Page 1

867

Spezialnähmaschine

Betriebsanleitung

Instruction manual

Instructions d’emploi

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Telefon +49 (0) 521 / 9 25-00 • Telefax +49 (0) 521 / 9 25 24 35 • www.duerkopp-adler.com

D

GB

F

Ausgabe / Edition: Änderungsindex Teile-Nr./Part.-No.:

01/2011 Rev. index: 08.0 Printed in Federal Republic of Germany 0791 867740

Keystone Sewing Machine Company, Inc.

Page 2

Alle Rechte vorbehalten.

Eigentum de r Dürkopp Adler AG und urheberrechtlich geschützt. Jede, auch auszugsweise

Wiederverwendung dieser Inhalte ist ohne vorheriges schriftliches Einverständnis der Dürkopp Adler AG

verboten.

All rights reser ved.

Property of Dürkopp Adler AG and copyrighted. Reproduction or publication of the content in any manner,

even in extracts, without prior written permission of Dürkopp Adler AG, is prohibited.

Tous droits réser vés.

Propriété de la société Dürkopp Adler AG et protégé par la loi sur le droit d’auteur. Une copie ou reproduction

par quelque procédé que ce soit du contenu sans accord écrite de l’auteur est interdite.

Copyright ©

Dürkopp Adler AG - 2011

Keystone Sewing Machine Company, Inc.

Page 3

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruction manual contains important information on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruction manual must always be available at the machine/sewing

unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, including equipping, troubleshooting during the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair) and/or

– Transport.

The user also has to assure that only authorized personnel work on the

machine.

The user is obliged to check the machine at least once per shift for

apparent damages and to immediatly report any changes (including the

performance in service), which impair the safety.

The user company must ensure that the machine is only operated in

perfect working order.

Never remove or disable any safety devices.

If safety devices need to be removed for equipping, repairing or

maintaining, the safety devices must be remounted directly after

completion of the maintenance and repair work.

Unauthorized modification of the machine rules out liability of the

manufacturer for damage resulting from this.

Observe all safety and danger recommendations on the machine/unit!

The yellow-and-black striped surfaces designate permanend danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

Keystone Sewing Machine Company, Inc.

Page 4

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

instruction book and operated by persons with appropriate training.

2. Before putting into service also read the safety rules and

instructions of the motor supplier.

3. The machine must be used only for the purpose intended. Use of

the machine without the safety devices is not permitted. Observe all

the relevant safety regulations.

4. When gauge parts are exchanged (e.g. needle, presser foot, needle

plate, feed dog and bobbin) when threading, when the workplace is

left, and during service work, the machine must be disconnected

from the mains by switching off the master switch or disconnecting

the mains plug.

5. Daily servicing work must be carried out only by appropriately

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance unit.

Exceptions to this are only adjustments and functions checks made

by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time as

the entire sewing unit is found to comply with EC directives.

13. The line cord should be equipped with a country-specific mains

plug. This work must be carried out by appropriately trained

technicians (see paragraph 8).

It is absolutely necessary to respect the safety

instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Keystone Sewing Machine Company, Inc.

Page 5

Contents Page:

Preface and general safety instructions

Part 1: Operating Instructions Class 867 – Original Instructions

(Edition 01/2011)

1 Product description ............................................ 5

2 Designated use ............................................... 5

3 Subclasses

3.1 Subclasseswithdirectdrive........................................ 11

4 Optional equipments

4.1 Optionnal equipment for machines with direct drive .......................... 18

5 Technical data

5.1 Technicaldatasubclasses......................................... 26

5.2 Technicaldataforsubclasseswithdirectdrive............................. 30

6. Operation

6.1 Threadingtheneedlethread........................................ 33

6.1.1 Threading the needle thread on machine without short thread cutter ............... 33

6.1.2 Threadingtheneedlethreadonmachinewithshortthreadcutter ................. 35

6.1.3 Threading the needle thread on subclass -190146........................... 36

6.2 Adjustingtheneedle-threadtension................................... 36

6.2.1 Adjustingtheneedle-threadtensiononautomotivemachines.................... 39

6.3 Openingthethreadtension......................................... 39

6.4 Switching the supplementary tension on and off with machines without

threadtrimmer ................................................ 40

6.5 Adjustingthethreadregulator....................................... 41

6.6 Winding on the hook thread ........................................ 42

6.7 Changing the hook-thread bobbin .................................... 43

6.7.1 Inserting the hook thread bobbin with machines equipped with residual thread monitor.... 44

6.8 Setting the hook thread tension ...................................... 45

6.9 Insertingandchangingtheneedlewithsingle-needlemachines.................. 46

6.10 Insertingandchangingtheneedlewithdouble-needlemachines.................. 47

6.11 Inserting and changing the needle with double-needle machines

withdisconnectableneedlebars ..................................... 48

6.12 Liftingthesewingfoot............................................ 49

6.13 Lockingthesewingfeetinliftedposition................................ 50

6.14 Sewing-footpressure............................................ 51

6.14.1Adjustingthesewingfootpressureonautomotivemachines.................... 52

6.15 Sewing-footstroke.............................................. 53

6.15.1Adjustingthesewingfootstrokeonautomotivemachines...................... 54

6.16 Settingthestitchlength........................................... 56

6.16.1Adjustingthestitchlengthonautomotivemachines ......................... 57

GB

Keystone Sewing Machine Company, Inc.

Page 6

Contents page:

6.17 Keypadonthemachinearm........................................ 58

6.18 Activating the needle bar with subclass 867-490322 ......................... 60

7 Efka DC1550/DA321G direct-current positioning drive

7.1 General..................................................... 61

8 Direct drive DAC Classic

8.1 General..................................................... 62

9Sewing..................................................... 63

10 Maintenance

10.1 Cleaningandtesting............................................. 65

10.2 Lubrication................................................... 67

10.3 Repair ..................................................... 68

Keystone Sewing Machine Company, Inc.

Page 7

1 Product description

The DÜRKOPP ADLER 867 is a special sewing machine for universal

use.

l

It is a flatbed double-lockstitch machine with bottom feed, needle

feed and alternating upper foot feed.

l

Depending on the subclass it comes as single or double needle

machine, with or without electromagnetic thread cutter, with or

without edge trimmer.

l

Equipped with a large or oversized two-piece vertical hook.

l

With a maximum of 20 mm fabric clearance when sewing feet are

lifted.

l

The residual thread length after thread trimming is about 15 mm

without short thread trimming device and about 7 mm with short

thread trimming device.

l

A safety clutch prevents a changing of the hook setting or a hook

damage in the case of a thread deflection into the shuttle track.

l

Automatic wick lubricating with an inspection glass on the arm for

machine and hook lubrication.

l

Integrated winder.

2 Designated use

The 867 is a sewing machine designed for sewing light to

medium-heavy material. Such material is generally made of textile

fibers, but it may also be leather. It is used in the clothing industry and

for domestic and motor-vehicle upholstery.

This special sewing machine can also be used to produce so-called

technical seams. In this case, however, the operator must assess the

possible dangers which may arise (with which DÜRKOPP ADLER AG

would be happy to assist), since such applications are on the one

hand relatively unusual and, on the other, so varied that no single set

of criteria can cover them all. The outcome of this assessment may

require appropriate safety measures to be taken.

Generally only dry material may be sewn with this machine. The

material may be no thicker than 10 mm when compressed by the

lowered sewing feet. The material may not contain any hard objects,

since if it does the machine may not be operated without an

eye-protection device. No such device is currently available.

The seam is generally produced with textile-fibre sewing thread of

gauge up to 11/3 NeB (cotton), 11/3 Nm (synthetic) or 11/4 Nm

(covering yarn).

Before using any other thread the possible dangers arising must be

assessed and appropriate safety measures taken if necessary.

5

GB

Keystone Sewing Machine Company, Inc.

Page 8

This special sewing machine may be set up and operated only

in dry, well-maintained premises. If the sewing machine is used in

premises which are not dry and well-maintained it may be

necessary to take further precautions (which should be agreed in

advance - see EN 60204-31:1999).

As manufacturers of industrial sewing machines we proceed on the

assumption that personnel who work on our products will have

received training at least sufficient to acquaint them with all normal

operations and with any hazards which these may involve.

3 Subclasses

867-160152 Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed,electro-magnetic thread cutter,

electro-pneumatic seam bartacking and sewing foot

lifting.

With small hook for light material up to 7 mm stitch

length.

867-260152 Double-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed,electro-magnetic thread cutter,

electro-pneumatic seam bartacking and sewing foot

lifting.

With small hook for light material up to 7 mm stitch

length.

867-190020 Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed and large hook.

867-190040 Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed and oversized hook (XXL).

867-290020 Double-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed and large hooks.

867-290040 Double-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed and oversized hooks (XXL).

867-190122 Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-magnetic thread cutter,

electro-pneumatic seam bartacking and sewing foot

lifting.

With large hook.

867-190125 Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-magnetic short thread cutter,

electro-pneumatic seam bartacking and sewing foot

lifting.

With large hook.

867-190142 Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-magnetic thread cutter,

electro-pneumatic seam bartacking and sewing foot

lifting.

With oversized hook (XXL).

6

Keystone Sewing Machine Company, Inc.

Page 9

867-190145 Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-magnetic short thread cutter,

electro-pneumatic seam bartacking and sewing foot

lifting.

With oversized hook (XXL).

867-190146 Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-magnetic short thread cutter,

electro-pneumatic seam bartacking, neat seam

beginning and sewing foot lifting.

With oversized hook (XXL).

867-90322 Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-pneumatic rapid stroke adjustment,

electro-magnetic thread cutter, connectable thread

tension, electro-pneumatic seam bartacking,

electro-pneumatic second stitch length and sewing

foot lifting.

With large hook and integrated sewing lamp.

867-190342 Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-pneumatic rapid stroke adjustment,

electro-magnetic thread cutter, connectable thread

tension, electro-pneumatic seam bartacking,

electro-pneumatic second stitch length and sewing

foot lifting.

With large hook and integrated sewing lamp.

867-190425 Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-pneumatic rapid stroke adjustment,

electro-magnetic short thread cutter, connectable

thread tension, electro-pneumatic seam bartacking,

electro-pneumatic second stitch length and sewing

foot lifting.

With large hook and integrated sewing lamp.

All controlling elements can be locked.

