Page 1

M-TYPE

PREMIUM

COMMANDER

USER

TRAINING

Page 2

Agenda Operator Training - 2 days (DAY 1)

09:00 - 09:15 Introduction, Overview of training program

09:15 - 10:00 Presentation of advantages and differences vs traditional machine (CLASSIC)

New features and functions

Advantages, Opportunities for customer

10:00 - 10:30 Machine Components

• Explication

• Differences vs CLASSIC machine

10:30 - 10:45 Break

10:45 - 12:15 Push Buttons

• Function Explication

• Favourite Button

Control Panel Commander Pro / Commander Basic

• Navigation

• Explication of the Main screen

• Explication of the function tiles

12:15 - 13:15 Lunch

2

Page 3

Agenda Operator Training - 2 days (DAY 1)

13:15 - 13:45 Operating modes, explication

Manual Mode

• Configuration of the main screen and status bar

• Description of the help button

• Explication of the parameter view

• Explication and settings of start and end backtack

• Exercise: Sewing in manual mode and backtack with pedal stop

14:00 - 14:45 • Explication of the function material thickness detection, specific settings

• Exercises:

Parameter settings, changing between the 1st and 2nd parameter values

of base parameters

• Explication of the navigation menu

14:45 - 15:00 Break

3

Page 4

Agenda Operator Training - 2 days (DAY 1)

15:00 - 16:15 Automatic mode

• Explication of mode and seam program

• Explication of the main screen and program selection

• Explication of the correction factors

• Exercises:

Sewing in automatic mode, select a predefined program, identify and

modify parameter settings

16:15 - 16:45 Conclusion, Questions

4

Page 5

Agenda Operator Training - 2 days (DAY 2)

09:00 - 09:30 Recapitulation of the 1st day

Questions

09:30 - 10:30 Programming

• Explication of program management

• Edit a program

• Settings of base parameters

• Explication of global program parameters

• Explication of specific parameters in the seam section

• Explication of additional parameters in automatic mode

(Segment end modes, stitch counting)

10:30 - 10:45 Break

10:45 - 12:15 • Automatic mode – Main screen

• Modify a program

• Exercises: Modification of parameter settings, sewing in automatic mode,

get used to navigation in the different menu levels

12:15 - 13:15 Lunch

5

Page 6

Agenda Operator Training - 2 days (DAY 2)

13:15 - 14:45 Programming Mode, creation of programs

• Create a new program

• Exercises: Creation of simple programs

14:45 - 15:00 Break

14:30 - 16:15 Programming Mode (cont.)

Exercises:

• Creation of complex programs comprising multiple seam sections,

forward/backward sewing in program, parameter settings in program

16:15 - 16:45 Conclusion, Questions

6

Page 7

Why M-TYPE PREMIUM?

• Productivity

• Higher efficiency due to programming functionality /

increased no. of operations per machine.

• Better Quality Results

• Automatic and more precise adjustment / finer calibration tuning

• Facility to reproduce parameter settings (more precise results)

• Impressive new features and settings not feasible with traditional machine

• Saving Time

• Rapid variation between programs

• Reduced machine set-up times

• Flexibility

• Positive impact on environment

• No compressed air needed (except some optional equipment)

• Universal and identical installation of software/programs

• Quick and easy program transfer with USB

• M2M (data transfer through network, LAN or WLAN)

7

Page 8

Differences PREMIUM vs. CLASSIC

NEW

• Digital function control with panel Commander

Pro

• Reproducible and reusable parameter

adjustment

• Creation of automated programs

• Automation of seam sections

• End backtack settings can vary from

adjustments of start backtack

• Sewing foot lift height adjustment (max. 20 mm)

• Automatic material thickness detection

• Jog Dial (electronic handwheel)

8

Page 9

Video

Stitch LengthThread TensionFoot Pressure

Footstroke

9

Page 10

Advantages/Opportunities

Problem:

• Small volume lot sizes

• Numerous models

• Dynamic model line

Solution/Opportunity:

