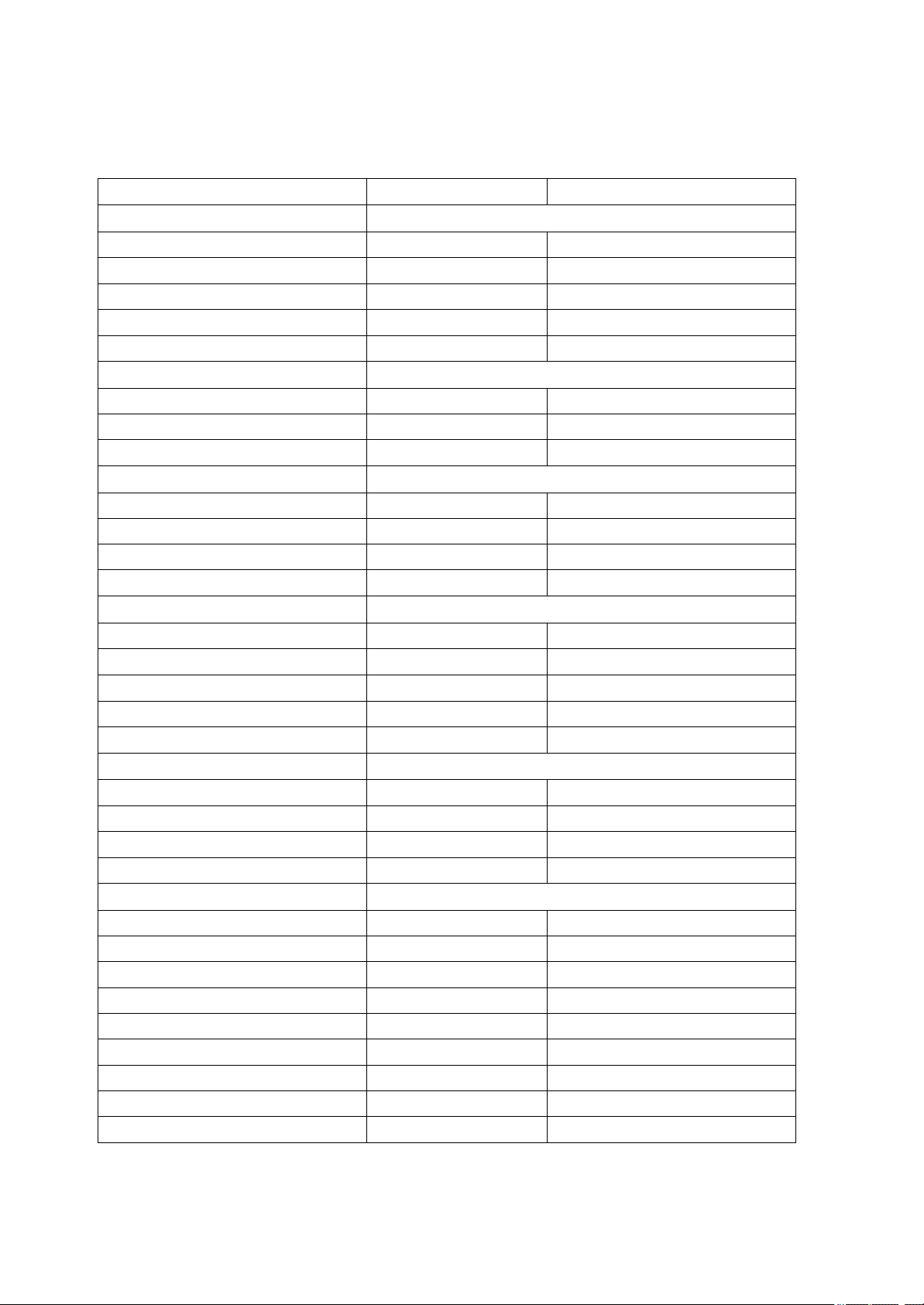

REGULAR SERVICE PERIOD(2)

Before

each

use

First

month

or 20

Hrs.

Every3

months

or 50

Hrs.

Every6

months

or 100

Hrs.

Every

year or

300

Hrs.

ITEM

Performed at every indicated month or

operating hour interval, whichever

comes first.

●

Engine oil

Check

○

Change

○

○

●

Air cleaner

Check

○

Clean

○

(1)

●

Sediment cup

Clean

○

●

Spark plug

Clean-Adjust

○

Replace

○

●

Spark arrester

Clean

○

●

Idle speed

Check-Adjust

○

●

Valve clearance

Check-Adjust

○

●

Combustion

chamber

Clean

After every 500 Hrs.

●

Fuel tank and

filter

Clean

○

●

Fuel tube

Check

Every 2 years(replace if necessary)

(1) Service more frequently when used in dusty areas.

(2) For commercial use, log hours of operation to determine proper maintenance intervals.

Engine Oil Change

Drain the oil while the engine is warm to assure rapid and complete draining.

1 Remove the drain plug and sealing washer, remove the oil filler cap, and drain the oil.

2 Reinstall the drain plug and sealing washer. Tighten the plug securely.

3 Refill with the recommended oil and check the oil level.

Wash your hands with soap and water after handling used oil.

Air Cleaner Service

A dirty air cleaner will restrict air flow to the carburetor. To prevent carburetor malfunction, service

the air cleaner regularly. Service more frequently when operating the generator in extremely dusty

areas.