867-190445 Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-pneumatic rapid stroke adjustment,

electro-magnetic short thread cutter, connectable

thread tension, electro-pneumatic seam bartacking,

electro-pneumatic second stitch length and sewing

foot lifting.

With oversized hook (XXL) and integrated sewing

lamp.

All controlling elements can be locked.

867-290122 Double-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-magnetic thread cutter,

electro-pneumatic seam bartacking and sewing foot

lifting.

With large hooks.

867-290142 Double-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-magnetic thread cutter,

electro-pneumatic seam bartacking and sewing foot

lifting.

With oversized hooks (XXL).

7

GB

Keystone Sewing Machine Company, Inc.

Page 10

867-290322 Double-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-pneumatic rapid stroke adjustment,

electro-magnetic thread cutter, connectable thread

tension, electro-pneumatic seam bartacking,

electro-pneumatic second stitch length and sewing

foot lifting.

With large hooks and integrated sewing lamp.

867-290342 Double-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-pneumatic rapid stroke adjustment,

electro-magnetic thread cutter, connectable thread

tension, electro-pneumatic seam bartacking,

electro-pneumatic second stitch length and sewing

foot lifting.

With oversized hooks (XXL) and integrated sewing

lamp.

867-290445 Double-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-pneumatic rapid stroke adjustment,

electro-magnetic short thread cutter, connectable

thread tension, electro-pneumatic seam bartacking,

electro-pneumatic second stitch length and sewing

foot lifting.

With oversized hooks (XXL) and integrated sewing

lamp.

All controlling elements can be locked.

867-392040 Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed.

With oversized hook (XXL). Equipped with moving

variable binding device.

867-392342 Single-needle double-lockstitch machine with

no-stroke lower feed, with needle feed, alternating

upper foot feed, electro-pneumatic thread

cutter, connectable thread tension,

electro-pneumatic seam bartacking,

electro-pneumatic rapid stroke adjustment and

sewing foot lifting. With oversized hook (XXL).

Equipped with moving variable binding device.

867-393342 Single-needle double-lockstitch machine with

no-stroke lower feed, with needle feed, alternating

upper foot feed, electro-pneumatic thread

cutter, connectable thread tension,

electro-pneumatic seam bartacking,

electro-pneumatic rapid stroke adjustment and

sewing foot lifting. With oversized hook (XXL).

Equipped with electro motor driven edge trimmer.

867-394342 Single-needle double-lockstitch machine with

no-stroke lower feed, with needle feed, alternating

upper foot feed, electro-pneumatic thread

cutter, connectable thread tension,

electro-pneumatic seam bartacking,

electro-pneumatic rapid stroke adjustment and

sewing foot lifting. With oversized hook (XXL).

Equipped with electro motor driven edge trimmer

and moving variable binding device.

8

Keystone Sewing Machine Company, Inc.

Page 11

867-490322 Double-needle double-lockstitch machine with

disconnectable needle bars, with bottom feed,

needle feed, alternating upper foot feed,

electro-pneumatic rapid stroke adjustment,

electro-magnetic thread cutter, connectable thread

tension, electro-pneumatic seam bartacking,

electro-pneumatic second stitch length and sewing

foot lifting.

With large hooks and integrated sewing lamp.

867-190020-70 700 mm long arm flatbed single-needle

double-lockstitch machine with bottom feed, needle

feed, alternating upper foot feed. With large hook.

867-190040-70 700 mm long arm flatbed single-needle

double-lockstitch machine with bottom feed, needle

feed, alternating upper foot feed. With oversized

hook (XXL).

867-190122-70 700 mm long arm flatbed single-needle

double-lockstitch machine with bottom feed, needle

feed, alternating upper foot feed, electro-magnetic

thread cutter, electro-magnetic seam bartacking and

sewing foot lifting. With large hook.

867-190322-70 700 mm long arm flatbed single-needle

double-lockstitch machine with bottom feed, needle

feed, alternating upper foot feed, electro-pneumatic

rapid stroke adjustment, electro-magnetic thread

cutter, connectable thread tension,

electro-pneumatic seam bartacking,

electro-pneumatic second stitch length and sewing

foot lifting.

With large hook and integrated sewing lamp.

867-190342-70 700 mm long arm flatbed single-needle

double-lockstitch machine with bottom feed, needle

feed, alternating upper foot feed, electro-pneumatic

rapid stroke adjustment, electro-magnetic thread

cutter, connectable thread tension,

electro-pneumatic seam bartacking,

electro-pneumatic second stitch length and sewing

foot lifting.

With oversized hook (XXL) and integrated sewing

light.

867-290020-70 700 mm long arm flatbed double-needle

double-lockstitch machine with bottom feed, needle

feed, alternating upper foot feed.

With large hooks.

9

GB

Keystone Sewing Machine Company, Inc.

Page 12

867-290040-70 700 mm long arm flatbed double-needle

double-lockstitch machine with bottom feed, needle

feed, alternating upper foot feed

With oversized hooks (XXL).

867-290122-70 700 mm long arm flatbed double-needle

double-lockstitch machine with bottom feed, needle

feed, alternating upper foot feed, electro-magnetic

thread cutter, electro-pneumatic seam bartacking

and sewing foot lifting.

With large hooks.

867-290322-70 700 mm long arm flatbed double-needle

double-lockstitch machine with bottom feed, needle

feed, alternating upper foot feed, electro-pneumatic

rapid stroke adjustment, electro-magnetic thread

cutter, connectable thread tension,

electro-pneumatic seam bartacking,

electro-pneumatic second stitch length and sewing

foot lifting.

With large hooks and integrated sewing lamp.

867-290342-70 700 mm long arm flatbed double-needle

double-lockstitch machine with bottom feed, needle

feed, alternating upper foot feed, electro-pneumatic

rapid stroke adjustment, electro-magnetic thread

cutter, connectable thread tension,

electro-pneumatic seam bartacking,

electro-pneumatic second stitch length and sewing

foot lifting.

With oversized hooks (XXL) and integrated sewing

light.

867-290342-100 1000 mm long arm flatbed double-needle

double-lockstitch machine with bottom feed, needle

feed, alternating upper foot feed, electro-pneumatic

rapid stroke adjustment, electro-magnetic thread

cutter, connectable thread tension,

electro-pneumatic seam bartacking,

electro-pneumatic second stitch length and sewing

foot lifting.

With oversized hooks (XXL) and integrated sewing

light.

10

Keystone Sewing Machine Company, Inc.

Page 13

3.1 Subclasses with direct drive

867-190020-M Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed and large hook.

867-190142-M Single-needle double-lockstitch machine with

bottom feed, needle feed, alter nating upper foot

feed, electro-magnetic thread cutter,

electro-pneumatic seam bartacking and sewing foot

lifting.

With oversized hook (XXL). Direct drive.

11

GB

Keystone Sewing Machine Company, Inc.