• Programmable sewing machine

• Execution of different seam

operations using the same machine

• long setup times

10

Page 11

M-TYPE PREMIUM

Operation panel Commander Basic / Commander Pro

11

Page 12

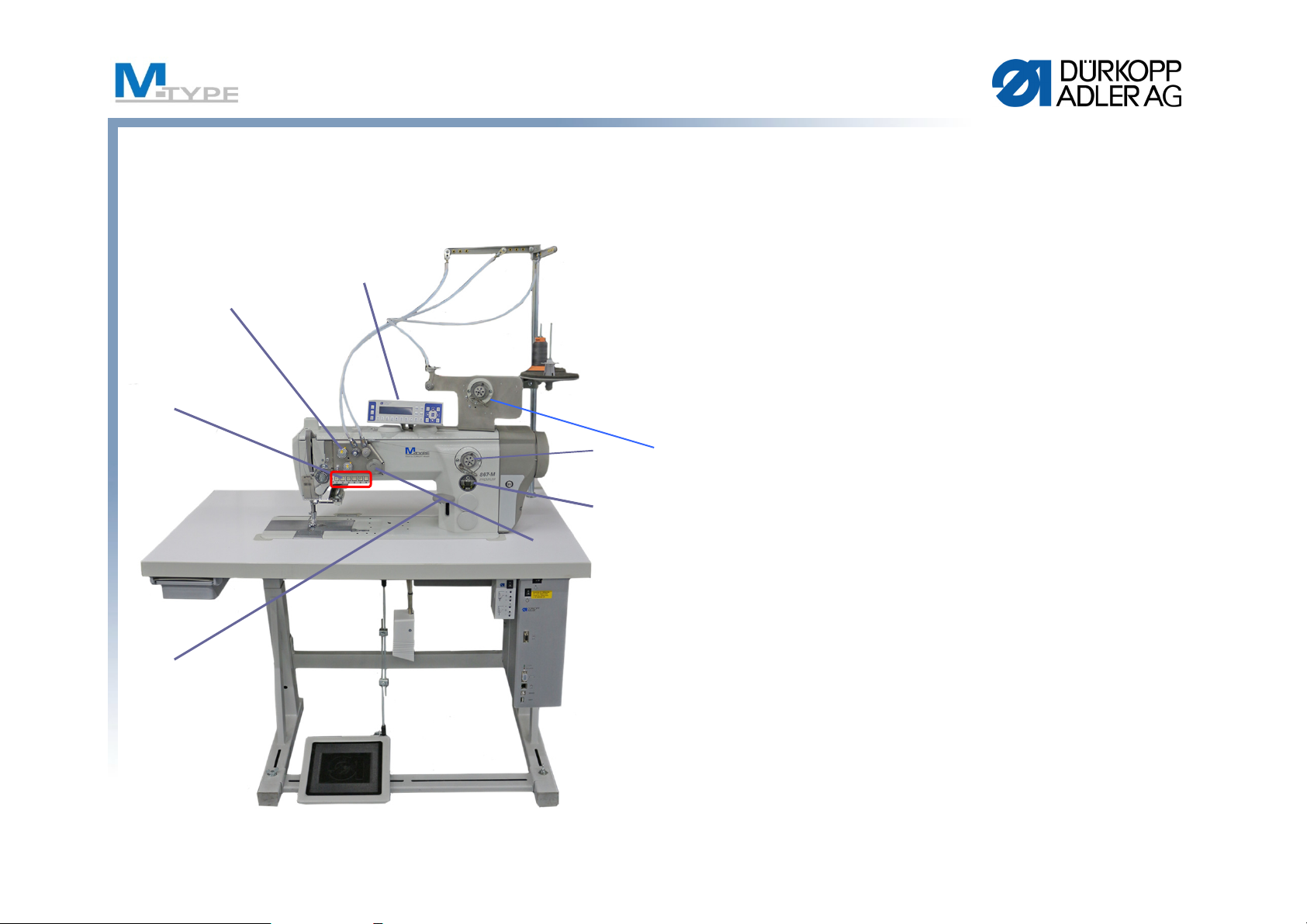

Machine Components

(1) Programmable thread tension

(2) Push buttons

(3) Stitch adjustment lever

(4) Bobbin winder /

(4a) motorized winder

(5) Oil level indicator

(6) Jog Dial (electronic hand wheel)

(7) Control panel OP3000 (standard)

Optional Commander Basic / Pro

(8) Hose guide

(9) Thread guide

12

Page 13

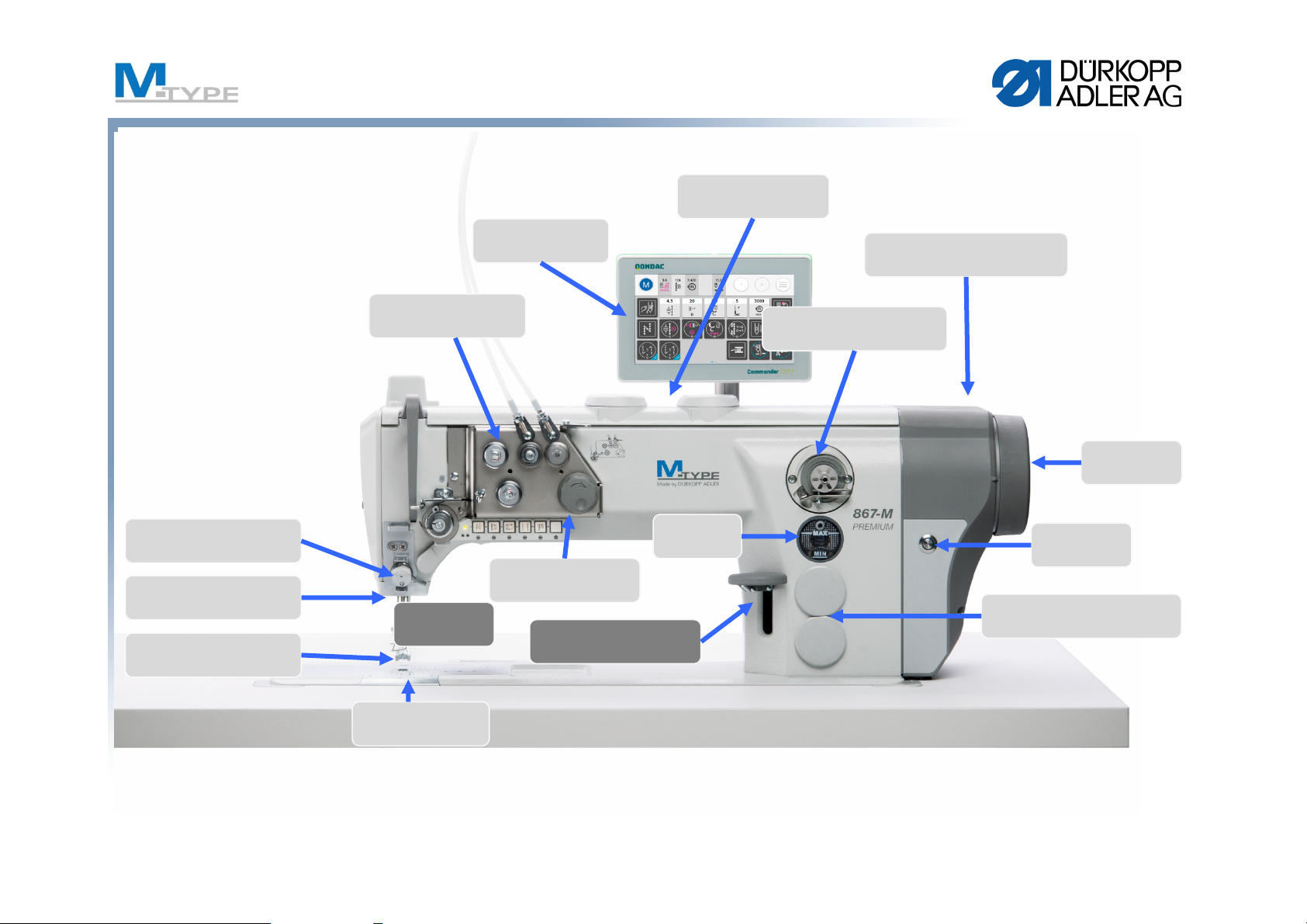

Machine Components

Control Panel

Commander Pro

Programmable foot

stroke (max. 9 mm)

Sewing machine motor

integrated in machine head

Thread Clamp

(optional equipment)

Sewing lamp LED

with dimmer

Programmable foot lift

(max. 20 mm)

Programmable

thread tension

Electronic

edge guide

Thread cutter and

vertical hook

Electronic hand

wheel (Jog Dial)

manual Stitch regulator

lever (optional)

Oil level

indicator

Bobbin winder with bobbin

winding mechanism

Hand wheel

Service Stop

Button

Programmable stitch length

(

max. 12 mm)