Page 18

18

Never run the generator without the air filter. Rapid engine wear will result.

1 Unsnap the air cleaner cover clips, remove the air cleaner cover, and remove the element.

2 Wash the air cleaner element in a solution of household detergent and warm water, then rinse

thoroughly, or wash in nonflammable or high flashpoint solvent. Allow the air cleaner

element to dry thoroughly.

3 Soak the air cleaner element in clean engine oil and squeeze out the excess oil. The engine

will smoke during initial startup if too much oil is left in the air cleaner element.

4 Reinstall the air cleaner element and the cover.

Fuel Sediment Cup Cleaning

The sediment cup prevents dirt or water, which may be

in the fuel tank from entering the carburetor. If

the engine has not been running for a long time, the

sediment cup should be cleaned.

1 Turn the fuel valve lever to the OFF position.

Remove the sediment cup, O-ring, and filter.

2 Clean the sediment cup, O-ring, and filter in

nonflammable or high flash point solvent.

3 Reinstall the filter, O-ring, and sediment cup.

4 Turn the fuel valve lever ON and check for leaks.

Spark Plug Service

To ensure proper engine operation, the spark plug must be properly gapped and free of deposits.

If the engine has been running, the muffler will be very hot. Be careful not to touch the muffler.

1 Remove the spark plug cap.

2 Clean any dirt from around the spark plug base.

3 Use a spark plug wrench to remove the spark plug.

4 Visually inspect the spark plug. Discard it if the insulator is cracked, chipped or fouled.

5 Measure the plug gap with a feeler gauge. Correct as necessary by carefully bending the side

electrode.

Page 19

19

The gap should be: 0.028 0.031 in (0.70 0.80 mm)

STORAGE

TIME

TO PREVENT HARD STARTING RECOMMENDED

SERVICE PROCEDURE

Less than 1

month

No preparation required

1 to 2 months

Fill with fresh gasoline and add gasoline conditioner.

2 months to 1

year

Fill with fresh gasoline and add gasoline conditioner. Drain the

carburetor float bowl. Drain the fuel sediment cup.

1 year or more

Fill with fresh gasoline and add gasoline conditioner. Drain the

carburetor float bowl. Drain the fuel sediment cup. Remove the

spark plug and put a tablespoon of engine oil into the cylinder head.

Pull recoil starter slowly to distribute the oil evenly in the cylinder.

Reinstall the spark plug. Change the engine oil.

After removal from storage, drain the stored gasoline into a suitable

container and fill with fresh gasoline before starting.

6 Check that the spark plug washer is in good condition, and

thread the spark plug in by hand to prevent cross-threading.

7 After the spark plug is seated, tighten with a spark plug

wrench to compress the washer.

-If installing a new spark plug, tighten 1/2 turn after the spark plug

seats to compress the washer. If reinstalling a used spark plug,

tighten 1/8 -1/4 turn after the spark plug seats to compress the

washer.

The spark plug must be securely tightened. An improperly tightened spark plug can become very hot

and could damage the engine. Never use spark plugs which have an improper heat range.

Before storing the unit for an extended period:

Be sure the storage area is free of excessive humidity and dust.

Service according to the table below:

STORAGE

Page 20

20

PROBLEM

POSSIBLE CAUSE

SOLUTION

The engine

will not start

Is there fuel in the tank?

Refill the fuel tank.

Is there enough oil in the

engine?

Add the recommended oil.

Is the spark plug in good

condition?

Readjust gap and dry the spark plug.

Replace it if necessary.

Is the fuel reaching the

carburetor?

Clean the fuel sediment cup.

No electricity

at the AC

receptacles

Is the AC circuit breaker ON?

Turn the AC circuit breaker ON.

Check the electrical appliance

or equipment for any defects.

·

Replace the electrical appliance or

equipment. ·Take the electrical

appliance or equipment to an

electrical shop for repair.

TROUBLESHOOTING

Note: Troubleshooting problems may have similar causes and solutions.

Page 21

21

GENERATOR ASSEMBLY AND MOUNTING

The Generator is supplied with a wheel kit. If you want to install the wheel kit on your unit, please

follow the instructions below. If you not use the wheel kit, please skip this section.

1. Place the bottom of the generator on a flat, even surface. You may temporarily place the

generator on blocks to ease assembly.

2. Attach the support leg to the cradle with bolts (M8x 16) and tighten nuts (M8) (see figure 1 ).

3. Attach the axles to the frame and tighten nuts (M12) (see figure 2).

4. Slide a wheel, hub to the inside, and a flat washer over the axle, then fix the wheel tightly with

a retaining pin (see figure 3, Figure 4).

5. Place the handles on the cradle tightly with bolts (M8x16) and tighten nuts (M8) gently.

Overtightening the handles will cause them to be very difficult to move. (Figure 5, Figure 6).

6. Make sure that all fasteners are tight and tight and tires are inflated between 15-40 PSI.

Figure

1

Figure 2

Figure 3

Figure 4 Figure 5 Figure 6

Page 22

22

CHANGE THE CARBON-BRUSH

CHANGE THE AVR

Page 23

Maintenance Log

MODEL: XP12000E

Date

Generator Hrs.

Maintenance Performed

Page 24

Product Support

Product Information, Application, Service Info & Warranty Questions

Please email us at support@duromaxgenerators.com

or call (800) 629-3325 Monday - Friday 7am to 5pm. PST

Loading...

Loading...