Page 14

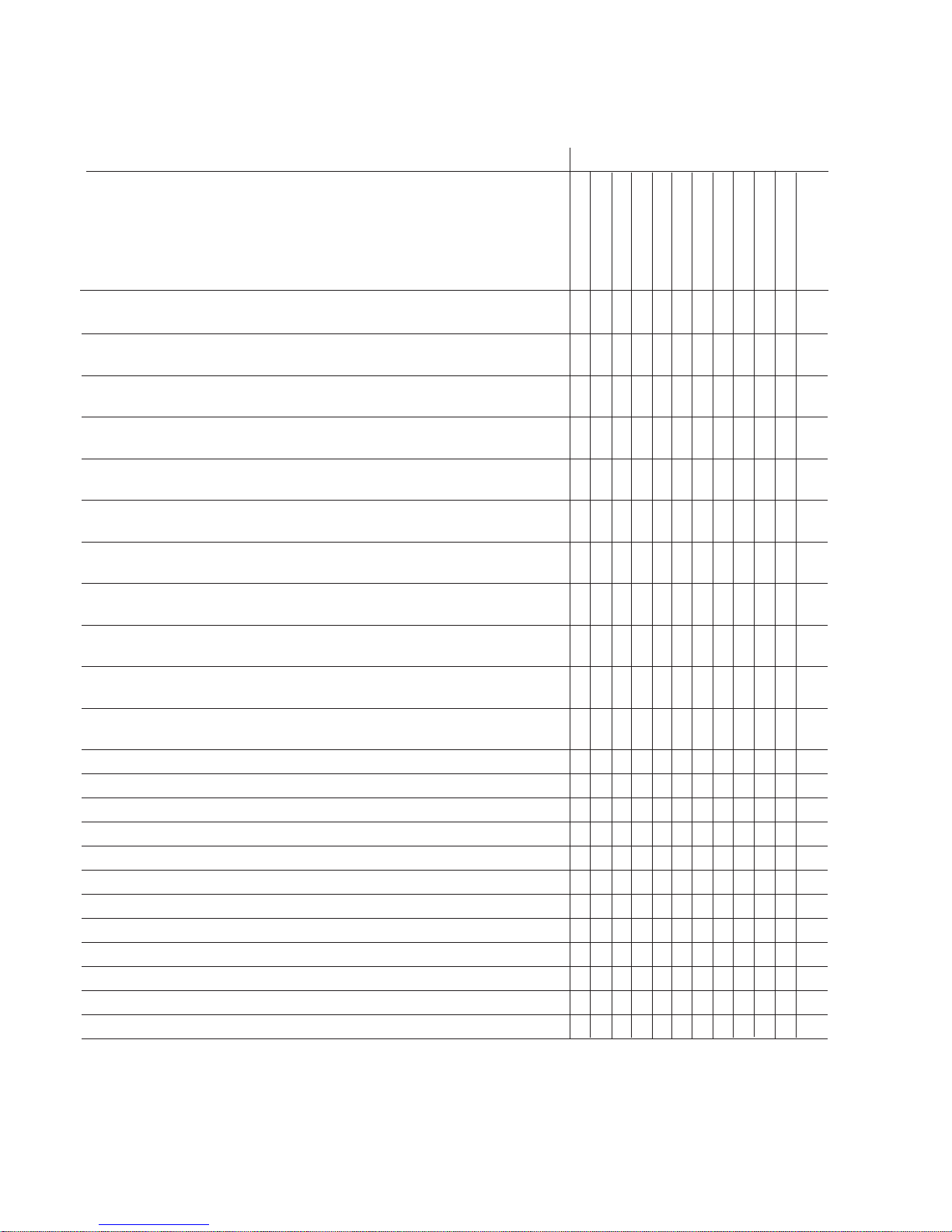

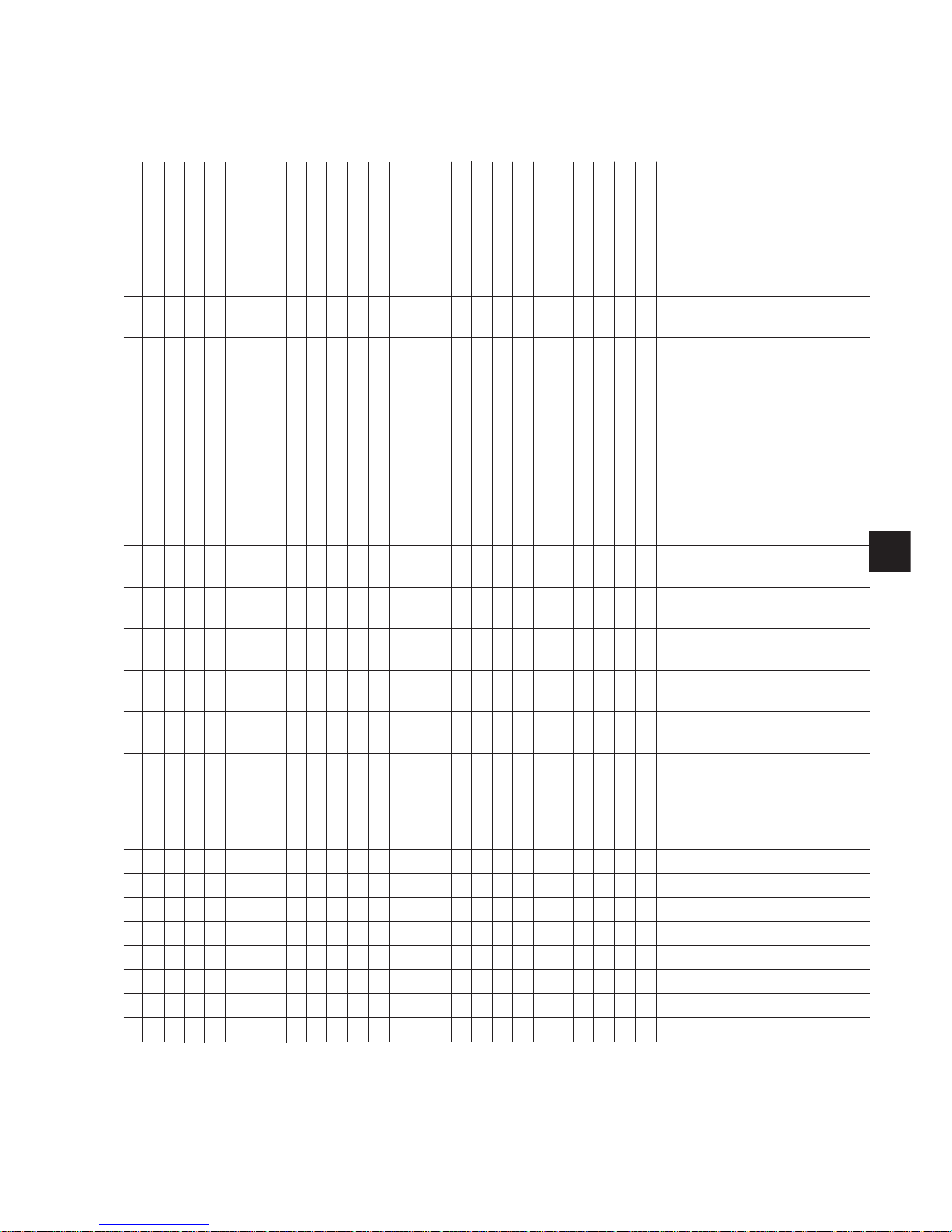

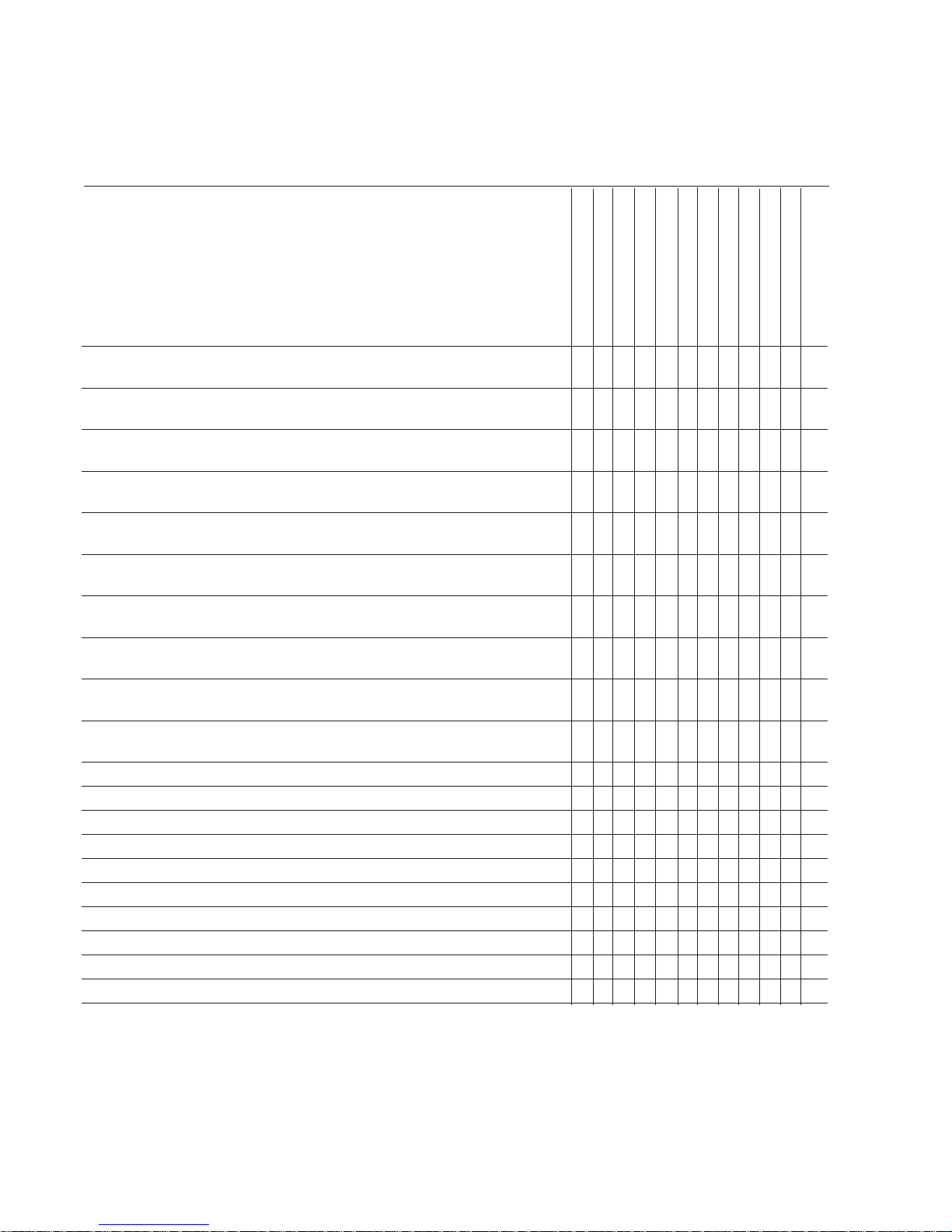

4 Optional equipments

For the 867 the following optional equipments are available:

Order No. Optional equipment Subclasses

867-160152

867-190020

867-190040

867-190122

867-190125

867-190142

867-190145

867-190146

867-190322

867-190342

867-190425

0867 590014 Electro-pneumatic needle cooler from the top xxxxxxxxx

(NK 20-1)

0867 590024 Electro-pneumatic needle cooler from the bottom x x x x x

(NK 20-2)

0867 590054 Electro-pneumatic needle cooler from the bottom x x x x x

(NK 20-5)

0867 590104 Thread monitor for hook thread large hook,

single-needle (RFW 20-1) x x

0867 590124 Thread monitor for hook thread large hook,

double-needle (RFW 20-2)

0867 590114 Thread monitor for hook thread oversized

hook (XXL), single-needle (RFW 20-3) x x

0867 590134 Thread monitor for hook thread oversized

hook (XXL), double-needle (RFW 20-4) x

0867 590164 Thread monitor for hook thread short thread cut.,

large hook, single-needle (RFW 20-7) x x

0867 590174 Thread monitor for hook thread short thread cut.,

oversized hook (XXL), double-needle (RFW 20-8) x

0867 590184 Thread monitor for hook thread short thread cut.,

large hook, double-needle (RFW 20-9) x x

9780 000108 WE-8 maintenance unit for pneumatic

optionalequipments xxxxxxxxxxx x

0867 490010 Operating panel L-bracket x x xxxxxxxxx x

0867 490100 Operating panel L-bracket for direct drive x

9822 510003 Halogen sewing lamp x x xxxxxxxxxx

9880 867100 Sewing lamp add-on kit x x xxxxxxxxx x

0798 500088 Sewing lamp transformer x x xxxxxxxxx x

9880 867103 Sewing lamp LED x x xxxxxxxxx x

9880 867102 Integrated LED lamp x x xxxxooooxx

9850 001089 Power supply cpl. for integr. sew. lamp./ LED . x x xxxxooooxx

0797 003031 Pneumatic connection package x x xxxxxxxxx x

0367 595124 Mechanical sewing foot lifting x x x x

0867 590354 Pneumatic sewing foot lifting (FLP 20-1) x x x x

0867 590464 Mechanical locking x x x

x = Optional equipment

o = Standard equipment

12

Keystone Sewing Machine Company, Inc.