13

Page 14

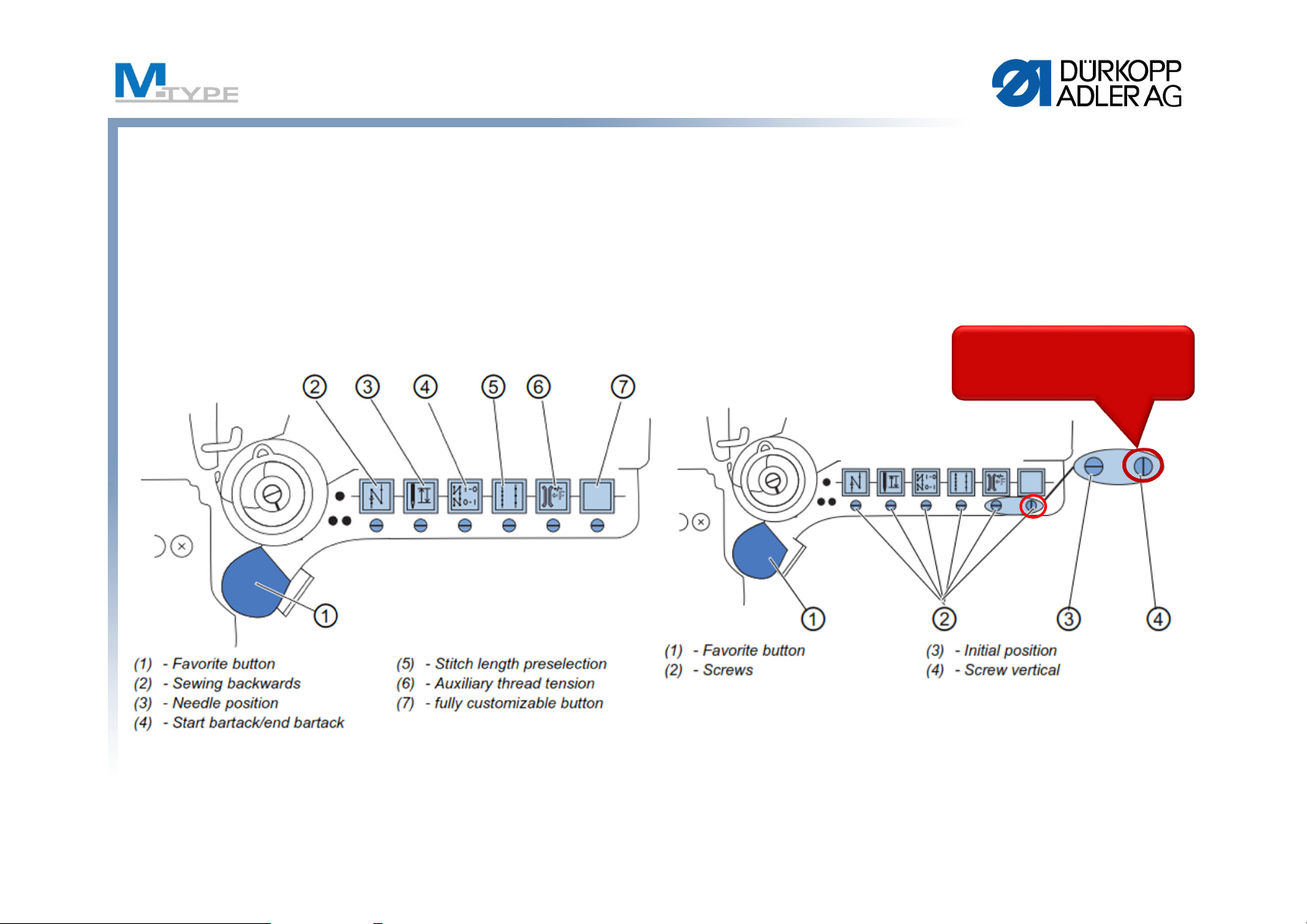

Push buttons (soft keys)

Function Buttons Favorite Button

press and turn

vertically!

14

Page 15

M-TYPE PREMIUM

Operation panel Commander Basic / Commander Pro

15

Page 16

Operation panel Commander Basic / Commander Pro

Commander Basic:

• 7” touch screen

• 4 GB Internal storage capacity

• Media formats: PDF / WebM VP8

• LED status indicator

• 2 USB ports

Commander Pro:

• In addition to the basic features, the

Commander Pro has an Ethernet interface

(for easy communication with QONDAC) and

an NFC-module

16

Page 17

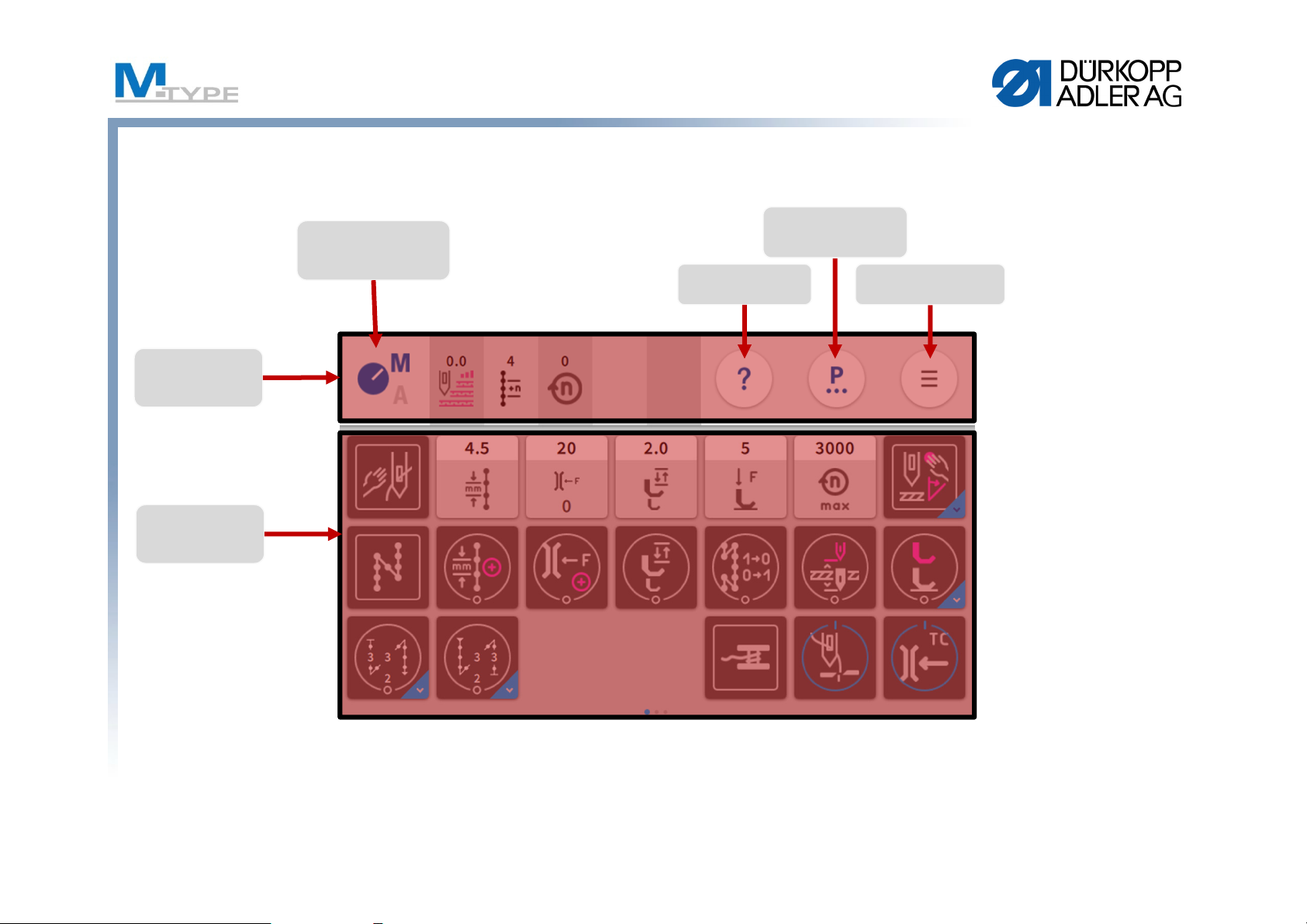

Main screen – Manual Mode

Status bar

Main screen

Manual/

Automatic-Modus

Parameterview

Help button

Navigation

17

Page 18

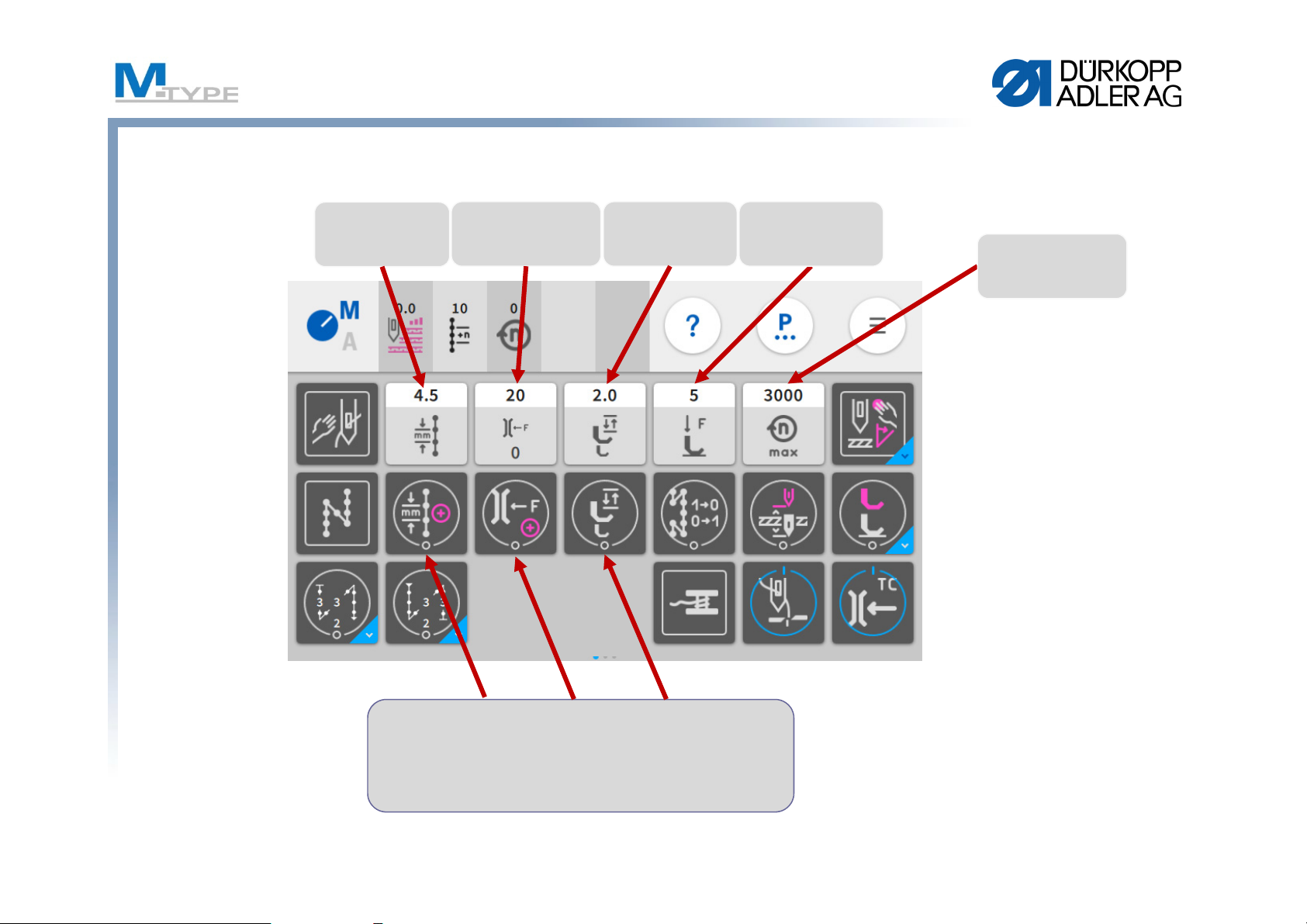

Commander Basic / Pro – Main screen

Stitch length

Thread tension

Sewing foot

stroke

Foot pressure

Max. Speed

the additional parameters

are indicated with the + sign

18

Page 19

Value Tiles with popover menu

• Settings of parameters which are

used often (light grey buttons)

• Adjustment in steps (plus and

minus button), overwriting the

value directly or continuous

adjustment (Slide bar)

