Page 1

DURO-LAST ® A.R.P. MEMBRANE

Description:

Duro-Last® A.R.P. Membrane (black in color) is fabricated

from a high tenacity, l ow shrink weft i nserted 18 x 14, 1000

Denier polye ster fabric that has been coated with a proven

thermoplastic alloy. This specially formulated permanent

thermoplastic alloy does not contain conventional

plasticizers that migrate from the coating. It is specially

formulated to be c ompa tible with aspha lt-b ased produ cts. It

is resistant to ultraviolet rays and microorganisms. The tear

and puncture strength of the polyester fabric are superb,

and it is impervious to most caustic chemicals, petroleum

products, animal fats and acids. It shows no ill effects from

either heat or cold.

The Duro-Last A.R.P. Membrane is non-curing to provide

excellent weldability for the entire life of the system. A

patch, curb, stack or any other necessary additions or

alterations can easily be accomplished by heat welding

(hot-air) the new Duro-Last membrane\accessory to the

existing m embrane. Heat welding (hot-air) is used to bond

all field seams. The welds can be made with a hand-held

unit or a walker welder. The hot air seaming eliminates the

need for chemicals, torches and other unsafe,

non-manageable seaming systems.

DATA SHEET

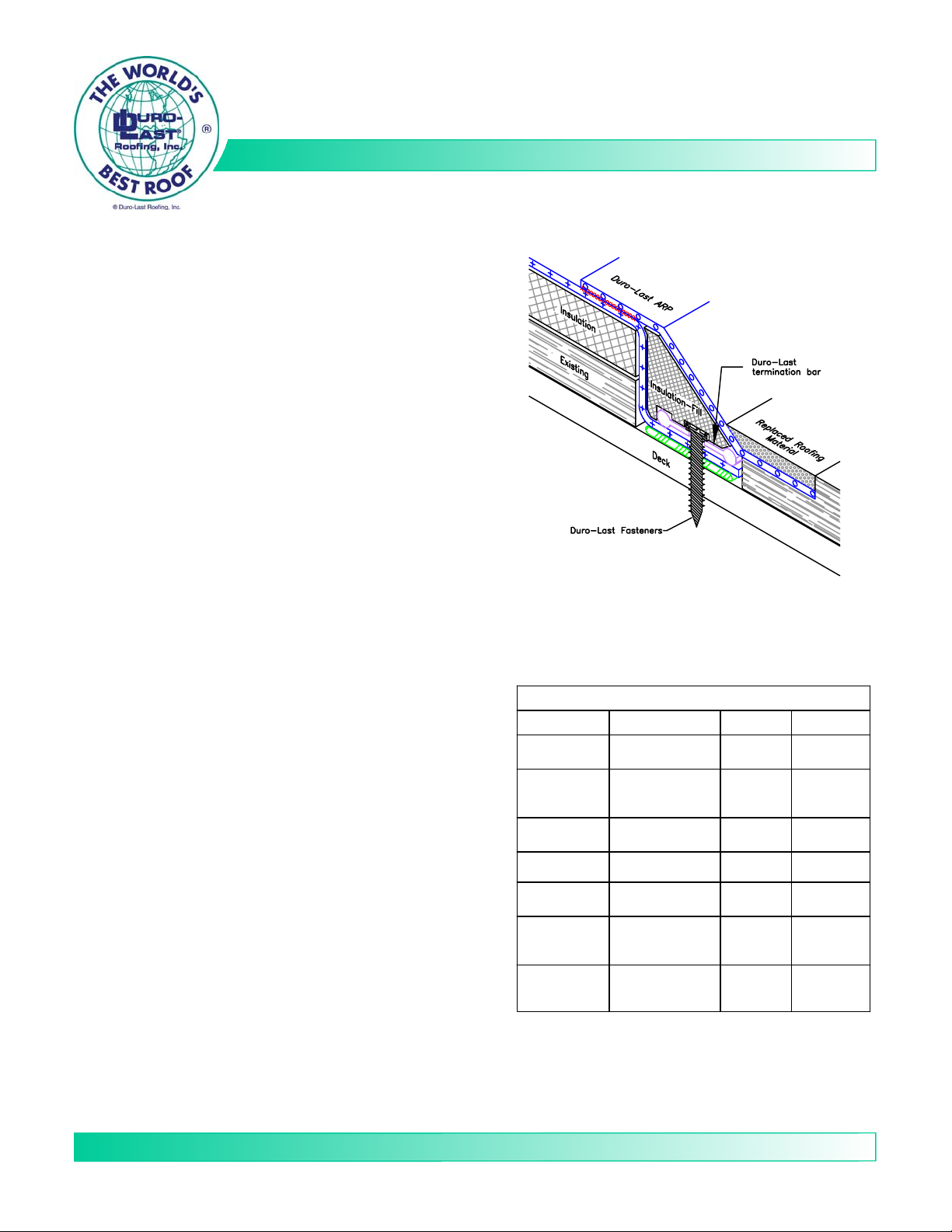

See detail drawing 1080 for

installation requirements.

Material Safety Data Sheet:

1. MSDS Number: 50033

Installation:

1. A.R.P. membrane is available for use only in details

requiring the Duro-Last roofing system to be tied-in to

asphalt roofing.

Note:

1. A.R.P. membrane must only be used for tie-in details

and is not meant to be used for primary waterproofing.

Description

Thickness

(nominal)

Tear Strength

Breaking

Strength

Elongation

Dimensional

Stability

Temperature

Flexibility

Water Vapor

Transmission

Duro-Last: The Proven Performer®

www.duro-last.com

"Duro-Last " an d " The World's Best Roof" are registered marks owned by Duro-Las t , Inc.

7

Low

PHYSICAL PROPERTIES

Test Method U.S. Metric

ASTM D-7 5 1 40 mil 1 mm

ASTM D-5587

Tongue Method

8"x8" sample

ASTM D-751 435 x 350 lb

ASTM D-751 27% 27%

ASTM D-1204

ASTM D-2136

0.5 inch (12.7 mm)

Mandrel

ASTM E-96

WVT

Procedure B

90 x 90 lb 400 x 400 N

< 1% < 1%

No Cracks

0 °F

< 0.25

Perms

No Cracks

800-248-0280

1935 x

1557 N

-17.8 °C

< 0.086

g/hr/m

2009

²

Loading...

Loading...