Page 15

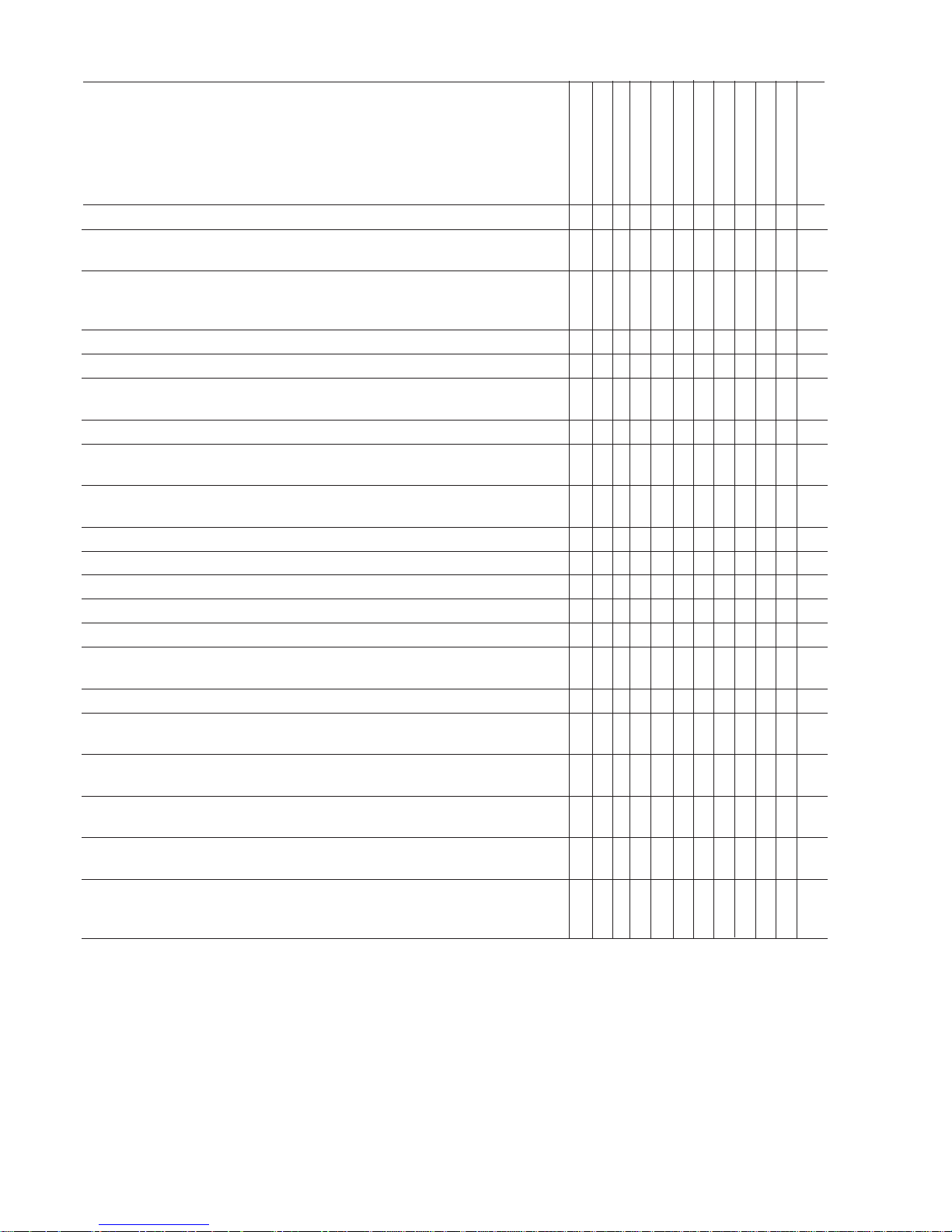

Subclasses

867-190445

867-260152

867-290020

867-290040

867-290122

867-290142

867-290322

867-290342

867-290445

867-392040

867-392342

867-393342

867-394342

867-490322

867-190020-70

867-190040-70

867-190122-70

867-190322-70

867-190342-70

867-290020-70

867-290040-70

867-290122-70

867-290322-70

867-290342-70

867-290342-100

xxxxxxx

xxxx

x

xx

xxx x xx

xxxx x

xxx

x

x

x x xx xx x xxx xx xx xx x x xxx xxx x

o o xx ooo oox oo oo xx oo oxx oooo

x x xx xx x xxx xx xx xx x x xxx xxx

x x xx xx x xxx xx xx xx x x xxx xxx

x x xx xx x xxx xx xx xx x x xxx xxx

x x xx xx x xxx xx xx xx x x xxx xxx x

o x xx xxo oox oo oo xx xo oxx xoxo

o x xx xxo oox oo oo xx xo oxx xooo

x x xx xx x xxx xx xx xx x x xxx xxx x

xx x xx xx

xx x xx xx

xxx

x = Optional equipment

o = Standard equipment

13

GB

Keystone Sewing Machine Company, Inc.

Page 16

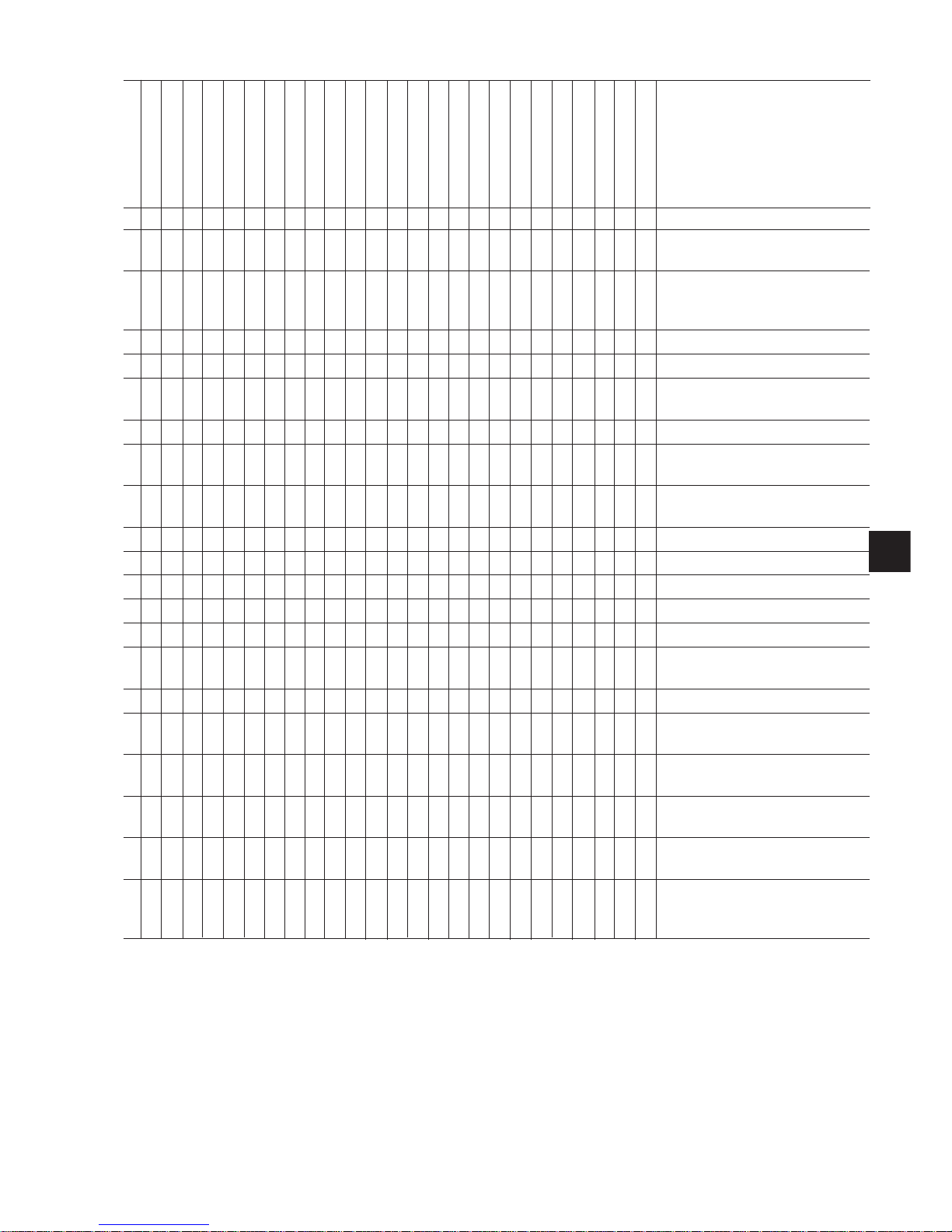

Order No. Optional equipment Subclasses

867-190020

867-190040

867-190122

867-190125

867-190142

867-190142-M

867-190145

867-190322

867-190342

867-190425

867-190445

N800 080021 Edge guide, swivelling x x xxxxxxx

N800 080022 Edge guide / Rule on the slide of the throat plate x x xxxxxx

(2

nd

seam distance)

N800 005646 Edge guide pneumatic driven w ith two adjustable x x xxxxxx

seam distances / Fixed on the slider of the throat

plate

N800 080001 Edge guide, swivelling

N800 080004 Edge guide, swivelling (like Del Veccia)

N800 005650 Seam center guide connectable pneumatically

xx

N800 005655 Seam center guide, swivelling (mechanically) x x x x x

0867 590074 Reflected light barrier for the automatic recognition x x xxxx xxx

of the material edge at the end of seam (LR 20-1)

9805 791113 USB memory key for data transfer with the x x xxxxxx x x

Efka control unit DA321G.

0667 156224 CLB 300 hook Core-Less-Bobbin x x

0868 150434 Low maintenance hook (large)

0868 150484 Low maintenance hook XXL (oversized)

9850 867001 PCB for oil monitoring

0667 595204 Kit for controlling element x x

0867 590984 Kit FK = Thread clamp with x x o x o x x x o

thread wiper function

0867 591004 Kit “Neat Seam Beginning” xxxxxxxx

0867 591204 Visual bobbin monitoring / Window in the throat x x x

plate slide + bobbin 26 mm with elongated holes

0867 591244 Visual bobbin monitoring / Window in the throat x x x

plate slide + bobbin 32 mm with elongated holes

0867 591224 Visual bobbin monitoring / Window in the throat x x

plate slide + bobbin 26 mm with elongated holes

0867 591234 Visual bobbin monitoring / Window in the throat x x

plate slide + bobbin 32 mm with elongated holes

0867 591244 Illumination kit for visual bobbin monitoring. x xxxxxxxx

Only in connection with 0867 591204,

0867 591214, 0867 591224, 0867 591234

x = Optional equipment

o = Standard equipment

14

Keystone Sewing Machine Company, Inc.