19

Page 20

HS1

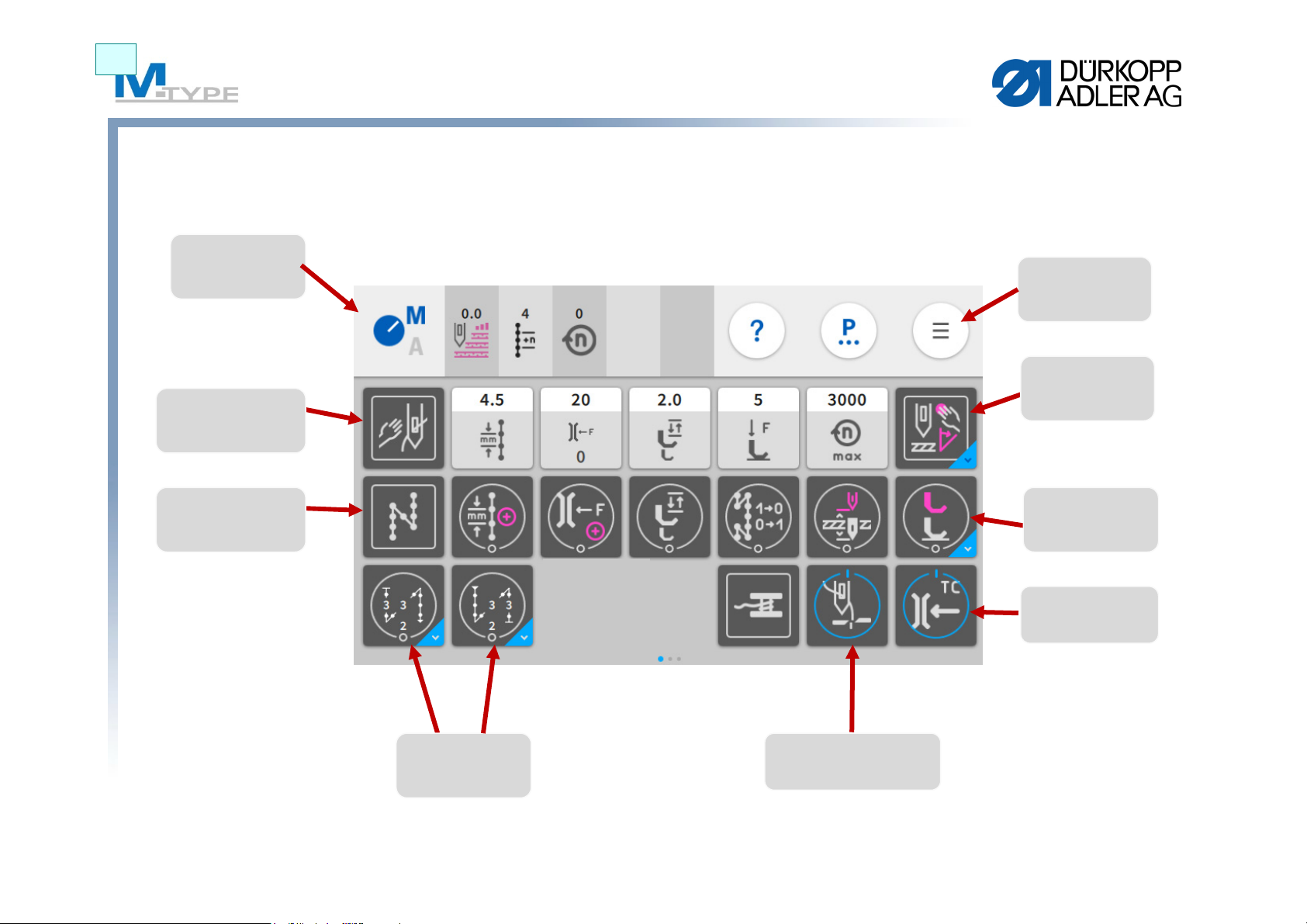

Functional Tiles (resting/tentative) – Freely configurable

Manual/

Automatic-

mode

Point position

Threading mode

Navigation

Manual backtack

Seam begin

and seam end

backtack

Sewing foot lift

Thread clamp

Thread trimmer

20

Page 21

Folie 20

HS1 neuer Screenshot mit 0 Stichen benötigt

Henrik Schuette; 06.02.2019

Page 22

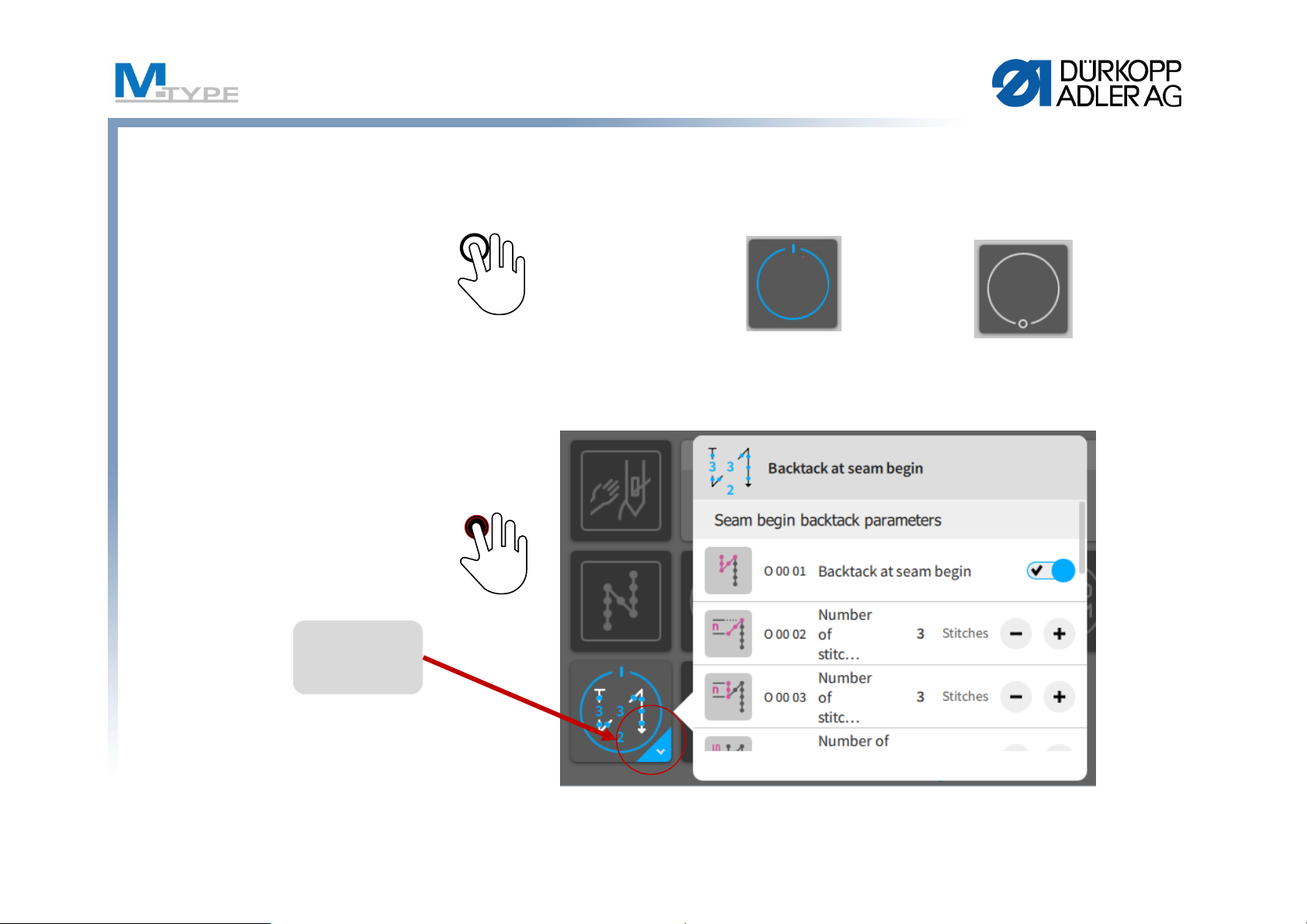

Multi-Functional Tiles with popover menu

On Off

• SingleTap

• Longpress

(1s press and hold)