Page 17

Subclasses

867-290020

867-290040

867-290122

867-290142

867-290322

867-290342

867-290445

867-392040

867-392342

867-393342

867-394342

867-490322

867-190020-70

867-190040-70

867-190122-70

867-190322-70

867-190342-70

867-290020-70

867-290040-70

867-290122-70

867-290322-70

867-290342-70

867-290342-100

xx

x xxxxxxxxxxx

x xxxxx

xxxx

x xxxxx

x xxxxx

xxxxx x xxxx

x x xx x x x x x xxx

xxxxx x x xxx xxxx

x x xx xx x xxx xx xx xx x x xxx

xxxxxxxxxxx

x xx xxxxxx

xxxxxxxxxxx

xxooo oooo xoo xooo

xx xx xx x x xxx

xxxxxxxxxx

xxxxxxxxxx

xx xx xx x x xx

xx x x x x

x = Optional equipment

o = Standard equipment

15

GB

Keystone Sewing Machine Company, Inc.

Page 18

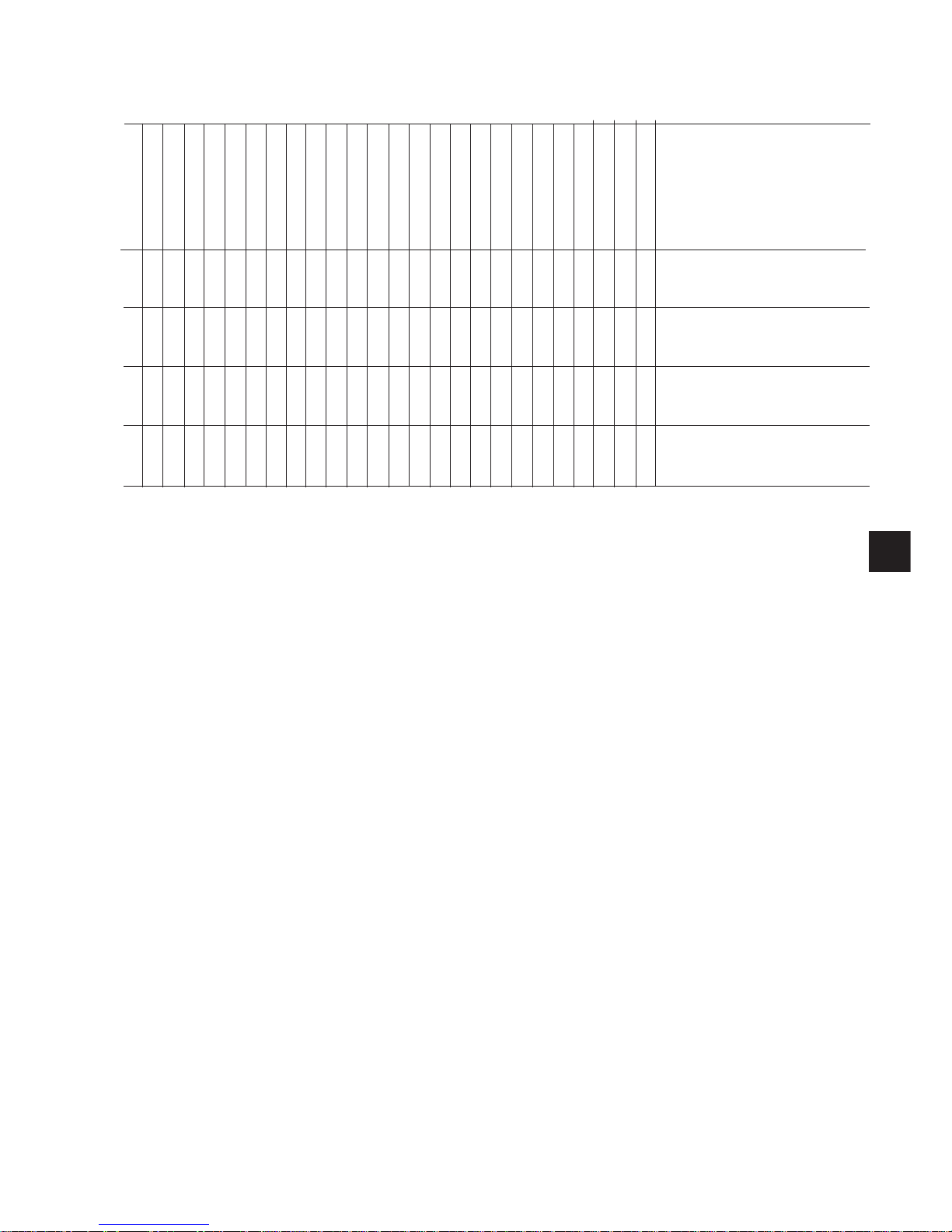

Stands

Order No. Optional equipment Subclasses

867-160152

867-190020

867-190040

867-190122

867-190125

867-190142

867-190145

867-190146

867-190322

867-190342

867-190425

MG55 400304 Stand set MG 55-3 x x xxxxxxxxx

for motor fitting beneath the table, with pedal

Table top size 1060 x 500 mm

MG55 400314 Stand set MG 55-3 x x x x x x

for motor fixed on machine head, with pedal

Table top size 1060 x 500 mm

MG55 400404 Stand set MG 58-63

for motor fitting beneath the table, with pedal

Table top size 1600 x 580 mm

MG55 400414 Stand set MG 58-63

for motor fixed on machine head, with pedal

Table top size 1600 x 580 mm

16

Keystone Sewing Machine Company, Inc.

Page 19

Subclasses

867-190445

867-260152

867-290020

867-290040

867-290122

867-290142

867-290322

867-290342

867-290445

867-392040

867-392342

867-393342

867-394342

867-490322

867-190020-70

867-190040-70

867-190122-70

867-190322-70

867-190342-70

867-290020-70

867-290040-70

867-290122-70

867-290322-70

867-290342-70

867-290342-100

x x xx xx x xxx xx xx

xx xxxxxxxxxx

xxxxxxxxxx

xx x xxx

17

GB

Keystone Sewing Machine Company, Inc.

Page 20

4.1 Optionnal equipment for machines with direct drive

For the 867 with direct drive, the following optional equipments are

available:

Order No. Optional equipment Subclasses

867-190020-M

867-190142-M

0867 590014 Electro-pneumatic needle cooler from the top x

(NK 20-1)

0867 590024 Electro-pneumatic needle cooler from the bottom x

(NK 20-2)

0867 590054 Electro-pneumatic needle cooler from the bottom

(NK 20-5)

0867 590104 Thread monitor for hook thread large hook,

single needle (RFW 20-1)

0867 590124 Thread monitor for hook thread large hook,

double needle (RFW 20-2)

0867 590114 Thread monitor for hook thread oversized x

hook (XXL), single needle (RFW 20-3)

0867 590134 Thread monitor for hook thread oversized

hook (XXL), double needle (RFW 20-4)

0867 590164 Thread monitor for hook thread short thread cut.,

oversized hook (XXL), single needle (RFW 20-7)

0867 590174 Thread monitor for hook thread short thread cut.,

oversized hook (XXL), double needle (RFW 20-8)

0867 590184 Thread monitor for hook thread short thread cut.,

large hook, single needle (RFW 20-9)

9780 000108 WE-8 Maintenance unit for pneumatic x x

optional e quimpments

0867 490100 Operating panel L-bracket for direct drive x o

9822 510003 Halogen sewing lamp x x

9880 867100 Sewing lamp add-on kit x x

0798 500088 Sewing lamp transformer x x

9880 867103 Sewing lamp LED x x

9880 867102 Integrated LED lamp x x

9850 001089 Power supply cpl. foe integrated sew. lamp / LED x x

0797 003031 Pneumatic connection package x x

0367 595124 Mechanical sewing foot lifting x

0867 590354 Pneumatic sewing foot lifting(FLP 20-1) x

x = Optional equipment

o = Standard equipment

18

Keystone Sewing Machine Company, Inc.

Page 21

Subclasses

19

GB

Keystone Sewing Machine Company, Inc.

Page 22

Order No. Optional equipment Subclasses

867-190020-M

867-190142-M

0867 590464 Mechanical locking x

N800 080021 Edge guide, swivelling x x

N800 080022 Edge guide / Rule on the slide of the throat plate x x

(2. seam distance)

N800 005646 Edge guide pneumatic driven w ith two adjustable x x

seam distances / Fixed on the slide of the throat

plate

N800 080001 Edge guide, swivelling x x

N800 080004 Edge guide, swivelling (like Del Veccia) x x

N800 005650 Seam center guide connected pneumatically

N800 005655 Seam center guide, swivelling (mechanically)

0867 590074 Reflected light barrier for the automatic recognition x

of the material edge at the seam end (LR 20-1)

9835 901005 Memo-Dongle for data transfer x x

for DA control units

0667 156224 CLB 300 hook Core-Less-Bobbin x

0868 150434 Low maintenance hook large x

0868 150484 Low maintenance hook oversized (XXL) x

9850 867001 PCB for oil monitioring x

0667 595204 Kit for controlling elements

0867 591004 Kit “Neat seam beginning” x

0867 590984 Kit FK = thread clamp with thread wiper function x

Stands

MG55 400304 Stand set MG 55-3 x

for motor fitting beneath the table, with pedal

Table top size 1060 x 500 mm

MG55 400314 Stand set MG 55-3 x

for motor fixed on the machine head, with pedal

Table top size 1060 x 500 mm

x = Optional equipment

o = Standard equipment

20

Keystone Sewing Machine Company, Inc.

Page 23

Subclasses

21

GB

Keystone Sewing Machine Company, Inc.

Page 24

Further optional equipments are available. Please contact our

application center (APC).

E-Mail: marketing@duerkopp-adler.com

Further available documents concerning the class 867:

0791 867801 Parts list

0791 867641 Service Instructions

0791 100700 Fitting Instructions for Sewing Lamp LED

0791 867701 Instructions for fitting seam center guide

N800 005655 (mechanically)

N800 005650 (pneumatically)

0791 867702 Instructions for fitting remaining thread

monitor

0791 867703 Instructions for fitting the reflecting light barrier

0791 867704 Instructions for fitting pneumatic

sewing foot lift FLP 14-1

0791 867705 Instructions for fitting for edge guide N800 080021

0791 867706 Instructions for fitting sewing foot lift pedal

0791 767707 Instructions for fitting pneumatic sewing foot

lift

0791 867771 Instructions for converting for lifting shaft

0791 867772 Instructions for converting bobbin hook CLB 300

0791 867773 Fitting instruction for the kit thread clamp

22

Keystone Sewing Machine Company, Inc.