Opening of backtack

popover

Indicator for

Longpress-

Popover

1s

21

Page 23

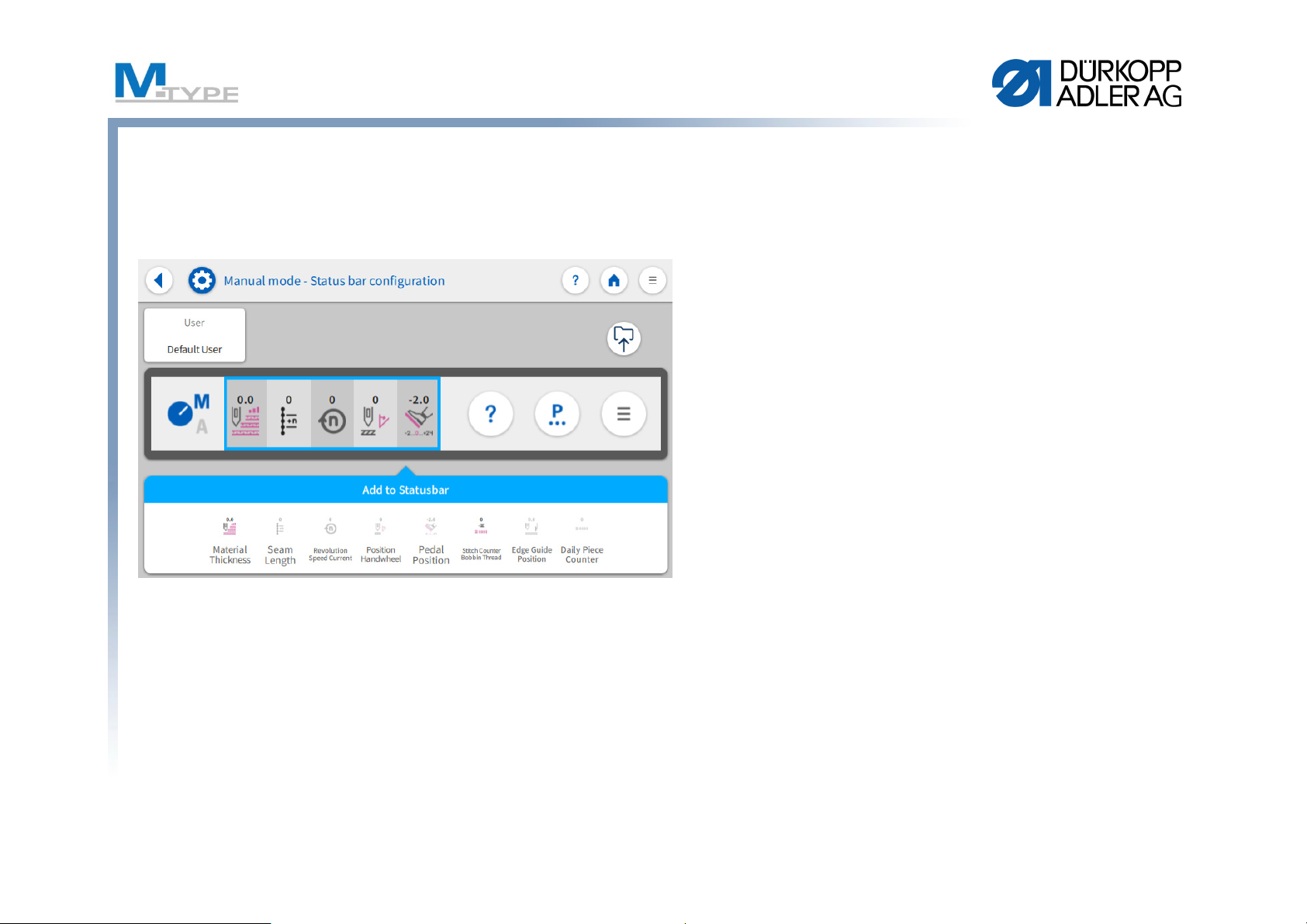

Status bar - Configuration

• Material thickness

• Seam length (Number of

stitches)

• Speed

• Handwheel position

• Pedal position

• Stitch Counter Bobbin

Thread

Select tiles via Drag and Drop

• Edge Guide Position

• Daily Piece Counter

22

Page 24

Main screen - Configuration

Select tiles via Drag and Drop

• Freely configurable

• 3 pages

• Every user can configure his

own main screen

• Function tiles for each

function

23

Page 25

Help Button

Help Button

Single Tap: Help mode is actived for single function.

Next tap opens an information advice.

Closing of the information window deactivates the help

button.

Long Press: Demo mode

No automatical deactivation of the help button after closing

of information advice.

Every following tap on functions opens information advices.

24

Page 26

Parameter view

Seam Begin

Seam

Global

Parameter

Seam End

25

Page 27

Parameter view – Segment

26

Page 28

Parameter view – Parameter

• Additional values (+)

• Stitch length

• Sewing foot stroke

• Needle

• Main parameter

• Bobbin monitor mode

• Point position

• Correction speed effect

• Correction material

thickness effect

27

Page 29

Parameter Seam begin / Seam end

Seam begin

Seam end

28

Page 30

Settings seam begin backtack / seam end backtack

On/Off

Single tap onto value opens

numerical keyboard

Increase or decrease value

If the function „Stitch

length default“ is activated,

the same stitch length is

used in the backtack as in

the seam

Indicator for Drop-Down

menue, opens further

settings

29

Page 31

Settings backtack

Speed of automatical

backtack

Single stitches per

pedal during backtack

0 = Off

1 = Single stitches with

backtack speed

2 = Single stitches with

pedal-dependent

sewing speed

Modification of number

of stitches in first or last

backtack section

If the function „Needle

thread tension default“ is

activated, then the same

tensionisusedin the

backtack as in the seam

Additional backtack

sequence before proper

backtack

Invert the direction of the

backtack

30

Page 32

Start backtack - Repetitions

1 Repetition

backtack

starts

backward

seam

2 Repetitions

backtack

starts

forward

seam

3 Repetitions

seam

4 Repetitions

seam

Impair Pair

31

Page 33

Exercise: Sewing in Manual Mode, other parameters

Pre-setting in Manual Mode

• modify the base parameters:

• stitch length 5.0 mm

• needle thread tension 25%

• sewing foot pressure 5

• sewing foot stroke 1,5 mm

• modify the other parameters

• Thread Trim active On

• Start bartack active (On)

• Number of backward stitches (3 points)

• Number of forward stitches (3 points)

• St.Len.Def – Default stitch length active (On)

• End bartack active (On)

• Number of backward stitches (4 points)

• Number of forward stitches (4 points)

• St.Len.Def – Default stitch length inactive (Off)

– backward stitch length (2.5 mm)

– forward stitch lengths (2.5 mm)

During sewing process

•start sewing

(automatic start backtack)

• activate/deactivate the auxiliary values:

•activate 2ndstitch length

nd

•activate 2

•activate 2

• deactivate the secondary values

• interrupt the sewing process (pedal)

• lift your foot from pedal

• continue sewing process / resume

• stop sewing, end of seam (pedal -2)

(automatic end backtack)

foot stroke

nd

thread tension

• Gap (edge guide): 10 mm

32

Page 34

Exercise: Backtack with Pedal Stop

Adjustment of backtacks

• other parameters P…

• Start backtack active (On)

• Number of backward stitches (3 points)

• Number of forward stitches (3 points)

• St.Len.Def – Default stitch length active (On)

• reduced Speed: 200

• Pedal Stop active (On)

• End backtack active (On)

• Number of backward stitches (3 points)

• Number of forward stitches (3 points)

• St.Len.Def – Default stitch length active (Off)

• Backward stitch length (3 mm)

• Forward stitch length(3 mm)

• reduced Speed: 200

• Pedal Stop active (On)

During sewing process

• start sewing

(automatic start backtack)

• interrupt the sewing process (pedal)

• lift you foot from pedal

• continue sewing process / resume

• stop sewing, end of seam (pedal -2)

(automatic end backtack)

With Pedal Stop you

can stop sewing during

bartack execution.

33

Page 35

Parameter Material thickness detection

• Material thickness detection On/Off

Goal:

Goal:

– Sewing foot stroke

consistent good

consistent good

sewing results

sewing results

Material

Material

Thickness

Thickness

Detection

Detection

– Stitch length

– Needle thread tension

– Sewing foot pressure

– Max. Speed – Maximum speed

• Modes

– linear

– 2. Value On/Off

– 2. Value On

34

Page 36

Example: Material thickness - Foot Stroke

9

8

7

6

Max. Thickness

Min. Thickness

5

4

3

2

1

2143

Min. Value (Seam parameter) Max. Stroke

5879

6

35

Page 37

Exercises: Adjustment Material thickness detection

Mode linear

• Active (On)

• Stroke

• Mode linear

• Sewing foot stroke 8.0

• Min. Material thickness 2.0 mm

• Max. Material thickness 5.0 mm

• Stitch length

• Mode linear

• Stitch length (10 %)

• Min. Material thickness 2.0 mm

• Max. Material thickness 5.0 mm

Mode 2. Value On/Off

• Stitch length

• Mode 2. Value On/Off

• Min. Material thickness 3.0 mm

Mode 2. Value On

• Stitch length

• Mode 2. Value On

• Min. Material thickness 2.0 mm

36

Page 38

Exercise: Sewing in Manual Mode, Gap and Gap+

Pre-setting in Manual Mode

• modify the base parameters :

• stitch length 3.8 mm

• thread tension 25%

• sewing foot pressure 5

• sewing foot stroke 3 mm

• modify the other parameters P…

• Thread trimmer active (On)

• Backtack at seam begin active (On)

• Number of stitches backward (3 points)

• Number of stitches forward (3 points)

• Stich length default active (On)

• End backtack active (On)

• Number of backward stitches (3 points)

• Number of forward stitches(3 points)

• Stich length default active (On)

• Gap (edge guide): 10 mm

During Sewing Process

•start sewing

(automatic start backtack)

• activate/deactivate the additional values

activate 2ndstitch length

nd

•activate 2

•activate 2

• activate 2

• deactivate the secondary values

• stop sewing, end of seam (pedal -2)

(automatic end backtack)

foot stroke

nd

thread tension

nd

gap (gap+)

• adjust the additional values:

•2ndstitch length 6.0 mm

nd

•2

• 2

thread tension 30%

nd

gap (edge guide distance) 20 mm

37

Page 39

Navigation Mode

Program-Management

to create, delete, copy

or edit programs

All types of settings

(depends of access

level)

Tutorials: PDFs

and videos

Logout and

opening of

Login-Screens

38

Page 40

Automatic mode

• Program selection

• Select from the program

list or search for the right

program by clicking on

the magnifying glass.

39

Page 41

Automatic mode

• During sewing process

• Indication of actual seam section

• Display of parameter values defined

in the seam section

• Program progress (program bar)

• Predefined number of stitches per

section

• Backtacks

• Switch between two seam sections with

a stop and with/without thread cutting

• Switch between two seam sections without stopping

• Cut off the program (pedal fully back, Pos. -2)

• Backtack and thread trim, if set in program

40

Page 42

Automatic mode: Main screen

Current seam-

progress

Switch to

previous or

next section

Pop over

tiles:

correction

parameters

could be

changed

Sketch of sewing

progress

Predefined number of stitches

per section

Threading

mode

Information tiles:

Preset value

Current value e.g.

Speed Correction /

Material Thickness

41

Page 43

Automatic Mode: Correction actors

• correction %age for stitch length and thread tension

•Test results

• Due to the influence

of different material

GOAL REALITY

Test the correction values

and adjust alteration %age

42

Page 44

Exercise: Identify configurations / settings

• Selection of programme no.10 SEAM 10 MANUEL

• Which program settings can you identify?

– Number of seam sections ?

– Backtacks ?

– Thread Trim ?

– Stop between seam sections ?

– Predefined number of stitches ?

43

Page 45

Automatic Mode: Sewing a program

• Program Selection

• Start sewing process

• Switch to previous and following seam section

• Function Button no. 6

• USEFUL! Favourite button (assign feature of function buttons)

• Skip a seam section of the program

• Cut off or cancel the program in the seam

and resume sewing process

• Pedal -1 (program remains stopped at cut off point)

• Pedal -2 (complete cancellation of program and return to starting point) /

or switch to following seam section (program switch by pedal)

44

Page 46

Exercise: Sewing in Automatic Mode

• Utilise a program consisting of several seam sections

– Select a program using the program selection:

Program 10 – SEAM 10 MANUEL

– Sew the program

• start backtack automatically executed

• switch to next seam section (function button no. 6 or )

• stop sewing in the program (foot lift)

• resume sewing process / continue

– Terminate program (Pedal -2)

• end backtack automatically executed

• thread trim

– Cancel the program

45

Page 47

Exercise: Sewing in Automatic Mode

• Sewing of a program consisting of several seam sections

and specific number of stitches per section

– Select a program using the program selection:

Program 20 – SEAM 20 AUTOMATIC

– Sew the program

• Start backtack automatically executed

• Automatic stop at the end of the section (after specific number of

stitches)

• Change to next section by sewing again after stopping at end of

section

– Terminate program (pedal -2)

• End backtack automatically executed

• Thread trim

46

Page 48

Conclusion Day 1

• Introduction to the M-TYPE PREMIUM machine

• Advantages, new functions

• Components of the machine

• Control Panel Commander Basic / Pro

• Manual Mode

• Parameter adjustment

• Start backtack / end backtack

• Material thickness detection

• Automatic Mode

• Sewing in automatic mode

• Correction Factors

47

Page 49

QUESTIONS?

48

Page 50

THANK YOU

FOR YOUR ATTENTION

49

Page 51

Recapitulation of First Day

• Control panel Commander Pro

• How to navigate in the menus

• Use of Softkey Menu, favourite button

• Manual Mode

• Adjustment of base parameters

• Adjustment of other parameters

• Thread trimmer

• Start backtack / End backtack

• Edge guide

• Parameter material thickness detection

• Automatic Mode

• Selection of a program

• Sewing in automatic mode

50

Page 52

Program management

51

Page 53

Program management

Create a new

program

Available programs

Delete highlighted

program

Copy highlighted

program

Searching function

52

Page 54

Program management

Create a seam

Delete a seam

Seam sketch

Configuration of main

screen and status bar

Copy a seam

Home button

-

Back to Main screen

Play button

-

Play selected Program

Seam settings

Available seams in

segment

53

Page 55

Edit a program

Back to program

management

1. Segment

(Sketch)

A seam segment

consist of segment

begin, segment and

segment end

Global seam

parameter

Switch between

Seams

Thread cutting is

only available in

the end of seams

54

Page 56

Segment parameter – Seam begin

Backtack activated

Segment

number

Backtack

deactivated for

segment end

Seam begin

Thread clamp

activated

Number of stitches

Sewing stop in the

end of segment

Backtack parameters are

similar to manual mode

in segment

55

Page 57

Segment parameter – Seam end – Sewing stop

Segment end

Stop at segment

end

+

Function at

segment end

Seam end (last segment)

Backtack activated

for seam end

Sewing Stop &

Thread Trimming

56

Page 58

Segment parameter

57

Page 59

Global seam parameters

• Additional values(+):

• Stitch length(+)

• Needle Thread tension(+)

• Sewing foot stroke(+)

• Program Cycle

• Next program

• Program cycle

• Main Parameters

• Needle thread clamp

• Bobbin monitor mode

• Counter mode (Daily piece counter)

• Point position

• Correction speed effect

• Correction material thickness

58

Page 60

Automatic mode: Main Screen

Switch to

previous or

next section

Pop over

tiles:

Parameters

could be

changed

Threading

mode

Sketch of sewing

progress

Bobbin wind

mode

Information tiles:

Preset value

Current value e.g.