Page 25

5 Technical data

Noise: Workplace-related emission value in accordance with DIN 45635-48-A-1-KL2

867-160152 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-190020 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-190040 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-190122 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-190125 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-190142 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-190142-M LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

867-190145 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-190146 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-190322 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-190342 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-190425 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-190445 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-260152 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-290020 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-290020-M LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

23

GB

Keystone Sewing Machine Company, Inc.

Page 26

867-290040 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-290122 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-290142 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-290322 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-290342 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ___ min

-1

Material:

867-290445 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-392040 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-392342 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-393342 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-394342 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-490322 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-190020-70 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-190040-70 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-190122-70 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-190322-70 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-190342-70 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-290020-70 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-290040-70 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

24

Keystone Sewing Machine Company, Inc.

Page 27

867-290122-70 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-290322-70 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-290342-70 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

867-290342-100 LC = _dB (A)

Stitch length: _ mm Sewing foot stroke: mm Speed: ____ min

-1

Material:

25

GB

Keystone Sewing Machine Company, Inc.

Page 28

5.1 Technical data subclasses

Subclasses

867-160152

867-190020

867-190040

867-190122

867 190125

867-190142

867-190145

867-190146

867-190322

867-190342

Type of stitch Lockstitch 301

Hook type

small

large

oversized

large

large

oversized

oversized

oversized

large

oversized

Numberofneedles 1111111111

Needle system 134-35

Needle size 180

(depending on E-No.) [Nm]

Max. thread thickness [Nm] 80/3 - 10/3

Stitch length [mm]

- Forward 12

- Backward 12

Numberadj.stitchlengths 1111112222

Max. number of stitches [min-1] 4000 3200 3800 3800 3400 3400 3800 3800 3400 3800

Number of stitches with

factory setting [min

-1

] 3400 3000 3400 3400 3400 3400 3400 3400 3400 3400

Max. lifting height [mm] 20 20 20 20 20 20* 20* 20* 20* 20*

(*only with turn-back device)

Max.sewingfootstroke [mm]9999999999

Operatingpressure [bar]-666666666

Air consumption per

working cycle [NL] - 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7

Dimensions (L x W x H) [mm] 690 / 220 / 460

Weight 55 55 55 55 55 55 55 55 55 55

with direct drive [kg] - 59 59 59 59 59 59 59 59 59

26

Keystone Sewing Machine Company, Inc.

Page 29

867-190425

867-190445

867-160152

867-290020

867-290040

867-290122

867-290142

867-290322

867-290342

867-290445

867-392040

867-392342

867-393342

867-394342

867-490322

Lockstitch 301

large

oversized

small

large

oversized

large

oversized

large

oversized

oversized

oversized

oversized

oversized

oversized

large

112222222211112

134-35

180

80/3 - 10/3

12

12

221111122212222

3000 3000 3500 3200 3500 3200 3200 3000 3000 3000 3000 3000

3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000

20 20 20* 20* 20* 20* 20* 20* 20* 20* 20* 20*

999999999999

- -6666666666

- - 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7

690 / 220 / 460 690 / 320 / 690 / 220 / 460

460

55 55 55 55 55 55 55 58 58 58 58 55

59 59 59 59 59 59

27

GB

Keystone Sewing Machine Company, Inc.

Page 30

Subclasses

867-190020-70

867-190040-70

867-190122-70

867 190322-70

867-190342-70

867-290020-70

867-290040-70

867-290122-70

867-290322-70

867-290342-70

Type of stitch Lockstitch 301

Type of hook

large

oversized

large

large

oversized

large

oversized

large

large

oversized

Numberofneedles 1111112222

Needle system 134-35

Needle size 180

(depending on E-No.) [Nm]

Max. thread thickness [Nm] 80/3 - 10/3

Stitch length [mm]

Forward 12

Backward 12

Numberadj.stitchlengths 1112211122

Max. number of stitches [min-1] 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000

Number of stitches with

factory setting [min

-1

] 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000

Max. lifting height [mm] 20 20 20 20 20 20 20 20 20 20

(*only with turn-back device)

Max.sewingfootstroke [mm]9999999999

Operatingpressure [bar]- -66666666

Air consumption per

working cycle [NL] - - 0.7 0.7 0.7 0.7 0.7 0.7 0.7 0.7

Dimensions (L x W x H) [mm] 1090 / 220 / 460

Weight 85 85 85 85 85 85 85 85 85 85

withdirectdrive [kg]89898989898989898989

28

Keystone Sewing Machine Company, Inc.

Page 31

867-290342-100

Lockstitch

301

oversized

2

134-35

180

80/3 - 10/3

12

12

2

3000

3000

20

9

6

0.7

1390 / 220 / 460

85/

89

29

GB

Keystone Sewing Machine Company, Inc.

Page 32

5.2 Technical data of subclasses with direct drive

Subclasses

867-190020-M

867-190142-M

Type of stitch Lockstitch 301

Hook type

large

oversized

Number of needles 1 1

Needle system 134-35

Needle size 180

(depending on E-No) [Nm]

Max. thread thickness [Nm] 80/3 -10/3

Stitch length [mm]

-Forward 12

-Backward 12

Number of adj. stitches 1 1

Max. number of stitches [min-1] 3200 3200

Number of stitches with

factory setting [min

-1

] 3000 3000

Max. lifting height [mm] 20 20*

(*only with turn-back device)

Max. sewing foot stroke [mm] 9 9

Operating pressure [bar] - -

Air consumption per

working cycle [NL] - -

Dimensions (L x W x H) [mm] 690 / 220 / 460

Weight

Direct drive [kg] 55 55

30

Keystone Sewing Machine Company, Inc.

Page 33

Notes:

31

GB

Keystone Sewing Machine Company, Inc.

Page 34

Threading scheme single-needle machine

Threading scheme double-needle machine

32

1

2

3

4

5

11

10

9

8

7

6

12

13

14

15

16

22

21

20

19

18

17

Keystone Sewing Machine Company, Inc.

Page 35

6. Operation

6.1 Threading the needle thread

6.1.1 Threading the needle thread on machine without short thread cutter

Caution: danger of injury !

Turn off the main switch.

The needle thread may only be threaded with the sewing machine

switched off.

Threading in the needle thread with single-needle machines

–

Put the thread reel on the thread stand and lead the needle thread

through the unwinder arm.

The unwinder arm must be in vertical position above the thread reels.

–

Thread in the thread through threading guide 1 and 2.

–

Conduct the thread clockwise around the pre-tensioner w heel 3.

–

Conduct the thread counter-clockwise around the supplementary

tensioner wheel 4.

–

Conduct the thread clockwise around the main tensioner wheel 5.

–

Pull the thread underneath the thread take-up spring 8 and

conduct it through the thread regulator 10 to the thread lever 11.

–

Conduct the thread through the thread lever 11 and the threading

guides 9, 7 and 6 on the needle bar.

–

Thread the thread into the needle eye.

Threading in the needle thread with double-needle machines

–

Put the thread reels on the thread stand and lead the needle

thread through the unwinder arm.

The unwinder arm must be in vertical position above the thread reels.

Thread for the left needle (as with single-needle machines)

–

Thread in the thread through threading guide 1 and 2.

–

Conduct the thread clockwise around the pre-tensioner 3.

–

Conduct the thread counter-clockwise around the supplementary

tensioner 4.

–

Conduct the thread clockwise around the main tensioner 5.

–

Pull the thread underneath the thread take-up spring 8 and

conduct it through the thread regulator 10 to the thread lever 11.

–

Conduct the thread through the thread lever 11 and the threading

guides 9, 7 and 6 on the needle bar.

–

Thread the thread into the needle eye.

Thread for the right needle

–

Thread in the thread through threading guide 12 and 13.

–

Conduct the thread clockwise around the pre-tensioner 14.

–

Conduct the thread counter-clockwise around the supplementary

tensioner 15.

–

Conduct the thread clockwise around the main tensioner 16.

–

Pull the thread underneath the thread take-up spring 19 and

conduct it through the thread regulator 21 to the thread lever 22.

–

Conduct the thread through the thread lever 22 and the threading

guides 20, 18 and 17 on the needle bar.

–

Thread the thread into the eye of the right needle.

33

GB

Keystone Sewing Machine Company, Inc.

Page 36

Threading scheme single-needle machine

Threading scheme double-needle machine

34

1

2

3

4

5

13

12

11

10

9

8

7

6

14

15

16

17

18

26

25

24

23

22

21

20

19

Keystone Sewing Machine Company, Inc.

Page 37

6.1.2 Threading the needle thread on machine with short thread cutter

Caution: danger of injury !

Turn off the main switch.

The needle thread may only be threaded with the sewing machine

switched off.

Threading in the needle thread with single-needle machines

–

Put the thread reel on the thread stand and lead the needle thread

through the unwinder arm.

The unwinder arm must be in vertical position above the thread reels.

–

Thread in the thread through threading guide 1 and 2.

–

Conduct the thread clockwise around the pre-tensioner wheel 3.

–

Conduct the thread counter-clockwise around the supplementary

tensioner wheel 4.

–

Conduct the thread clockwise around the main tensioner wheel 5.

–

Pull the thread underneath the thread take-up spring 8 and conduct it

through the thread regulator 10 to the thread lever 11.

–

Conduct the thread through the thread lever 11 and the threading

guides 9, 7 and 6 on the needle bar.

–

Thread the thread into the needle eye.

–

Check the length of the thread, without fail. See the picture on the

opposite to see the max. allowed length - thread lever at its UDC.

Threading in the needle thread with double-needle machines

–

Put the thread reels on the thread stand and lead the needle thread

through the unwinder arm.

The unwinder arm must be in vertical position above the thread reels.

Thread for the left needle (as with single-needle machines)

–

Thread in the thread through threading guide 1 and 2.

–

Conduct the thread clockwise around the pre-tensioner 3.

–

Conduct the thread counter-clockwise around the supplementary

tensioner 4.