Speed Correction /

Material Thickness

59

Page 61

Exercise: Edit Mode – Modify program P10

1. Select the program P 10 – SEAM 10 Manuel and press

2. Select segment 1.

3. Modify the following parameter settings:

• Segment 1:

• stitch length 6 mm

• sewing foot stroke 2.5 mm

• thread tension 30

• stitch count : mode 1 (count stitches), number of stitches 10

• Segment End Mode : Stop active On, Thread trim inactive Off, Needle Up inactive Off, Foot lifted inactive Off

• start backtack: inactive Off

• end backtack: inactive Off

• Foot lifted: when sewing stops on the seam: inactive Off

• Segment 2:

• stitch length 3 mm

• sewing foot stroke 5 mm

• stitch count: mode 0 (not counted)

• Segment End Mode: Stop active On, Thread trim active On, Needle Up active On, Foot lifted active On

• start backtack: inactive Off

• end backtack: active On

• Global parameters of program:

• name of the program: TEST TRAINING

• FabricThickness: active On

• Sewing foot stroke: Mode 2.Value On/Off, Min. Material thickness: 3 mm

• stitch lengths: Mode linear, Stitch Length 6mm, Min. Material thickness: 2 mm, Max.Material thickness: 5 mm

60

Page 62

Programming Mode: Create a program

• Open the navigation and press „Programming“

• Press in the left box

• Edit the name of the program via double tap on the name

• Press (in the right box) to edit the first seam in the

program.

• Set the parameters for the seam segment (Field „Segment“)

• Adjust the global parameters of the program (Field „Program

parameters“ (vertical bar)

• Add a new seam segment via pushing

• Delete a seam section with

• Press or to save program and quit programming mode.

61

Page 63

Exercise: Create a Simple Program

Create a program consisting of one seam section only

• Create program P 7 PROGRAM SIMPLE

• Add a segment

• Set the seam section parameters:

• stitch length 4 mm

• sewing foot stroke 3 mm

• needle thread tension 25

• Segment End Modes:

Stop active On, Thread trim active On, Needle Up inactive Off, Foot lifted inactive Off

• start backtack: active On

• end backtack: active On

• Foot lifted: inactive Off

• Adjust the global parameters of the program:

• Program Name: P 7 PROGRAM SIMPLE

• Bobbin: Mode Software, counter 500 points, MotorStop active On, Reset necessary active On

• Counter Mode: On, Up.

• Sew the program (test with material)

• Modify any parameter settings in the edit mode if necessary

62

Page 64

Exercise: Create a complex Program

Create a program consisting of several seam sections

• Create the program

P 8 COMPLEX PROGRAM

• Segment 1:

• stitch length 3.8 mm

• sewing foot stroke 1.5 mm

• needle thread tension 25

• stitch count: number of stitches 12

• Seg.End Mode: Stop active On, Thread

Trim inactive Off, Needle Up inactive Off,

Foot lifted inactive Off

• start backtack: active On

• end backtack: inactive Off

• Foot lifted: Off

(foot lift at sewing stop on the seam)

• Segment 2:

• stitch length 6 mm

• sewing foot stroke 5 mm

• stitch count: mode 0 (not counted)

• Seg.End Mode: Stop active On,

Thread Trim active On,

Needle Up active On, Foot lifted On

• start backtack: inactive Off

• end backtack: active On

• Global parameters of program:

• program name: COMPLEX PROGRAM

• FabricThickness: active On

• Stroke: Mode 2.Value On/Off,

Min. Material thickness 3 mm

• stitch lengths: Mode linear,

Min. Material thickness: 2 mm,

Max. Material thickness: 5 mm

63

Page 65

Exercise: Create a program BACKTACK

Creation of a program with backward sewing

• Create the program

P 9 BACKTACK

• Segment 1:

• stitch length 4 mm

• sewing foot stroke 4 mm

• sewing foot pressure 3

• thread tension 25%

• maximum speed: 200

• Foot lifted: inactive Off

• Seg.End Mode: Stop On, Thread Trim

Off, Needle Up Off, Foot lifted Off

• number of stitches backward: 2 pt

• Segment 2:

• Stitch count.: number of stitches 4 pt

• Segment 3:

• number of stitches backwards: 2 pt

64

Page 66

Exercise: Programme « Cross »

1

2

3

4

5

6

stitch length: 3,5 mm

sewing foot stroke 3 mm

sewing foot pressure 3

thread tension 20%

maximum speed: 200

Segment 1: 2 forward stitches

Segment 2: 4 backward stitches

Segment 3: 2 forward stitches, Foot lifted active On

--> turn the material 90°

Segment 4: 2 forward stitches,

Foot lifted inactive Off

Segment 5: 4 backward stitches

Segment 6: 2 forward stitches

4

Starting point

turn point

3

1

6

5

2

65

Page 67

Practice various programs

• Basic parameters

• stitch length: 3,4 mm

• thread tension: 20

• sewing foot pressure: 2

• sewing foot stroke: 10

• Programs for chapes (bag handles, etc.)

• Backtacks

66

Page 68

Exercise: Create a complex program

Create a program consisting of divers seam sections

• Create the program

P 30 SEWING TEST

• Section 1:

• stitch length 4 mm

• sewing foot stroke 4 mm

• sewing foot pressure 3

• thread tension 25

• number of stitches: 0 pt

• maximum speed: 200 rmp

• Segment End: Stop active On, Thread Trim

inactive Off, Needle Up inactive Off,

Foot lifted active On, H. Foot lifted 13 mm

• start backtack: inactive Off

• end backtack: inactive Off

• Foot lifted (at stop in the seam): inactive Off

• Guide: Gap 3 mm

Start

sewing

• stitch count: number of stitches 7

• Section 3:

• stitch count: number of stitches 7

• Section 4:

• stitch count: number of stitches 0

• Section 5:

• stitch count: number of stitches 7

• Section 6:

• stitch count: number of stitches 7

• Section 7:

• stitch count: number of stitches 2

• Segment End: Thread Trim inactive Off,

Needle Up inactive Off,

Foot lifted inactive Off

• Section 2:

67

Page 69

Programming Mode: Copy / Delete a program

1. Select the program you want to copy

2. Press

3. Press to adjust a seam in the program and adjust the

parameters of the selected section

4. To delete a program press button in the program

management

68

Page 70

Conclusion Day 2

• Edit Mode: Modify / Edit programs

• Global program parameters

• Parameters of seam section

• Programming Mode

• Create programs

• Adjust basic parameters, parameters for the seam sections and

global program parameters

• Copy / Delete a program

69

Page 71

BEST PRACTICE

• Useful sequence for creation of programs

(Adding a new section in the program copies the values of

the previous section)

• Pre-set of default values for programs in technical mode

(values used for first section)

• Copy a program and modify settings

70

Page 72

QUESTIONS?

71

Page 73

THANK YOU

FOR YOUR ATTENTION

72

Page 74

33719 Bielefeld

Allemagne

Tél. : +49 (0) 521 925 00

E-Mail: service@duerkopp-adler.com

www.duerkopp-adler.com

DÜRKOPP ADLER AG

Potsdamer Str. 190

Subject to design changes - Part of the machines shown with additional equipment - Printed in Germany

© Dürkopp Adler AG – Additional Instructions – 0791 867729 EN - 00.0 - 04/2019

Loading...

Loading...