–

Conduct the thread clockwise around the main tensioner 5.

–

Pull the thread underneath the thread take-up spring 8 and conduct it

through the thread regulator 10 to the thread lever 11.

–

Conduct the thread through the thread lever 11 and the threading

guides 9, 7 and 6 on the needle bar.

–

Thread the thread into the needle eye.

–

Check the length of the thread, without fail. See the picture on the

opposite to see the max. allowed length - thread lever at its UDC.

Thread for the right needle

–

Thread in the thread through threading guide 14 and 15.

–

Conduct the thread clockwise around the pre-tensioner 16.

–

Conduct the thread counter-clockwise around the supplementary

tensioner 17.

–

Conduct the thread clockwise around the main tensioner 18.

–

Pull the thread underneath the thread take-up spring 23 and conduct

it through the thread regulator 25 to the thread lever 26.

–

Conduct the thread through the thread lever 26 and the threading

guides 21,20 and 19 on the needle bar.

–

Thread the thread into the eye of the right needle.

–

Check the length of the thread, without fail. See the picture on the

opposite to see the max. allowed length - thread lever at its UDC.

35

GB

Keystone Sewing Machine Company, Inc.

Page 38

6.1.3 Threading the needle thread on subclass -190146

–

Thread in the thread through the threading

guide 1.

–

Thread in the thread around the pre-tensioner

wheel 2.

–

Conduct the thread through the thread clamp 3.

–

Thread in the thread through the threading

guide 4 on the thread retainer and the eyelets 8

on the tension plate.

–

Conduct the thread through the main tensioner

wheels 7 and 6.

–

Conduct the thread from above through the

tension discs 5.

36

1

2

3

4

8

7

6

5

Keystone Sewing Machine Company, Inc.

Page 39

Notes:

37

GB

Keystone Sewing Machine Company, Inc.

Page 40

Fig. A: Correct thread interlacing in the center of the

material

Fig. B: Needle-thread tension too weak

or

hook-thread tension too strong

Fig. C: Needle-thread tension too strong

or

hook-thread tension too weak

38

321

54

676

Keystone Sewing Machine Company, Inc.

Page 41

6.2 Adjusting the needle-thread tension

Pre-tensioner

When the main tensioner 2 and supplementary tensioner 3 are open

(e.g. when the sewing feet are raised) the needle thread must be

under slight residual tension. This residual tension is produced by the

pre-tensioner 1.

The pre-tensioner 1 simultaneously affects the length of the end of the

severed needle thread (the starting thread for the next seam).

–

Basic setting:

Turn knurled nut 4 until its front is flush with the bolt 5.

–

To shorten the starting thread:

Turn knurled nut 4 clockwise.

–

To lengthen the starting thread:

Turn knurled nut 4 anticlockwise.

Main tensioner

The main tensioner 2 should be set to the minimum possible tension.

The looping of the threads must be in the center of the material.

With thin material excessive thread tension can cause unwanted

gathering and thread breakage.

–

Adjust the main tensioner 2 so that the stitches are uniform.

To increase tension - turn the knurled nut clockwise

To decrease tension - turn the knurled nut anti-clockwise

Supplementary tensioner

The supplementary tensioner 3 can be switched in to effect a rapid

change in needle-thread tension during operation (e.g. with thickened

seams).

–

Set the supplementary tensioner 3 lower than the main

tensioner 2.

6.2.1 Adjusting the needle-thread tension on automotive machines

On automotive machines, it is possible to secure the main tensioner 2

and the supplementary tensioner 3 against altering through the user.

Adjusting the thread tension

–

Loosen the screw 6 and remove the interlock mechanism 7.

–

Adjust the needle-thread tension according to the description

given under chapter 6.2.

–

Put on the interlock mechanism 7 again and secure it by fastening

the screw 6.

39

GB

Keystone Sewing Machine Company, Inc.

Page 42

6.3 Opening the thread tension

Subclasses

867-190020, 867-190020-M, 867-190040, 867-290020, 867-290040,

867-190020-70, 867-190040-70, 867-290020-70, 867-290040-70

When lifting the sewing feet with the knee switch, main and

supplementary tension are automatically opened.

Subclasses

867-160152, 867-190122, 867-190125, 867-190142, 867-190142-M,

867-190145, 867-190146, 867-190322, 867-190342, 867-190425,

867-190445, 867-260152, 867-290122, 867-290142, 867-290322,

867-290342, 867-290445, 867-392342, 867-393342, 867-394342,

867-490322, 867-190122-70, 867-190322-70, 867-190342-70,

867-290122-70, 867-290322-70, 867-290342-70, 867-290342-100

The thread tension is automatically opened when trimming the thread.

40

Keystone Sewing Machine Company, Inc.

Page 43

6.4 Switching the supplementary tension on and off with machines without

thread trimmer

The supplementary tension is being switched on and off with lever 1.

Switching on

–

Push the handle 2 of lever 1 to the left.

Switching off

–

Push the handle 2 of the lever 1 to the right.

41

GB

1

2

Keystone Sewing Machine Company, Inc.

Page 44

6.5 Adjusting the thread regulator

Caution: danger of injury !

Turn off the main switch.

The thread regulator may only be adjusted with the sewing machine

switched off.

The thread regulator 1 controls the quantity of needle thread required

for stitch formation.

The thread regulator must be precisely adjusted for an optimum result.

At the correct setting the needle-thread loop must slide at low tension

over the thickest point of the hook.

–

Undo screw 2.

–

Adjust the thread regulator 1.

Thread regulator to the left = more thread

Thread regulator to the right = less thread

–

Tighten screw 2.

Adjustment information:

If the maximum quantity of thread is required the thread-tensioning

spring 3 must be pulled upwards about 0.5 mm from its lower limit

position. This is the case when the needle-thread loop passes the

maximum hook diameter.

42

32 1

Keystone Sewing Machine Company, Inc.

Page 45

6.6 Winding on the hook thread

–

Put the thread reel on the thread stand and conduct the needle

thread through the unwinder arm.

–

Conduct the thread through the thread guide 5, around the

tensioner 4 and through the thread guide 3.

–

Place the thread behind the blade 6 and sever it.

–

Fit the bobbin 1 onto the bobbin winder.

Hint

There is no need to wind the thread onto the bobbin by hand.

–

Press the bobbin-winder lever 2 into the bobbin.

–

Sewing

The bobbin-winder lever terminates the process as soon as the

bobbin is full.

The bobbin winder always stops in such a position that the blade 6

is in the insertion position (see right-hand illustration).

–

Remove the full bobbin 1, place the thread behind the blade 6 and

sever it.

–

Fit empty bobbin onto the bobbin winder for the next winding

process and press the bobbin-winder lever 2 into the bobbin.

CAUTION !

If the thread is not to be wound on during sewing, it is essential

for the sewing foot to be locked in the raised position and the

sewing-foot stroke set to the smallest value.

43

GB

54 3 2 1

26

Keystone Sewing Machine Company, Inc.

Page 46

6.7 Changing the hook-thread bobbin

Caution: danger of injury !

Turn off the main switch.

The hook-thread bobbin may only be changed with the machine

switched off.

Remove the empty bobbin

–

Raise up the flap 1 and remove the empty bobbin.

Insert a full bobbin

–

Insert the bobbin 2 so that it moves in the opposite direction of the

hook when unwinding.

–

Conduct the hook thread through the slot 3 and underneath the

spring 4.

–

Pull the hook thread through the s lot 6 and continue pulling until it

stands out about 3 cm.

–

Close the flap 1 and pull the hook thread through the thread

guiding 5 of the flap.

44

654

1

2

3

Keystone Sewing Machine Company, Inc.

Page 47

6.7.1 Inserting the hook thread bobbin with machines equipped with residual thread monitor

CAUTION !

The hook bobbin has to be inserted so that the groove 1 is tur ned

downwards.

The area around the bobbin housing and the light barrier has to be

cleared of sewing dust !

Wind up the bobbin thread

CAUTION !

When winding up the thread, the groove 1 has to be positioned

towards the machine. Thus the t hread is first wound into the

supply groove 2.

45

GB

1

2

Keystone Sewing Machine Company, Inc.

Page 48

6.8 Setting the hook thread tension

Caution: danger of injury !

Turn off the main switch.

The hook-thread tension may only be adjusted with the machine

switched off.

Setting the tension spring 2

–

Set the tension spring 2 by turning the adjustment screw 1.

Increase the hook thread tension =

Turn screw 1 clockwise

Decrease the hook thread tension =

Turn screw 1 counterclockwise

46

21

Keystone Sewing Machine Company, Inc.

Page 49

6.9 Inserting and changing the needle with single-needle machines

Caution: danger of injury !

Turn off the main switch.

The needle may only be changed with the sewing machine switched off.

–

Turn the hand wheel, until the needle bar 1 has reached its highest

position.

–

Loosen screw 2.

–

Pull the needle downwards out of the needle bar 1.

–

Push in the new needle into the hole o f the needle bar 1 until it

stops.

Attention!

The needle scarf 3 must point towards the hook.

–

Tighten screw 2.

CAUTION!

When changing to another needle size, the distance between hook

and needle must be readjusted (see service instructions).

Ignoring the above mentioned hint can cause the following mistakes:

When inserting a thinner needle:

–

Missed stitches

Damage of the thread

When inserting a thicker needle:

–

Damage of the hook tip

Damage of the needle

47

GB

21

1

3

2

Keystone Sewing Machine Company, Inc.

Page 50

6.10 Inserting and changing the needle with double-needle machines

Caution Danger of Injury !

Turn off the main switch.

The needle may only be changed with the sewing machine switched off.

–

Turn the hand wheel until the needle bar 1 has reached its highest

position.

–

Loosen screw 3.

–

Pull the needle downwards out of the needle holder 2.

–

Push the new needle into the hole of the needle holder 2 until it

stops.

Attention!

Seen from the operating side, the needle scarf 4 of the right

needle must point to the right side and the needle scarf of t he left

needle point to the left side (see drawing).

–

Tighten screw 3.

CAUTION !

When changing to another needle size, the distance between hook

and needle must be readjusted (see service instructions).

Ignoring the above mentioned hint can cause the following mistakes:

When inserting a thinner needle:

–

Missed stitches

Damage of the thread

When inserting a thicker needle:

–

Damage of the hook tip

Damage of the needle

48

1

2

3

4

Keystone Sewing Machine Company, Inc.

Page 51

6.11 Inserting and changing the needle with double-needle machines

with disconnectable needle bars

Caution Danger of Injury !

Turn off the main switch.

The needle may only be changed with the sewing machine switched off.

–

Turn the hand wheel until the needle bar has reached its highest

position.

Needle distance up to 3.2 mm

–

Loosen screw 1.

–

Pull the needle downwards out of the needle holder 2.

Needle distance greater than 3.2 mm

–

Loosen screw 4.

–

Pull the needle downwards out of the needle holder 3.

–

Push the new needle into the hole of the needle holder 2 or 3 until

it stops.

Attention!

Seen from the operating side, the needle scarf 4 of the right

needle must point to the right side and the needle scarf of t he left

needle point to the left side.

–

Tighten screw 1 or 4.

CAUTION !

When changing to another needle size, the distance between hook

and needle must be readjusted (see service instructions).

Ignoring the above mentioned hint can cause the following mistakes:

When inserting a thinner needle:

–

Missed stitches

Damage of the thread

When inserting a thicker needle:

–

Damage of the hook tip

Damage of the needle

49

GB

21 34

Keystone Sewing Machine Company, Inc.

Page 52

6.12 Lifting the sewing foot

Subclasses

867-190020, 867-190020-M, 867-190040, 867-290020, 867-290040,

867-190020-70, 867-190040-70, 867-290020-70, 867-290040-70

The sewing feet can be lifted mechanically by actuating the knee

lever 1.

Subclasses

867-160152, 867-190122, 867-190125, 867-190142, 867-190142-M,

867-190145, 867-190146, 867-190322, 867-190342, 867-190425,

867-190445, 867-260152, 867-290122, 867-290142, 867-290322,

867-290342, 867-290445, 867-392342, 867-393342, 867-394342,

867-490322, 867-190122-70, 867-190322-70, 867-190342-70,

867-290122-70, 867-290322-70, 867-290342-70, 867-290342-100

The sewing feet can be lifted electro-pneumatically by actuating the

pedal 2 or the knee lever 1.

Raising the sewing foot mechanically (knee lever)

–

To adjust the position of the material (e.g. for corrective purposes),

push the knee lever 1 to the right.

The sewing foot stays in the up position as long as pressure is

maintained on the knee lever 1.

Raising the sewing foot electro-pneumatically (pedal)

–

Press the pedal 2 half-way back.

The sewing feet are raised w ith the machine at a halt.

–

Press the pedal 2 all the way back.

The thread is severed and the sewing foot raised.

50

21

Keystone Sewing Machine Company, Inc.

Page 53

6.13 Locking the sewing feet in lifted position

–

Push the lever 1 downwards.

The sewing feet are locked in lifted position.

–

Push the lever 1 upward.

The sewing feet’s position is unlocked.

Or

–

Lift the sewing feet pneumatically by pushing the knee switch.

The lever 1 then moves back into its initial position.

51

GB

1

12

Keystone Sewing Machine Company, Inc.

Page 54

6.14 Sewing-foot pressure

The required sewing-foot pressure is set with the setting wheel 2.

CAUTION !

The material must not ”swim”.

Do not set a higher pressure than is necessary.

–

To increase the sewing-foot pressure = turn the setting wheel 2

clockwise.

–

To decrease the sewing-foot pressure = turn the setting wheel 2

anti-clockwise.

6.14.1 Adjusting the sewing foot pressure on automotive machines

On automotive machines, the setting wheel 2 for the sewing-foot

pressure is secured against altering through the user.

Adjusting the sewing foot pressure

–

Loosen the screw 4 and remove the interlock mechanism 3.

–

Adjust the sewing foot pressure according to the description given

under chapter 6.13.

–

Put on the interlock mechanism 3 and secure it by fastening the

screw 4.

52

43 2

Keystone Sewing Machine Company, Inc.

Page 55

6.15 Sewing-foot stroke

The special sewing machine 867 has, depending on the subclass, as

standard equipment two setting wheels for the sewing foot stroke.

With the left setting wheel 2 the standard sewing foot stroke from 1 to

9 mm is selected.

With the right setting wheel 1 an increased sewing foot stroke from 1

to 9 mm is selected.

–

Turning the setting wheel 1 and 2 (1 to 9)

1 = minimal sewing foot stroke

9 = maximal s ewing foot stroke

Automatic limiting of the number of stitches

Machines without thread trimmer

With these machines the speed is not controlled

Please take into consideration the hint and the chart on the next side.

Machines with thread trimmer

The sewing-foot stroke and stitch rate are interdependent. A

potentiometer is linked mechanically with the adjusting wheel. By

means of this potentiometer the control unit detects what foot-stroke

has been set and restricts the speed of rotation accordingly.

Machines with electro-pneumatic rapid stroke adjustment

With fabric parts that are thicker or in order to sew over cross seams,

the increased sewing foot stroke (setting wheel 1) can be switched on

during the sewing process by actuating the knee switch 3 beneath the

table top. .

As with the machines that are equipped with a thread trimmer, the

potentiometer is also available.

CAUTION Danger of breakage!

The standard sewing foot stroke that is set with the setting wheel 2

may never exceed the stroke set with the setting wheel 1.

53

GB

21

3

Keystone Sewing Machine Company, Inc.

Page 56

6.15.1 Adjusting the sewing foot stroke on automotive machines

On automotive machines, the setting wheels 4 and 6 for the sewing

foot stroke are secured against altering through the user.

Adjusting the sewing foot stroke

–

Loosen the screws 5.

–

Adjust the sewing foot stroke according to the description given

under chapter 6.14.

–

Secure the setting wheels 4 and 6 against altering using the

screws 5.

54

65 4

Keystone Sewing Machine Company, Inc.

Page 57

HINT !

In order to ensure an operation as safe as possible and a high

durability, the max. speed as shown in the chart should not been

exceeded.

Subclasses Range of stitch lengths Sewing foot stroke max. speed

[mm] pos. of setting wheel [min

-1

]

0867-160152

0867-190122 1-3 3400

0867-190142 0-6 4 3100

0867-190142-M 5 2500

0867-190145

0867-190146

0867-190322 6-9 1800

0867-190342 6-9 1-4 3000

0867-190445 5 2500

0867-490322

6-9 1800

0867-190020 9-12 1-5 2000

0867-190020-M 6-9 1800

0867-190040 0-9 1-4 3000

0867-260152 5 2500

0867-290445 6-9 1800

0867-290020

0867-290040

0867-290322 9-12 1-5 2000

0867-290342 6-9 1800

0867-392342

0867-393342

0867-394342

With double-needle machines having a needle distance of more than 20 mm, the max. speed may amount

up to 2000 min

-1

.

55

GB

Keystone Sewing Machine Company, Inc.

Page 58

6.16 Setting the stitch length

The special sewing machines 867 are, depending on the subclass,

equipped with two setting wheels. Thus, two different stitch lengths

can be sewn, that are activated by actuating a key (see chapter 6.16).

The two stitch lengths are set with the setting wheels 1 and 2 on the

machine arm.

–

Set the higher stitch length with the upper setting wheel 1.

Setting 1 = min. stitch length

Setting 12 = max. stitch length

–

Set the smaller stitch length with the lower setting wheel 2.

Setting 1 = min. stitch length

Setting 12 = max. stitch length

The stitch length are the same for both, forward and backward

sewing.

–

For the manual sewing of tacks, push the stitch regulator lever 3

downward.

The machine sews backward stitches as long as the s titch

regulator lever 3 is being pushed.

Hint

In order to facilitate the setting of stitch lengths, the stitch length that

remains unchanged should be activated with key 2 (see chapter 6.16).

CAUTION Danger of breakage!

The stitch length set with the lower setting wheel 2 must not exceed

the stitch length set with the upper setting wheel 1.

56

1

2

3

Keystone Sewing Machine Company, Inc.

Page 59

6.15.1 Adjusting the stitch length on automotive machines

On automotive machines, the setting wheels 3 and 4 for the stitch

length are secured against altering through the user.

Adjusting the stitch length

Caution: danger of injury !

Turn off the main switch.

The stitch length may only be adjusted with the machine switched off.

–

Loosen the clamping screws 5.

–

Introduce a 3 mm Allen key via the holes 6 to reach the clamping

screws 5.

–

Adjust the stitch length according to the description given under

chapter 6.15.

–

Fasten the clamping screws 5 again.

57

GB

43

5

Keystone Sewing Machine Company, Inc.

Page 60

6.17 Key pad on the machine arm

Key Function

1

Supplementary thread tension

If the key is lit up:

Supplementary thread tension is switched on.

If the key is not lit up:

Supplementary thread tension is switched off.

2

2ndstitch length

If the key is lit up:

Higher stitch length (upper setting wheel) is active

If the key is not lit up:

Smaller stitch length (lower setting wheel) is active

3

Recalling or suppressing the initial or final bartack.

If the initial and final bartacks are generally

switched on, the next bartack is switched off by

actuating the key.

If the initial and final bartacks are generally

switched off, the next bartack is switched on by

actuating the key.

4

Setting the needle in high or low position.

The function of the key can be defined with the

parameter F-140.

1 = Needle high

2 = Needle high/low

3 = Single stitch

4 = Single stitch with 2nd stitch length/ short stitch

5 = Needle high, when outside position 2

The factory setting is 1 = Needle high.

5

Manually sewing backward.

The machine sews backward s titches as long as

the key is being pushed.

11

(only 867-393342, 867-394342)

Switching ON/OFF the edge trimmer.

The knife remains switched off after sewing foot

lifting.

58

876 5 43 21

10

9

11

Keystone Sewing Machine Company, Inc.

Page 61

+

-

(only 867-392342)

After switching on the special sewing machine, the

binding device is moving synchronously with the feeder.

Pressing the + key = fullness facility of the binding device

activated.

Pressing the - key = reduced motion of the binding device.

Neither + nor - key pressed = synchronous motion.

LED Function

7and8

Display for empty bobbin w ith residual thread monitor

(left/ right bobbin)

10

LED display “power on"

The function of key 9 can be selected with the screw 6 underneath the

key 5.

–

Selecting a function.

Example: 5 = Manually sewing backward.

–

Turn in the screw 6 underneath the key 5 and tur n it 90° to the

right (the slot stands vertically).